避免代价高昂的错误,参考我们的加工厂指南。了解一体式与传统结构、切割参数及维护技巧,助您实现完美石英切割。

Selecting the right bridge saw for quartz countertops means matching machine rigidity to engineered stone's unforgiving nature. Quartz's density and resin composition cause chipping and stress fractures-demanding absolute stability and precise control.

This guide delivers a proven four-step framework for choosing machines that master quartz fabrication. Start with a solid, vibration-dampening monoblock design, then balance axis configuration (3-axis vs. 5-axis) with your production needs.

Optimize spindle power and blade selection for quartz's hardness. For specific equipment challenges, get professional advice by consulting our engineers to ensure your investment pays off.

Get actionable steps and data-driven insights on critical technical specifications, proven cutting parameter testing, and maintenance strategies. Choose a quartz cutting machine that enhances quality, efficiency, and profitability.

Quick-Check: Key Decision Factors for a Quartz Bridge Saw

Before diving deep, here are the five most critical factors to evaluate. Use this as a quick checklist when comparing models:

- Machine Structure: Monoblock vs. Traditional Welded Frame. A heavier, single-piece frame is non-negotiable for minimizing vibrations and preventing chipping.

- Axis Configuration: 3-Axis vs. 5-Axis CNC. The choice depends entirely on whether you need to perform complex, curved, or intricate miter cuts.

- Blade & Spindle: Power (HP), RPM Range, and Blade Compatibility. Quartz requires high spindle power (20HP+) and the correct diamond blade type to avoid heat damage and ensure clean cuts.

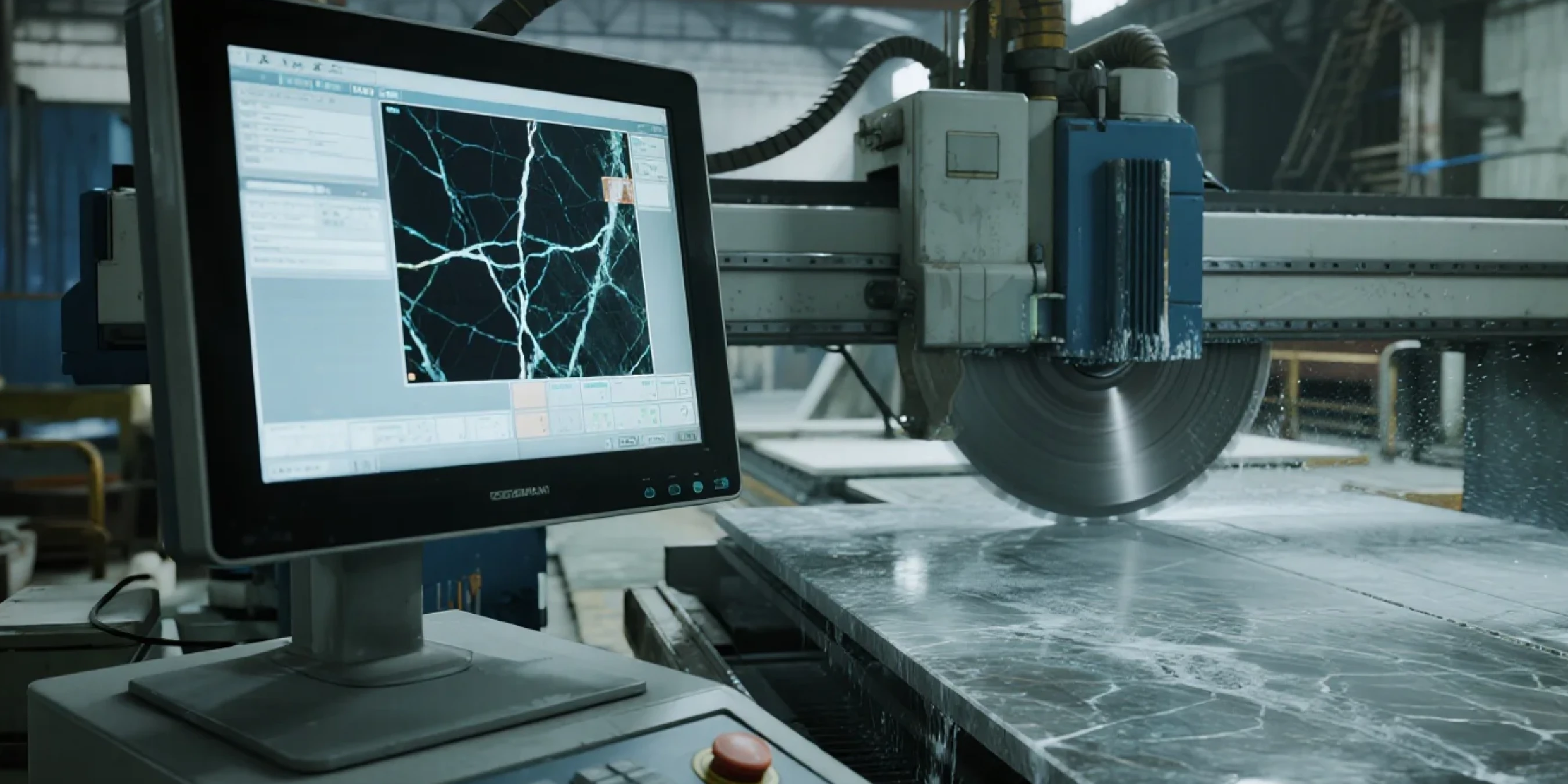

- Software & Automation: Ease of Use and Key Features. Modern software with features like digital slab photography can dramatically reduce waste and setup time.

- Table & Support: Material Handling and Stability. A hydraulic tilt and rotation table is essential for safely and efficiently handling large quartz slabs.

Step 1: Match the Machine Structure to Your Quality Standards

The foundation of a perfect cut lies in the machine's structural integrity. For a material as dense and brittle as quartz, any vibration during the cutting process will transfer directly to the blade. This results in chipping, micro-fractures, and a poor finish.

Why Monoblock Structure is Preferred for Quartz Cutting

A monoblock bridge saw, constructed with a heavy, single-piece cast iron or steel base and gantry, offers superior rigidity. This design dampens vibrations far more effectively than traditional machines with bolted or welded steel frames. At Dinosaw, our experience shows that fabricators using our monoblock saws report up to a 70% reduction in edge chipping on difficult quartz varieties.

The stability ensures the diamond blade maintains a consistent cutting path. This is critical for achieving the sharp, clean edges that high-end countertop projects demand.

Table Tilt & Rotation: A Must-Have for Efficient Slab Handling

Handling a 600 lb quartz slab is not only a safety risk but also a major production bottleneck. A bridge saw equipped with a hydraulic tilt table (typically 0-85°) allows for effortless loading of slabs directly from an A-frame. When combined with a 90° or 360° rotating table, your operator can position the slab for multiple cuts without needing a crane or additional manpower after the initial loading.

This feature alone can reduce slab handling time by over 50% and significantly lowers the risk of costly slab breakage.

Step 2: Choose Your Axes - 3-Axis vs. 5-Axis for Quartz Fabrication

The "axis" count determines the machine's range of motion and the complexity of the cuts it can perform. This is one of the most significant factors influencing the machine's price and capability.

When a 3-Axis Saw is Enough: For Straight Cuts and Basic Miters

A 3-axis bridge saw operates on the X (length), Y (width), and Z (depth) axes. It is the workhorse for standard countertop fabrication, excelling at making precise straight cuts. Most 3-axis saws also feature a tilting head (often considered a 4th, manual or semi-automatic axis) to perform 0-45° miter cuts for standard edge profiles.If your business primarily focuses on high-volume production of standard rectangular or L-shaped countertops with simple edges, a robust 3-axis machine is a cost-effective and highly efficient choice.

Why 5-Axis CNC is the Future for High-End Quartz Countertops

A true 5-axis CNC bridge saw adds two rotational axes (A and C), allowing the blade to tilt and rotate simultaneously. This opens up a world of possibilities for custom quartz fabrication. With a 5-axis machine, you can effortlessly cut complex curves for islands, sinks, and shower bases, as well as perform intricate mitered cuts for waterfall edges and built-up aprons-all in a single automated program.As reported by the Natural Stone Institute , demand for custom designs in both residential and commercial projects is growing. This makes a 5-axis machine a strategic investment for future-proofing your business.

To clarify the differences, here is a direct comparison:

| Feature | 3-Axis Bridge Saw | 5-Axis CNC Bridge Saw |

|---|---|---|

| Primary Use | Straight cuts, 90° angles, simple 45° miters | Complex curves, intricate shapes, any-angle miters |

| Automation | Semi-automatic; requires manual setup for angles | Fully automated; programmed via CAD/CAM software |

| Best For | High-volume, standardized countertop production | Custom, high-end residential and commercial projects |

| Key Advantage | Lower initial cost, simple operation | Unmatched versatility, reduced labor, higher-margin jobs |

| Our Recommendation | - | 5-Axis Bridge Saw Machine for Granite, Marble, Quartz Stone |

Step 3: Deep Dive into Technical Specs - What Really Matters for Quartz

Once you've settled on the structure and axis configuration, the technical details will determine the machine's day-to-day performance.

Spindle Power (HP) & RPM: Finding the Sweet Spot

Quartz is significantly harder and more abrasive than many natural stones. Cutting it efficiently requires a spindle motor with sufficient power. We recommend a minimum of 20 HP (15 kW) for a primary production saw. This ensures the blade maintains its optimal rotational speed (RPM) even under heavy load, preventing it from slowing down and causing chipping or burning the resin binders in the quartz.Equally important is a variable frequency drive (VFD), which allows you to control the spindle's RPM. A typical range of 1,000 to 3,000 RPM provides the flexibility to match the blade speed to the specific blade diameter and quartz brand you are cutting, a key factor we will discuss in the parameter testing section.

The Blade is Your Business: Selecting the Right Diamond Blade

The best bridge saw is useless without the right blade. For quartz, you must use a diamond blade specifically engineered for engineered stone. These blades typically feature:

- A Harder Metal Bond: This holds the diamond particles, and a harder bond is needed to withstand the abrasiveness of quartz, ensuring a longer blade life.

- Specific Segment Design: Look for blades with narrow "J-slot" or "keyhole" gullets. These are designed to reduce cutting stress and improve cooling, which is vital to prevent heat from damaging the resin.

- High-Quality Diamonds: The concentration and quality of the diamonds directly impact cutting speed and finish.

When cutting quartz, it is always a best practice to select the right diamond blade that is specifically designated for engineered stone for optimal results.

How to Find the Perfect Cutting Parameters: A 4-Step Test Method

There is no single "magic number" for quartz cutting parameters, as different brands (Caesarstone, Silestone, etc.) have slightly different compositions. The best practice is to perform a systematic test on a scrap piece of the material you will be cutting.

Initial Safe Settings:

Always start with a conservative setting based on your blade manufacturer's recommendation. If none is available, a safe starting point for a 16-inch (400mm) blade on 3cm quartz is:

- Spindle Speed (RPM): ~1,800 RPM

- Feed Rate (Cutting Speed): 80-100 inches/minute (~2-2.5 meters/minute)

The Test Cut Process:

On a piece of scrap material from the same slab, perform a straight cut approximately 2 feet (50-60 cm) long. This provides enough length to accurately assess the performance.

Evaluating the Cut:

Use three senses to evaluate the test cut:

- Look (Visual): Examine the top and bottom edges of the cut. Is there any chipping? Is the cut edge smooth or does it show signs of blade deviation?

- Listen (Audio): A smooth, consistent whirring sound is ideal. A loud, high-pitched screeching can indicate the RPM is too high or the feed rate is too fast for the material.

- Measure (Ammeter): Check the machine's ammeter during the cut. The motor should be running at approximately 75-90% of its full load amperage. This is the "sweet spot" for efficiency and longevity. If the amps are too low, you are cutting too slowly; if they are spiking or at 100%, you are overloading the motor.

Adjustment Strategy:

Based on your evaluation, adjust one variable at a time:

- If Chipping Occurs: Your first adjustment should be to decrease the feed rate by 10-15%. This gives the diamond segments more time to cleanly cut the material.

- If the Cut is Perfect but Amps are Low: Gradually increase the feed rate by 10% increments until the ammeter reads in the optimal 75-90% range. This maximizes your production speed without sacrificing quality.

- If the Motor is Overloaded (High Amps): Immediately reduce the feed rate. This is the most critical adjustment to prevent damage to the motor and blade.

Step 4: Beyond the Machine - Software, Maintenance, and Support

A modern bridge saw is more than just hardware. The software and a clear maintenance plan are crucial for long-term success.

User-Friendly CNC Software: From Photo to Path

For CNC-enabled saws, intuitive software is key. Look for systems that include slab photography (also called a "slabsmith" or "photogrammetry" feature). This technology allows you to take a high-resolution picture of the slab, import it into the software, and then digitally position your parts to nest them perfectly, avoiding fissures and matching veins.

According to market analysis by Grand View Research , material yield is a top concern for fabricators, and this technology directly addresses it by reducing waste.

Essential Maintenance Checklist for Your Bridge Saw

Consistent maintenance is the best way to ensure accuracy and prevent costly downtime. Implement this simple checklist:

Daily:

- Clean the machine of all slurry and stone dust.

- Inspect the diamond blade for any visible damage or segment loss.

- Check that all safety guards and emergency stops are functioning.

Weekly:

- Lubricate all linear guides and moving parts according to the manufacturer's specifications.

- Clean the water recycling and filtration system.

- Check the tension and condition of all belts.

Monthly:

- Verify the machine is level and the gantry is square.

- Inspect all electrical connections and cables for wear.

- Clean the main spindle and check the condition of the blade flange.

For more detailed instructions, refer to our comprehensive guide on Bridge Saw Troubleshooting

Conclusion: Your Next Step to Perfect Quartz Cutting

Choosing the right bridge saw for quartz is a strategic decision that directly impacts your workshop's quality, efficiency, and profitability. By prioritizing a rigid monoblock structure, selecting the appropriate axis configuration for your business needs, and understanding the critical technical specifications, you can make an informed investment.

Remember that the machine is only part of the equation. Using the correct diamond blades and employing a systematic method to determine cutting parameters are just as important. By following the framework laid out in this guide, you can confidently choose a machine that will serve as the reliable heart of your quartz fabrication business for years to come.

Frequently Asked Questions (FAQs)

What is the best blade size for cutting 3cm quartz countertops?

The best blade size for 3cm (1-1/4") quartz is typically a 16-inch (400mm) or 18-inch (450mm) diameter blade. This size provides an optimal balance of cutting depth, stability, and surface speed (SFM). A 16-inch blade on a saw with a 20HP motor can efficiently cut through 3cm material in a single pass while maintaining the rigidity needed to prevent blade deflection and chipping.

How do you prevent quartz from chipping when cutting with a bridge saw?

To prevent chipping, you must address four key areas. First, use a high-quality monoblock bridge saw to eliminate vibration. Second, use a diamond blade specifically designed for quartz with a hard bond. Third, ensure the blade flanges are clean and torqued correctly for maximum stability. Finally, use the 4-step testing method described above to find the optimal, slower feed rate for the specific material, and ensure a generous flow of clean water to cool the blade.

Can a 3-axis bridge saw cut 45-degree miters for waterfall edges?

Yes, most modern 3-axis bridge saws have a head that can tilt from 0 to 45 degrees (or more), allowing them to cut perfect miters for waterfall edges and aprons. While a 5-axis CNC saw can automate this process along with curves, a 3-axis saw is perfectly capable of producing high-quality mitered edges for straight-line applications, making it a viable option for many fabrication shops. For more complex projects, you might also be interested in our Granite Bridge Saw Buyer's Guide .

What is the main difference between a bridge saw and a gantry saw?

The main difference is in their construction and movement. In a bridge saw, the "bridge" which holds the cutting head moves along two rails (the Y-axis), while the cutting head itself moves side-to-side along the bridge (the X-axis). In a gantry saw, the entire gantry structure, supported on legs at both sides, moves along the full length of the cutting table, which is a design more common in very large-scale industrial applications for block cutting.

How much power (HP) does a bridge saw for quartz really need?

For professional quartz fabrication, a minimum of a 20 HP (15 kW) main spindle motor is strongly recommended. Quartz's density and hardness require significant torque to maintain blade speed during a cut. An underpowered motor (e.g., 10-15 HP) will be forced to run at slower feed rates, will be under constant strain, and is more likely to cause chipping because the blade can slow down mid-cut, increasing stress on the stone's edge.

Is water required when cutting quartz?

Absolutely. Cutting quartz is a wet process, and a continuous, high-volume flow of water is mandatory. Water serves two critical purposes: it cools the diamond blade to prevent the diamonds from glazing over and the metal bond from overheating, and it suppresses the dangerous crystalline silica dust. According to workplace safety standards referenced by organizations like OSHA, wet cutting is a primary engineering control to protect workers from silicosis.

How often should a bridge saw be calibrated?

A bridge saw's calibration should be checked monthly as part of a regular maintenance schedule. However, a full professional recalibration should be performed at least annually or any time you notice a decline in cutting accuracy (e.g., cuts are not perfectly square, mitered edges don't align). Events such as moving the machine or a significant collision also warrant an immediate calibration check.

Can you cut curves on a bridge saw?

Yes, but only on a 5-axis CNC bridge saw. A standard 3-axis machine can only perform straight cuts. A 5-axis machine uses its rotating head and advanced software to interpolate the X, Y, Z, A, and C axes simultaneously, allowing it to follow a curved path smoothly and accurately. This capability is essential for fabricating custom kitchen islands, round tabletops, or shower bases.

English

English 中文

中文