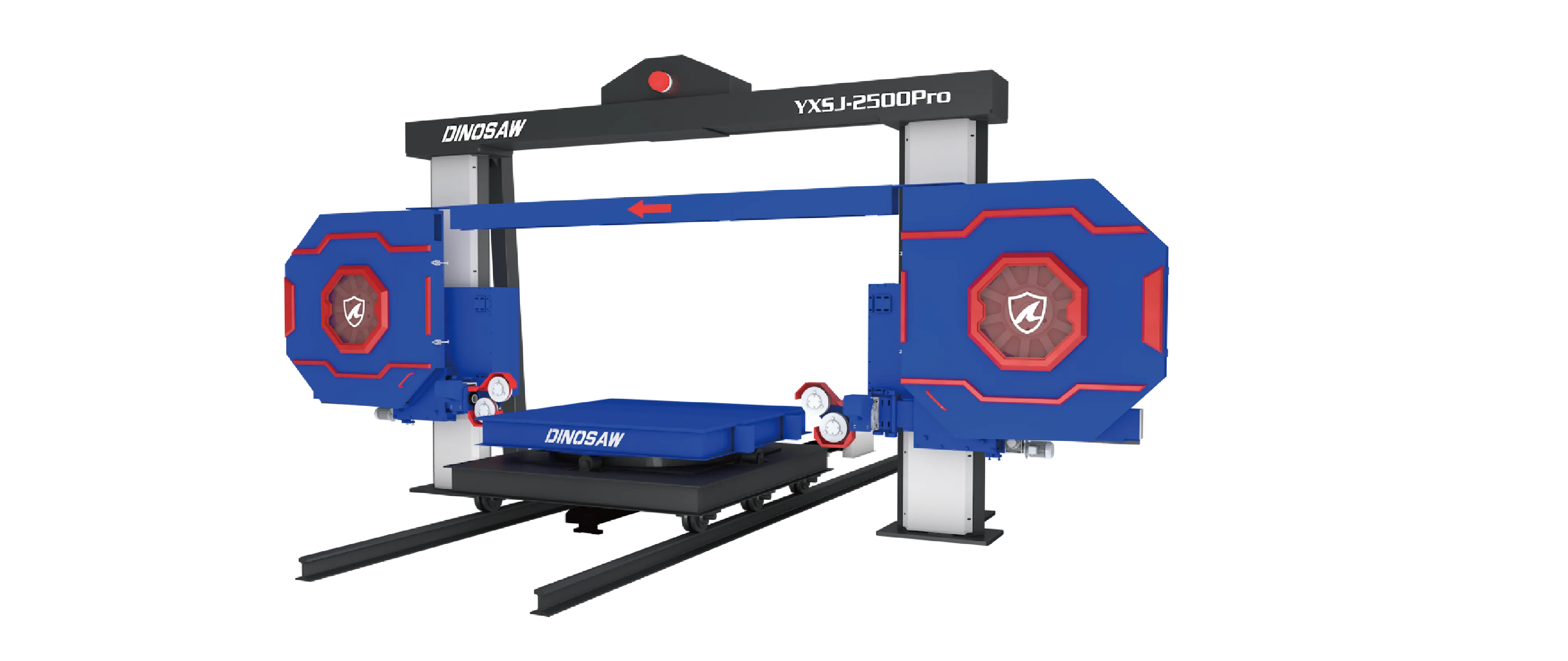

Multi‑Wire Saw Boosts Marble Yield 20%+, Ultra‑Thin Cuts

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

Countries Served Worldwide

Innovative technology patents

Industry machinery expertise

Mechanical Design | Embedded Systems | PLC & CNC Control | Software & App Development | AI Vision Applications

High-Tech Enterprise

National Certification

Specialized & Innovative Enterprise

Technical Innovation Certification

CNC Demonstration Project

Wire Saw Product Certification

CE Certification

EU Market Access

100+ Patents

Technical Innovation & IP Protection

ISO Certification

International Quality

Continuously improve productivity for user

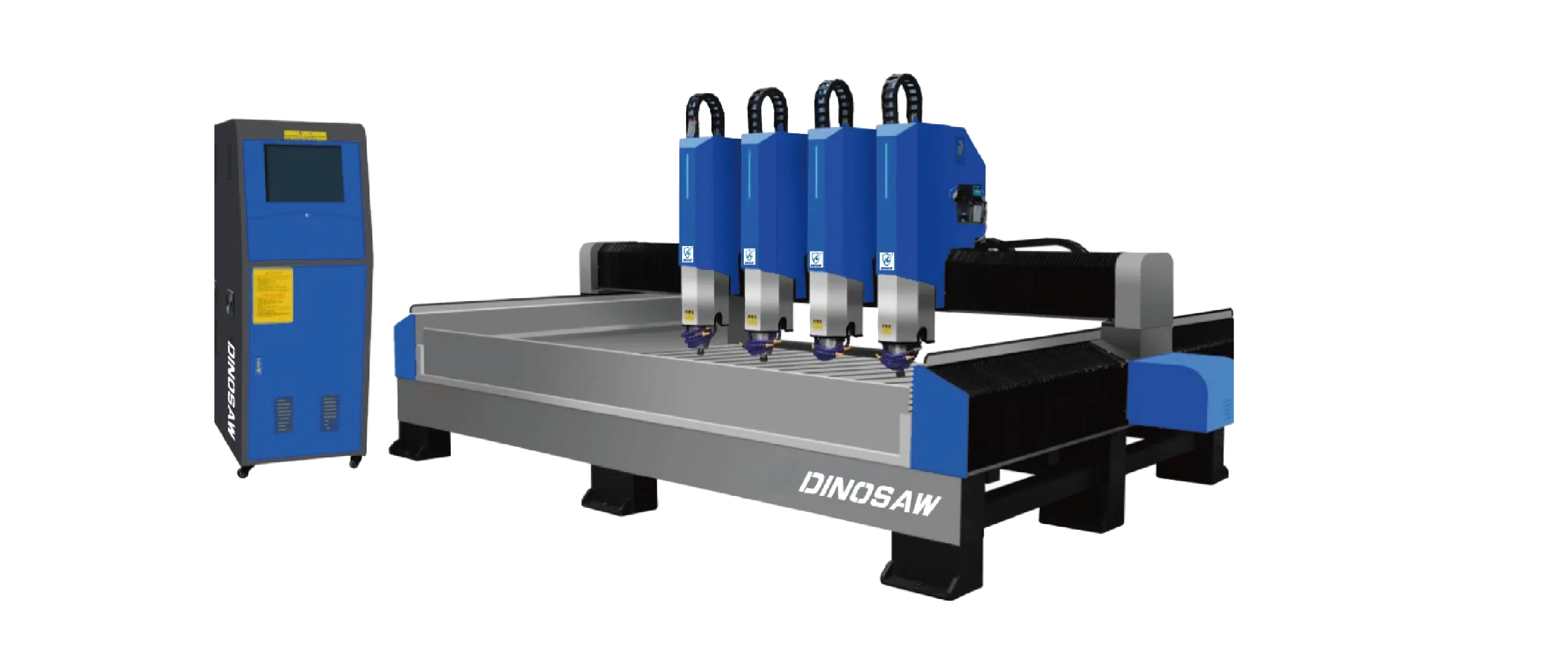

Single and multi-wire saw equipment for batch cutting of thin plates, profiling, and special material cutting, providing efficient stone processing solutions.

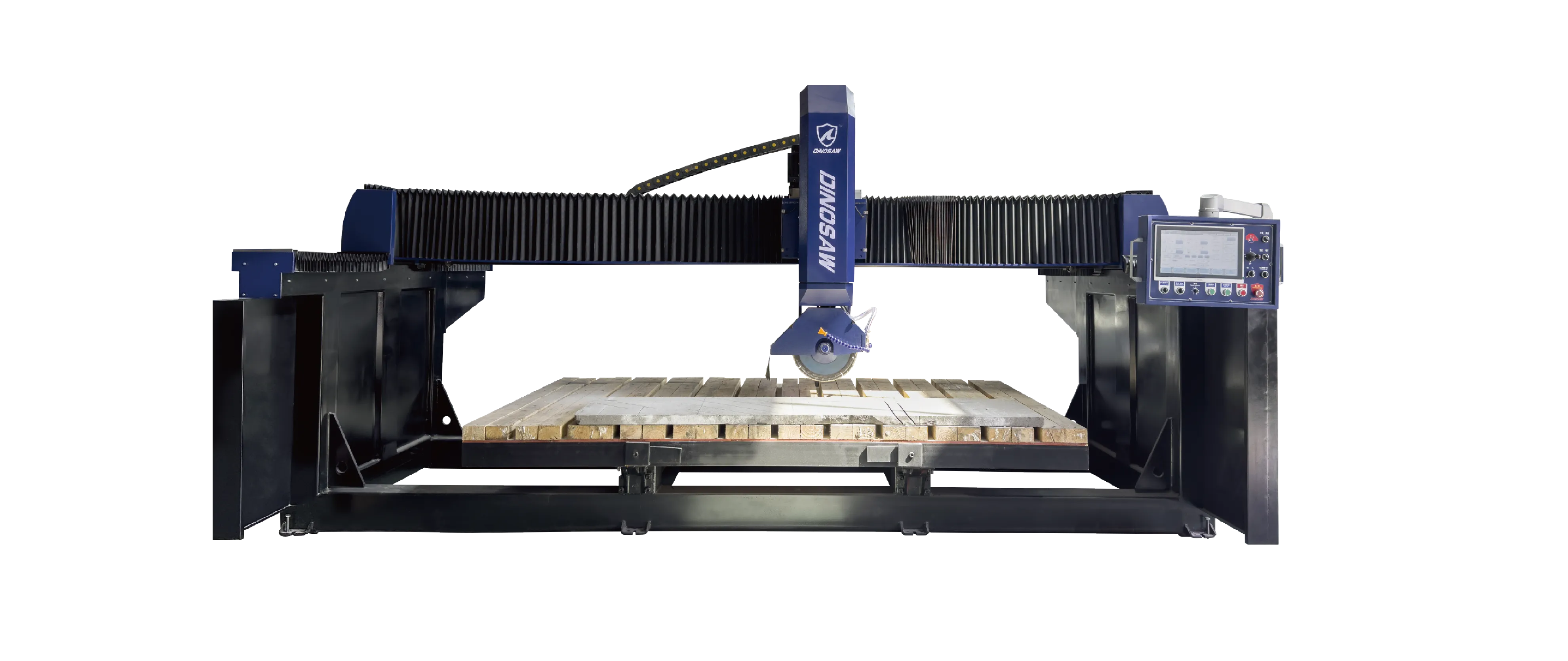

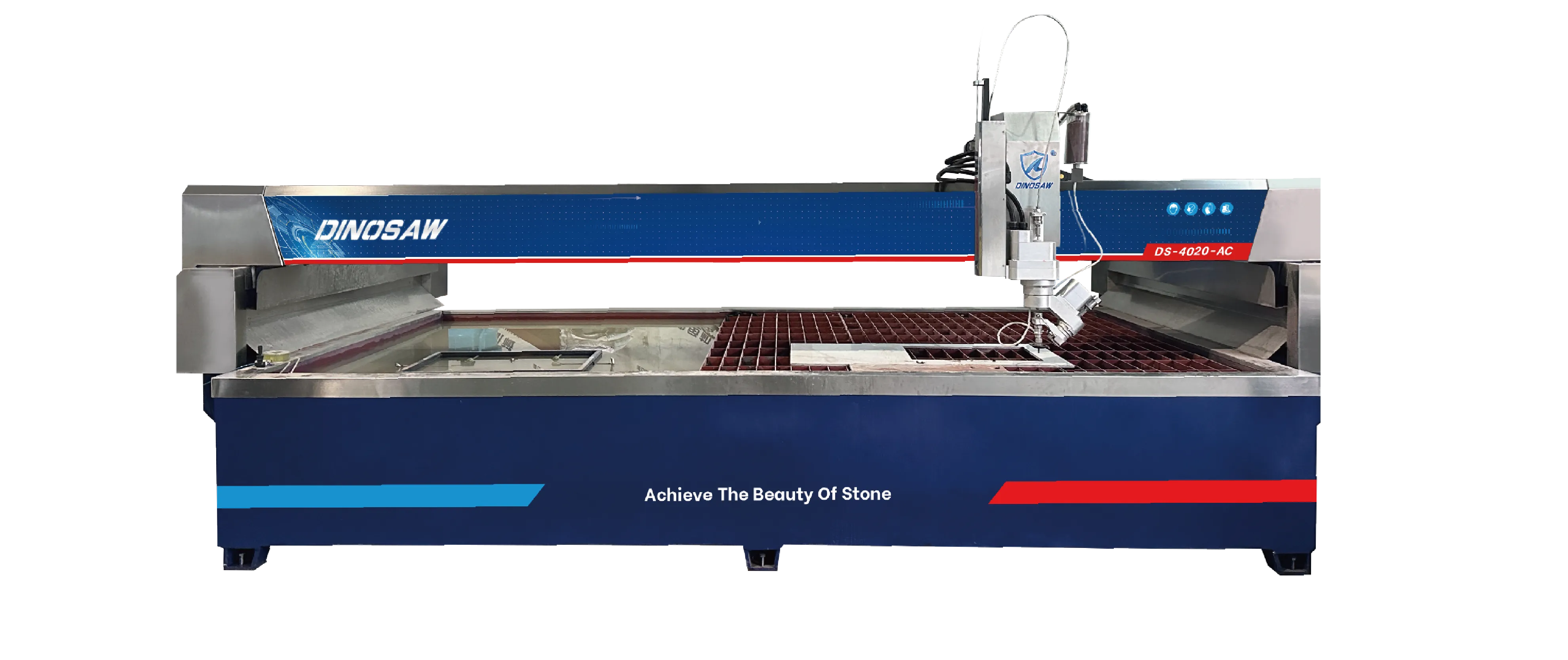

Bridge cutting machines and stone cutting equipment for precise and rapid cutting of various stone materials, suitable for countertop processing and building decoration material production.

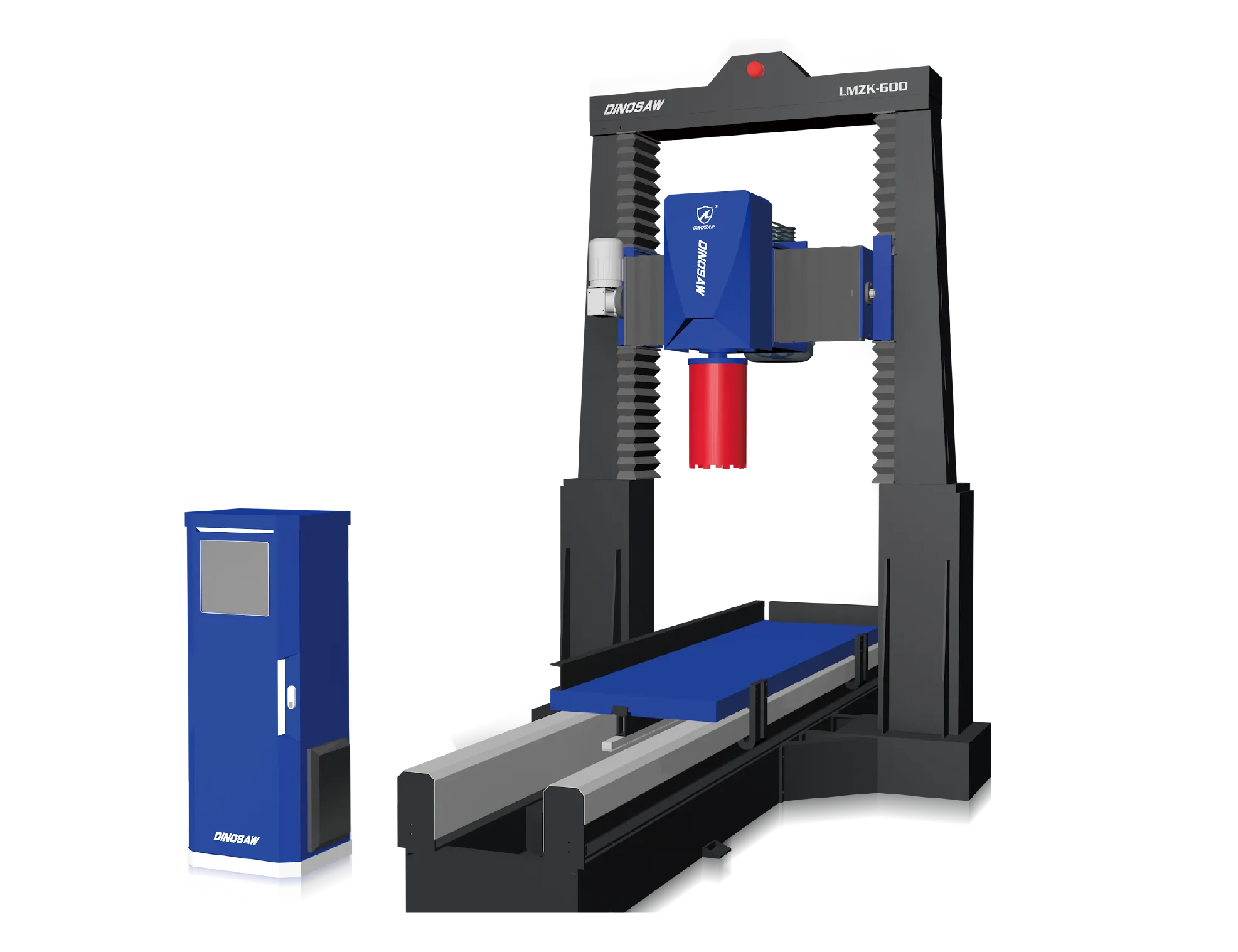

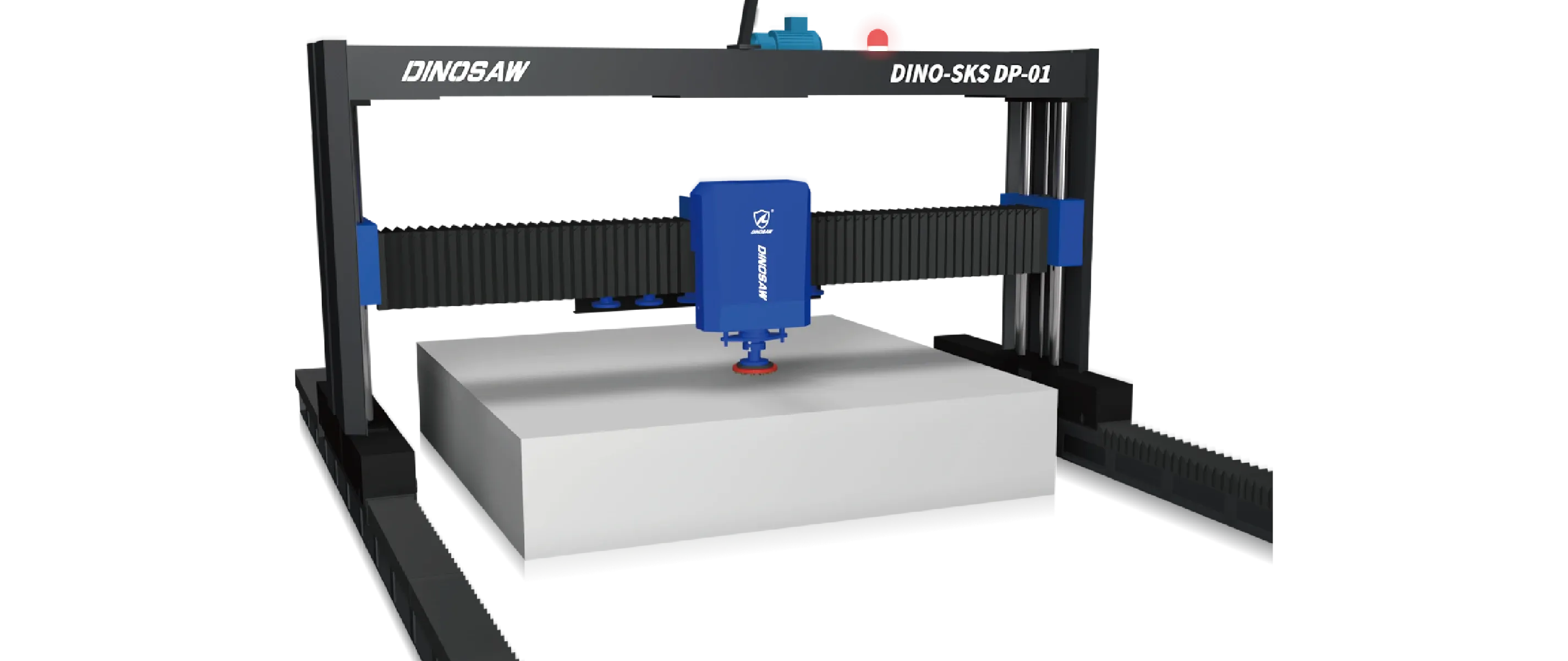

Intelligent profiling equipment for processing complex shaped products such as railings and vases, applicable to building decoration and artistic sculpture creation.

Efficient grinding and polishing equipment to enhance surface quality, meeting high-end building and decoration requirements.

Specialized mining equipment, including diamond wire saws, double-blade cutting machines, and quarry chain saws.

Advanced equipment such as water jet cutting machines and machining centers, suitable for special material processing and innovative applications across multiple fields.

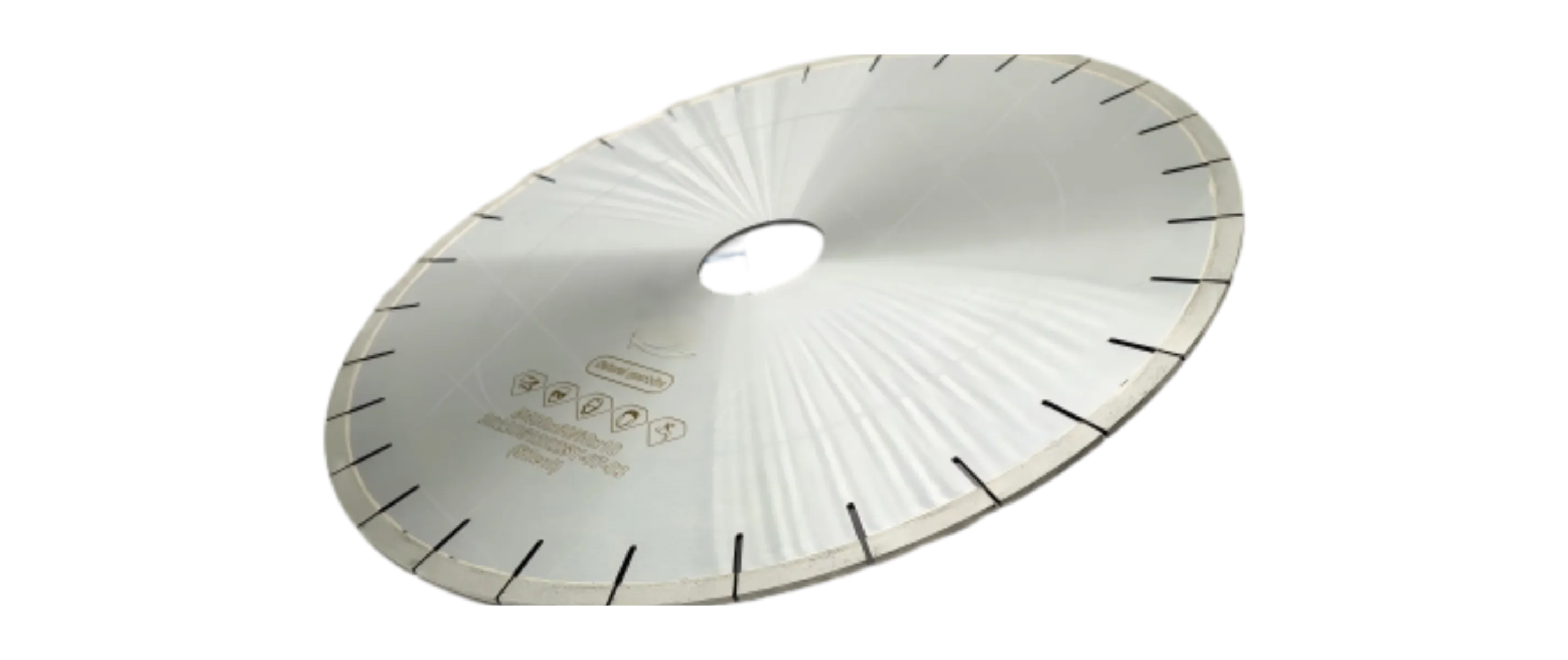

Professional diamond tools for cutting, grinding, and drilling, providing efficient and durable solutions for processing various stone and hard materials.

English

English

Get A Easy Solution

Chat Online

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Hello 👋 How can we help?