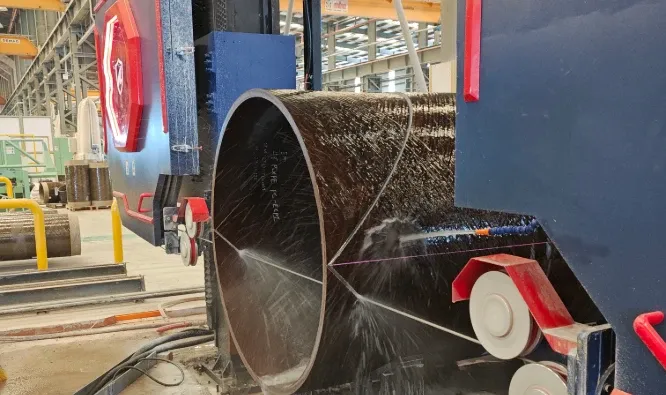

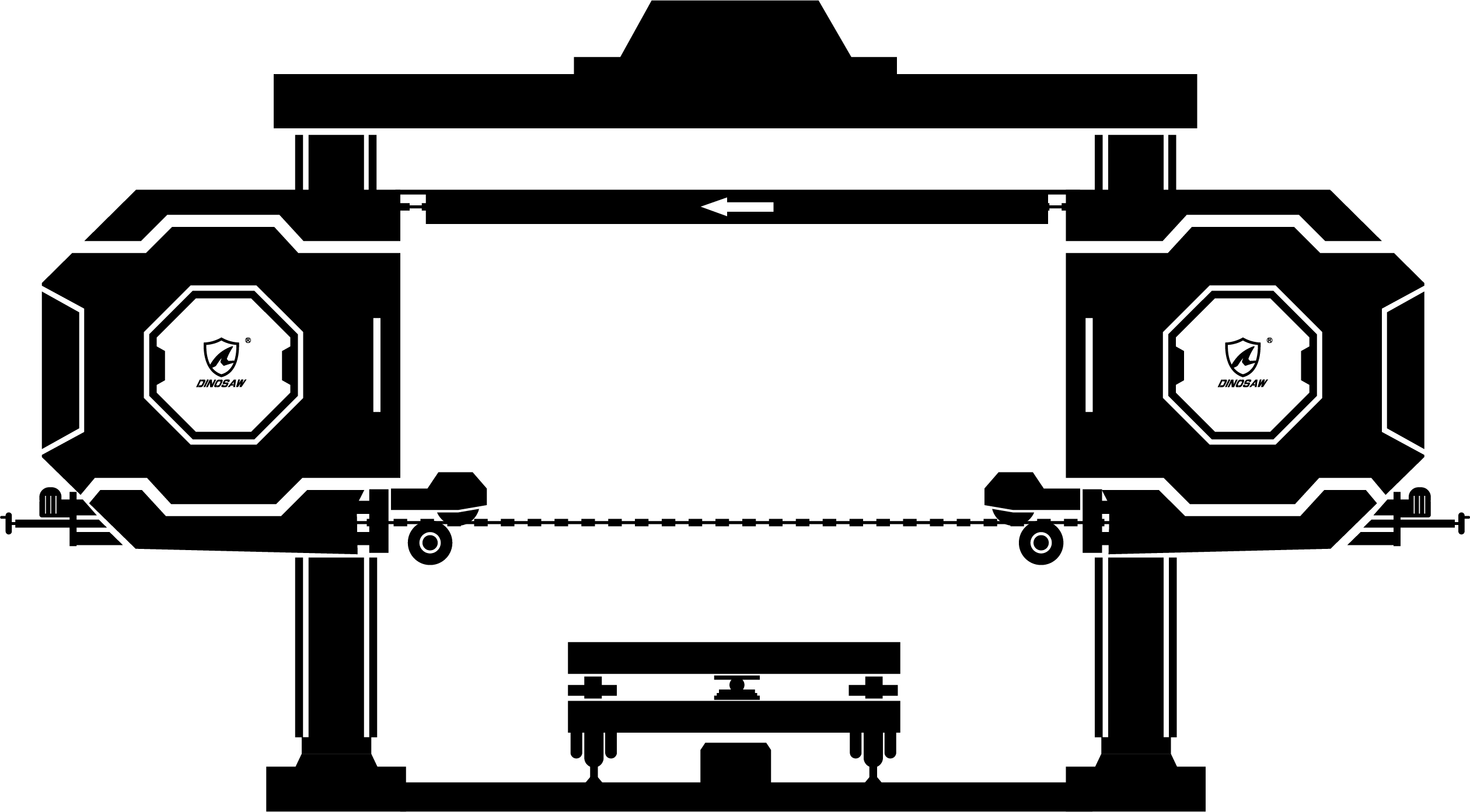

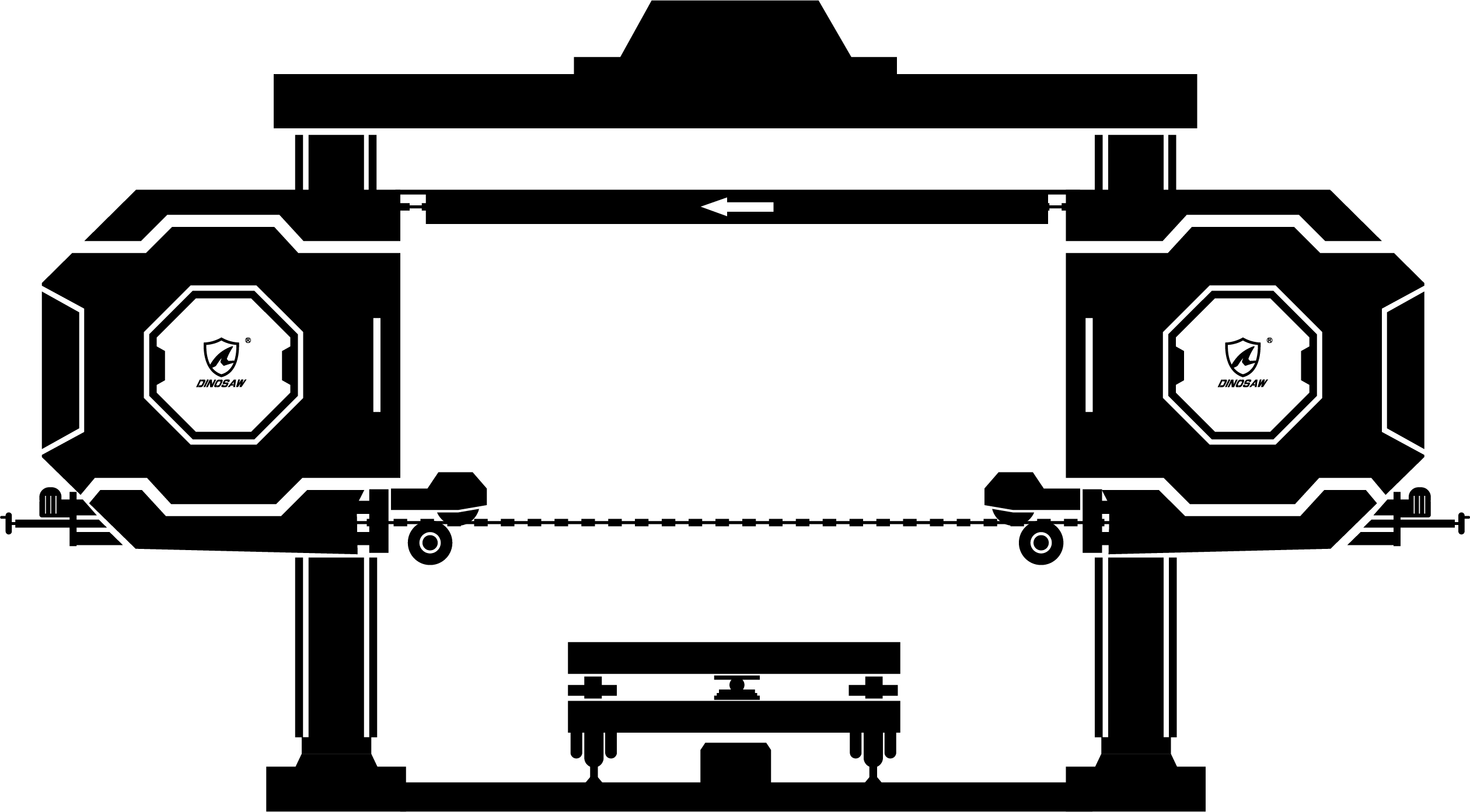

Precision CNC Diamond Wire Cutting Machine

May 8, 2025

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

| Materials & Applications | Recommended Equipment | Core Technical Advantages & ROI |

| Granite & Marble: Intricate text carving, arc slabs, columns, and luxury furniture. | Diamond Wire Saw Cutting Machine Pro | 1.Exclusive Closed-Loop System: This technology eliminates downtime and ensures uninterrupted precision for high-value stone processing. 2. HT250 Premium Cast Iron: The monoblock structure absorbs high-frequency vibrations, maintaining stability for complex 3D shapes. 3. Proprietary CNC Logic: Full-servo control maintains a tolerance within ±1 mm. |

| Block Squaring & Trimming: Rapid processing and alignment of large-scale stone blocks. | Stone Block Cutting Wire Saw Machine | 1.High-Torque Servo Drive: Dual 600mm flywheels with real-time tension feedback increase response speed by 20%. 2. Stress-Relieved Design: Advanced structural balancing reduces column stress by 31%, significantly extending Dinosaw machine service life. |

| Foamed Ceramics: Architectural lettering, window casings, and decorative lines. | CNC Diamond Wire Saw Cutting Machine for Foamed Ceramics | 1.Ultra-High Speed: Dinosaw machine achieves a 1000mm/min cutting speed with a smooth finish, removing the need for secondary polishing. 2. Operational Efficiency: Consumable costs drop by 10%, while material yield increases by 5-10%. |

| Tombstone Processing: High-efficiency cutting, beveling, and complex geometry. | CNC Diamond Wire Saw Machine (Tombstone Edition) | 1.Multi-Slab Parallel Processing: This equipment supports simultaneous cutting of multiple slabs, boosting efficiency by 900%. 2. Advanced 3D Pathing: Optimized for 45° bevels and intricate curvilinear designs. |

| Granite Kerbstones: Standardized production and complex curved kerbstone shaping. | Diamond Wire Saw Cutting Machine for Kerbstone | 1.High-Volume Productivity: Dinosaw machine achieves an output of 10-20 pieces per hour (at ~20cm thickness), ensuring rapid turnaround for large-scale infrastructure. 2. Breaking Thickness Barriers: Dinosaw machine handles extra-thick tombstones and massive industrial blocks that traditional 5-axis bridge cutters cannot process due to blade diameter limitations. 3. Curved Continuous Output: This equipment specializes in both rapid standardized lines and high-precision curved kerbstone production. |

English

English

Get A Easy Solution

Chat Online

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Hello 👋 How can we help?