Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

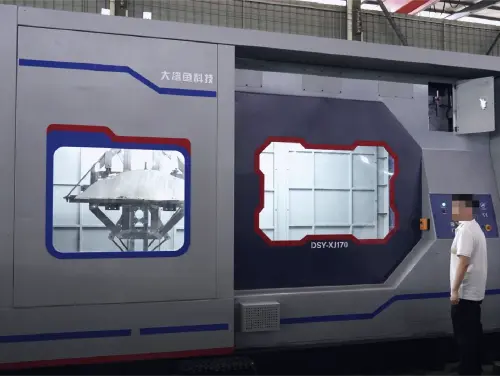

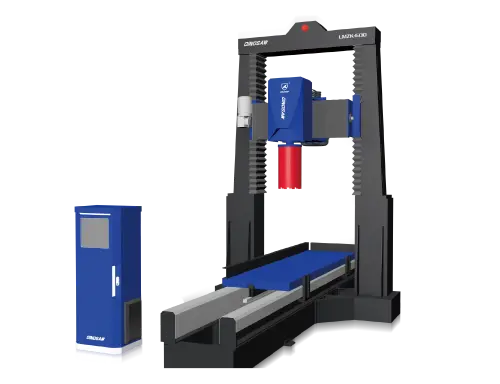

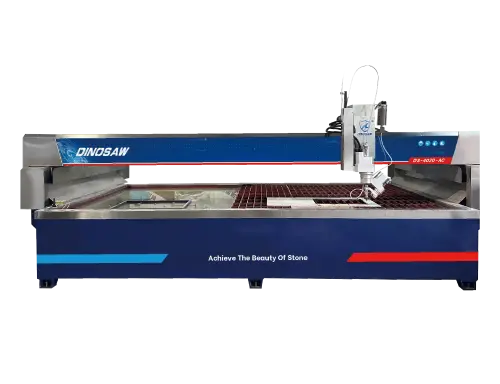

Precision CNC Diamond Wire Cutting Machine

Customizable CNC wire saw

Compatible Materials & Products

Precision cutting for optics, semiconductors & composites

Sapphire & Optical Glass > Precision Components

Sapphire and optical glass components require precisely controlled dimensional tolerances and good surface quality for applications in LED substrates, optical lenses, and photonics. Traditional cutting methods introduce micro-fractures and require extensive post-processing.

DINOSAW Diamond Wire Cutting Machine processes these materials using 0.35-0.6mm diamond wire at speeds of 20-50m/s with controlled tension. The system can produce straight cuts, angled cuts, and custom profiles while maintaining good flatness. For quartz glass with 7.0 Mohs hardness and sapphire with 9.0 Mohs hardness, our technology delivers good optical flatness with minimal subsurface damage.

This versatile cutting capability enables manufacturers to achieve higher production yields with less post-processing time, directly translating to reduced production costs and faster delivery times for optical components used in semiconductor lithography, medical imaging, and aerospace applications.

Silicon & SiC > Semiconductor Wafers

The semiconductor industry requires silicon and silicon carbide wafers with consistent dimensional tolerances and acceptable thickness variation. These specifications directly impact device yield and performance in integrated circuits and power electronics.

Our Diamond Wire Cutting Machine slices silicon and SiC ingots with 0.35-0.6mm diamond wire at controlled feed rates. The wet cutting process maintains moderate substrate temperatures during operation, reducing thermal stress. Multi-axis CNC control ensures good parallelism across wafers, while achieving acceptable thickness uniformity and surface roughness suitable for subsequent processing.

These capabilities translate to good wafer yield rates, reduced material loss compared to slurry-based methods, and faster production cycles. Manufacturers gain quantifiable advantages in production economics while meeting the specifications required for semiconductor devices and power electronics.

Graphite & Carbon Composites > Industrial Parts

Graphite and carbon-carbon composite materials with hardness of 1-2 Mohs and tensile strength of 30-80MPa require precision cutting without structural damage for aerospace components, semiconductor fixtures, and electrodes. These materials combine high-temperature stability (up to 3000°C) with electrical conductivity (104-105 S/m).

Our Diamond Wire Cutting System processes these materials using 0.5-1.0mm diamond wire at cutting speeds of 30-84m/s with continuous debris removal. The physical cutting action achieves good dimensional tolerances with acceptable surface roughness while maintaining structural integrity. Unlike electrical discharge methods that create heat-affected zones, our technique preserves material properties throughout the workpiece.

This specialized cutting capability reduces material waste and delivers finished components requiring minimal secondary operations. Manufacturers in aerospace, semiconductor, and energy sectors gain components with verified structural integrity and consistent electrical/thermal properties essential for high-temperature applications (>2000°C).

Ceramics & Piezoelectrics > Electronic Elements

Advanced ceramics (Al2O3, ZrO2, AlN) and piezoelectric materials with hardness values of 7-9 Mohs and compressive strength of 300-2500MPa require precision cutting that preserves electrical properties. These materials form critical components in electronic substrates, sensors, and transducers where dimensional accuracy directly impacts functional performance.

Our Diamond Wire Cutting Machine processes these brittle materials using 0.5-0.8mm diamond wire with controlled wire tension and cutting speeds of 20-60m/s. For piezoelectric ceramics with d33 coefficient values of 300-700pC/N, our system maintains acceptable electromechanical coupling factors. When processing alumina (99.5% purity) and other technical ceramics, the diamond wire technology achieves good flatness and surface quality without introducing excessive internal stress or microcracks.

This ceramic cutting capability enables manufacturers to produce electronic components with good yield rates and consistent electrical performance. The preservation of material properties and dimensional control translates to higher reliability in finished electronic devices used in medical, automotive, and industrial applications.

Rare Earth Magnets > High Performance Magnets

Neodymium-iron-boron (NdFeB) magnets with energy products of 30-52 MGOe and coercivity of 10-30 kOe present significant machining challenges due to their hardness (Hv 550-650), brittleness, and strong magnetic fields (1.0-1.4 T). Precision cutting is essential for motor components, MRI systems, and energy storage applications.

Our Diamond Wire Cutting System processes magnetic materials using specialized non-magnetic fixturing and 0.5-0.8mm diamond wire at cutting speeds of 20-50m/s. The controlled cutting process maintains moderate substrate temperatures, preventing demagnetization that occurs at higher temperatures for standard N grades. For N52 grade NdFeB magnets, our technology delivers good dimensional accuracy with minimal edge chipping while preserving magnetic flux density within acceptable ranges of pre-machining values.

This specialized magnetic material processing capability enables manufacturers to produce complex-shaped magnets with consistent magnetic properties and precise dimensions. The combination of good tolerances and preservation of magnetic characteristics provides performance improvements in end applications such as electric vehicle motors, wind turbine generators, and high-efficiency speakers.

Quartz Glass Cutting

Optical Component Manufacturing

An optical manufacturer needed better precision for high-purity quartz glass components. Using 0.5mm wire at 50m/s, our machine delivered superior accuracy and finish. The system eliminated micro-fractures, reduced post-processing and enabled direct optical-grade production.

Sapphire Processing

Custom Profile Cutting for LED Substrates

An LED manufacturer faced micro-cracks and low yields with sapphire substrates. Our system with 0.5mm wire at 50m/s improved yields and flatness with minimal subsurface damage. The process maintained thickness uniformity and reduced waste, enabling higher production output.

Carbon-Carbon Composite Cutting

Cylindrical Cutting for Carbon-Carbon Composites

An aerospace manufacturer needed cylindrical C/C composite heat shields without thermal damage. Our system with 0.8mm wire at 70m/s achieved precise cuts with no heat-affected zone. This preserved structural integrity, enabling direct-to-spec production with minimal finishing.

Specs and options

Specifications customizable upon request.

Tailored Machine Configurations

Our diamond wire cutting machines can be customized to meet specific industry requirements. Contact us for specialized solutions tailored to your unique production needs.

Industry-Specific Solutions

We offer optimized configurations for semiconductor, optical, aerospace, jewelry, and other industries. Each solution is engineered with parameters precisely calibrated for your material and application.

Flexible Customization Options

Available customizations include working area dimensions, wire diameter compatibility, cooling systems, fixturing solutions, and specialized software adaptations.

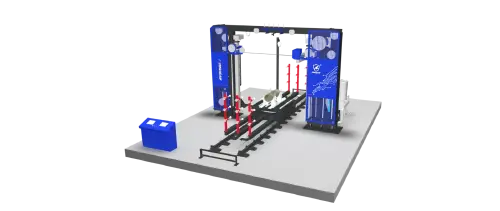

Multi-axis control with thin diamond wire saw for precision cutting

Precision Cutting at High Speed. From Profiles to Cylinders

0.1mm Precision Cutting

Servo system delivers stress-free surface with no wire marks

Customizable Large-Scale Cutting

Cut materials up to several meters in size, with custom dimensions available for oversized projects

CNC Simple Operation

CNC system requires no programming skills - simply set parameters and start automatic processing

Wide Material Compatibility

Diamond wire cuts high-hardness materials with minimal interaction, preserving material properties

Minimal Material Loss

Ultra-thin 0.35-0.5mm wire diameter creates narrow cutting kerf, reducing waste

High-Speed Cutting Efficiency

Wire speed up to 84m/s significantly increases production throughput and processing velocity

Versatile Cutting Capabilities

One machine performs straight, curved, cylindrical, slicing and profile cutting

Zero Thermal Damage

Cutting process eliminates heat-affected zones, preserving material properties and structure

Eco-Friendly Operation

Recycling system captures debris and cutting fluid, reducing environmental impact and costs

FAQs

Common Questions About Precision CNC Diamond Wire Cutting Machine

What is diamond wire cutting technology?

Diamond wire cutting is an industrial cutting process that uses a metal wire (0.35-1mm diameter) impregnated with diamond particles to slice through hard materials. The process relies on physical abrasion between diamond particles and the workpiece surface.

Our CNC Diamond Wire Cutting Machine uses fixed abrasive diamond wire technology, where diamond particles are electroplated to the wire core. This configuration provides consistent cutting performance with wire speeds up to 84m/s and controlled tension. The system precisely cuts materials with hardness from 1-9 Mohs while maintaining good dimensional tolerances.

Key technical advantages include: reduced material loss compared to traditional methods, good surface quality directly from cutting, and minimal thermal damage through precision cooling during high-speed operation.

What materials can a diamond wire cutting machine cut?

Our Industrial CNC Diamond Wire Cutting Machine is engineered to process materials with hardness values from 1-9 Mohs scale with specific performance parameters for each material category:

• Semiconductor materials: Silicon (7 Mohs), silicon carbide (9.5 Mohs), gallium arsenide (4.5 Mohs)

• Optical materials: Sapphire (9 Mohs), quartz glass (7 Mohs), optical glass (5-6 Mohs)

• Carbon-based materials: Graphite (1-2 Mohs), carbon-carbon composites (3-4 Mohs)

• Advanced ceramics: Alumina (9 Mohs), zirconia (8.5 Mohs), aluminum nitride (8 Mohs)

• Piezoelectric materials: PZT ceramics (6-7 Mohs), lithium niobate (5-6 Mohs)

• Magnetic materials: Neodymium-iron-boron (NdFeB) (Hv 550-650) and other rare earth magnets

• Precious stones: Jade (6-7 Mohs), luxury stones (3-7 Mohs), crystal (7 Mohs), marble (3-4 Mohs)

The system automatically adjusts cutting parameters (wire speed, tension, feed rate) based on material properties, delivering optimized surface quality and dimensional accuracy for each specific material type.

How precise is diamond wire cutting? What accuracy can I expect?

Our diamond wire cutting system delivers industry-leading precision with:

• Positioning accuracy: <0.1mm across the entire working range

• Surface finish: Smooth surface with no wire marks

• Kerf width: Varies based on wire diameter (0.35-1mm)

These precision capabilities are achieved through our servo-controlled wire tensioning system, rigid machine structure, and advanced CNC control. For materials like quartz glass and optical components, we consistently achieve excellent flatness. For semiconductor applications, we maintain good thickness uniformity throughout the cutting process. Our technology delivers significantly better results than traditional cutting methods while maintaining superior surface quality with no wire marks, often requiring minimal post-processing.

Diamond wire saw vs. slurry cutting - which is better for hard materials?

For hard and brittle materials, diamond wire cutting offers significant advantages over traditional slurry-based methods:

• Cutting speed: Diamond wire processes materials 2-3x faster than slurry sawing

• Material efficiency: 30-40% less material loss with thinner kerf (0.4-1.1mm vs. 1.5-3.0mm)

• Surface quality: Better surface finish (Ra 0.2-0.8μm vs. 1.0-2.5μm) with fewer microcracks

• Environmental impact: Significantly reduced slurry waste and contamination

While slurry cutting has lower initial tooling costs, diamond wire cutting delivers substantially lower total cost of ownership through faster cutting speeds, higher quality results requiring less post-processing, and better material yield. The ROI advantage is particularly significant for high-value materials like optical quartz, sapphire, and technical ceramics.

Diamond wire saw vs. laser cutting - which is better for hard materials?

When comparing diamond wire cutting to laser cutting for hard materials, several key differences determine optimal technology selection:

• Material compatibility: Diamond wire handles a broader range of materials (1-9 Mohs), while laser cutting struggles with highly reflective materials like copper and aluminum

• Thermal impact: Diamond wire produces minimal heat-affected zones, preserving material properties; laser cutting generates significant heat (1000-1500°C) that can alter material characteristics

• Cutting thickness: Diamond wire effectively cuts thick materials (up to meters) while maintaining precision; laser cutting efficiency decreases dramatically with material thickness

• Surface quality: Diamond wire delivers surface finish without micro-cracks; laser cutting often requires secondary finishing operations

• Operating costs: Diamond wire has higher initial investment but lower running costs through better material yield and energy efficiency

For precision hard materials like quartz, sapphire, and technical ceramics, diamond wire cutting typically delivers superior overall value through better dimensional accuracy, material preservation, and lower total processing costs.

How difficult is it to operate a DINOSAW diamond wire cutting machine?

Our CNC diamond wire cutting machines are designed for straightforward operation, even for operators with minimal experience. The system features:

• Intuitive touchscreen interface with pre-set material parameters

• One-button operation for standard cutting tasks

• Automatic wire tensioning and feed rate control

• Self-diagnostic system for maintenance alerts

New operators typically achieve proficiency after just 1-2 days of training. For complex custom profiles, our machines include simplified programming capabilities that don't require extensive CNC knowledge. Most customers report that their teams can master basic operations within one week and advanced cutting tasks within two weeks. We provide comprehensive training materials and remote support to ensure smooth implementation in your production environment.

What maintenance does a diamond wire cutting machine require?

Our diamond wire cutting machines require minimal maintenance compared to conventional cutting equipment. Regular maintenance includes:

• Daily (15 minutes): Wire inspection, coolant level check, and debris removal

• Weekly (30 minutes): Lubrication of moving parts and filtration system cleaning

• Monthly (2 hours): Complete cleaning, wire guide inspection, and system calibration

• Semi-annual (4 hours): Full preventive maintenance service

Diamond wire typically requires replacement after 50-200 hours of cutting, depending on material hardness and cutting parameters. The machine's self-diagnostic system monitors critical components and alerts operators to maintenance needs before failures occur. Most customers maintain over 95% uptime with this maintenance schedule, with consumables (wire, coolant, filters) typically accounting for 5-8% of operating costs. We provide comprehensive maintenance training and remote diagnostic support to minimize downtime.

How does diamond wire cutting impact production efficiency?

Diamond wire cutting significantly enhances production efficiency across several metrics:

• Cycle time reduction: 50-70% faster processing compared to conventional methods

• Single-pass cutting: Many materials require just one cutting operation with minimal post-processing

• Multi-axis capability: Complete complex shapes in a single setup, reducing handling time

• Improved reliability: Average uptime of 95%+ with minimal maintenance requirements

Certifications & Standards

Precision Cutting at High Speed. From Profiles to Cylinders

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready for Precision Cutting from Profiles to Cylinders at 84m/s?

Diamond wire cuts optical materials, semiconductors, and technical ceramics with minimal thermal damage

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文