Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

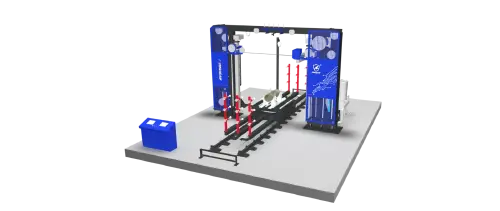

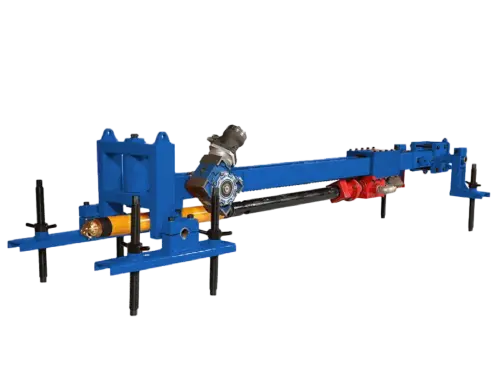

Nuclear Decommissioning Gantry Dry CNC Wire Saw Cutting Machine

MSGQ-SC

Compatible Materials & Products

Precision Metal Cutting for Nuclear Power Plant Decommissioning

Stainless Steel > Gloveboxes

Nuclear power plant gloveboxes made from stainless steel require precise dismantling during decommissioning to prevent contamination spread and ensure worker safety.The DINOSAW Gantry Dry Wire Saw Machine employs diamond wire technology with remote operation to cut through stainless steel gloveboxes with exceptional precision. Its air cooling system (-20°C) prevents heat damage while maintaining optimal cutting performance.

The waterless technology eliminates the risk of contamination that would occur with traditional wet cutting methods, making it ideal for radioactive environments where containment is critical.This cutting method significantly reduces radiation exposure risks for personnel while ensuring complete structural integrity throughout the dismantling process.

Carbon Steel > Shield Plates

Shield plates composed of carbon steel serve as critical radiation barriers in nuclear power plants and demand specialized cutting techniques during decommissioning operations.

The DINOSAW system's precision diamond wire technology delivers controlled cuts through thick carbon steel shield plates with minimal vibration. The machine's dual-axis movement capability allows for both horizontal and vertical cutting directions, providing flexibility when handling large shield plates with complex geometries. Remote operation keeps personnel at a safe distance while the integrated laser positioning system ensures cutting accuracy to within millimeters even on massive structures.

This advanced approach maximizes material recovery potential while maintaining strict adherence to radiation exposure protocols throughout the decommissioning process.

Cast Iron > Large Valves

Large cast iron valves in nuclear power plants present unique dismantling challenges due to their density, irregular shapes, and potential internal contamination.

The DINOSAW Gantry Dry Wire Saw excels at cutting through dense cast iron valve components with its high-tension diamond wire system. The machine's adaptable cutting paths enable precise sectioning of complex valve geometries without generating excessive heat or vibration. The dry cutting process eliminates the need for cooling fluids that could spread contamination, while the remote operation interface allows technicians to control cutting parameters from a safe distance, continuously monitoring progress through integrated camera systems.

This specialized cutting approach significantly reduces handling time and secondary waste generation compared to conventional valve disassembly methods.

Various Metals > Irregular Structures

Nuclear decommissioning frequently involves dismantling irregular metal structures with complex geometries and varying material compositions that resist conventional cutting approaches.

The DINOSAW Gantry Dry Wire Saw Machine offers unmatched versatility when cutting irregular structures composed of various metals. Its diamond wire technology maintains consistent cutting performance across different metal types and thicknesses found within a single component. The precision control system allows operators to program complex cutting paths that follow the exact contours of irregular structures. With remote operation capability and real-time monitoring, technicians can make instantaneous adjustments to optimize cutting performance while maintaining safe distance from radioactive materials.

This adaptive cutting solution dramatically reduces project timelines while ensuring complete structural dismantling with minimal secondary waste generation.

Mixed Alloys > Radiation Vessels

Radiation vessels in nuclear power plants typically incorporate multiple alloy layers and specialized materials designed to contain radioactive substances, requiring sophisticated dismantling technologies.

The DINOSAW Gantry Dry Wire Saw Machine precisely sections radiation vessels with its advanced diamond wire technology that maintains cutting efficiency across varying alloy compositions. The system's precision cooling technology directs -20°C air exactly at the cutting point, preventing thermal expansion while maintaining structural integrity. Remote operation capabilities allow technicians to execute complex cutting sequences from a safe location, while the dry cutting process eliminates cross-contamination risks associated with liquid coolants that could transport radioactive particles.

This specialized cutting approach ensures complete vessel dismantling while maximizing material segregation for optimized waste classification and disposal pathways.

Nuclear Power Plant Decommissioning

Safe Dismantling with Zero Cross-Contamination

A European nuclear power plant utilized DINOSAW Gantry Dry Wire Saw to dismantle primary circuit components safely. The remote operation system allowed technicians to maintain a significant safety distance while achieving precision cuts on radioactive components. The dry cutting technology eliminated liquid waste issues, substantially reducing decontamination costs and accelerating the decommissioning timeline.

Specialized Dismantling Contractor

Enhancing Project Efficiency with Versatile Cutting

A leading decommissioning contractor deployed DINOSAW Gantry Dry Wire Saw across multiple critical infrastructure projects. The system's ability to cut both horizontally and vertically through mixed materials significantly reduced equipment changeover time. Contractors reported completing complex dismantling operations much faster while maintaining stricter safety compliance compared to conventional methods.

Special Environment Operations

Enabling Safe Cutting in Radiation-Controlled Areas

A government research facility deployed DINOSAW technology to dismantle experimental equipment in a radiation-controlled environment. The system's waterless operation eliminated cross-contamination concerns while maintaining optimal cutting performance. Remote operation capabilities allowed technicians to perform precision cuts from a monitoring room, significantly reducing radiation exposure while maintaining full visual control.

Specs and options

Specifications customizable upon request.

This is a custom-designed equipment. Detailed technical specifications are not publicly displayed due to safety and confidentiality protocols. Please contact us directly for a tailored solution proposal.

Advanced cutting equipment designed specifically for nuclear decommissioning challenges

Precision Dismantling, Zero Contamination

Enhanced Safety

Remote operation keeps personnel at a safe distance from radiation sources, significantly reducing exposure risk

Zero Contamination

Dry cutting eliminates liquid waste and cross-contamination risks, reducing decontamination costs

Precision Air Cooling System

Innovative cooling technology directs cold air at cutting points, preventing heat damage while maintaining structural integrity

Fixed & Mobile Configuration Options

Available in stationary and transportable systems for flexible deployment in nuclear decommissioning environments

Environmentally Compliant Operation

Meets strict radiation safety protocols and environmental standards required in nuclear decommissioning projects

Precision Cutting in Any Direction

Dual-axis movement enables precise horizontal and vertical cutting on complex structures

Multi-Material Versatility

Effectively cuts stainless steel, carbon steel, cast iron and mixed alloys with consistent performance

FAQs

Common Questions About DINOSAW Nuclear Decommissioning Gantry Dry CNC Wire Saw Machine

What is a Gantry Dry CNC Wire Saw Machine and how does it work?

The DINOSAW Gantry Dry Wire Saw Machine is a specialized cutting system designed for nuclear power plant decommissioning applications. It utilizes a diamond-embedded wire running at high speed through a pulley system to cut through various metals and materials.

The system operates on the principle of abrasion, where the diamond particles on the wire remove material as the wire moves through the workpiece. Unlike traditional cutting methods, our dry wire technology uses air cooling instead of liquid coolants, eliminating contamination risks in radioactive environments.

The gantry frame provides structural support and precise movement control in both horizontal and vertical directions, allowing for complex cutting operations on various components while maintaining millimeter-level accuracy.

Why choose dry cutting over wet cutting for nuclear decommissioning?

Dry cutting eliminates the need for cooling fluids that could become contaminated with radioactive particles during the cutting process. This significantly reduces secondary waste generation and simplifies the decontamination process, resulting in lower cleanup costs.

Our specialized air cooling system efficiently manages cutting temperatures without introducing liquids that could transport radioactive contaminants throughout the work area or into drainage systems. This is particularly critical in controlled environments where containment of radioactive materials is the highest priority.

Additionally, dry cutting provides better visibility of the cutting area and eliminates the need for complex liquid collection and filtration systems, making the overall operation safer, cleaner, and more efficient for nuclear decommissioning projects.

What materials can the DINOSAW Gantry Dry Wire Saw effectively cut?

The DINOSAW Gantry Dry Wire Saw Machine effectively cuts through a wide range of metals commonly found in nuclear decommissioning sites, including stainless steel, carbon steel, cast iron, and various specialized alloys. The diamond wire cutting system maintains consistent cutting performance regardless of material composition or thickness variations encountered during dismantling operations.

Our diamond wire technology is specifically engineered to handle complex components with mixed materials, such as reinforced concrete structures with embedded steel, composite panels with multiple metal layers, and specialized radiation containment vessels.

The cutting efficiency remains high even when transitioning between different materials within the same component.The system can also process hardened or heat-treated metals, exotic alloys, and materials with irregular geometries that would challenge conventional cutting methods, making it exceptionally versatile for diverse decommissioning scenarios.

How is operator safety ensured during cutting operations?

Operator safety is ensured through multiple integrated systems. The primary protection comes from our remote operation technology, which allows personnel to control the cutting process from a safe distance, significantly reducing radiation exposure compared to conventional methods.

Our comprehensive safety features include integrated emergency stop systems accessible from multiple control points, and redundant communication networks that maintain operational control even in case of primary system failure.

Additionally, the system's waterless cutting technology eliminates contamination spread through liquids. All operations are continuously monitored through multiple high-definition cameras with recording capabilities for safety verification and training purposes.

How does the DINOSAW system compare to traditional cutting methods?

The DINOSAW Gantry Dry Wire Saw Machine offers several significant advantages over traditional cutting methods used in nuclear power plant decommissioning. Compared to mechanical saws, plasma cutters, or oxy-fuel systems, our diamond wire technology generates minimal vibration and heat, preventing structural destabilization and reducing the risk of releasing embedded contaminants during the dismantling process.

Our system achieves faster cutting speeds than conventional methods when processing thick materials, while simultaneously reducing secondary waste generation. The remote operation capability dramatically decreases personnel radiation exposure compared to manual cutting approaches that require operators to work in closer proximity to radioactive components.

Unlike traditional methods that often have material or thickness limitations, the DINOSAW system can cut through mixed materials of varying thicknesses in a single operation, eliminating the need for multiple specialized tools and reducing project timelines for complex decommissioning projects.

Does the system comply with international nuclear safety standards?

Yes, the DINOSAW Gantry Dry Wire Saw Machine is designed and manufactured to comply with the most rigorous international nuclear safety standards for decommissioning equipment. Our system meets or exceeds requirements set by the International Atomic Energy Agency (IAEA), the Nuclear Regulatory Commission (NRC), and the European Nuclear Safety Regulators Group (ENSREG) for specialized dismantling tools.

The equipment is certified for use in controlled radiation environments and undergoes comprehensive testing for radiation resistance, electromagnetic compatibility, and operational reliability under extreme conditions. All electronic components are specially shielded to prevent radiation-induced malfunctions, and the control systems implement fail-safe protocols that default to the safest operational state in case of any system anomaly.

Additionally, our quality management system is certified to ISO 9001 and ISO 14001 standards, with specific compliance to nuclear industry requirements such as 10 CFR 50 Appendix B and ASME NQA-1. Each system undergoes rigorous factory acceptance testing and site-specific validation before commissioning for nuclear decommissioning applications.

What are the differences between fixed and mobile configurations?

The DINOSAW Gantry Dry Wire Saw Machine is available in both fixed and mobile configurations to accommodate different nuclear power plant decommissioning project requirements. The fixed installation provides maximum stability and precision for permanent cutting stations within a facility, featuring robust anchoring systems and enhanced rigidity for consistent performance during extended dismantling operations.

The mobile configuration offers strategic deployment flexibility with a self-contained transport system that allows the entire wire saw cutting unit to be relocated between different areas or facilities. This version includes quick-setup stabilization systems, integrated power management, and compact design optimized for movement through standard doorways and corridors while maintaining cutting capabilities for various radiation-controlled environments.

Both configurations utilize identical diamond wire cutting technology and remote operation systems, ensuring consistent performance regardless of setup. The choice between fixed and mobile wire saw equipment depends primarily on project scope, facility layout, and whether the decommissioning operations will be concentrated in one area or distributed across multiple locations during the nuclear power plant dismantling process.

How do wire saw temperature controls impact cutting performance and safety?

The DINOSAW Gantry Dry Wire Saw Machine features an advanced temperature control system that precisely maintains diamond wire operating temperature between 45-50°C during cutting operations. This temperature range represents the optimal balance between cutting efficiency and safety in nuclear decommissioning environments.

Maintaining this specific temperature window delivers several critical benefits: it prevents overheating that could compromise the diamond wire's structural integrity and cutting performance; it eliminates the risk of thermal expansion in radioactive materials that could release contaminants; and it ensures the cutting process generates minimal heat-induced dust, further reducing airborne contamination risks.

Our proprietary cooling technology achieves this precise temperature control without using liquid coolants, instead employing directed air cooling systems specifically calibrated for different material types and thicknesses. The system continuously monitors wire temperature through multiple thermal sensors and automatically adjusts cooling parameters to maintain optimal operating conditions throughout the cutting process.

Certifications & Standards

Precision Dismantling, Zero Contamination

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Transform Your Nuclear Decommissioning Project?

Experience DINOSAW safety and efficiency. Request your specialized solution today.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Nuclear Decommissioning Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文