Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

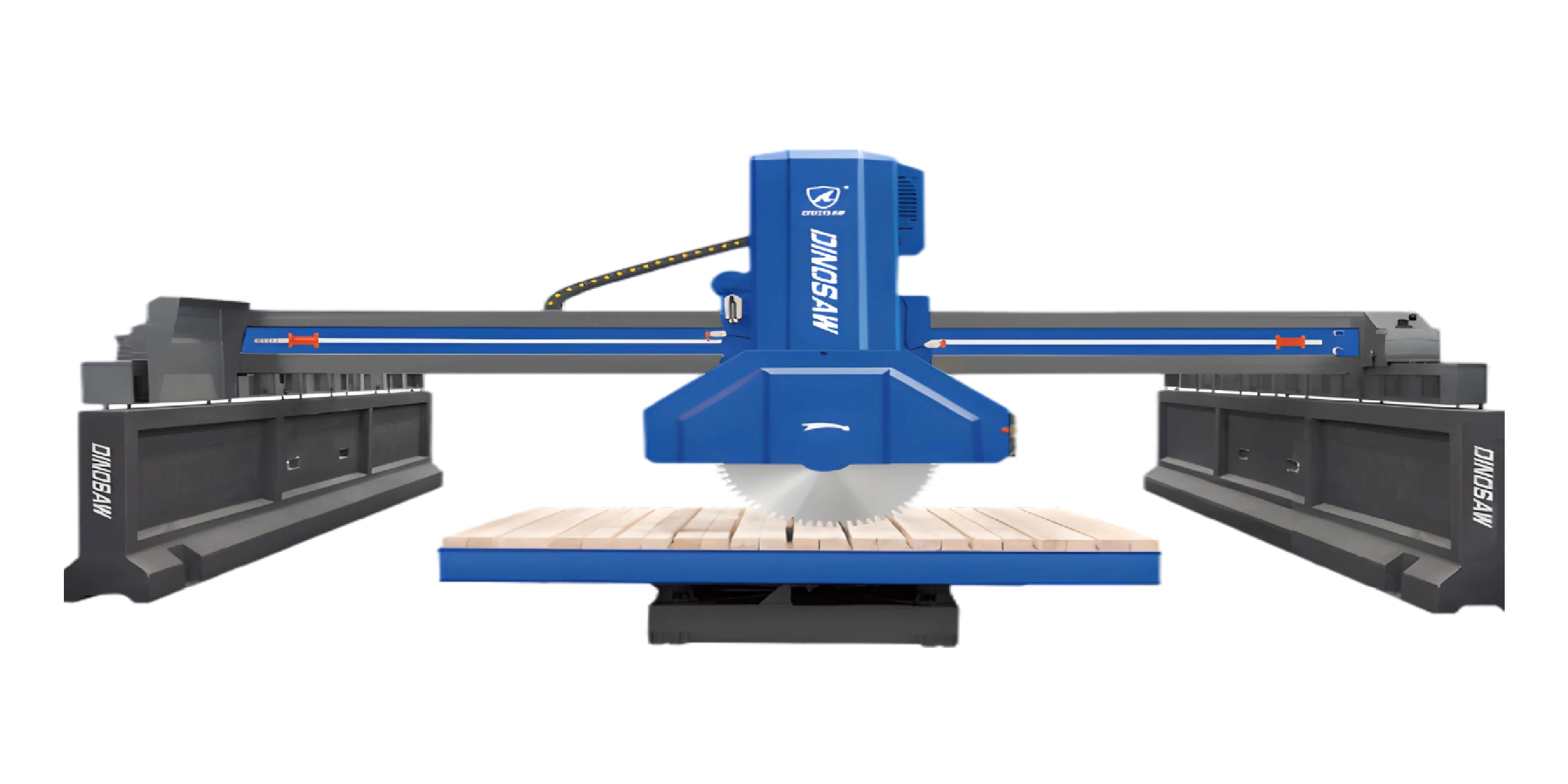

Explore the technical principles of a Bridge Cutting Machine. Learn how its cast iron beam, ground rails, and solid guide columns ensure cut quality and reduce blade wear.

A Bridge Cutting Machine's performance isn’t magic; it’s the direct result of smart engineering. The secret to a clean, fast cut lies in how the machine’s structure manages force and minimizes vibration. Superior structural stiffness, combined with precisely machined moving parts, is what stabilizes the cutting process, protects the blade, and ultimately delivers a higher-quality product.

Talk to us for a tailored bridge cutting machine setup today.

This article dives into the technical principles of a modern Bridge Cutting Machine. We’ll break down its core components, explain how they work together to ensure stability, and provide typical operating ranges to help you understand what makes these machines so effective.

Architecture: A System Built for Stability

A Bridge Cutting Machine is composed of a few key structural elements working in concert. The main system includes a heavy crossbeam (the "bridge") that moves along two parallel side beams (the X-axis). A cutting head assembly travels back and forth along this bridge while also moving vertically up and down on guide columns (the Z-axis). The stone slab rests on a worktable, which can often rotate to position the slab for different cuts without needing to move it manually.

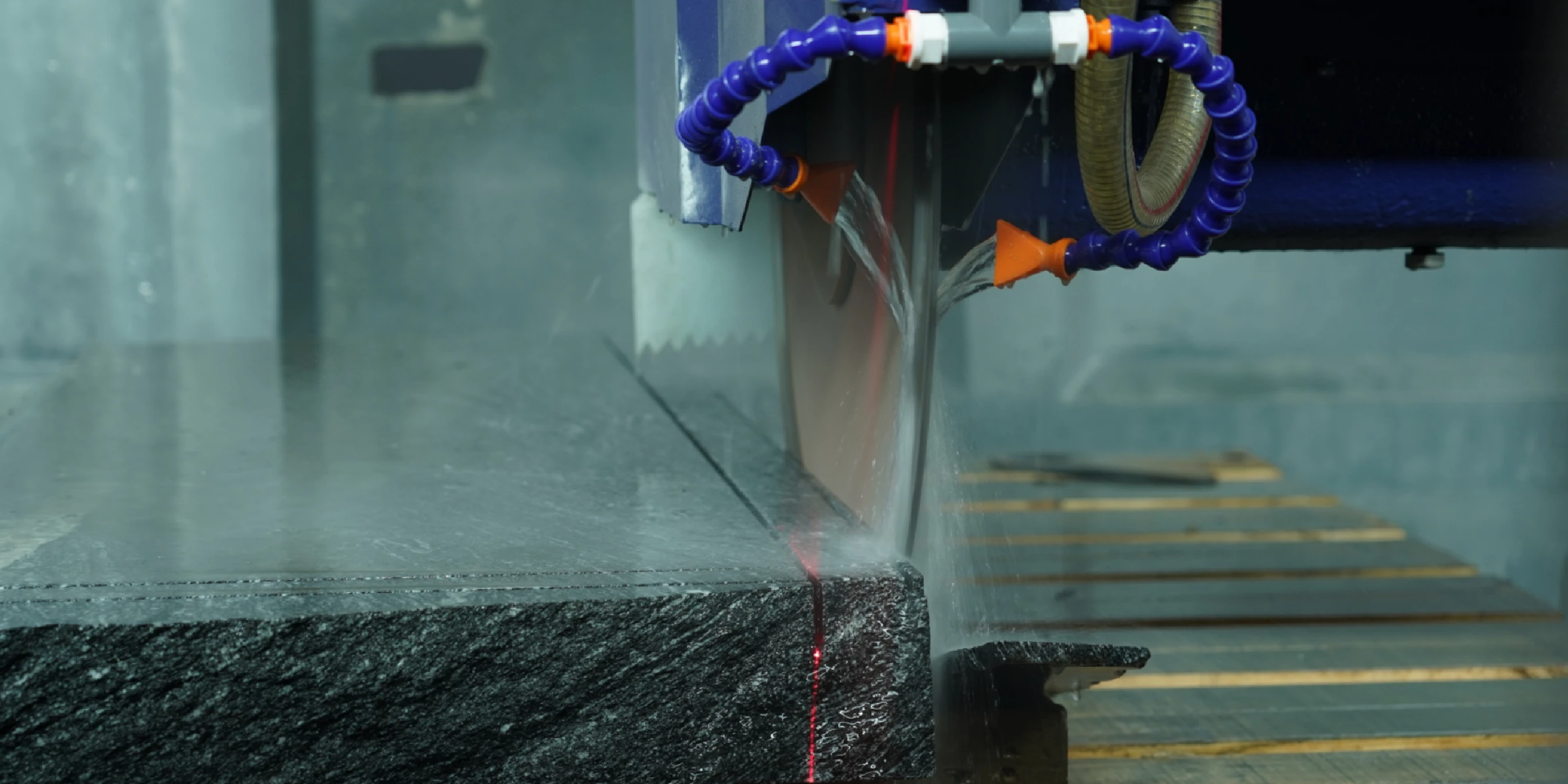

Vibration is the primary enemy, originating from the motor, the blade’s impact with the stone, and any minor imbalances. A well-designed structure dampens these vibrations through mass (heavy cast iron), rigidity (solid, reinforced beams), and precision (minimal gaps in moving parts). This ensures the blade's cutting edge remains stable, preventing chatter and extending its life.

What is the structural role of a cast iron beam in vibration reduction?

The primary role of a heavy, stress-relieved cast iron beam is to act as a vibration dampener. Its mass absorbs the high-frequency vibrations from the motor and blade, preventing chatter. This is the key to achieving a clean cut quality and preventing premature blade wear.

Core Components and Their Technical Roles

Every part of a Bridge Cutting Machine has a specific job. Here are the most critical components and how they contribute to performance.

- Stress-Relieved Cast Iron Beam: The main crossbeam is made from heavy cast iron that has undergone an aging process to relieve internal stresses. Its sheer mass is its greatest asset, as it naturally absorbs vibrations from the cutting head, preventing them from affecting the cut.

Precision-Ground Rails: The surfaces on which the bridge and cutting head travel are ground to be perfectly flat and smooth. This creates a minimal contact gap, eliminating the wobble or play that can lead to inaccurate cuts and a poor finish.

Why do precision-ground rails matter for kerf stability?

Precision-ground rails ensure the bridge moves on a perfectly smooth surface with minimal gaps, eliminating "wobble." This stable path is essential for a stable kerf (the cutting channel), ensuring the cut is straight and consistent on a bridge saw marble slab.

- Reinforced I-Beam Side Beams: The parallel rails are built on a foundation of standard I-beam steel, welded for rigidity. They are often fitted with an anti-bump device, providing another layer of resistance against vibrations generated during cutting.

- Solid Guide Columns with Hard Chrome: For vertical movement, the cutting head relies on solid round steel columns, not hollow tubes. This prevents flexing under load. A hard chrome plating adds a durable, low-friction surface that works with the timed, automatic lubrication system to ensure they remain consistently greased, preventing wear and stuttering.

How do solid, hard-chromed guide columns improve vertical accuracy?

Solid guide columns are more rigid than hollow ones and resist flexing as the cutting head moves. The hard-chrome plating provides a durable, low-friction surface that ensures the head maintains its exact vertical position without drift, which is critical for precise depth control.

How does timed auto-lubrication prevent long-term wear?

An auto lubrication system prevents long-term wear by consistently applying grease to critical moving parts. This avoids the damage from friction that occurs when manual maintenance is missed, helping the machine maintain its accuracy over its entire lifespan.

- Main Motor and Spindle: The powerhouse of the machine, this unit must provide consistent torque to avoid slowing down in dense materials. The spindle assembly must be perfectly balanced to prevent introducing new vibrations into the system.

- Control System (PLC/HMI): The PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) are the brains of the operation, allowing operators to set parameters like cutting speed, depth, and cut sequences.

- Rotary Worktable: A worktable that can rotate (e.g., 90 or 360 degrees) is a massive efficiency booster, perfect for countertop cutting, as it allows for complex cuts without needing to re-position a heavy slab.

Manufacturer-Reported Speed Ranges

Blade speed (RPM) is critical and must be matched to the blade diameter and stone type. Running too fast can cause glazing or premature wear, while running too slow reduces efficiency. Here are some typical manufacturer-reported RPM ranges for a granite bridge saw:

- For a Blade Diameter of 1400mm: ~722 r/min

- For a Blade Diameter of 1200mm: ~840 r/min

- For Ø1000mm Blade: ~1020-1085 r/min

- For Ø800mm Blade: ~1250 r/min

Note: These are general, manufacturer-reported guidelines. Always verify with your specific machine and blade manufacturer's recommendations.

What are the signs of incorrect RPM settings?

If the RPM is too high, you might hear a high-pitched squeal or see scorch marks on the stone. If it's too low, the cutting will feel slow and may strain the motor. Always start with the manufacturer-reported RPM ranges and fine-tune based on the material's feedback.

Common Failures and Mitigation

Even robust machines can show symptoms of wear or misalignment. Here are a few things to watch for:

What failure symptoms point to rail or column issues?

Observe for jerky movements, new or increased noise, or a sudden loss of cutting squareness. These often point to rail or column issues. Diagnose by first checking for debris on the rails, then for lack of lubrication on the columns. Regular inspection as part of the maintenance schedule is the best prevention.

- Symptom: Audible chatter or visible vibration.

- Likely Cause: Worn guide components, loose fittings, or an imbalanced blade.

- Fix/Prevention: Check lubrication on guide columns. Inspect rails for debris. Ensure the blade is properly mounted and not damaged.

- Symptom: Cuts are not perfectly square.

- Likely Cause: Rail misalignment or wear in the bridge travel mechanism.

- Fix/Prevention: Re-calibrate the machine's squareness. Check for and clean any debris on the side beam rails that could cause deviation.

- Symptom: Scorch marks or rapid blade glazing.

- Likely Cause: Insufficient coolant flow or incorrect RPM/feed rate.

- Fix/Prevention: Check coolant nozzles for blockages. Reduce feed rate or adjust RPM according to material hardness.

Compatibility and Integration

A modern Bridge Cutting Machine must integrate smoothly into a digital workshop. Compatibility extends to the PLC/HMI, which should be intuitive, and the drives, which must respond precisely to control inputs. For automated production lines, look for interfaces like OPC UA or Profinet, which are commonly used industrial protocols for machine-to-machine communication. This allows the bridge saw to connect with other equipment, a crucial factor for a comprehensive.

How do PLC/HMI settings interact with physical cutting parameters?

The PLC/HMI is the brain that translates your strategy into machine commands, such as feed rate and RPM. It's crucial that these digital settings are appropriate for the physical realities of the stone and blade to avoid damage or poor results on your infrared bridge saw. An incorrect setting can easily lead to a broken slab or a damaged blade.

Are integration protocols like OPC UA always necessary?

Not for a standalone bridge cutter. However, in an automated line where the machine needs to communicate with conveyors, loaders, or a central factory system, protocols like OPC UA are essential. They enable different machines to speak a common language, which is required for coordinated, smart factory operations.

English

English 中文

中文