Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

From CNC Bridge Saws to Robotic Arms, this is the ultimate guide for stone fabricators. Discover the 8 key CNC stone machines transforming the stone industry and learn how automation can boost your factory's precision, speed, and profitability.

Here's what I've noticed after walking through hundreds of stone shops: the most profitable ones aren't necessarily the biggest. They're the smartest. While competitors struggle with manual errors and turn away complex jobs, these shops use CNC automation to handle work others can't.

The difference? They stopped working harder and started working smarter. Manual cutting means inconsistent results. CNC cutting means perfect repeatability every single time.

Stone demand is growing, but skilled labor is shrinking. The shops surviving this shift are the ones investing in automation today. According to Grand View Research, automation is becoming essential for meeting market demand.

What CNC Actually Means for Your Shop

Think of CNC as your most reliable craftsman. One who never gets tired, never makes mistakes, and works exactly the same way every time. The computer reads your design file and tells the machine exactly where to cut.

Automation takes this further. It connects multiple machines together, so your slab moves from cutting to shaping to polishing with minimal handling. Less touching means fewer chips, cracks, and accidents.

The immediate benefits you'll see: perfect precision that eliminates costly errors, dramatically faster production speeds, and safer operations with fewer injuries.

Ready to see which CNC machine could solve your biggest production challenge? Contact a Dinosaw Machine expert today for a personalized consultation. We'll analyze your current workflow, identify bottlenecks, and recommend the exact automation solution that fits your shop's needs and budget.

The 8 Essential CNC Stone Machines

Every successful automated stone shop uses these eight types of machines. Each serves a specific purpose. Here's what they actually do and when you need them.

Primary Cutting Equipment

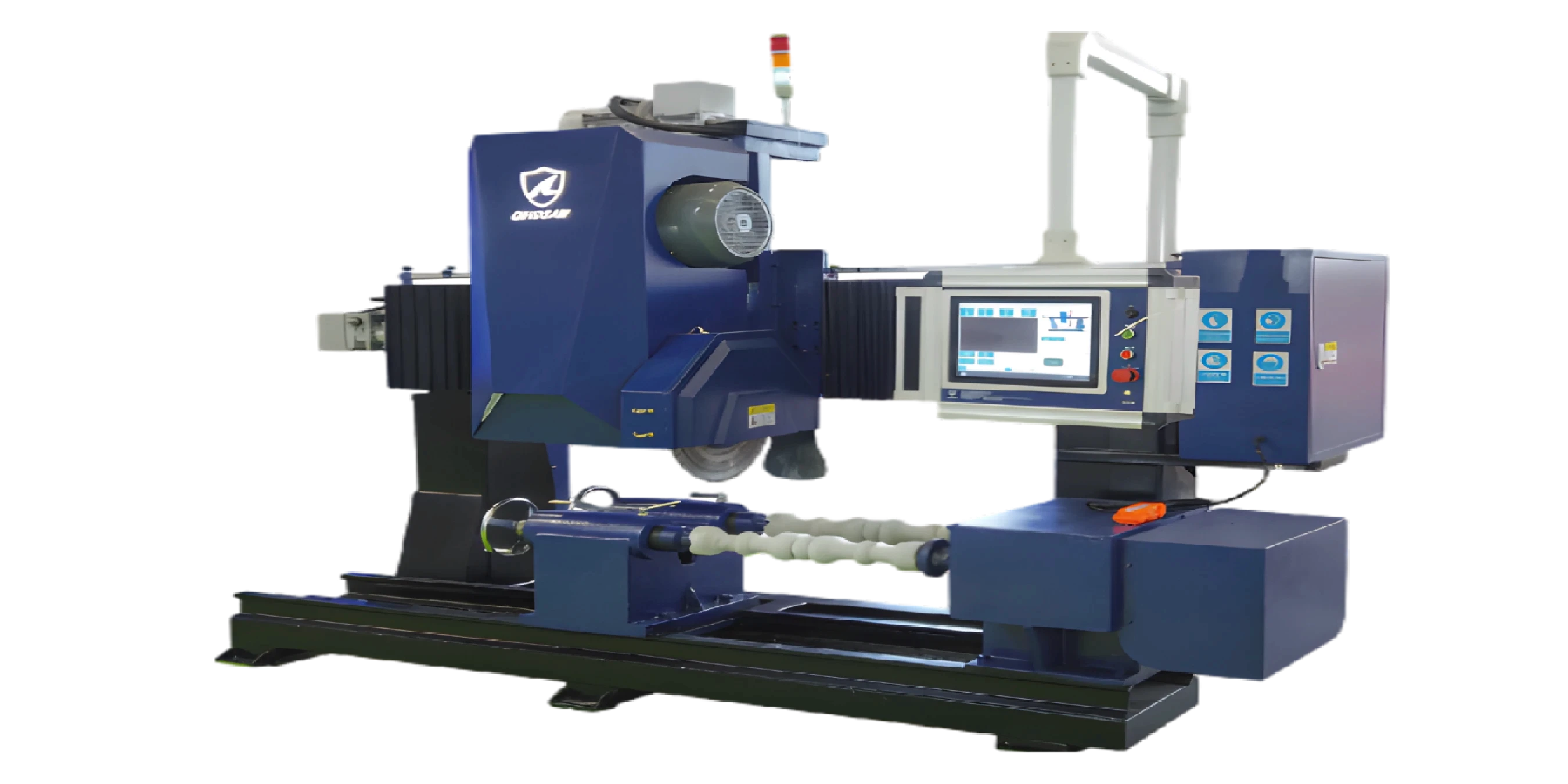

1. CNC Bridge Saw: The Workhorse

Walk into any busy stone shop, and you'll see one of these. It's a massive saw blade that rides on rails above your slab. That's the "bridge" part.

What makes it special? You program it once, and it cuts the same pattern perfectly every time. Kitchen countertops, tiles, architectural panels – this machine handles the bulk of your cutting work.

Best for: High-volume straight cuts, angled cuts, basic countertop fabrication

2. CNC Wire Saw: The Block Cutter

This one uses a continuous diamond wire instead of a blade. Think of it like a giant cheese cutter, but for granite blocks weighing tons.

Wire saws cut through virtually any thickness. Quarries use them to extract blocks. Fabricators use them for massive architectural pieces like columns and large sculptures.

Best for: Thick blocks, quarry operations, large architectural elements

3. Waterjet Cutter: The Precision Artist

Here's the machine for jobs that demand perfection. It shoots water at 60,000 PSI mixed with garnet abrasive. No heat, no stress cracks, no chipping.

I've seen waterjets cut intricate floor medallions that would be impossible by hand. The edge quality is so good it often needs no polishing.

Best for: Intricate designs, delicate materials, medallions, perfect edge quality

Shaping and Detail Work

4. Stone Lathe: The Column Specialist

This machine spins a stone block while cutting tools shape it. Perfect for anything round: columns, balusters, vases, decorative bowls.

For architectural restoration work, a stone lathe is invaluable. You can replicate historical details with perfect accuracy.

Best for: Columns, balusters, turned architectural elements, round objects

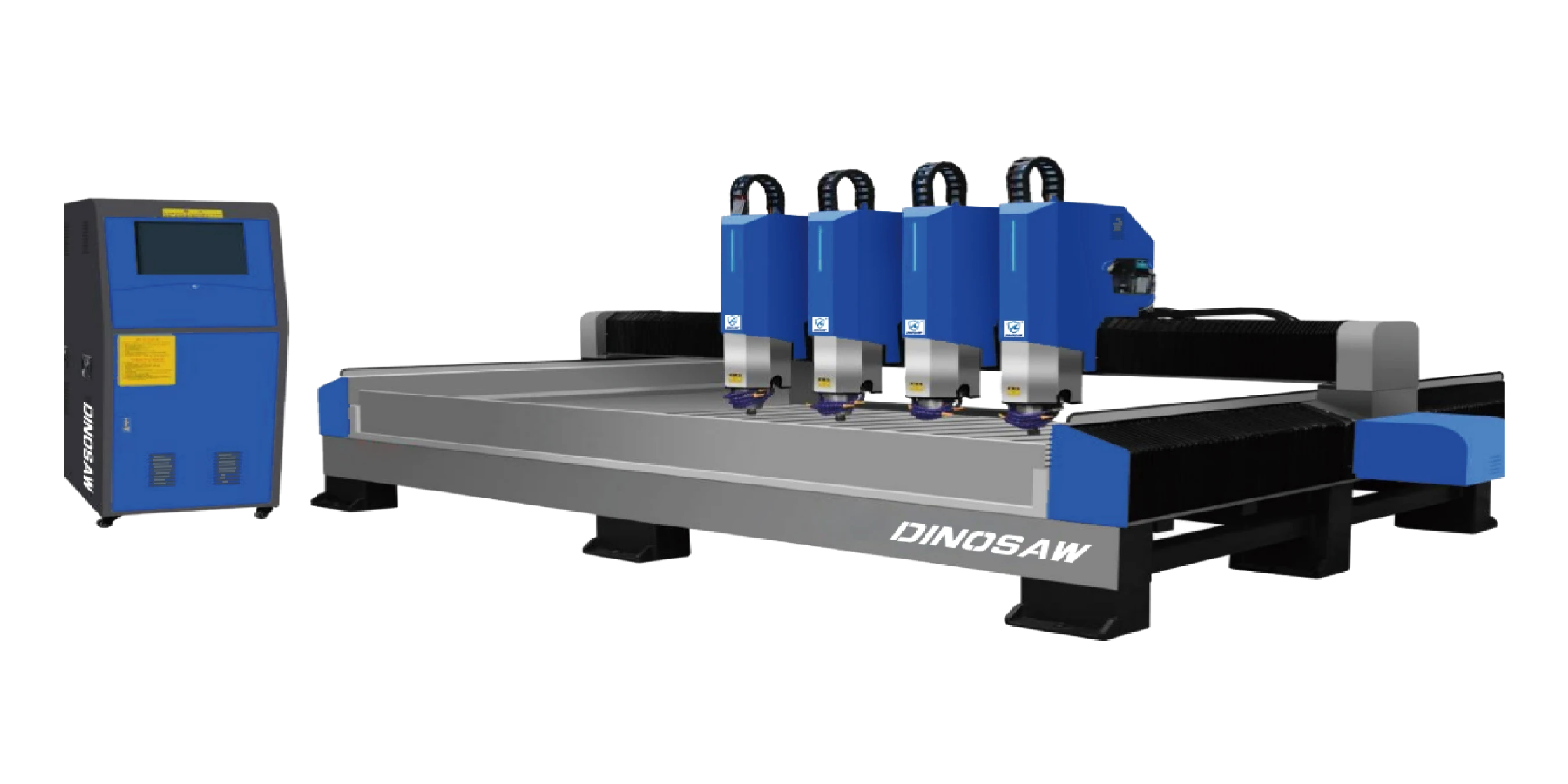

5. CNC Stone Router: The Detail Master

This is your Swiss Army knife. After the bridge saw makes the primary cuts, the router handles everything else. Sink cutouts, faucet holes, edge profiles, engraving.

One machine replaces multiple manual operations. Program it to cut a sink hole, drill faucet holes, and add a decorative edge profile – all in one setup.

Best for: Sink cutouts, engraving, edge profiling, detailed fabrication work

Advanced Machining Solutions

6. 5-Axis CNC Bridge Saw: The All-in-One Solution

This is where things get impressive. Take a bridge saw and add full 5-axis movement. Now it can cut, miter, drill, and shape in one machine.

I've watched these machines take a raw slab and produce a finished countertop with waterfall edges, sink cutouts, and polished edges – without moving the piece once.

Best for: Complete countertop fabrication, complex angles, waterfall edges

7. Stone Robot Arm: The Artistic Genius

Six axes of movement. No dead spots. This machine can reach any surface from any angle. It's like having a master sculptor who never gets tired.

For 3D sculptures, curved architectural elements, or complex artistic pieces, nothing else comes close. The freedom of movement is almost unlimited.

Best for: 3D sculptures, artistic work, complex curved surfaces, architectural art

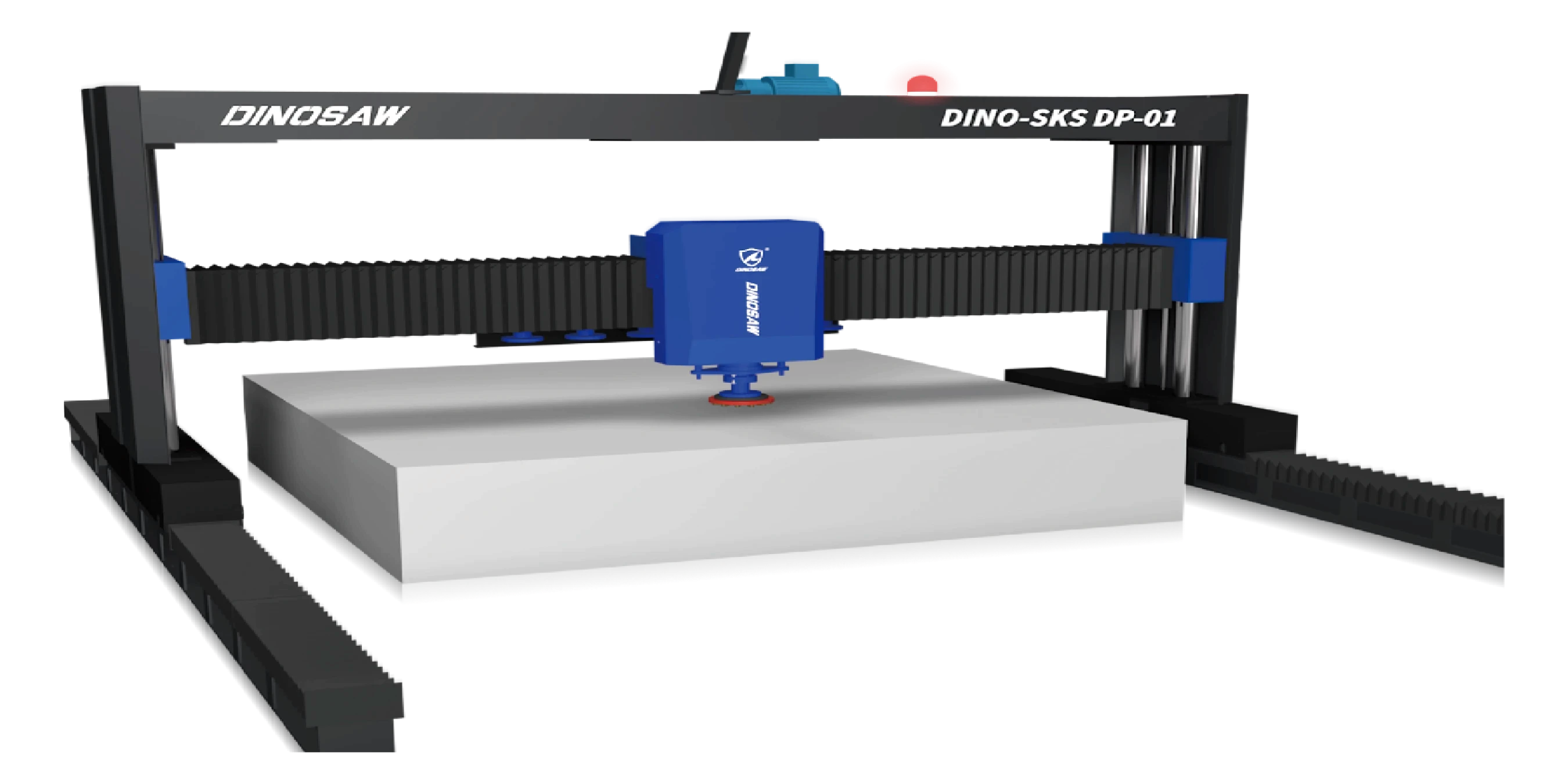

8. CNC Polishing Machine: The Finishing Touch

Polishing by hand is backbreaking work. These machines use multiple heads with progressively finer abrasives to create a perfect mirror finish.

Consistency is everything in polishing. This machine delivers the same quality across the entire surface, every single time.

Best for: Slab polishing, consistent surface finishing, high-volume production

Building Your System: Beyond the Machine

Buying a CNC machine is just the start. Success comes from building a complete system around it.

Software: The Real Brain

Your CAD/CAM software is where everything starts. It takes your design and creates the toolpaths that drive the machine.

Modern software has gotten much easier to use. Most use graphical interfaces where you import drawings, select tools, and generate cutting paths without writing code.

Training: Your Team's Evolution

Your operators transform from manual laborers to skilled technicians. This isn't about replacing people – it's about upgrading their roles.

A well-trained operator maximizes machine output and minimizes errors. That directly impacts your profitability.

Support: Your Long-term Partner

CNC machines are long-term investments. You need a supplier who provides training, technical support, and reliable parts availability. The machine is only as good as the support behind it.

Getting Started: Your Next Steps

The question isn't whether to automate. It's how and when.

Look at your current operations. Where are your biggest bottlenecks? That's your starting point. Maybe it's primary cutting with a bridge saw. Maybe it's detailed work with a router. Start there and build your system.

Every successful stone shop I know started with one machine and built from there. The key is choosing the right first step for your specific needs. Contact a Dinosaw Machine expert today for a personalized consultation and discover which automation solution fits your factory best.

Common Questions About CNC Stone Machines

What's the main benefit of CNC stone machines?

Consistency and precision. Manual work varies with operator skill and fatigue. CNC produces identical results every time, eliminating costly errors and material waste.

How much do these machines cost?

Varies widely. A basic CNC router starts around $50,000. A high-end 5-axis bridge saw can cost $300,000+. Consider total cost of ownership including training, software, and maintenance.

Is CNC programming difficult to learn?

Modern software is surprisingly user-friendly. Most operators become proficient within weeks with proper training. The graphical interfaces eliminate most hand-coding.

What materials can these machines handle?

All stone types: granite, marble, limestone, travertine. Plus engineered materials like quartz surfaces, ultra-compact surfaces, ceramics, and porcelain slabs.

Can CNC machines do engraving and lettering?

Absolutely. CNC routers excel at detailed engraving work. Text, logos, decorative patterns – all from digital files with incredible precision and consistency.

What's the difference between a bridge saw and 5-axis bridge saw?

A standard bridge saw cuts straight and angled lines. A 5-axis version adds full head articulation for mitered cuts, plunge cutting, and complex shaping – all in one setup.

English

English 中文

中文