Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

For business leaders: a strategic overview of multi-wire saw technology. Understand the ROI levers, from a 10-25% yield increase to a 30% reduction in energy costs, and how to plan for adoption.

For business leaders in the stone fabrication industry, capital equipment investments must be justified by clear returns and strategic advantages. This guide synthesizes the value proposition of advanced multi-wire saw technology, using the DINOSAW Intelligent Multi-Wire Saw to illustrate the impact on profitability and operational excellence.

Have a question or need a quote? Contact us now.

The Primary Value Levers of Multi-Wire Saw Technology

For a fabrication business, investing in a multi-wire saw is not just an equipment upgrade; it's a strategic move that directly impacts core financial and operational metrics. The value is unlocked through several key levers, all rooted in confirmed engineering specifications:

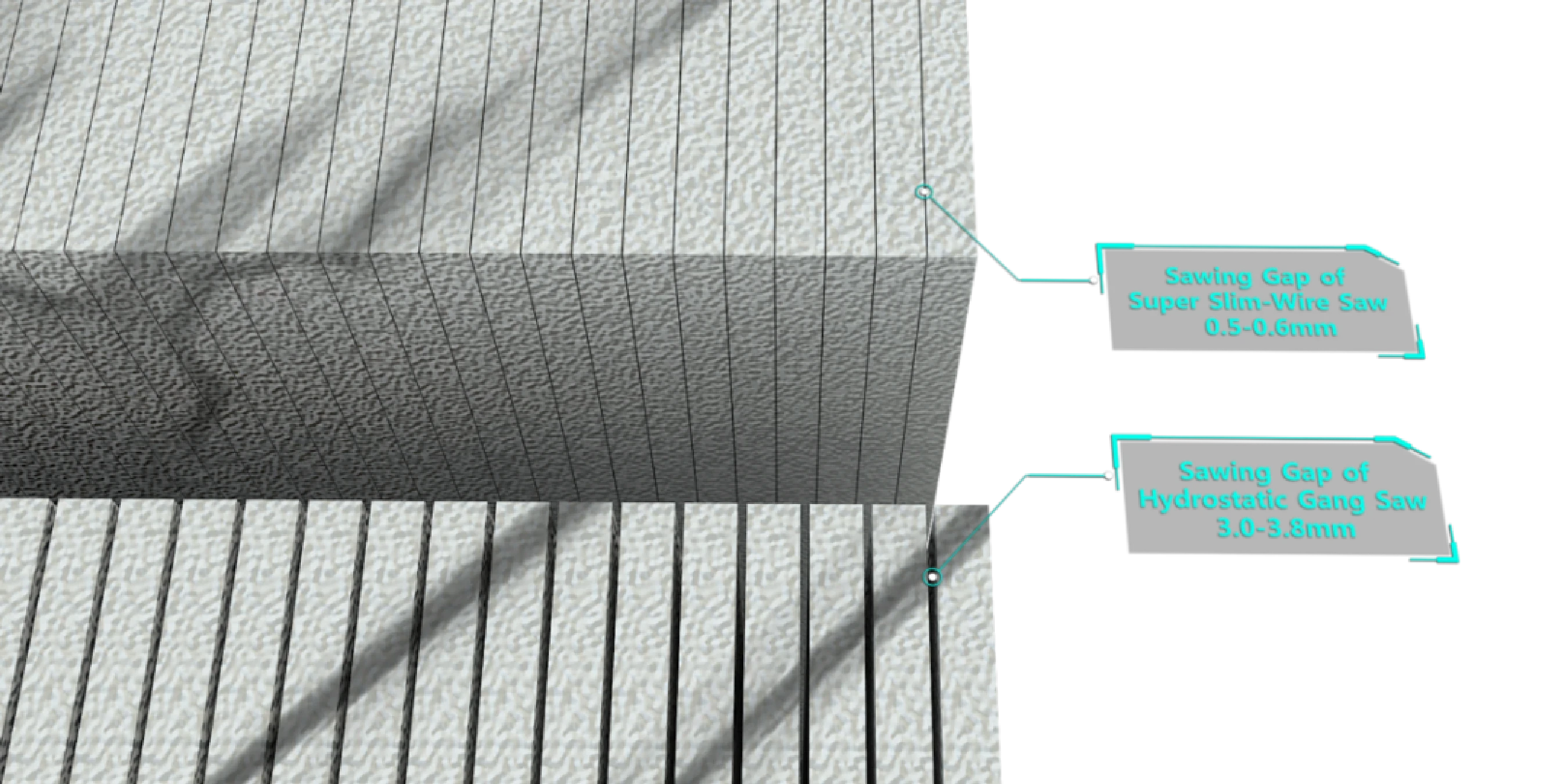

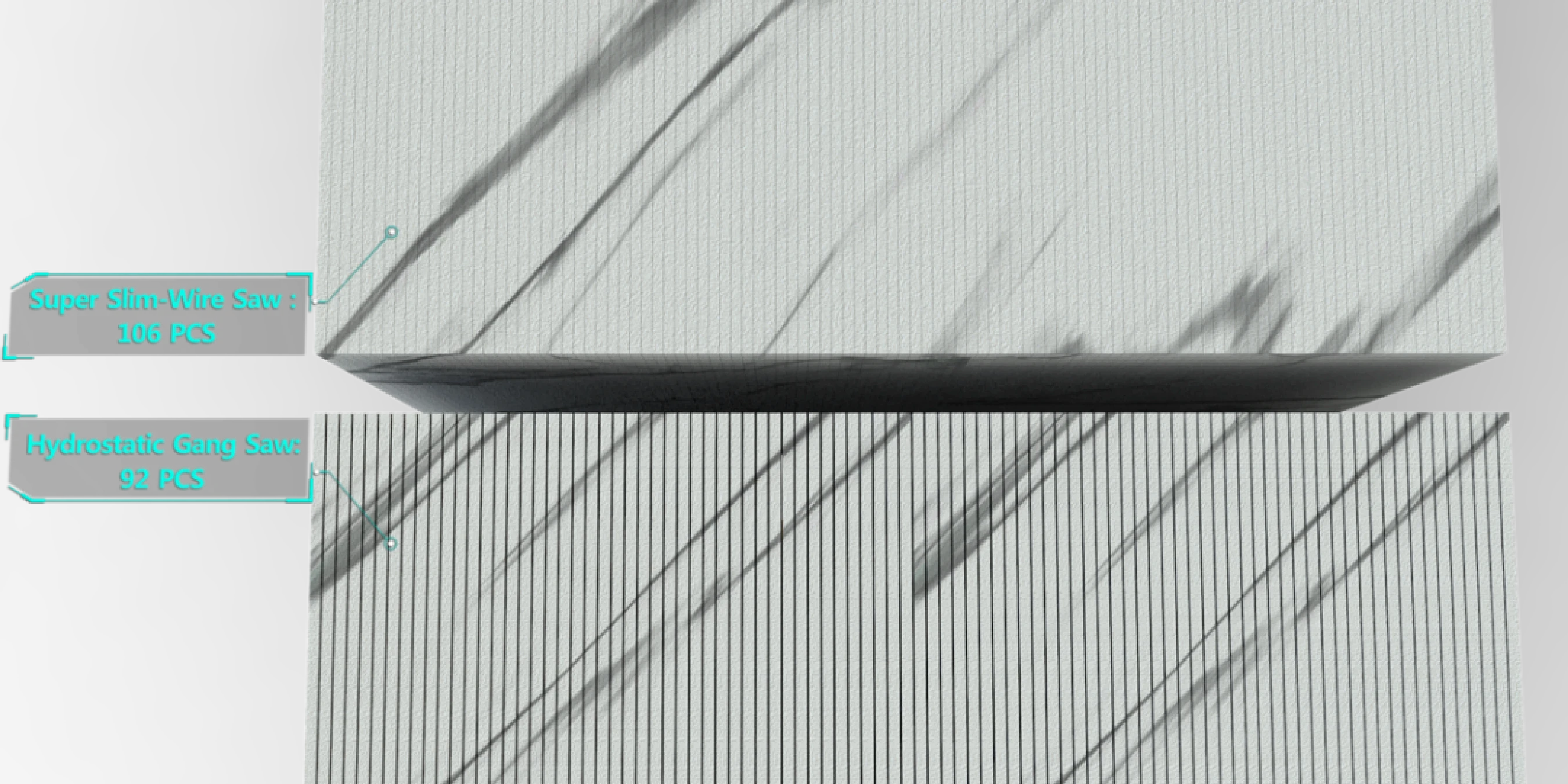

- Enhanced Material Yield & Revenue: By utilizing ultra-thin diamond wires (0.45–0.6 mm) to create a kerf of only ~0.5 mm, the technology increases finished slab yield by a significant 10–25%. For every block of high-value marble, onyx, or jade, this translates directly into more sellable product and higher revenue from the same raw material cost base.

- Reduced Operating & Consumable Costs: The system is engineered for efficiency, reducing energy consumption by approximately 30% compared to traditional methods. Furthermore, the precision constant-tension system (maintaining ±0.5 N) reduces the rate of costly wire breakage by ~60%, lowering consumable expenses and minimizing production downtime.

- Increased Throughput & Market Responsiveness: The ability to slice entire blocks (up to 3600 × 2200 × 2000 mm) in a single pass at high speed (30 m/s) dramatically shortens project lead times. This allows the business to take on larger contracts and respond more quickly to market demand for large-format and book-matched slabs.

- Improved Product Quality & Reduced Labor: A superior surface finish is achieved through the stability of the heavy HT250 cast-iron frame (reducing vibration by 20%) and the precision of the cutting process. This minimizes the need for secondary grinding and polishing, directly cutting down on labor costs and associated process time.

Building the Financial Model: Inputs, Outputs, and Sensitivity

A robust ROI calculation requires a clear financial model. While a detailed multi-wire ROI analysis is essential, the key inputs and outputs for your business case will include:

Model Inputs

- Capital Expenditure (CapEx): The total landed cost of the machine.

- Operating Costs (OpEx): Electricity (factoring in the ~30% reduction), coolant, and consumables, notably the cost of diamond wire.

- Material Costs: Average cost per block of your primary stone types.

- Labor Costs: Operator wages and post-processing labor hours.

Model Outputs

- Increased Revenue: Calculated from the 10–25% increase in saleable square meters per block.

- Cost Savings: Quantified reductions in energy, labor, and consumables.

- Key Metrics: Payback Period, Net Present Value (NPV), and Internal Rate of Return (IRR).

We recommend running a sensitivity analysis to understand how profitability changes with fluctuations in stone block prices or diamond wire costs, which provides a clearer picture of investment risk and reward.

Implementation Roadmap: From Pilot Program to Full-Scale Rollout

A structured adoption plan mitigates risk and ensures a smooth transition. We recommend a phased approach:

Phase 1: Pilot Program.

Deploy the first machine on a line dedicated to high-value materials. This controlled environment is ideal for validating performance against your specific materials and operational context. For more on how this fits into the broader technology landscape, review our multi-wire vs. circular saw comparison.

Phase 2: Define and Measure Acceptance KPIs.

Establish clear, measurable success criteria against your current baseline. Examples include:

- Quantitative KPIs: Confirmed material yield increase (%), cycle time per block (hours), energy consumption (kWh/block), unplanned downtime (%), and slab rejection/rework rate (%).

- Qualitative KPIs: Operator feedback on ease of use, observed improvement in surface finish, and measured reduction in workshop noise levels.

Phase 3: Standardize and Scale.

Once KPIs are met and the ROI is validated, use the data from the pilot to justify further investment. The learnings from the first machine should be used to create standardized operating procedures (SOPs) and maintenance schedules for a facility-wide rollout.

Risks, Boundaries, and Change Management

While powerful, the technology has boundaries. It is optimized for high-throughput slabbing of blocks and is less suitable for one-off, intricate shape cutting. Successful implementation also requires a commitment to change management, including structured operator and technician training on the new SOPs, safety protocols, and maintenance requirements to maximize uptime and leverage features like the 18,000-hour MTBF of the IP67-rated traverse subsystem.

Compliance, EHS, and Vendor Due Diligence

This technology offers significant Environmental, Health, and Safety (EHS) benefits. The fully enclosed wet-cutting system reduces workplace noise by 30-50 dB (supporting compliance with ≤85 dB standards) and limits hazardous silica dust ingress to below 0.1 mg/m³. When evaluating vendors, your due diligence checklist should include not just the machine's technical specifications (like its 290 kW power and durable carbon-fiber rollers), but also the provider's training programs, warranty details, and proof of regional certifications (e.g., CE/UL).

Executive FAQ

What is the single biggest financial benefit?

The 10–25% increase in material yield, which drops directly to the bottom line by generating more revenue from an existing cost base.

How does this technology future-proof our operations?

It enables the production of ultra-thin and large-format slabs, which are in high demand in modern architecture, positioning your business as a leader in high-margin products. It also significantly improves workplace safety and environmental compliance.

What is the most critical factor for a successful implementation?

A combination of proper planning—starting with a pilot program—and a commitment to training your team.

Cross-links to the Full Series

For a deeper understanding of specific aspects of this multi-wire saw technology, please refer to the other articles in this series:

English

English 中文

中文