Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

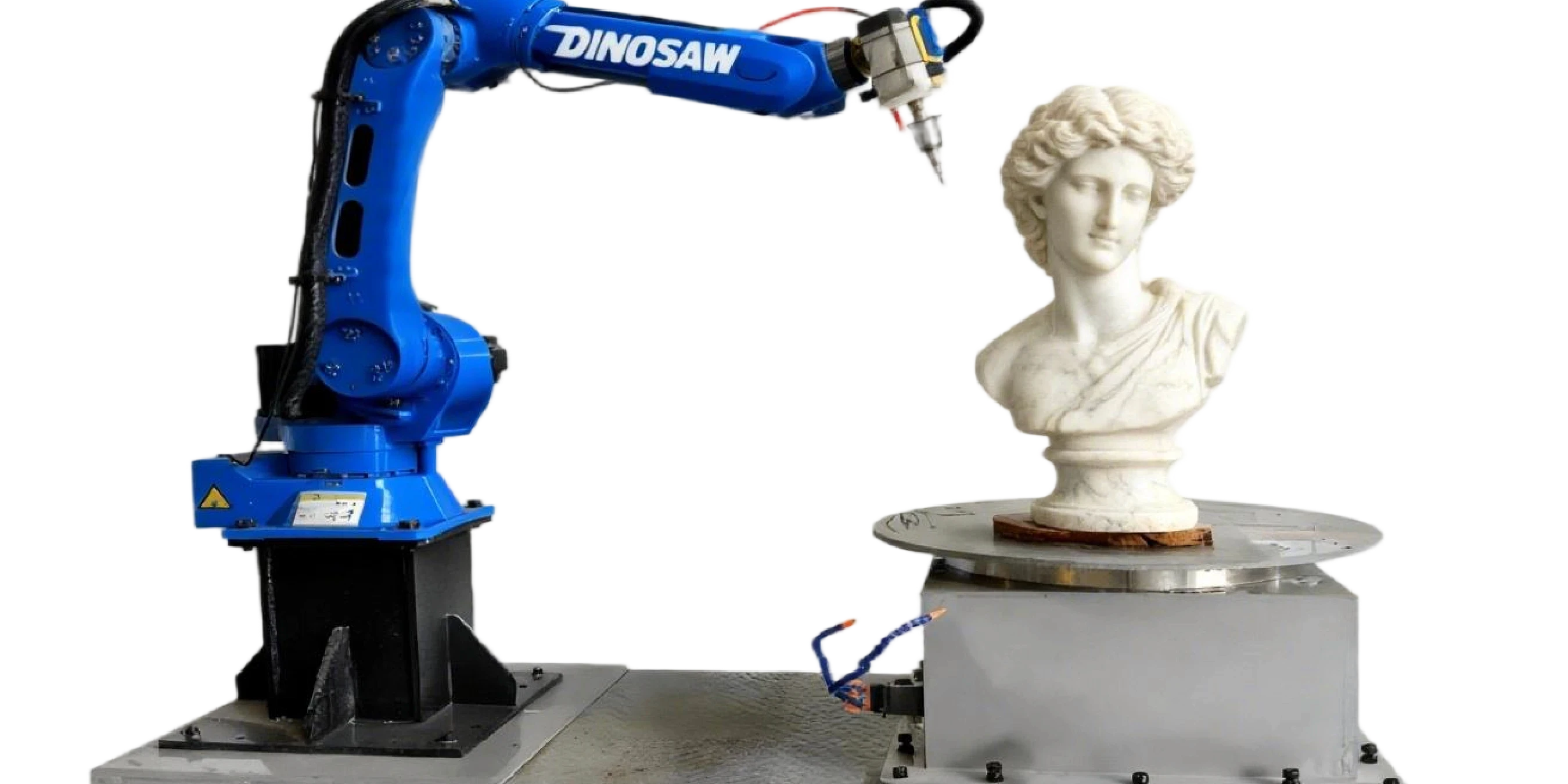

7‑axis robotic carving boosts throughput and consistency. Ideal for memorial lettering, religious statues and architectural reliefs. Clean finish, 24/7 automation. Read the guide.

Stone carving buyers face three core blockers today: skilled-labor shortages, inconsistent manual quality, and slow project turnarounds. A 7-axis robotic stone carving cell upgrades throughput and repeatability while protecting margin—ideal for memorials, religious statues, and architectural reliefs. See the Dinosaw robotic stone carving system for a proven path to precision and ROI.

Ready to validate the ROI of robotic automation for your specific stone fabrication needs? Talk to our specialists for a site-specific demo.

From Bottlenecks to Gains: The ROI of Robotic Stone Engraving

Shifting from manual to a fully robotic workflow addresses critical operational pain points with quantifiable improvements. For procurement managers, the value of robotic stone processing is in the measurable impact on the bottom line.

Pain Point 1: Inconsistent Quality & High Rework

- Metric-Driven Solution: A stone carving robot achieves a positional repeatability of ±0.06 mm (manufacturer-reported), reducing letter-depth variance to a negligible level and reducing production time by ~40% vs manual engraving .

Pain Point 2: Low Throughput & Labor Dependency

- Metric-Driven Solution: Skilled artisan shortages and the slow pace of hand-carving limit weekly output. The ability to run 24/7 with automated toolpaths means weekly output targets around 50 granite tombstones are achievable in comparable deployments .

Pain Point 3: High Material Waste

- Metric-Driven Solution: Manual errors or inefficient cutting paths result in scrapped blocks of expensive stone. Optimized CAM software generates toolpaths that maximize material utilization, potentially reducing scrap by up to 30% on complex projects.

Pain Point 4: Accelerated Tool Wear

- Metric-Driven Solution: Incorrect feed rates or spindle speeds burn through costly diamond tools. The system maintains optimal parameters for each DINOSAW diamond bit and material combination, extending tool life by managing load and temperature, thereby lowering the tool wear rate and cost per-piece.

Pain Point 5: High Energy Consumption

- Metric-Driven Solution: Inefficient machinery and non-optimized processes lead to higher energy costs. Modern robotic arms and intelligent toolpaths reduce idle time and wasted movements, lowering the overall energy per cut and contributing to more sustainable operations.

The Anatomy of a 7-Axis Stone Carving Robot Cell

Understanding the components of a robotic carving cell is key to appreciating its capabilities. This is the foundation of modern stone CNC processes, a synergy of hardware and software designed for the harsh environment of stone fabrication.

- Mechanical Core: A high-payload 6-axis industrial robot (e.g., KUKA) with a reach sized to your largest part envelope (confirm during layout), mm/in is mounted alongside a servodriven rotary table with a diameter matched to max block size (confirm during fixture design), mm/in. This 7th axis allows the workpiece to be turned, enabling the carving of complex, undercut features without manual repositioning.

- Control and Software: An industrial controller synchronizes all seven axes. The entire process is programmed offline using CAM software like SprutCAM, which translates a 3D model into precise robot movements and tool commands. This is a core part of modern stone automation workflow.

- Safety and Protection: The cell operates within a protective enclosure with safety interlocks. The robot itself is often outfitted with a protective suit, and the system is designed with a high IP rating (e.g., IP65) to withstand the abrasive dust and water slurry inherent in stone carving.

Site-specific constraints must be evaluated before installation. These include foundation stability to handle dynamic loads, adequate electrical supply (e.g., stable 3-phase power per local code (confirm during facility audit)), and sufficient shop ventilation and water management systems.

Mini-Cases: Robotic Carving from Theory to Real-World ROI

The true value of a 7-axis carving robot is best illustrated through its application in real-world scenarios.

Case 1: Batch Production with a Granite Memorial Engraving Robot

- Initial Situation: A memorial manufacturer faced a bottleneck in lettering. Manual sandblasting was inconsistent, and skilled engravers were scarce, leading to long lead times and a high rework rate of around 15%.

- Action: A DINOSAW 7-axis carving cell was installed. Jobs were programmed via OLP software, and the robot used DINOSAW V-groove lettering bits to engrave names, dates, and motifs. Custom fixtures ensured high repeatability.

- Quantified Result: The rework rate dropped to below 2%, weekly production capacity doubled, and lettering depth was held to a consistent tolerance. The automated process allowed the manufacturer to offer more complex decorative elements at a competitive price.

- Replication Prerequisites: Standardized blank tombstone sizes, robust fixture design for quick changeovers, and an operator trained in basic robot operation and program loading.

Case 2: Using a Marble Sculpture Replica Robot

- Initial Situation: A contemporary artist wanted to produce a limited edition of 20 identical marble sculptures. The cost and time required for manual replication by master carvers were prohibitive.

- Action: The original clay model was captured with a high-resolution 3D scanner. The data was used to program the robot, which performed a two-stage carving process: first, roughing out the general shape with a DINOSAW ball-nose end mill, then switching to a smaller, tapered DINOSAW engraving bit for fine details. An artisan performed the final hand-polishing.

- Quantified Result: Production time per sculpture was reduced from three months to three weeks. According to reports from studios like Monumental Labs, this method cuts delivery times for sculptures from months to weeks. Dimensional accuracy across all 20 pieces was within 1 mm of the original scan.

- Replication Prerequisites: Access to high-fidelity 3D scanning, CAM software proficiency, a diverse library of DINOSAW carving bits, and a skilled artisan for the final aesthetic finishing.

Case 3: Architectural Relief Carving & Heritage Restoration

- Initial Situation: A historical building required replacement of weathered limestone relief panels for a project focused on architectural relief carving. Finding artisans to match the original style was nearly impossible.

- Action: An intact section of the original relief was 3D scanned on-site. The digital model was used to program the heritage restoration stone robot to carve new limestone blocks, with the 7-axis capability being crucial for deep undercuts, including for features like a column capital carving robot would produce.

- Quantified Result: The replacement panels were a perfect match, satisfying historical preservation standards. The project was completed in two months, a task that would have taken over a year manually. This aligns with industry reports, such as the restoration where digitally assisted carving was key.

- Replication Prerequisites: Portable 3D scanning equipment, software skills for restoring digital models, and access to compatible limestone blocks.

Case 4: Religious Statue Stone Carving

- Initial Situation: A studio producing religious statues (e.g., marble Madonnas, granite Buddha sculpture stone robot projects) needed to increase output while maintaining delicate, expressive quality.

- Action: A master design was created in CAD. The robot executed the physically demanding roughing and semi-finishing work for the religious statue stone carving. For delicate features, force-control technology [TBD] was used to prevent over-cutting. A master carver then provided the final touches.

- Quantified Result: The studio increased its capacity by 300%, enabling it to take on larger commissions. The robot handled 90% of the material removal, freeing up master artisans to focus on the highest-value finishing work.

- Replication Prerequisites: High-quality CAD models, a comprehensive set of fine-detail DINOSAW engraving bits and burrs, effective dust/slurry management, and a quality assurance process involving an experienced artisan.

FAQs — Applications & Buying Considerations

What problems does a stone carving robot actually solve?

It significantly reduces letter-depth variance (to a ±0.06 mm repeatability, manufacturer-reported), boosts throughput 2–3x with 24/7 operation, and cuts material scrap with optimized CAM software.

How do robots handle granite variability for memorial lettering?

Through probing to register the block, simulating toolpaths to avoid collisions, and using conservative passes for hard grain. However, sourcing consistent blocks from the quarry remains critical. See Top stone cutting machine brands for more context.

What dust-control standards apply to memorials and architectural reliefs?

Depending on jurisdiction, follow local dust regulations. Design for high-efficiency dust extraction and sealed enclosures (e.g., IP65) to protect quality and operator health during extended carving; appropriate PPE is recommended.

How to fixture irregular blocks (tombstones, relief panels) without damage?

Common approaches include robust clamping and adjustable supports; verify toolpaths and fixture clearance in CAM simulation. Vacuum solutions may be considered case-by-case.

Typical cycle-time gains for batch memorial production?

Typical reductions of 50–75% versus manual methods are common. The 7-axis capability eliminates the need for manual repositioning, allowing for continuous, unattended operation that drastically reduces idle time.

Tooling for memorial lettering vs religious statues?

For hard granite memorials, use robust DINOSAW V-groove lettering bits. For softer marble statues common in religious statue stone carving (e.g., Buddha, Madonna), a two-stage process is better: ball-nose mills for roughing, then tapered engraving bits for finishing. See DINOSAW diamond tools for stone.

What projects are not recommended?

Highly porous or fragile stones may require resin stabilization or special handling; assess case-by-case. Sandstone is often workable with adaptive toolpaths.

When should I contact DINOSAW for a demo?

If your target is around 50 granite tombstones per week, you work with mixed materials, or you aim to cut production time by ~40% versus manual engraving, a demo can validate ROI for your site.

Risks, Prerequisites, and Summary

Prerequisites & Risks

Investing in a robotic carving system requires careful planning. Key prerequisites include rigorous operator training, a stable work-holding (fixturing) strategy, and a consistent supply of quality material. The primary operational risks are managing abrasive dust and accounting for material variability.

Summary

In summary, robotic carving is highly applicable for businesses aiming to scale production of items with high repeatability (memorials, architectural elements) or to enable cost-effective creation of complex sculptures.

Suitability is material‑dependent: highly porous or fragile stones may require resin stabilization or special handling; sandstone is often workable with adaptive toolpaths and appropriate fixturing/cooling. Assess case‑by‑case via small‑scale trials before full production.

English

English 中文

中文