Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

A practical guide to stone cutting technology. Compare multi-wire saws vs. bridge saws and waterjets on material yield, energy use, and TCO to make the right investment decision.

Choosing the right stone cutting technology is a critical capital investment decision with long-term impacts on profitability and operational efficiency. This guide provides a decision-making framework for procurement teams to determine when a multi-wire saw, such as the DINOSAW Intelligent Multi-Wire Saw, is the optimal choice.

Have a question or need a quote? Contact us now.

The Core Decision: Yield, Quality, and Throughput

The decision to invest in a multi-wire saw hinges on key business drivers where its advantages are most pronounced:

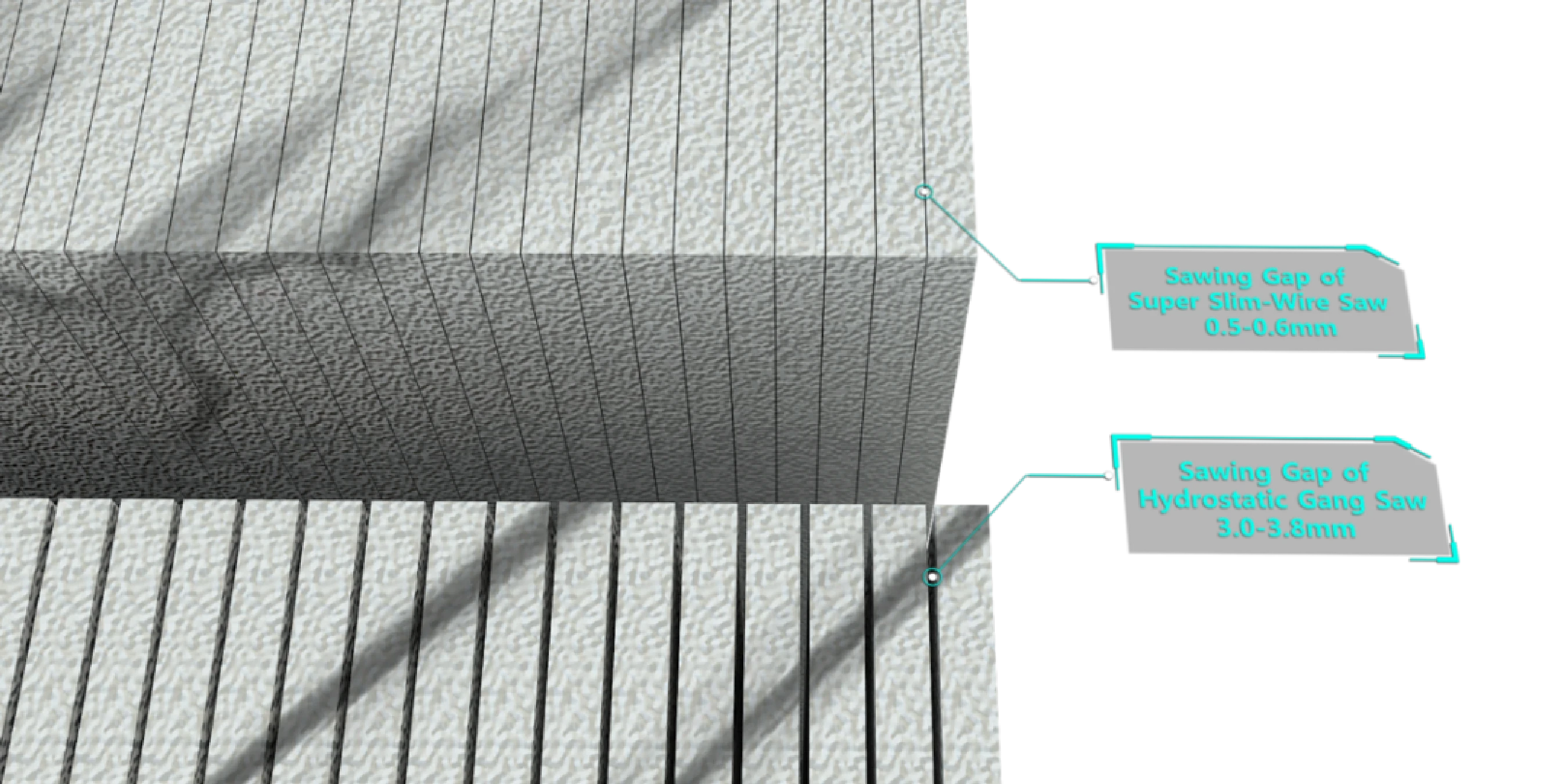

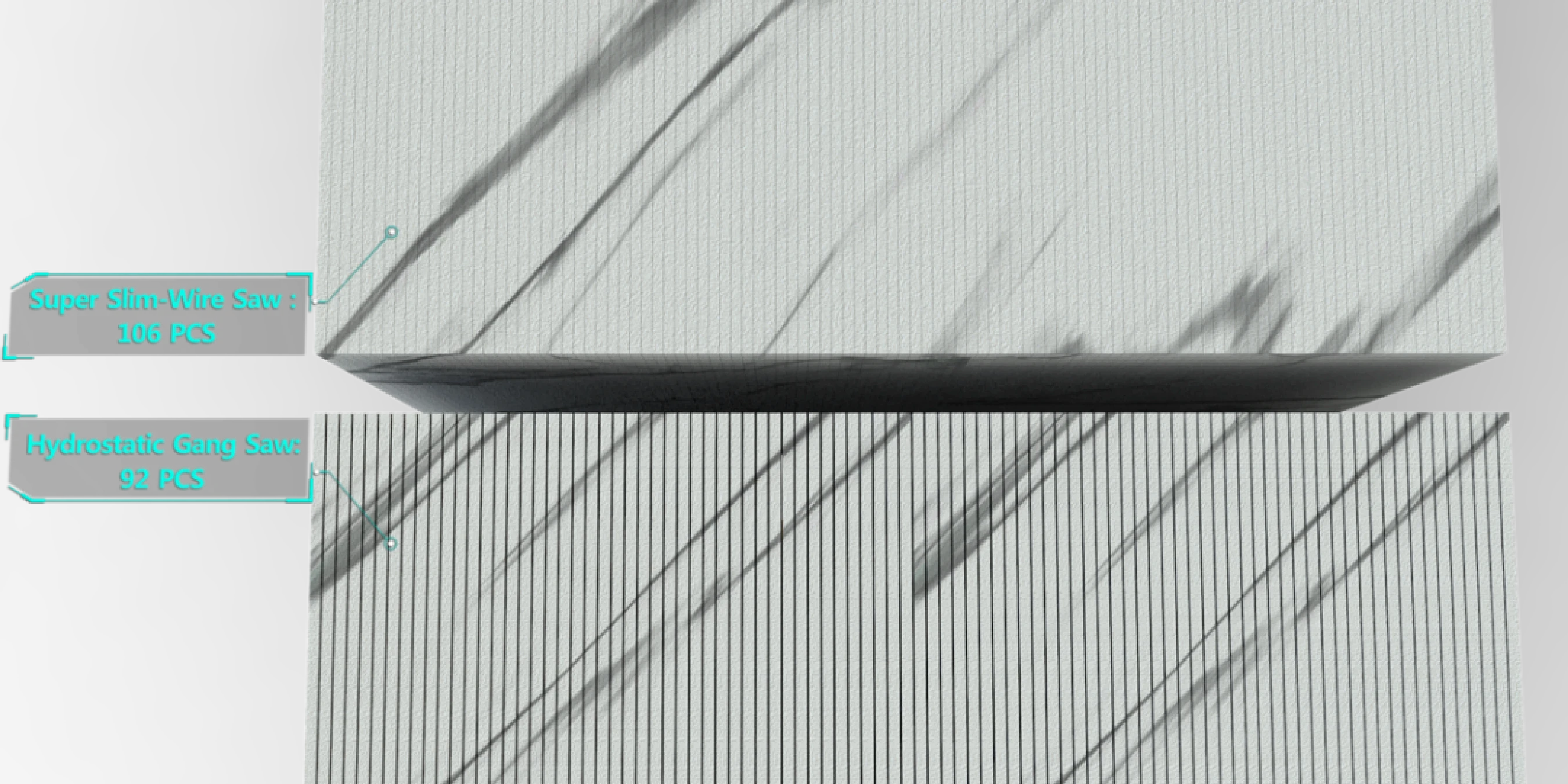

- Material Yield: Increases slab output by 10-25% from the same block by reducing kerf waste to ~0.5 mm.

- Energy & Environmental Efficiency: Reduces energy consumption by ~30% and noise by 30-50 dB compared to traditional methods.

- Production Volume: Processes large blocks (up to 3600×2200×2000 mm3600×2200×2000mm) into multiple slabs simultaneously, dramatically increasing throughput.

If these factors are critical to your operation, a detailed multi-wire ROI analysis is a logical next step.

If-Then Decision Framework for Technology Selection

Use this framework to map your needs to the most suitable technology.

- IF your primary business is processing high-value marble or rare stone blocks into multiple thin slabs with a high throughput target...THEN: A Multi-Wire Saw is strongly recommended. Its minimal kerf loss maximizes yield, and its parallel cutting capability delivers the required throughput.

- IF you are cutting standard stone for countertops and lowest initial capital cost is the top priority...THEN: A conventional Bridge Saw or Gantry Saw is a viable option. While material yield is lower and energy consumption higher, the upfront investment is less. The comparison between multi-wire and circular saws is critical here.

- IF your work involves highly intricate, custom 2D shapes or lettering, and cutting path flexibility is more important than slabbing speed... THEN: A Waterjet Cutter is the superior choice. It offers unparalleled precision for complex geometries that wire saws cannot produce.

- IF you need to process very large, irregular blocks into thick slabs, and precision is secondary to raw cutting power... THEN: A heavy-duty Quarry Band Saw or a gantry wire saw may be more appropriate for primary cutting operations.

- IF you are producing large-format panels where thickness consistency across the entire surface is critical... THEN: A Multi-Wire Saw is highly advantageous. The fixed, parallel nature of the wire array ensures a level of planarity that is difficult to achieve with single-blade systems over large dimensions.

Neutral Comparison of Key Decision Factors

Precision & Surface Finish:

• Multi-Wire Saw: Excellent. Produces a smooth surface with minimal subsurface damage, ideal for thin or brittle materials.

• Bridge/Band Saw: Fair. Can leave blade marks and induce micro-fractures, often requiring more secondary polishing.

• Waterjet: Excellent. Produces a very fine finish with no thermal stress, but is slow and less economical for slabbing.

Material Yield (Kerf Loss):

• Multi-Wire Saw: Highest Yield. Kerf is only ~0.5 mm, increasing material utilization by 10-25%.

• Bridge/Band Saw: Lowest Yield. Kerf can be 5-10 mm or more, turning valuable material into dust.

• Waterjet: High Yield. Kerf is typically around 1 mm, but cutting speed is very low for this application.

Consumables & TCO:

- Multi-Wire Saw: Diamond wire, guide pulleys, electricity, coolant. Wire is a significant cost, so knowing how to choose the right diamond wire is essential. TCO is offset by higher yield and lower energy use (~30% less).

- Bridge/Band Saw: Diamond blades, electricity, coolant. Blades require frequent re-tipping or replacement.

- Waterjet: Garnet abrasive, high-pressure pump parts, electricity. Abrasive cost and disposal are major factors.

Procurement Considerations

Footprint & Work Envelope: Multi-wire saws are large machines requiring significant factory space for the unit and its slurry management systems. The DINOSAW DS-U-G2236 model accommodates a maximum block size of 3600 × 2200 × 2000 mm.

Training, Warranty, and Certifications: Beyond technical specs, procurement should evaluate the supplier's support package. Ask for details on operator and maintenance training programs, the warranty period and what it covers, and available certifications (e.g., CE for EU, UL for US) to ensure compliance with local regulations.

English

English 中文

中文