Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Discover how multi-wire saws increase material yield by 10-25% and reduce waste for ultra-thin luxury slabs, large-format walls, and rare materials. Learn the key operating benefits.

The demand for ultra-thin, large-format stone slabs is surging, but traditional cutting methods often result in high material waste and damage. This article explores how advanced multi-wire saw technology addresses these critical pain points, using the DINOSAW Intelligent Multi-Wire Saw as a benchmark for performance in demanding applications.

Have a question or need a quote? Contact us now.

The Core Problem: Profitability Lost to Waste and Damage

For fabricators working with premium materials like luxury marble, onyx, or jade, every millimeter of material counts. Key pain points include:

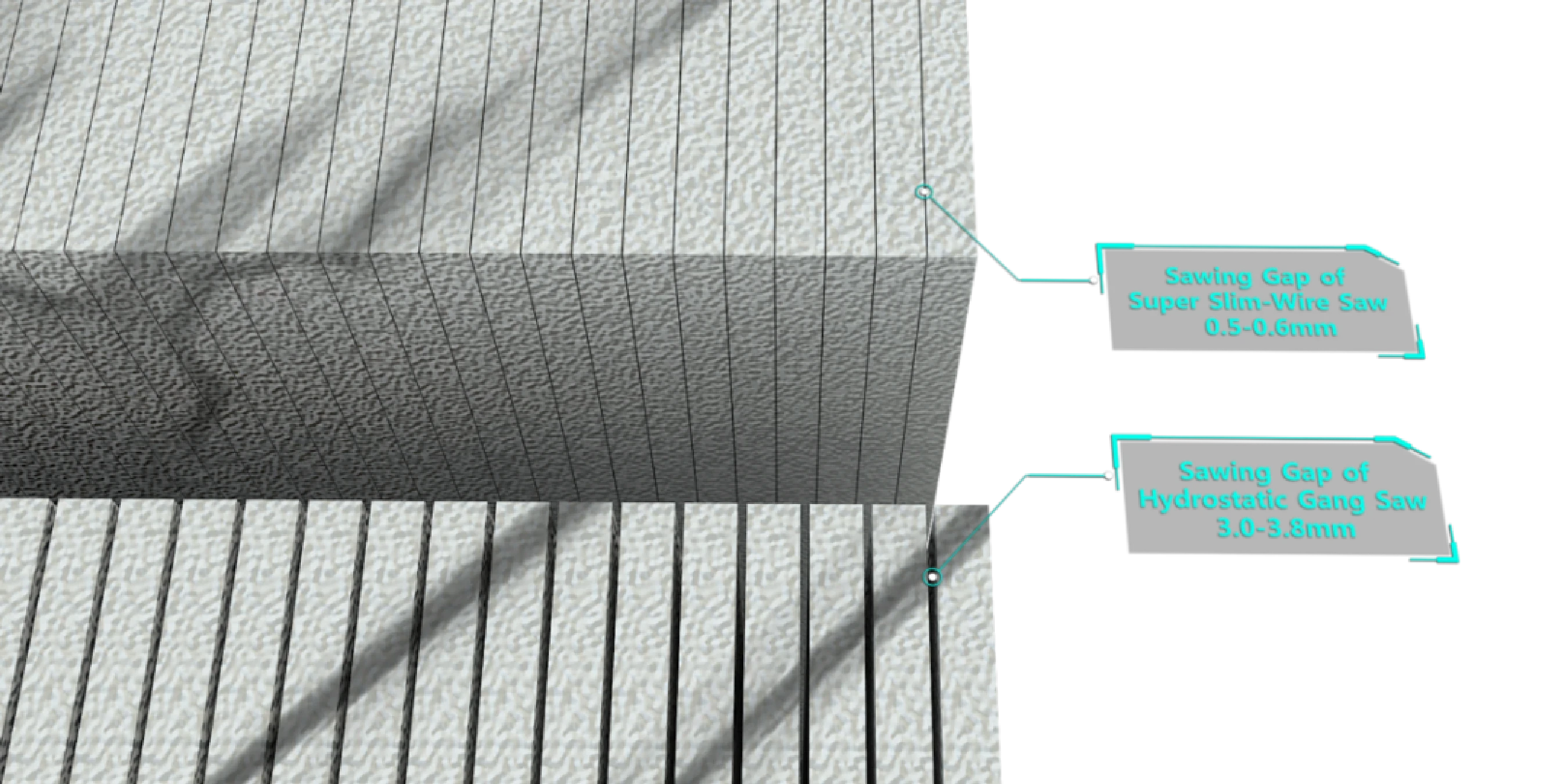

- Excessive Kerf Loss: Conventional saws have thick blades, turning a significant percentage of an expensive block into dust. This directly reduces the number of sellable slabs obtainable from a single block.

- Poor Surface Integrity: Aggressive cutting methods can introduce micro-fractures, chipping, and a rough surface, requiring extensive and costly secondary grinding and polishing.

- Low Yield and High Fracture Rate: The mechanical stress induced by bridge saws or band saws is often too high for delicate, brittle, or internally flawed materials, leading to catastrophic slab fractures and total loss.

- Throughput Bottlenecks: Single-blade methods are inherently slow, creating a significant bottleneck when processing large blocks or fulfilling high-volume orders for projects like hotel lobbies or feature walls.

The Multi-Wire Solution: A Paradigm Shift in Precision and Yield

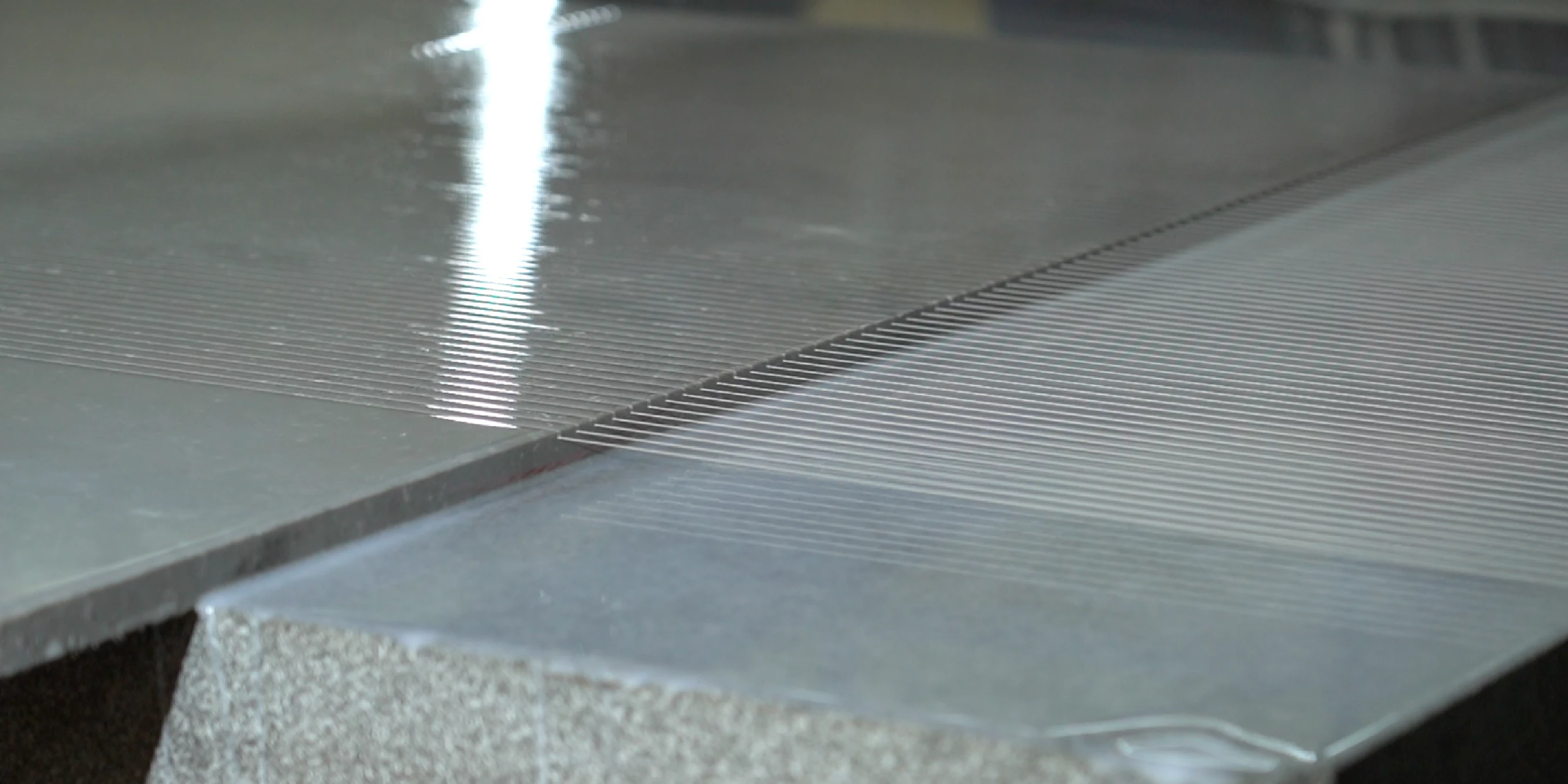

The DINOSAW Intelligent Multi-Wire Saw leverages a fundamentally different approach. By using an array of very thin, diamond-impregnated wires moving at high speed (30 m/s), it simultaneously slices a block into multiple slabs with surgical precision.

The key solution components include:

- Multi-Wire Diamond Cutting: Using diamond wires with a diameter of 0.45–0.6 mm creates a kerf as narrow as ~0.5 mm. This drastically reduces material waste and can increase slab yield by 10–25% compared to traditional methods.

- Advanced Tension Control: Each wire in the array is maintained at a precise, actively controlled tension with an accuracy of ±0.5 N. This stability, supported by a rigid HT250 cast-iron frame that reduces vibration by 20%, is critical for ensuring geometric accuracy and minimizing subsurface damage.

- Optimized Wet Cutting Management: A constant flow of coolant lubricates the wires, flushes away slurry, and prevents thermal damage. Housed within a full enclosure, this system is crucial for maintaining a clean cut, achieving a superior surface finish, and significantly reducing worksite dust and noise.

Applications and Operating Benefits

The machine's design unlocks capabilities for high-value applications where precision and material preservation are paramount.

Ultra-Thin Luxury Marble Slabs

Producing ultra-thin slabs (e.g., 3-5 mm) for wall cladding is a challenge with conventional saws due to high breakage rates. The gentle cutting action and narrow ~0.5 mm kerf of the multi-wire saw are ideal for this delicate application, enabling the production of thin slabs with a high success rate and superior surface finish, reducing the need for post-cut grinding.

Large-Format Background Walls

For commercial projects requiring numerous book-matched slabs from a single block of onyx or marble, consistency is key. A multi-wire saw processes the entire block in a single pass, ensuring consistent thickness and pattern continuity across large dimensions (up to 3600 × 2200 × 2000 mm). This dramatically improves throughput compared to single-blade saws. For more on this, see the multi-wire vs. circular saw comparison.

Premium Jade and Rare Stone Processing

When slicing high-value materials like jade boulders, every millimeter saved from kerf loss translates directly to profit. The ultra-thin diamond wires maximize the number of sellable panels from each boulder. Success in this area requires expertise in how to choose a diamond wire saw with the correct diamond grit for hard, abrasive materials.

Wet vs. Dry Cutting Policy

For stone applications, wet cutting is the universal standard and is non-negotiable. It is required for dust suppression (health and safety), cooling the wire and stone to prevent thermal shock and micro-fractures, and efficient removal of cutting slurry to maintain a clean cut path and excellent surface finish. The machine's full enclosure and wet cutting system work together to reduce noise by 30-50 dB and improve environmental compliance. A detailed multi-wire ROI analysis often factors in these safety and environmental benefits.

Comparison: Multi-Wire vs. Alternative Technologies

When evaluating cutting technologies, the tradeoffs are clear:

- vs. Bridge Saws/Band Saws: Multi-wire saws offer vastly superior yield due to minimal kerf. They also produce a much better surface finish with less subsurface damage. While initial investment may be higher, the material savings (10-25% yield increase) and reduced labor in finishing provide a strong ROI.

- vs. Waterjet: Waterjet cutting offers exceptional precision for intricate shapes but is extremely slow for slabbing entire blocks and has a higher operational cost. For producing parallel slabs, a multi-wire saw provides dramatically higher throughput.

Summary: Suitable vs. Non-Recommended Scenarios

The DINOSAW Intelligent Multi-Wire Saw excels in high-value, high-throughput slabbing operations where material yield and surface quality are paramount. It is the ideal choice for producing ultra-thin slabs, large-format panels, and processing brittle or expensive materials like luxury marble, onyx, and jade.

It is less suitable for one-off custom shape cutting, for which other technologies may be more appropriate. For those exploring heavy-duty shaping, it's worth understanding why gantry wire saws excel in different contexts.

English

English 中文

中文