Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Discover the best CNC software for stone cutting and fabrication. Our 2025 review covers top CAD/CAM solutions for granite, marble, and quartz, from free options to advanced 5-axis systems.

3 Questions to Ask Before You Buy

Before we jump into specific programs, let's get real about what you actually need. A high-volume countertop shop and a custom architectural carver? They might as well be in different industries.

- What's your main work? Are you doing 90% kitchen countertops or tackling complex 3D architectural pieces? Your daily reality should drive this decision, not fancy features you'll never use.

- Who's using this? Got a dedicated CAD programmer? Great, go complex. Shop floor operators making quick adjustments? You need something they can actually use without a PhD.

- Standalone or integrated? Standalone gives you flexibility but comes with setup headaches. Integrated systems cost more upfront but eliminate compatibility nightmares.

💡 Need help choosing? Get our free software selection guide based on your specific shop needs

The 10 Stone Cutting Programs That Actually Work

1. Alphacam Stone: The Heavy Hitter

Best for: Large shops tackling complex 5-axis work

This is the software that separates the pros from everyone else. Alphacam's 5-axis toolpath strategies are genuinely impressive, and the tool library management is about as comprehensive as it gets. Industry veterans swear by its simulation capabilities - they've saved countless expensive slabs from becoming expensive mistakes.

The catch? You better have someone who knows what they're doing. This isn't software you hand to a new operator and expect miracles.

Ease of Use: 4/5 | Price: $$$$ | Learning Curve: Steep but worth it

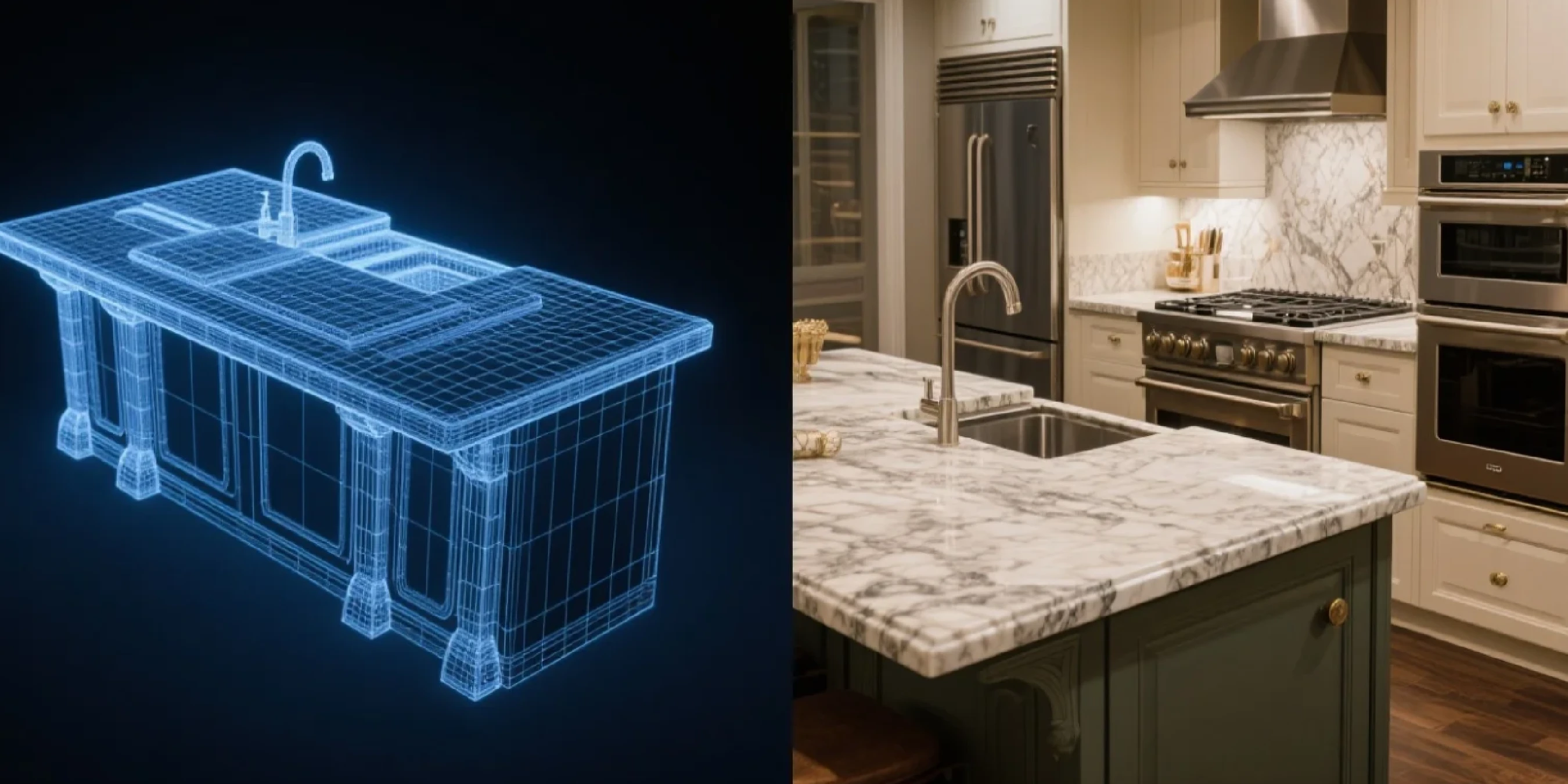

2. DDX EasySTONE: The Countertop King

Best for: High-volume countertop production

There's a reason this dominates European fabrication shops. The entire workflow is built around countertop reality - digital slab layout, vein matching that actually works, and nesting that doesn't make you want to throw your computer out the window. When paired with machines like the DINOSAW 5 axis Bridge Saw, it's honestly hard to beat.

What makes it special? Everything just works together. No fighting with post-processors or wondering if your toolpaths will actually run.

Ease of Use: 5/5 | Price: $$$ | Best Feature: Intuitive workflow

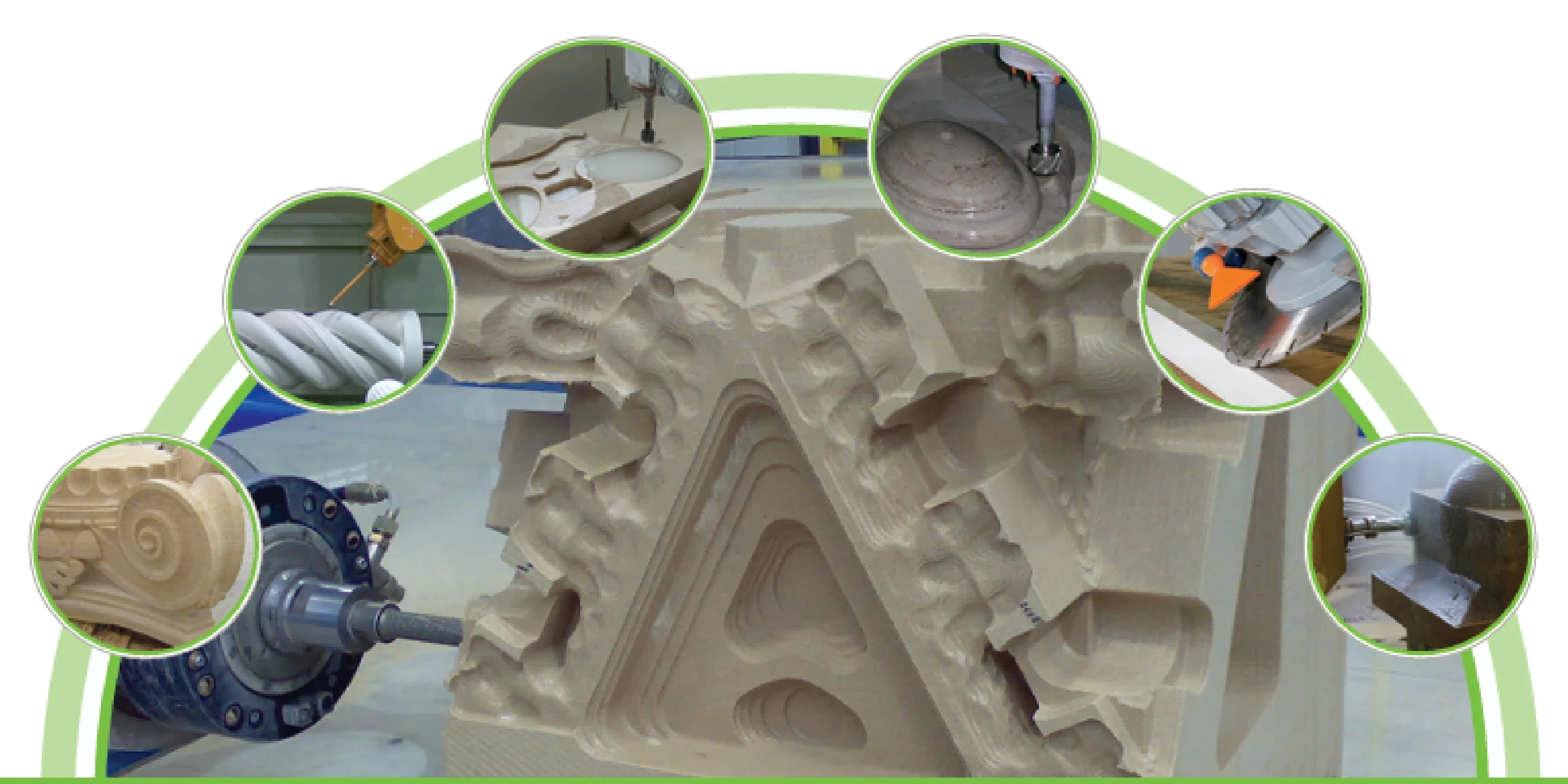

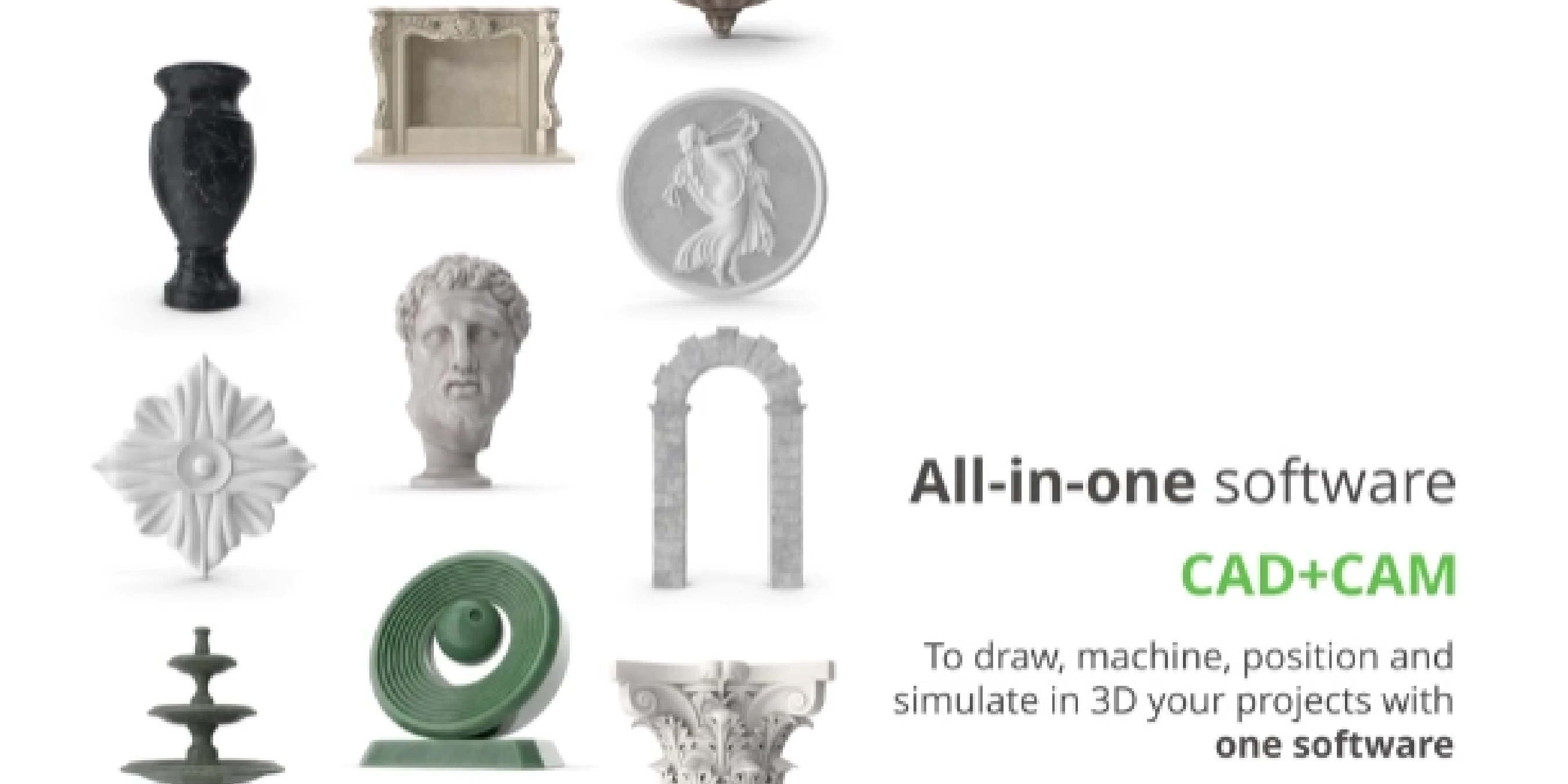

3. Fresta CAD/CAM: The Multi-Tool Specialist

Best for: Shops running saw and waterjet combinations

Here's where Fresta shines - managing toolpaths when you're switching between saw blades and waterjet heads on the same job. The lead-in optimization and piercing strategies are genuinely smart, and if you're running mixed equipment, this could solve a lot of headaches. It's specialized, sure, but when you need what it does, nothing else really comes close.

Ease of Use: 4/5 | Price: $$$$ | Sweet Spot: Mixed equipment setups

4. Autodesk Fusion 360: The Smart Money Choice

Best for: Design-heavy shops with diverse materials

Look, Fusion isn't stone-specific out of the box. But here's why it made the list - professional CAD and CAM for a subscription fee that won't make your accountant cry. Get the post-processor right, and you've got serious power for way less money than the big names.

Perfect if you're also working with other materials or need serious design capabilities. The learning curve is real, but so is the value.

Ease of Use: 3/5 | Price: $$ | Value: Outstanding for multi-material shops

5. Taglio CAD/CAM: The Production Workhorse

Best for: Small to medium shops prioritizing speed

Sometimes simple wins. Taglio's interface makes sense from day one - straight cuts, basic curves, slab management that doesn't require a manual. Your operators can actually use this without extensive training, which means less downtime and more productivity.

Not fancy, but reliable. That counts for a lot in daily production.

Ease of Use: 5/5 | Price: $$$ | Strength: Fast operator training

6. Rhinoceros 3D + RhinoCAM: The Creative Powerhouse

Best for: Custom architectural and artistic work

When clients want something that's never been done before, this is your tool. Rhino can model virtually any shape you can imagine, and RhinoCAM can figure out how to cut it. We're talking high-value, bespoke projects that justify the premium pricing.

The learning curve is steep - 3D modeling is an art form. But for unique, high-margin work? Nothing else comes close.

Ease of Use: 3/5 | Price: $$$$ | Best For: Complex 3D projects

7. Pegasus CAD-CAM: The Efficiency Expert

Best for: High-volume operations focused on material yield

The nesting algorithms here are legitimately impressive. When material costs are eating your margins, Pegasus can squeeze more parts out of each slab than you thought possible. For large-scale operations, this efficiency translates directly to profit.

Setup takes time and planning, but once it's dialed in, the waste reduction is remarkable.

Ease of Use: 4/5 | Price: $$$$ | ROI: Material savings

8. BobCAD-CAM for Stone: The Value Champion

Best for: Growing shops on a budget

Comprehensive features including 5-axis support at a price that won't break the bank. The interface feels a bit dated compared to premium options, but the functionality is solid. It's a smart choice when you're scaling up but aren't ready for enterprise-level investment.

Bottom line: you get a lot of capability for your money.

Ease of Use: 3/5 | Price: $$ | Value: Hard to beat

9. FreeCAD (with Path Workbench): The Zero-Dollar Option

Best for: Startups and learning

It's free, and it works for basic cutting operations. That's about where the good news ends. The learning curve is brutal, the interface feels like it was designed by engineers for engineers, and you'll be spending a lot of time on forums figuring things out.

But hey - if your budget is literally zero, it's better than nothing. Just be prepared for a lot of DIY troubleshooting.

Ease of Use: 2/5 | Price: Free | Reality Check: You get what you pay for

10. DINOSAW Intelligent System: The Future

Best for: Shops investing in integrated equipment

This isn't just software - it's a complete operating system designed specifically for stone machinery. Everything works together because it was designed together. Visual interface, preloaded parameters, and the kind of simplicity that lets operators focus on production instead of programming.

It represents where the industry is heading - away from compatibility struggles toward purpose-built solutions that just work.

Ease of Use: 5/5 | Price: Bundled with equipment | Value: Measured in efficiency gains

What's the Bottom Line?

The truth? There's no one-size-fits-all answer. For most countertop shops, something like DDX EasySTONE makes the most sense - it's built for what you actually do every day. If you're pushing creative boundaries, Rhino and RhinoCAM give you the freedom to create anything. Budget-conscious? Fusion 360 delivers serious value.

But here's what we're seeing more of - shops choosing integrated systems like DINOSAW because they eliminate the guesswork. No post-processor issues, no compatibility problems, just a system designed to work together from day one.

Whatever you choose, focus on what actually solves your daily problems. Fancy features you'll never use aren't worth the extra complexity or cost.

Frequently Asked Questions

What's the difference between CAD and CAM software for stone cutting?

CAD is where you design the part - drawing countertop shapes, defining edge profiles, modeling sculptures. CAM takes that design and figures out how to cut it, generating the actual toolpaths and G-code that tells your machine what to do. Most modern software combines both functions.

Can I use regular CNC software for stone?

Technically yes, but it's a bad idea. Stone software handles things like large-diameter saw blades, 5-axis sink cut-outs, and chipping prevention strategies that regular CNC software doesn't understand. Using the wrong software can damage tools and machines.

How much should I expect to spend on stone CNC software?

It varies wildly. Free options like FreeCAD exist but require serious DIY effort. Mid-range solutions like Fusion 360 cost a few hundred per year. High-end specialized software can run thousands or tens of thousands. Often the best software comes bundled with new machinery.

What's the easiest software for beginners?

Task-specific software is usually easiest to learn. DDX EasySTONE for countertops or DINOSAW Intelligent System for their machines are designed with simplicity in mind. They use visual interfaces and logical workflows instead of requiring complex programming knowledge.

Do I need 5-axis capability for my stone business?

Depends on your work. Simple flat cutting? No. But modern countertop work often requires under-mount cut-outs, angled cuts, and complex edge profiles - all 5-axis operations. It's becoming standard for anything beyond basic cutting and is essential for higher-value jobs.

What's a post-processor and why should I care?

It's the translator between your CAM software and your specific machine. Every machine speaks a slightly different G-code dialect, and the post-processor converts generic toolpaths into machine-specific instructions. Get this wrong, and you'll have errors, crashes, and unexpected behavior. This is why integrated systems are so appealing - the post-processor is perfect from day one.

English

English 中文

中文