Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

See how pressure, pump type and abrasive use affect cost and edge quality. Cold‑cutting benefits, ROI tips for granite, marble and quartz. Read the guide.

This comprehensive guide moves beyond superficial specifications. We'll give you a strategic framework for evaluating waterjet capabilities specifically for materials like granite, marble, quartz, and sintered stone.

We'll explore the critical interplay between pump types, pressure, and nozzle configuration. You'll discover how these elements contribute to the precision of complex cuts and the longevity of your abrasive tools.

By the end of this article, you'll gain actionable insights into selecting the right waterjet setup. You'll understand its true operational costs and learn to integrate it seamlessly into your existing workflow. We'll cover everything from fundamental mechanics to advanced optimization strategies, ensuring your investment delivers exceptional value and unparalleled craftsmanship in every cut.

Contact Our Specialists on WhatsApp

Why Generic Horsepower Advice Fails in the Stone Industry

Standard advice on waterjet horsepower often overlooks the unique properties of natural and engineered stone. This leads to suboptimal performance, increased material waste, and higher operational costs for stone fabricators.

Unlike metals, stone materials present specific challenges that demand a tailored approach to waterjet parameters. Let's break down why generic advice falls short.

The Unique Challenges: Chipping, Micro-Fissures, and Material Brittleness

Stone materials-whether granite, marble, quartz, or the increasingly popular sintered stone- possess varying degrees of hardness, brittleness, and abrasive resistance. These properties directly influence how the material reacts to the high-pressure waterjet stream.

💥Chipping Challenges

Especially prevalent in brittle materials like some granites and sintered stone. Improper cutting speeds or insufficient pressure can lead to unsightly edge chipping, requiring extensive post-processing or even material scrap. This critical issue can significantly erode profit margins.

🔬Micro-Fissures Risks

While not always visible to the naked eye, excessive cutting force or incorrect parameters can induce micro-fissures below the surface of the cut. Over time, these can compromise the structural integrity of the stone, leading to breakage during handling or even after installation.

⚡Material Brittleness

The inherent brittleness of many stone types means they're susceptible to cracking or fracturing if the waterjet stream isn't properly controlled. This necessitates a fine balance of power and precision.

Moving Beyond Speed: Balancing Cutting Quality with Throughput

For general manufacturing, faster cutting often equals higher productivity. However, in stone fabrication, speed cannot come at the expense of quality.

A perfectly cut edge minimizes the need for secondary finishing processes like grinding and polishing, saving significant time and labor. The goal is achieving the optimal balance between:

- Edge Quality: A clean, chip-free edge that requires minimal or no post-processing

- Throughput: The volume of material cut within a given timeframe

- Material Yield: Maximizing the usable material from each slab, especially for expensive natural stones

Quick Chart: Recommended PSI Ranges for Granite, Marble, Quartz, and Sintered Stone

The ideal PSI for cutting stone varies significantly based on material hardness and desired finish. This chart provides a general guideline:

| Stone Type | Hardness (Mohs Scale) | Recommended PSI Range | Typical Thickness (mm) | Key Consideration |

|---|---|---|---|---|

| Granite | 6-7 | 45,000 - 65,000 | 20-50 | High abrasion resistance, requires higher PSI for speed |

| Marble | 3-4 | 35,000 - 55,000 | 20-40 | Softer, susceptible to chipping at very high pressure |

| Quartz (Engineered) | 7 | 50,000 - 65,000 | 20-50 | Consistent hardness, good for high-pressure cuts |

| Sintered Stone | 6-7 | 55,000 - 75,000 | 12-30 | Very dense, prone to chipping if not cut precisely |

Note: These are general ranges; actual optimal PSI will depend on specific machine, abrasive type, and desired finish.

The Core Components of Your Waterjet's Power System

Understanding the components that generate and deliver the high-pressure waterjet stream is fundamental to optimizing its performance for stone cutting. It's a symbiotic relationship where each part plays a crucial role.

The Pump: Understanding Direct Drive vs. Intensifier Pumps

The pump is the heart of any waterjet system, generating the immense pressure required for cutting. Two primary types dominate the market:

⚙️Intensifier Pumps

Most common in industrial stone cutting. They use hydraulic pressure to intensify incoming water pressure, often reaching up to 60,000 PSI, 90,000 PSI, or even higher.

Pros:

- Capable of extremely high pressures

- Ideal for thick or very hard materials

- Generally more robust for continuous industrial use

Cons:

- Higher initial cost

- More complex maintenance

- Typically lower energy efficiency

🔧Direct Drive Pumps

These pumps directly pressurize water using a crankshaft and plungers. They are generally simpler in design.

Pros:

- Lower initial cost

- Simpler maintenance

- Higher energy efficiency for lower pressure applications

Cons:

- Typically limited to lower pressure ranges (up to ~60,000 PSI)

- May not be ideal for very thick or extremely hard stone

For stone fabricators demanding high precision and the ability to cut a wide range of materials efficiently, intensifier pumps like those found in the DinoSaw 5 Axis CNC Waterjet Machine are often the preferred choice due to their superior pressure capabilities.

Horsepower (HP): The Engine Driving the System

Horsepower in a waterjet system refers to the power of the electric motor driving the pump. More horsepower generally means the pump can:

- Generate higher pressures: A more powerful motor can drive the pump to achieve higher PSI

- Sustain higher flow rates: Allowing for larger orifices or multiple cutting heads, increasing productivity

- Maintain pressure stability: Crucial for consistent cut quality, especially during long or intricate cuts

However, simply having more HP doesn't automatically equate to better performance for stone. The efficiency with which that HP is converted into cutting power, and how it aligns with your specific material and throughput needs, is what truly matters.

An oversized motor might lead to unnecessary energy consumption without a proportional increase in usable cutting efficiency for your application.

Pressure (PSI): The Force Behind the Cut

PSI is the direct measurement of the force exerted by the waterjet stream. This is arguably the most critical parameter for cutting performance in stone fabrication, directly influencing:

- Cutting Speed: Higher PSI generally leads to faster cutting speeds through a given material

- Edge Quality: Optimal PSI reduces delamination and chipping, especially important for visible edges

- Material Penetration: Essential for cutting thicker slabs or harder materials

For instance, cutting dense sintered stone at 90,000 PSI will typically be faster and result in a cleaner edge than at 60,000 PSI, assuming all other factors are constant. However, excessively high PSI on softer stones like marble can lead to erosion or even damage if not properly controlled.

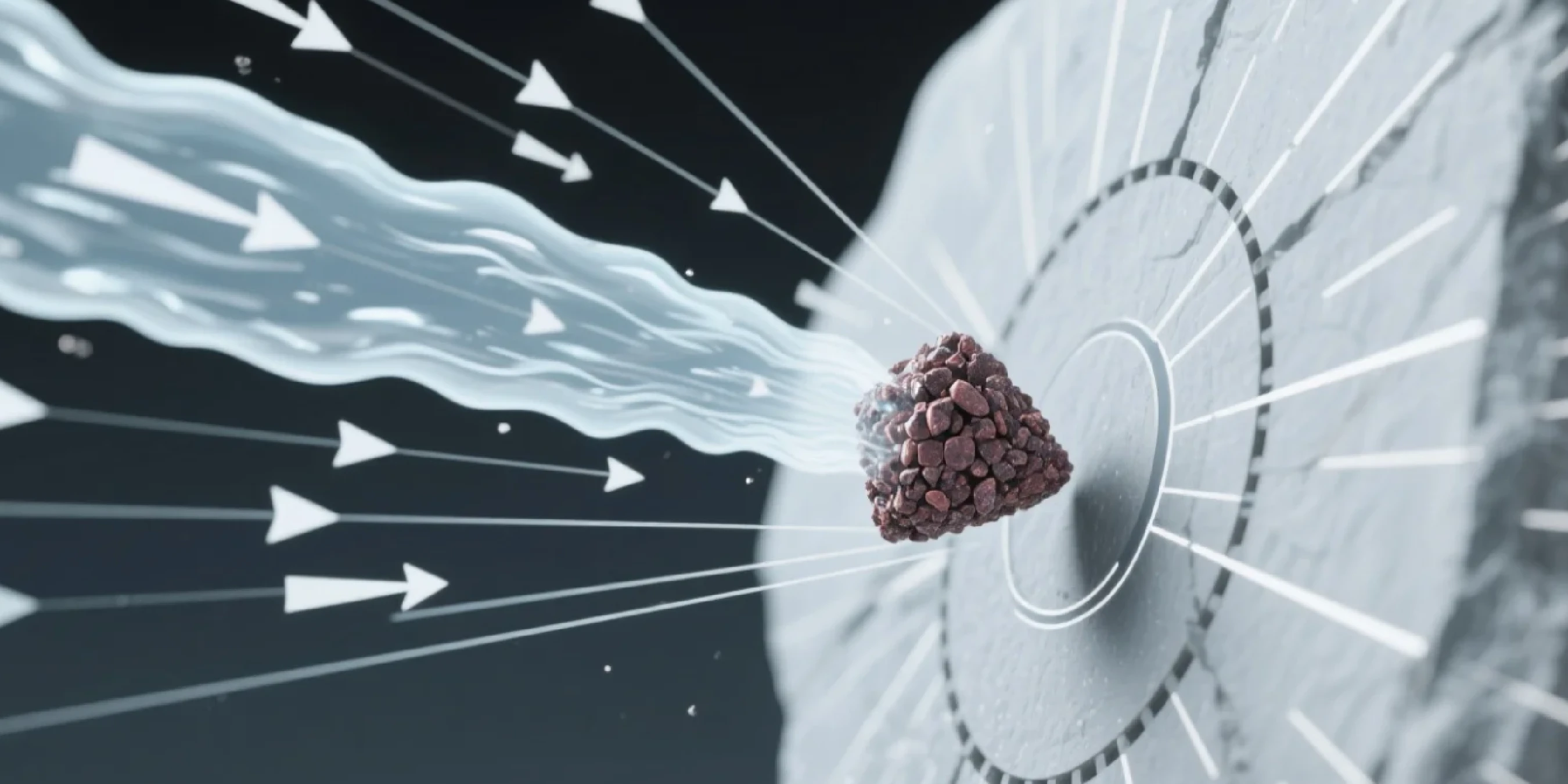

Orifice and Nozzle: Where Power Becomes Precision

The orifice and nozzle (also known as the focusing tube) are the final, crucial components that shape the high-pressure water into a precise cutting tool:

A tiny jewel (often diamond or sapphire) with a very small diameter (e.g., 0.005 to 0.015 inches). It converts the high-pressure water into a high-velocity, coherent stream. The smaller the orifice, the higher the velocity of the water, but the lower the flow rate, requiring less HP to achieve very high pressure.

🎯Nozzle/Focusing Tube

A longer tube (e.g., 2 to 6 inches) made of a wear-resistant material (like tungsten carbide or composite). It guides the water stream and introduces the abrasive garnet, focusing the mixture into a highly effective cutting beam. The length and diameter of the focusing tube influence the stream's coherence and cutting power at a distance from the nozzle.

The combination of HP, PSI, orifice size, and nozzle geometry must be finely tuned to the specific stone material and desired cut quality. An imbalance can lead to wasted power, poor cut quality, or rapid wear of consumables.

The Real Cost of Cutting Stone: A TCO Analysis

While the initial purchase price of a waterjet machine is significant, the true financial impact on a stone fabrication business is determined by its Total Cost of Ownership (TCO). This includes not only the capital expenditure but also ongoing operational costs that can vary dramatically based on how the machine is configured and operated.

Understanding these factors is crucial for maximizing profitability.

Calculating Abrasive Consumption: How PSI Directly Impacts Your Biggest Expense

Abrasive garnet is often the largest consumable cost in waterjet cutting. Its consumption rate is directly influenced by several factors, including:

- PSI: Higher PSI generally allows for faster cutting, which can reduce the time spent cutting, but the rate of abrasive flow usually needs to increase with PSI to maintain cutting efficiency

- Orifice & Nozzle Size: Larger orifices and nozzles require more abrasive

- Material Hardness & Thickness: Cutting harder or thicker stone naturally demands more abrasive

- Cutting Speed: Slower speeds generally mean more abrasive is consumed per linear foot of cut

For example, a typical 36 HP waterjet system cutting granite might consume 1.0 - 1.5 lbs of abrasive per minute. If garnet costs $0.30 per pound, that's $18 - $27 per hour just in abrasive. Optimizing your cutting parameters can yield significant savings over time.

The Hidden Costs: Electricity, Water Usage, and Maintenance Schedules

Beyond abrasives, other operational costs contribute substantially to TCO:

⚡Electricity

The motor driving the highpressure pump consumes significant electricity. A 50 HP pump running for 8 hours a day, 5 days a week, can incur substantial monthly energy bills. Modern systems often incorporate energy-saving features like variable frequency drives (VFDs).

Water Usage

While waterjets use relatively little water per minute for cutting, overall water consumption includes the cutting stream itself, cooling for the pump, and often a water softening or filtration system. Recycling systems are crucial for minimizing this cost and environmental impact.

🔧Maintenance

Regular maintenance of the pump (seal kits, oil changes), abrasive delivery system, and cutting head components (nozzles, orifices) is essential. Neglecting maintenance leads to costly downtime and premature component failure.

TCO Scenario: 60k PSI vs. 90k PSI for a Quartz Countertop Project

Let's consider a scenario for cutting a standard 3 cm (1.2 inch) quartz countertop with complex sink cut-outs, comparing a 60,000 PSI system vs. a 90,000 PSI system.

| Cost Factor | 60,000 PSI System | 90,000 PSI System | Notes |

|---|---|---|---|

| Abrasive Consumption | 1.2 lbs/min ($21.60/hr) | 1.5 lbs/min ($27.00/hr) | Higher PSI may require more abrasive flow for optimal speed, but can cut faster overall |

| Electricity (Pump only) | $3.50/hr (~50 HP pump) | $4.50/hr (~75 HP pump) | Higher HP pump for 90k PSI consumes more power |

| Water (including cooling) | $0.50/hr | $0.60/hr | - |

| Maintenance & Parts | $2.00/hr | $2.50/hr | Higher pressure systems may have slightly faster wear on certain components |

| Total Hourly Op. Cost | $27.60/hr | $34.60/hr | - |

| Cutting Speed | 10 inches/min | 15 inches/min | 90k PSI offers 50% faster cutting speed, significantly reducing project time for complex jobs |

Impact Analysis:

While hourly cost is higher, the cost per linear foot of cut or per project may be lower due to increased throughput. For instance, a 100-inch cut: 60kPSI=10min $4.60; (90k PSI = 6.67 min) $3.85. The faster system is actually cheaper per cut. This simplified scenario highlights that a higher hourly operational cost doesn't always translate to a higher cost per finished piece. The increased cutting speed and potentially superior edge quality of a 90,000 PSI system can significantly reduce labor time, rework, and material waste, ultimately leading to a lower TCO and higher profitability for complex stone projects.

Need Expert Advice?

Don't leave your profits to chance. Get expert advice to calculate the exact Total Cost of Ownership for your specific stone fabrication needs.

Contact Our Specialists on WhatsApp

Optimizing Your Waterjet for Specific Stone Fabrication Tasks

The versatility of waterjet technology lies in its ability to adapt to a wide array of stone cutting tasks. By fine-tuning your machine's parameters and leveraging its capabilities, you can achieve optimal results for specific applications.

Task 1: Complex Sink Cut-outs in Quartzite

Quartzite, known for its hardness and beautiful veining, can be challenging to cut without chipping or creating micro-fissures. For intricate sink cut-outs, especially with tight radii and polished edges, precision is paramount.

Parameter Focus:

- Higher PSI (60,000 - 75,000 PSI): Essential for cleanly penetrating hard quartzite, minimizing friction, and reducing the likelihood of chipping

- Smaller Orifice/Nozzle Combination: Creates a finer, more precise stream, crucial for tight corners and intricate geometries

- Optimized Cutting Speed: Slower initial piercing speed, followed by a steady, carefully calibrated cutting speed to maintain edge quality

Technique: Utilize advanced CAD/CAM software to generate smooth, continuous cutting paths. Consider a brief dwelling time at corners to ensure full material removal without over-cutting.

Task 2: Intricate Inlays in Marble

Marble inlays demand exceptional accuracy and minimal kerf (the width of the cut) to ensure a tight fit between pieces and reduce material waste, especially when working with expensive, exotic marbles.

Parameter Focus:

- Medium to High PSI (40,000 - 60,000 PSI): Sufficient to cut marble efficiently while avoiding excessive force that could cause internal damage

- Very Small Orifice (e.g., 0.005 - 0.007 inches): To achieve the absolute minimum kerf width, maximizing material yield

- Reduced Abrasive Flow Rate: While abrasive is needed, a slightly lower flow rate, combined with a smaller orifice, can achieve a finer cut with less material removal

Technique: Utilize "nesting" features in your software to arrange inlay pieces as closely as possible on the slab, further reducing waste. The exceptional precision of a 5-axis waterjet is ideal for these tasks.

Task 3: Thick Countertop Edge Profiling

For thick stone countertops (e.g., 50mm or 75mm), edge profiling is a common task. While waterjets can cut thick materials, comparing their efficiency with dedicated CNC tooling is important.

Waterjet Approach

Advantages:

- Can cut complex, non-linear profiles in a single pass

- Especially useful for custom designs where a router bit cannot easily follow

- Reduces tool changes

Disadvantages: - Slower for very thick, straight profiles compared to a CNC bridge saw

- Abrasive cost increases significantly with thickness

CNC Tooling Approach

Advantages:

- CNC 5 Axis Bridge Saw machines excel at rapidly cutting straight and gently curved profiles

- Often faster and more cost-effective for high-volume, less intricate profiling

Disadvantages: - Limited by tool geometry

- Requires multiple passes for deep or complex profiles

- Generates more dust

The optimal choice often depends on the complexity of the profile and the production volume. For highly custom, intricate profiles, waterjet excels. For high-volume, standard profiles, a CNC bridge saw is often more efficient.

Advanced Topics: VFDs, Software, and System Integration

To truly maximize your waterjet's potential, consider advanced features and strategies that go beyond basic cutting parameters. These elements enhance efficiency, reduce costs, and improve overall shop productivity.

Is a Variable Frequency Drive (VFD) Worth the Investment for Your Shop?

A Variable Frequency Drive (VFD) is an electronic device that controls the speed of an electric motor by varying the frequency and voltage of its power supply. For waterjet pumps, a VFD can be a game-changer:

🎯Improved Control

Provides finer control over pump pressure, which can be precisely matched to the specific cutting task, further optimizing quality and abrasive use.

Energy Savings

The pump doesn't always need to run at full speed. During piercing, dwelling, or when the cutting head is off, a VFD can reduce pump speed, significantly cutting electricity consumption. This is especially impactful for intensifier pumps.

🔧Reduced Wear & Tear

By allowing the pump to ramp up and down smoothly, a VFD reduces mechanical stress on the motor and pump components, extending their lifespan and lowering maintenance costs.

For high-volume stone fabricators, the energy savings and extended equipment life offered by a VFD can result in a quick return on investment, making it a highly worthwhile upgrade.

How Modern Software (CAD/CAM) Maximizes Efficiency and Reduces Waste

Modern CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software are the brains behind your waterjet's operations. Advanced features directly contribute to efficiency and profitability:

🧩Nesting Algorithms

Intelligent nesting software can automatically arrange parts on a slab to maximize material utilization, drastically reducing waste, especially for expensive stone.

🎮Simulation

Allows fabricators to visualize the entire cutting process before it begins, identifying potential collisions, errors, or inefficiencies, thus preventing costly mistakes.

🛣️Tool Path Optimization

Minimizes non-cutting head movements, reduces pierce points, and ensures smooth, efficient cutting paths, saving time and abrasive.

📊Material Databases

Some software includes material-specific cutting parameters, suggesting optimal PSI, speed, and abrasive flow for different types of stone.

Investing in robust, industry-specific CAD/CAM software is as crucial as the hardware itself for unlocking the full potential of your waterjet system.

The Hybrid Approach: Integrating Your Waterjet with a 5-Axis CNC Saw for Maximum Productivity

Many leading stone fabrication shops are adopting a hybrid approach, combining the strengths of different cutting technologies. Integrating a waterjet with a 5-axis CNC bridge saw offers unparalleled versatility and efficiency:

Waterjet for Intricacies

The waterjet excels at complex internal cuts, sink cut-outs, intricate designs, and drilling faucet holes in hard-to-reach areas. Its ability to start a cut anywhere on the slab without pre-drilling is invaluable.

5-Axis CNC Saw for Speed & Volume

A DinoSaw CNC 5 Axis Bridge Saw or similar machine is unmatched for fast, straight cuts, large arcs, and precise edge profiling. For highvolume countertop production, it's the workhorse.

Optimized Workflow

The waterjet can perform the intricate work, then the slab moves to the CNC saw for rapid primary cutting. This synergistic approach maximizes throughput while maintaining high quality across all tasks, reducing bottlenecks and material handling.

According to a 2024 industry report by Fortune Business Insights, the global countertop market is projected to grow significantly, reaching over USD 140 billion by 2032. This growth underscores the need for fabricators to adopt diversified, efficient cutting solutions to remain competitive and meet increasing demand.

Conclusion: Making the Smartest Power Decision for Your Stone Business

Selecting the right waterjet system for your stone fabrication business is a strategic decision that extends far beyond a simple comparison of horsepower and PSI. It requires a holistic understanding of how these parameters influence cut quality, abrasive consumption, energy costs, and overall operational efficiency for the specific stone materials you process.

By focusing on the Total Cost of Ownership (TCO), optimizing parameters for different tasks, and considering advanced features like VFDs and integrated software, you can transform your waterjet from a mere cutting tool into a powerful profit center.

Ultimately, the best waterjet system is one that aligns perfectly with your production goals, material demands, and long-term financial objectives, ensuring precision in every cut and sustained profitability for your business.

Ready to Transform Your Stone Fabrication Efficiency?

Don't hesitate to reach out for a personalized consultation and quote for the DinoSaw 5 Axis CNC Waterjet Machine.

Chat with Us on WhatsApp

Frequently Asked Questions

What is the ideal PSI for cutting granite with a waterjet?

The ideal PSI for cutting granite typically ranges from 45,000 to 65,000 PSI. Granite is a hard, abrasive material, so a higher PSI within this range will generally result in faster cutting speeds and cleaner edges, minimizing chipping. However, factors like granite thickness, desired edge finish, and the specific abrasive flow rate will influence the optimal setting. For very thick slabs or intricate cuts, higher pressures might be used.

How does waterjet horsepower affect the quality of stone cuts?

Horsepower primarily influences the pump's ability to maintain high PSI and flow, which indirectly affects cut quality. Horsepower dictates the maximum pressure an intensifier pump can achieve and sustain, as well as the flow rate for the waterjet stream. Consistent high pressure (derived from sufficient HP) is crucial for a smooth, clean cut, preventing delamination and micro-fissures in brittle stone. Insufficient HP for a desired PSI can lead to pressure drops and inconsistent cut quality.

What is the difference between an intensifier pump and a direct drive pump for stone waterjet cutting?

Intensifier pumps are generally preferred for industrial stone cutting due to their higher pressure capabilities. Intensifier pumps use hydraulics to intensify water pressure to very high levels (up to 90,000 PSI or more), making them ideal for cutting hard and thick stone efficiently. Direct drive pumps, while simpler and more energy-efficient at lower pressures, typically have a lower maximum PSI (~60,000 PSI), making them less suitable for the demanding requirements of many stone fabrication tasks.

How can I reduce abrasive costs when cutting stone with a waterjet?

Optimizing PSI and cutting speed for each material, along with efficient nesting, are key to reducing abrasive costs. Abrasive garnet is a major operational expense. To reduce costs, use the lowest effective PSI and abrasive flow rate that still achieves the desired cut quality and speed for a specific stone. Implement advanced nesting software to maximize material yield from each slab, reducing the total linear feet cut. Regular maintenance of the abrasive delivery system also prevents waste.

Is a 5-axis CNC waterjet beneficial for stone countertop fabrication?

Yes, a 5-axis CNC waterjet offers significant benefits for complex stone countertop fabrication. A 5-axis waterjet, like the DinoSaw 5 Axis CNC Waterjet Machine, excels at cutting complex sink cut-outs, angled cuts, and intricate designs in countertops that a traditional 3-axis system cannot. Its ability to create bevels and tapers in a single pass greatly enhances precision, reduces secondary finishing, and maximizes design flexibility, leading to superior product quality and faster turnaround times.

What role does CAD/CAM software play in waterjet stone cutting efficiency?

CAD/CAM software is critical for optimizing tool paths, maximizing material yield, and preventing errors. Modern CAD/CAM software allows fabricators to design precise patterns, automatically nest parts on a slab for optimal material usage, and generate efficient cutting paths that minimize non-cutting movements. This reduces abrasive consumption, saves time, and prevents costly mistakes, directly contributing to the overall efficiency and profitability of waterjet stone cutting operations.

English

English 中文

中文