Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

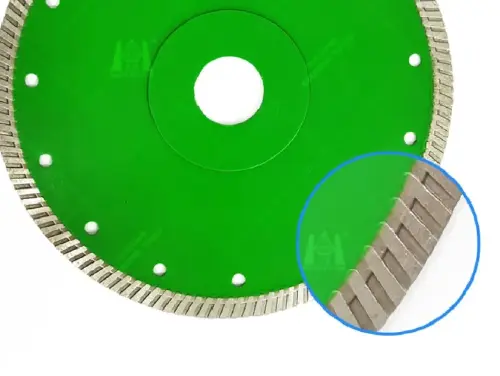

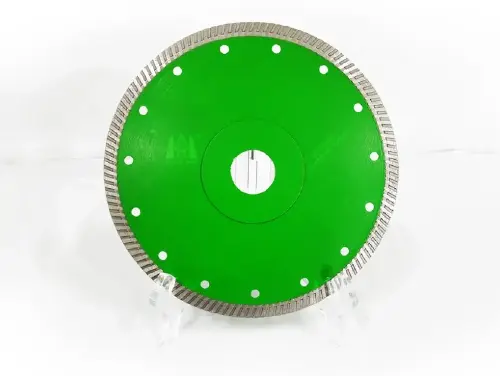

Sintered Continuous Turbo Diamond Cutting Disc

105-230mm/4.13"-9"

Compatible Materials & Products

Fast, clean cuts on granite, marble, concrete and porcelain. For angle grinders / circular saws.

Granite > Smooth slab cutting

Cutting hard, crystalline granite demands a high-performance diamond cutting disc that resists abrasion and controls chipping.

Our disc features a turbo continuous rim designed for superior heat dissipation and debris evacuation in both dry/wet conditions. The robust sintered bond is engineered to hold diamonds securely, ensuring consistent sharpness when used with an angle grinder or circular saw.

This results in fast, clean cuts with low chipping, extending the disc's service life and reducing rework, making it ideal for high-volume slab processing and precise on-site trimming.

Marble > Edge trimming & profiling

While softer than granite, marble is prone to edge bruising and requires a flawless finish to minimize polishing time.

This diamond cutting disc utilizes a continuous rim to ensure uninterrupted contact, reducing vibration and impact. The turbo design maintains a high cutting speed, essential for efficient workshop or on-site operation with hand-held tools. A thin-kerf option further enhances precision.

The result is a remarkably clean, smooth edge ready for immediate polishing, helping installers improve efficiency and achieve high-end finishes with less effort.

Concrete > Expansion-joint sawing

Concrete's abrasive aggregates can quickly dull a standard disc, leading to overheating and slow progress, especially in dry cutting scenarios.

The turbo rim geometry is optimized for aggressive material removal, promoting airflow and dust evacuation. Its durable sintered bond ensures fresh diamond layers are consistently exposed, maintaining cutting performance even through rebar. It's built for demanding use on a circular saw or a high-power angle grinder.

This leads to faster, straighter expansion joint cutting with a dependable service life, improving productivity on construction and renovation sites.

Porcelain tile > Low-chip cutting

Dense, brittle porcelain tiles are highly susceptible to chipping, demanding an ultra-smooth cutting action.

Our thin-kerf diamond cutting disc features a specially designed turbo continuous rim that minimizes impact and ensures stable, precise passes. The fine-grit diamond in the sintered bond is formulated for low chipping performance, making it ideal for delicate dry/wet cutting tasks on angle grinders.

With the correct RPM and a steady feed, operators can achieve chip-free edges that meet the highest standards for luxury tiling, reducing waste and ensuring a flawless installation every time.

Specs and options

Specifications customizable upon request.

| Diameter | Segment Width | Segment Height | Arbor | |

|---|---|---|---|---|

| Inches | mm | mm | mm | mm |

| 4.13" | 105 | 1.8 / 2.4 | 8/10 | 20 |

| 4.3" | 110 | 1.8 / 2.0 | 8/10 | 20 |

| 4.5" | 115 | 2.4 | 10 | 20 |

| 5" | 125 | 2.6 | 8/10 | 20 |

| 5.12" | 130 | 2.6 | 10 | 22.23 |

| 6" | 150 | 2.6 | 8/10 | 25.4 |

| 7" | 180 | 2.8 | 10 | 25.4 |

| 8" | 200 | 2.8 | 10 | 25.4 |

| 9" | 230 | 3 | 10 | 25.4 |

Cut Faster. Finish Cleaner.

Turbo continuous rim for hard materials—speed with low chipping.

High cutting speed

Turbo rim channels airflow/coolant and clears swarf to maintain fast feed under dry or wet cutting.

Low‑chipping edges

Continuous rim stabilizes the kerf, producing smooth edges on granite, marble and porcelain tiles.

Durable sintered bond

Balanced matrix retains grit and exposes fresh diamonds for long, consistent life.

Versatile dry/wet use

Works with angle grinders and circular/table saw setups.

Clean narrow kerf

Thin turbo design supports precise lines and reduced material loss.

Consistent surface finish

Smooth exit reduces post‑cut polishing time and rework.

FAQs

Common Questions About Sintered Continuous Turbo Diamond Cutting Disc

Can this turbo continuous rim disc cut porcelain tiles?

Porcelain's dense and brittle nature makes it prone to chipping, especially during dry cuts.

For best results, select a thin-kerf continuous turbo rim disc. Maintain a steady feed rate and ensure the tile is securely supported in a straight line. Prioritize wet cutting whenever possible, as it significantly reduces heat, suppresses dust, and minimizes chipping.

Before starting, verify that your tool's maximum RPM and linear speed match the disc's specifications. Always use the correct flange and safety guard. We recommend referencing the EN 13236 marking and usage guidelines and performing a test cut on a scrap piece of tile.

How to choose settings for granite slab cutting?

To effectively cut granite, always use wet cutting with a continuous support table to ensure stability. Avoid applying lateral pressure or excessive force; maintain a straight cutting path to prevent blade deviation and ensure a clean edge. The turbo rim design is crucial as it enhances debris removal and cooling.

Start with a mid-range RPM as specified by your tool's manufacturer, and finely adjust based on the cut edge quality and any signs of overheating (e.g., burn marks).

Before cutting large slabs, perform a 50–100 mm test cut. This allows you to optimize the feed rate and coolant flow to achieve minimal chipping and a stable, high-quality kerf.

Does it work for concrete expansion joints?

Yes, this disc is suitable for cutting expansion joints in flooring and for renovation projects. However, concrete contains abrasive aggregates that can cause overheating, especially during dry cutting. The turbo rim design enhances airflow and dust extraction. For long, continuous cuts, wet cutting is highly recommended to maintain consistent cooling.

Ensure the disc's diameter and arbor hole (e.g.,20/22.23/25.4 mm) match your equipment. Always use appropriate Personal Protective Equipment (PPE) and dust collection systems.

If you encounter steel rebar, reduce the feed rate while maintaining a stable linear speed to prevent damage to the disc.

What certifications are relevant for diamond cutting discs?

DINOSAW products are backed by a robust quality management system, demonstrated by our CE marking and ISO certification.

For safety and marking, the EN 13236 standard provides a crucial framework for superabrasive products. While this is a reference for our manufacturing and labeling practices, it is not a certification claim.

When purchasing, you can request compliance documentation. Always check the product label for essential information: diameter, arbor size, maximum RPM/linear speed, and safety pictograms.

Which tools can I use—angle grinder or circular saw?

This disc is compatible with both angle grinders and circular/table saws, provided the diameter and arbor hole size match your tool's specifications.

Common arbor sizes include 20 mm, 22.23 mm, and 25.4 mm. Always confirm your tool's flange, guard, and RPM range are compatible.

Generally, smaller diameter discs (105–150 mm) are used with angle grinders for versatility, while larger discs (180–230 mm) are typically mounted on circular or table saws for deeper, straighter cuts.

How to extend disc life and keep edges clean?

To maximize lifespan and maintain cut quality, always maintain a straight feed path, avoiding lateral loads or sudden stops. Wet cutting is preferable whenever the application allows.

If the disc starts to glaze (become dull) or show signs of overheating (blueing), dress the blade with a suitable abrasive material or reduce the feed rate. Ensure dust extraction systems are clean to improve cooling.

Replace the disc when the segment height approaches its wear limit or if you notice a significant increase in kerf surface roughness.

When should I choose a thin-kerf disc for tiles?

A thin-kerf disc is the preferred choice for high-density, brittle materials like porcelain, sintered stone, and vitrified tiles, as it minimizes the risk of chipping.

The thin turbo continuous rim reduces the contact area and impact force, leading to superior edge integrity. Wet cutting provides additional stability and cooling for an even cleaner finish.

Always perform a test cut on a scrap piece to find the optimal balance between cutting speed and edge quality. Start with a mid-range RPM and maintain a steady, controlled feed rate for the best results.

Do you support customization and OEM/ODM?

Yes, we offer comprehensive customization services, including adjustments to diameter, arbor bore, bond formulation, and turbo rim geometry. We also provide private labeling and custom packaging solutions to meet your branding needs.

To initiate a custom project, please provide your target material, machine specifications (from the nameplate), and estimated annual volume. Our technical team will then develop a tailored specification and sample plan.

For large-volume orders, we can implement phased delivery schedules and quality traceability coding for enhanced supply chain management.

How do you handle quality warranty and defects?

Our warranty covers defects in materials and workmanship, and we provide full production batch traceability for quality assurance.

Defect analysis is a data-driven process. We assess operating parameters such as RPM, feed rate, coolant usage, work-piece support, and visual cues like cutting color or odor to determine the root cause.

To file a claim, please submit photos of the defect, the batch ID from the packaging, and your operating parameters. We will then process a replacement or provide technical guidance for re-inspection in accordance with our policy.

Certifications & Standards

Turbo continuous rim for hard materials—speed with low chipping.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Get Faster, Cleaner Cuts Today

Tell us your material and machine specs—we’ll match diameter, bore and bond for best speed and edge quality.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Diamond Cutting Disc Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文