Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

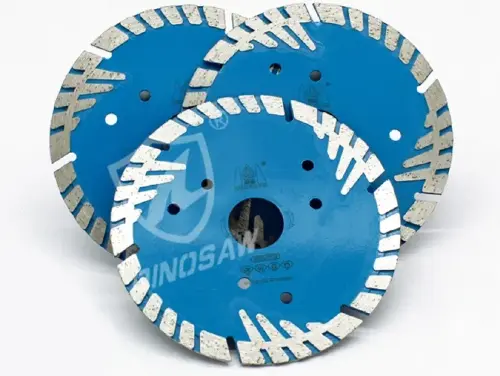

Sintered Bevel Turbo Segmented Diamond Cutting Disc

105-230mm/4.13"-9"

Compatible Materials & Products

Fast dry/wet cutting across stone, concrete and hard brick

Granite > Expansion joints cutting

Granite is hard and brittle, so dry/wet slotting demands fast chip evacuation and stable heat control to prevent edge chipping.

A turbo segmented diamond cutting disc on an angle grinder clears debris quickly and drives airflow for cooling; the sintered bond keeps diamonds engaged under load, while bevel protective teeth shield the core in deep passes.

Result: clean, chip‑controlled kerfs and faster expansion joint creation with durable performance across variable hardness.

Marble > Edge trimming and slotting

Marble finishing prioritizes neat edges and minimal post‑polish time; overheating can stain or bruise the surface.

A turbo segmented diamond disc provides fine cutting action with improved cooling and slurry clearance; bevel teeth stabilize deep slotting and limit core wear, supporting consistent kerf width.

Outcome: smooth, chip‑free edges, reliable slot geometry, and faster trims for premium tiling work.

Sandstone > Fast surface grooving

Abrasive sandstone loads discs quickly and generates heat on broad grooves.

Turbo segmented geometry reduces contact area and maintains feed rate; open segments eject fines efficiently, while the sintered bond balances diamond exposure and retention.

Value: rapid surface grooving with stable temperatures, fewer dressings, and consistent depth across large areas.

Concrete > Deep cutting for openings

Concrete with hard aggregates creates dust, heat, and variable resistance in deep cuts.

A turbo segmented diamond cutting disc improves chip clearance and cooling; the sintered bond sustains aggressive cutting, and bevel protective teeth help prevent core damage during repeated passes.

Benefit: faster opening creation, stable kerf geometry, and durable performance for site cut‑outs, dry or wet.

Hard brick > Masonry cut‑off

Hard brick demands balanced aggression and cooling to avoid burning and edge crumbling.

Turbo serrations sustain speed with reduced contact, and open segments evacuate fines; bevel teeth extend disc life on repetitive masonry cut‑offs using angle grinders.

Outcome: clean, burn‑free cuts, reliable productivity, and less rework on site.

Specs and options

Specifications customizable upon request.

| Diameter | Segment Width | Segment Height | Protective Segments | Arbor | |

|---|---|---|---|---|---|

| Inches | mm | mm | mm | pcs | mm |

| 4.13" | 105 | 2.4 | 8 | 3 | 20 |

| 4.5" | 115 | 2.4 | 8 | 3 | 20 |

| 5" | 125 | 2.4 | 8 | 3 | 22.23 |

| 6" | 150 | 2.6 | 8 | 4 | 25.4 |

| 7" | 180 | 2.8 | 8 | 4 | 25.4 |

| 9" | 230 | 3 | 8 | 5 | 25.4 |

Cut Faster, Stay Cooler, Last Longer

Turbo segmented diamond disc for stone/concrete; bevel teeth protect the core.

High‑Speed Cutting

Turbo segmented diamond cutting disc accelerates debris removal and airflow cooling.

Core Protection & Durability

Bevel protective teeth reduce core contact in deep passes, extending disc life in heavy‑duty cutting.

Dry/Wet Cutting Flexibility

Works with angle grinders on granite, marble, sandstone, concrete, hard brick—consistent performance.

Clean Kerf, Reduced Chipping

Controlled aggression and turbo rim deliver chip‑controlled edges, cutting rework and polish time.

Stable Kerf Geometry

Segment layout maintains kerf width and straightness—ideal for joints, trims, and slotting.

Cooling Efficiency in Deep Cuts

Turbo serrations and open segments enhance cooling during repetitive deep passes on concrete and stone.

FAQs

Common Questions About Sintered Segmented Bevel Turbo Cutting Disc

Can this diamond cutting disc dry-cut granite?

Granite is hard/brittle; dry cutting raises heat and chipping risk.

A turbo segmented diamond cutting disc improves debris evacuation and airflow cooling; use controlled feed, PPE, and light passes; product supports dry/wet cutting.

For fastest rates and edge quality, consider light wetting and verify diameter/arbor/RPM placeholders per EN 13236 guidance.

Which materials can this disc slot or trim effectively?

Slotting/trimming need clean kerfs and stable cooling.

Suitable for granite, marble, sandstone, concrete, hard brick; turbo segmented geometry maintains feed and clears slurry/fines; bevel protective teeth stabilize deep passes.

Choose bond/grit placeholders by hardness; confirm angle grinder model, arbor, and maximum RPM per EN safety.

Does the bevel protective teeth really extend disc life?

Deep cuts can contact and wear the steel core, reducing life.

Bevel protective teeth reduce core contact during aggressive passes, preserving the core and supporting longer service life in heavy-duty dry/wet jobs.

Keep straight feed, avoid lateral pressure, and dress as needed to maintain clean kerfs.

How does the turbo segmented rim improve cutting speed?

Contact area, loading, and heat limit feed rate.

Serrated turbo rim reduces continuous contact, boosts airflow, and clears debris/slurry quicker; the sintered bond balances diamond exposure/retention under load for sustained speed.

Use steady feed and proper PPE; choose dry/wet mode based on jobsite constraints.

How do I choose diameter, arbor, and RPM for my grinder?

Mismatched specs reduce performance and may be unsafe.

Match disc diameter and arbor to tool spec; ensure the grinder’s RPM does not exceed the disc’s max allowed per EN 13236/oSa guidance.

Share your grinder model; request spec placeholders (diameter/arbor/RPM) via quote to confirm compatibility.

Is this cutting disc suitable for both dry and wet cutting on site?

Jobsite conditions vary; water supply may be limited.

The disc is designed for universal dry/wet cutting across granite, marble, sandstone, concrete, and hard brick; wetting improves cooling and edge quality, dry mode favors simplicity.

Choose mode by finish and speed requirements; confirm PPE and dust control when dry‑cutting.

How do I judge wear and decide when to replace the disc?

Worn discs run hot, vibrate, and cut slowly.

Inspect segment height and edge condition placeholders; persistent burning, vibration, or reduced feed indicate end‑of‑life; follow oSa/EN safety guidance.

Keep simple dressing tools, replace when symptoms persist, and record tool hours for preventive maintenance.

Will this disc reduce chipping on porcelain or marble edges?

Brittle ceramics and marble chip easily under heat and aggressive contact.

Turbo rim and controlled aggression produce cleaner kerfs; wet cutting further improves cooling and chip control; choose finer grit placeholders for delicate edges.

Use shallow passes, steady feed, and confirm RPM; switch to wet mode for premium finishes.

Diamond cutting disc vs. continuous rim blade—when to choose?

Different rims suit different finishes and speeds.

Turbo segmented discs favor speed, cooling, and debris removal—ideal for concrete and hard stone; continuous rim favors ultra‑smooth finishes on delicate ceramics but may run slower.

Pick turbo segmented for general site speed and cooling; select continuous rim for premium tile finishing; confirm grinder specs and wet/dry mode.

Certifications & Standards

Turbo segmented diamond disc for stone/concrete; bevel teeth protect the core.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Get Faster, Cooler Cuts on Stone & Concrete

Request specs and a tailored quote for your grinder setup.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Diamond Cutting Disc Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文