Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

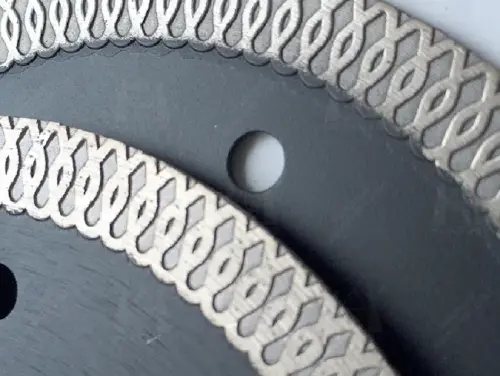

Ultra-Thin Turbo Mesh Diamond Cutting Disc for Porcelain

105-250mm/4.13"-10"

Compatible Materials & Products

Precision Cutting Disc for Hard Tiles & Decorative Stone

Porcelain Tile > Chip-Free Cutting

Porcelain's hardness makes it prone to chipping, a major challenge when using handheld angle grinders. Achieving clean edges without damaging the tile is critical for a professional finish and minimizing waste.

Our disc's ultra-thin profile and turbo mesh rim are engineered for stable, low-vibration operation on angle grinders. This design allows the disc to slice smoothly through dense porcelain rather than fracturing it, ensuring minimal cutting resistance.

This results in flawlessly straight, chip-free cuts, reducing material waste and rework. It boosts on-site productivity and delivers the high-end finish required for premium residential and commercial projects.

Ceramic > Smooth Glaze Cutting

When cutting ceramic on a tile saw, the key challenge is to slice through the brittle glaze without causing flaking, while also cleanly cutting the softer body. An improper blade can easily ruin the tile's aesthetic appeal.

This diamond blade features a high concentration of fine-grade grit in a hot-pressed sintered bond, designed for smooth abrasion. The mesh design efficiently removes dust and slurry, preventing heat buildup that could crack the glaze.

This allows for exceptionally smooth cuts that preserve the integrity of the glaze, making it ideal for achieving perfect finishes on backsplashes, floors, and walls with standard wet tile saws.

Marble > Clean Edge Fabrication

Marble is a crystalline stone susceptible to edge chipping if cut with excessive force or vibration, a common issue with handheld tools. Fabricators need perfectly clean edges for seamless joints in high-value installations.

This cutting disc combines an ultra-thin kerf with a continuous turbo rim that reduces lateral stress on the material. The design ensures rapid debris evacuation and cooling, preserving the stone's integrity at the cutting line.

The result is a sharp, clean cut with minimal chipping, reducing the need for secondary polishing. This improves fabrication efficiency and lowers labor costs while delivering a pristine look for high-end marble work.

Sintered Stone > High-Speed Handheld Cutting

Sintered stone is extremely hard and tensioned, posing a significant challenge for portable tools like circular saws and angle grinders. It requires a disc that can withstand high stress without losing cutting speed or causing fractures.

Our blade is made with a reinforced steel core and a diamond segment designed for ultra-compact surfaces. The fish mesh rim actively cools the disc and reduces stress concentrations during high-speed cutting.

This enables faster cutting compared to standard abrasive discs, increasing workshop throughput. It provides a reliable solution for fabricating sintered stone, minimizing the risk of costly material breakage.

Large-Format Porcelain Tiling with Angle Grinder

Achieving Zero-Chipping on Premium Tiles

Our ultra-thin cutting disc enables flawless, chip-free cuts on large-format porcelain, reducing waste by over 15%. The turbo mesh rim ensures rapid cooling, allowing for continuous dry cutting that accelerates installation schedules on-site.

Marble Countertop Fabrication

Delivering Miter Joints with Perfect Edges

Fabricators use our diamond disc to achieve perfectly straight, clean edges on marble for mitered waterfall countertops. Its stability minimizes the need for post-cut grinding, saving labor time and delivering a premium, seamless finish.

Specs and options

Specifications customizable upon request.

| Diameter | Diameter | Segment Width | Segment Height | Arbor |

|---|---|---|---|---|

| Inches | mm | mm | mm | mm |

| 4.13" | 105 | 1.4 | 10 | 16 |

| 4.5" | 115 | 1.4 | 10 | 16 |

| 5" | 125 | 1.4 | 10 | 20 |

| 6" | 150 | 1.6 | 10 | 20 |

| 7" | 180 | 1.8 | 10 | 22.23 |

| 9" | 230 | 2 | 10 | 22.23 |

| 10" | 250 | 2 | 10 | 22.23 |

Clean Cuts, Fast Performance, No Chips.

Fast, chip-free cutting disc for porcelain and ceramic.

Superior Chip-Free Cutting

The ultra-thin profile and turbo mesh rim minimize chipping on hard porcelain, even with angle grinders.

Enhanced Cutting Efficiency

Hot-pressed sintering and a specialized bond allow for faster cutting, reducing project time on handheld tools.

Excellent Heat Dissipation

The unique mesh design actively cools the disc, enabling stable dry cutting without warping or burning.

Long Tool Lifespan

Premium diamond grit and a strong sintered bond ensure high wear resistance for a longer service life.

Versatile Application Range

One disc for multiple materials, including tile, marble, and ultra-hard sintered stone, from 105mm to 250mm.

Wet and Dry Use Compatibility

Optimized for both dry cutting on angle grinders and wet cutting on tile saws for maximum flexibility.

FAQs

Common Questions About Ultra-Thin Diamond Cutting Disc for Porcelain

Can a 115mm diamond disc cut porcelain dry with an angle grinder?

Yes. Dry cutting porcelain with a 115mm (4.5") angle grinder generates intense heat, risking damage to both the disc and the tile. The challenge is to manage this heat while ensuring a clean, chip-free cut.

Our turbo mesh diamond disc is specifically designed for this task. Its intricate pattern creates air channels that cool the cutting edge, preventing overheating. The ultra-thin design minimizes resistance, allowing for a smooth cut rather than a brittle fracture.

For best results, use light pressure and make intermittent passes to allow for air cooling. This disc complies with EN 13236 safety standards for superabrasives, ensuring reliable performance.

How to choose between this turbo mesh disc and a continuous rim blade for a tile saw?

The choice depends on your priority: cutting speed and dry use versus the absolute finest finish with wet cutting.

Use this Turbo Mesh Disc for:

- Speed and efficiency, especially on hard porcelain.

- Dry cutting with an angle grinder or circular saw.

- Versatility across multiple hard materials.

Choose a standard continuous rim blade when using a wet tile saw for the absolute smoothest, glass-like finish, as the uninterrupted edge minimizes micro-chipping.

What does "sintered" mean and why is it important for a cutting disc?

Sintering is a manufacturing process where diamond particles and a metal powder matrix are fused under extreme heat and pressure. This creates the cutting segment of the disc.

This process is crucial because it creates a powerful bond that holds the diamonds securely. As the disc wears, the metal matrix erodes to expose new, sharp diamond crystals, ensuring consistent cutting performance over a long period.

Compared to electroplated or brazed discs, sintered tools offer a significantly longer lifespan and are better suited for cutting hard, abrasive materials like porcelain, providing a lower total cost of ownership.

What arbor sizes fit my angle grinder or tile saw?

Ensuring the disc fits your tool's arbor (the central mounting spindle) is critical for safety and performance. Different tools and regions use different standard sizes.

Our diamond cutting discs are available with several standard arbor sizes to fit most handheld tools, including:

- 22.23 mm (7/8"): The most common size for angle grinders.

- 20 mm & 16 mm: Often supplied with reducing rings/washers for compatibility.

Always verify your machine's arbor size before ordering. We offer sizes from 105mm to 250mm, and custom arbor configurations are available upon request for specific industrial applications.

How do you handle OEM/ODM requests for diamond cutting discs?

We offer a structured OEM/ODM process for clients requiring customized solutions. The key challenge is translating specific performance requirements—like cutting speed, lifespan, or finish quality for a unique material—into a viable product design.

Our process involves a detailed technical consultation to define your needs. We then develop a custom solution by adjusting parameters like:

- Diamond Bond Formulation: Tailoring the metal matrix and diamond concentration.

- Segment Design: Customizing the shape and layout of the cutting segments.

- Branding & Packaging: Applying your logo and custom packaging.

To start the process, contact our B2B sales team with your technical specifications and volume estimates to receive a detailed proposal and timeline.

Certifications & Standards

Fast, chip-free cutting disc for porcelain and ceramic.

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Get a Quote for Your Precision Cutting Needs

Contact our experts to find the perfect blade for your project and boost your efficiency.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Diamond Cutting Disc Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?

中文

中文