Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Understand Slab Polishing Machine's conveyor/beam dynamics, head power, and abrasive systems for granite and marble. Includes failure modes and starter settings.

From an engineering perspective, achieving a consistent, high-quality polish on natural stone slabs at production scale is a function of mechanical stability and tightly controlled process variables. The core principle of a continuous polishing line is to decouple the complex polishing process into a linear sequence of simpler, repeatable steps. Stable mechanics, combined with matched abrasive systems, create predictable finishing windows for different materials like granite and marble, ultimately enabling fewer changeovers and higher yield.

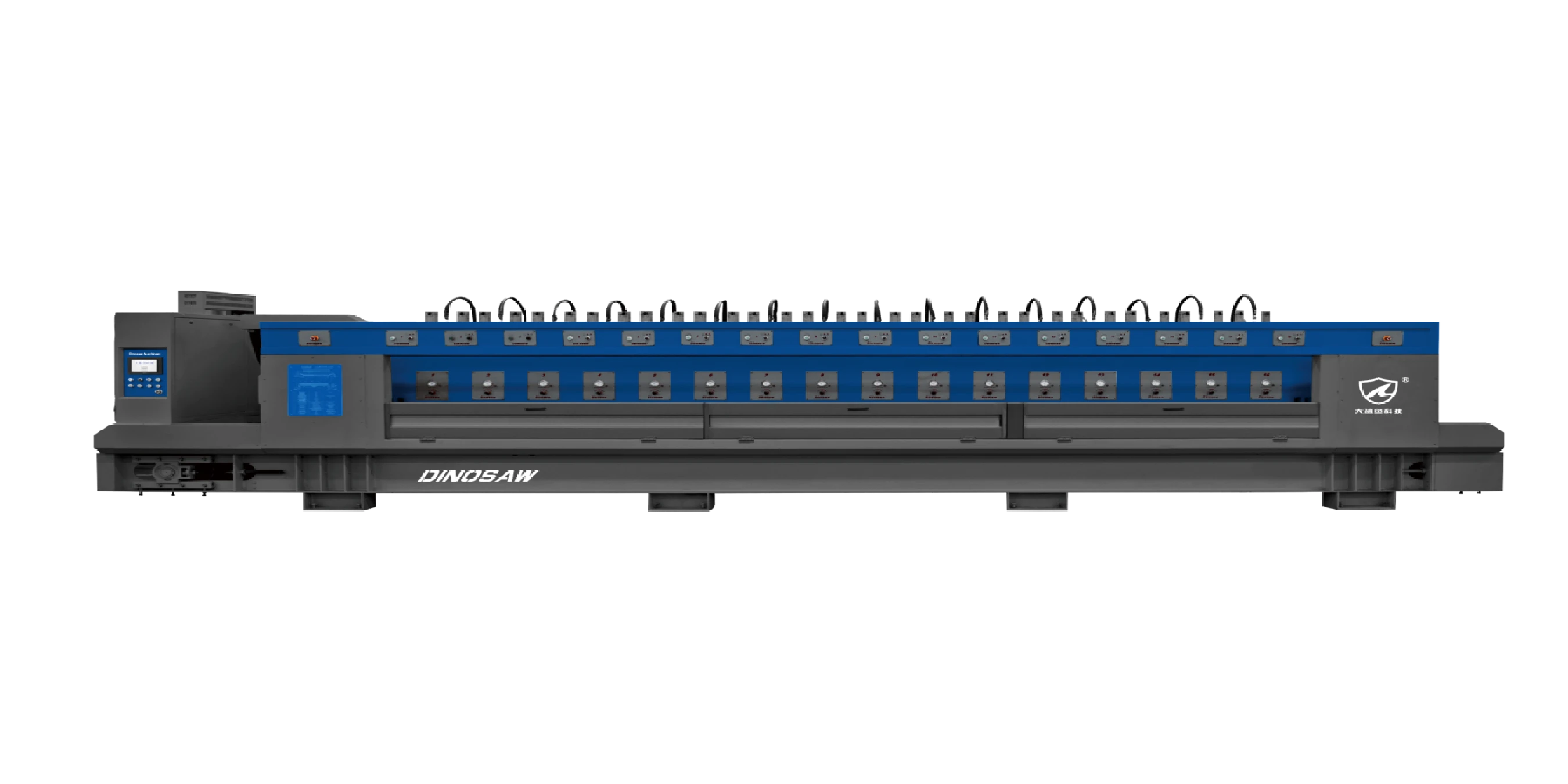

This guide provides a technical breakdown of the system architecture, key component parameters, common failure modes, and integration points for engineering and maintenance teams responsible for specifying or operating these lines. Our automatic stone polishing machine for slab serves as the reference for this discussion.

Request a parameter window for your slab mix and finish targets.

System Architecture: A Modular Approach

The machine’s architecture is a modular system where each component has a distinct role in transporting the slab, applying mechanical force, and managing consumables. The integration of these modules via a central PLC determines the line's overall performance and flexibility.

- Conveyor System: The foundation of the line, this belt-driven system transports slabs at a precise, variable speed. Consistency here is critical for preventing dwell marks and ensuring even exposure to each polishing head.

- Cross-Beam Assembly: Mounted above the conveyor, this rigid beam carries the polishing heads and oscillates laterally across the slab width. The swing speed and pattern are synchronized with the conveyor speed to ensure complete, overlapping coverage.

- Multi-Head Spindle System: The heart of the machine, comprising 10 to 24 individual motorized spindles. Each head is equipped with a specific abrasive grade, moving from coarse grinding to fine polishing. The number of heads dictates the process gradient and maximum achievable gloss at speed.

- Pneumatic Pressure and Water Loop: Each head applies downward pressure via a pneumatic system, ensuring constant contact with the slab surface. A continuous flow of water acts as a lubricant and coolant while flushing away stone slurry.

- Electrical Control & Inverters: A central PLC synchronizes all motors. Each motor (conveyor, cross-beam, spindles) is controlled by a dedicated inverter, allowing for fine-tuned speed and torque adjustments to match the material and abrasive type.

- Optional Modules: This includes automatic loading/unloading racks and slab turnover machines, which can be integrated to create a fully automated line, minimizing manual handling.

Key Component Parameters and Operating Ranges

The following manufacturer-reported parameter ranges, based on models like the TBMJ and DBMJ series, define the operational window. Real-world optimal settings will depend on slab type, thickness, and desired finish.

| Component / Parameter | Typical Range | Engineering Implication |

|---|---|---|

| Belt Advancement Speed | 0–3,800 mm/min | Determines throughput and contact time under each head. Slower speeds for harder materials or deeper grinding. |

| Cross-Beam Swing Speed | 0–3,800 mm/min | Must be synchronized with belt speed to create a consistent, overlapping polishing pattern and avoid streaks. |

| Useful Working Width | 600–2,100 mm | Defines the maximum slab width the machine can process. Ensure it matches your inventory. |

| Useful Working Thickness | 15–50 mm | Defines the acceptable slab thickness range. Thinner slabs may require lower head pressure. |

| Spindle Motor Power | 7.5–15 kW per head | For marble that requires a higher gloss after polishing, a higher spindle power (11–15 kW) is needed. In contrast, polishing granite usually only requires lower power for achieving a smooth surface. |

| Water Consumption | 15–28 m³/h | Critical for cooling and slurry removal. Insufficient flow causes overheating and defects. Requires adequate supply and drainage/recycling. |

| Pneumatic Pressure | ≈1.0 MPa | Controls the downforce of each head. Must be precisely regulated; too high can cause fractures, too low results in an incomplete polish. |

Parameter Quick-Reference

This continuous polishing line for granite/marble operates within a wide parameter window, including a belt speed of 0–3500/3800 mm/min, variable cross-beam swing, a useful working width of 600–2100 mm, and thickness capability of 15–50 mm, with water consumption between 15-28 m³/h and spindle power of 7.5–15 kW per head.

Common Failure Modes and Mitigation

A systematic approach to troubleshooting is key to maintaining uptime and quality.

- Symptom: Gloss Banding (visible streaks).

- Cause: Mismatched belt and cross-beam speeds, or a clogged nozzle on one head.

- Fix: Verify speed synchronization in the PLC. Inspect and clean all water nozzles.

- Symptom: Chatter Marks (wavy patterns).

- Cause: Mechanical vibration from a worn spindle bearing, unbalanced abrasive, or incorrect head pressure.

- Fix: Isolate the responsible head. Inspect bearings for play. Check abrasive for uniform wear and proper mounting. Adjust pressure.

- Symptom: Edge Burn or Chipping.

- Cause: Excessive pressure or insufficient water flow, especially on thin or fragile slabs.

- Fix: Reduce pneumatic pressure on the final heads. Increase water volume. Check for slab flatness before entry.

- Symptom: Uneven Abrasive Wear.

- Cause: Misaligned head or inconsistent downforce.

- Fix: Recalibrate head alignment and verify pneumatic pressure for each head individually.

System Compatibility and Integration

Modern polishing lines must integrate smoothly into a digital factory environment. Key compatibility points include:

- PLC and I/O: The central controller uses standard industrial I/O. Confirm communication protocols if connecting to a plant-wide monitoring system.

- Inverter Mapping: Variable Frequency Drives (VFDs) control motor speeds. The mapping should ensure stable torque, especially for the spindle motors under the fluctuating load of wet polishing.

- Automation Modules: Turnover machines and loading racks are available in different configurations (e.g., standard vs. Pedrini-style). Ensure mechanical and electrical interfaces are compatible during specification.

Frequently Asked Questions

How do cross-beam swing speed and belt speed interact?

They are fundamentally linked. The ratio of belt speed (Y-axis) to cross-beam speed (X-axis) determines the angle and density of the polishing path. A higher belt-to-beam ratio creates a more open, linear pattern, increasing throughput but reducing dwell time. A lower ratio creates a denser, overlapping pattern, which is better for initial grinding stages but slower.

What inverter mapping strategy best stabilizes motor torque?

Vector control (or Field-Oriented Control, FOC) is generally preferred for spindle motors. Unlike simpler V/Hz control, vector control independently manages the motor's magnetic flux and torque, providing more stable RPM and power delivery, even as the load changes when the abrasive contacts or leaves the stone.

When should I increase water flow versus lowering head pressure?

Increase water flow first if you suspect overheating (e.g., edge burning, glazing on the abrasive). This is a cooling and lubrication issue. Lower head pressure if you see signs of mechanical stress, like micro-fractures, chipping, or if the motor current is spiking, indicating excessive force.

Why does head count affect material removal uniformity?

More heads allow for a more gradual transition between abrasive grits. A 20-head line can have many small, incremental steps from coarse to fine, ensuring each head only removes a small amount of material. This reduces the load on each motor and results in a flatter, more uniform surface compared to a 10-head line trying to achieve the same finish with fewer, more aggressive steps.

What are the typical abrasive grades for granite vs. marble?

For granite (G-series), a common sequence for Fickert abrasives start with metalbond diamonds (e.g., 24, 36, 60, 120 grit) for grinding, followed by magnesium Fickerts(e.g., 60, 120, 220, 320 grit) and resin-bond Fickerts (e.g., 400, 600, 800, 1200, 1500 grit) for polishing. For marble (M-series), Frankfurt abrasives start at a finer grit and progress through a LUX or buffing compound for the final gloss. These are starting points and must be tuned. Our guide on stone grinders provides more context.

Is CE certification sufficient for all of Europe?

Yes, the CE mark indicates compliance with EU-wide health, safety, and environmental protection legislation. According to the EU Machinery Regulation 2023/1230 , a CE-marked machine can be legally placed on the market in any country within the European Economic Area (EEA). However, local work-safety regulations regarding installation and operation may still apply.

How do I measure gloss per ISO 2813?

Measuring gloss according to ISO 2813 involves using a calibrated gloss meter at a specific angle (20°, 60°, or 85°). For stone surfaces, the 60° geometry is most common. The device projects a light beam onto the surface and measures the amount of reflected light to provide a quantitative Gloss Unit (GU) reading.

English

English 中文

中文