Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Step‑by‑step SOPs, Top10 issue flows, maintenance intervals, and EU/CE safety checklist for granite and marble polishing lines.

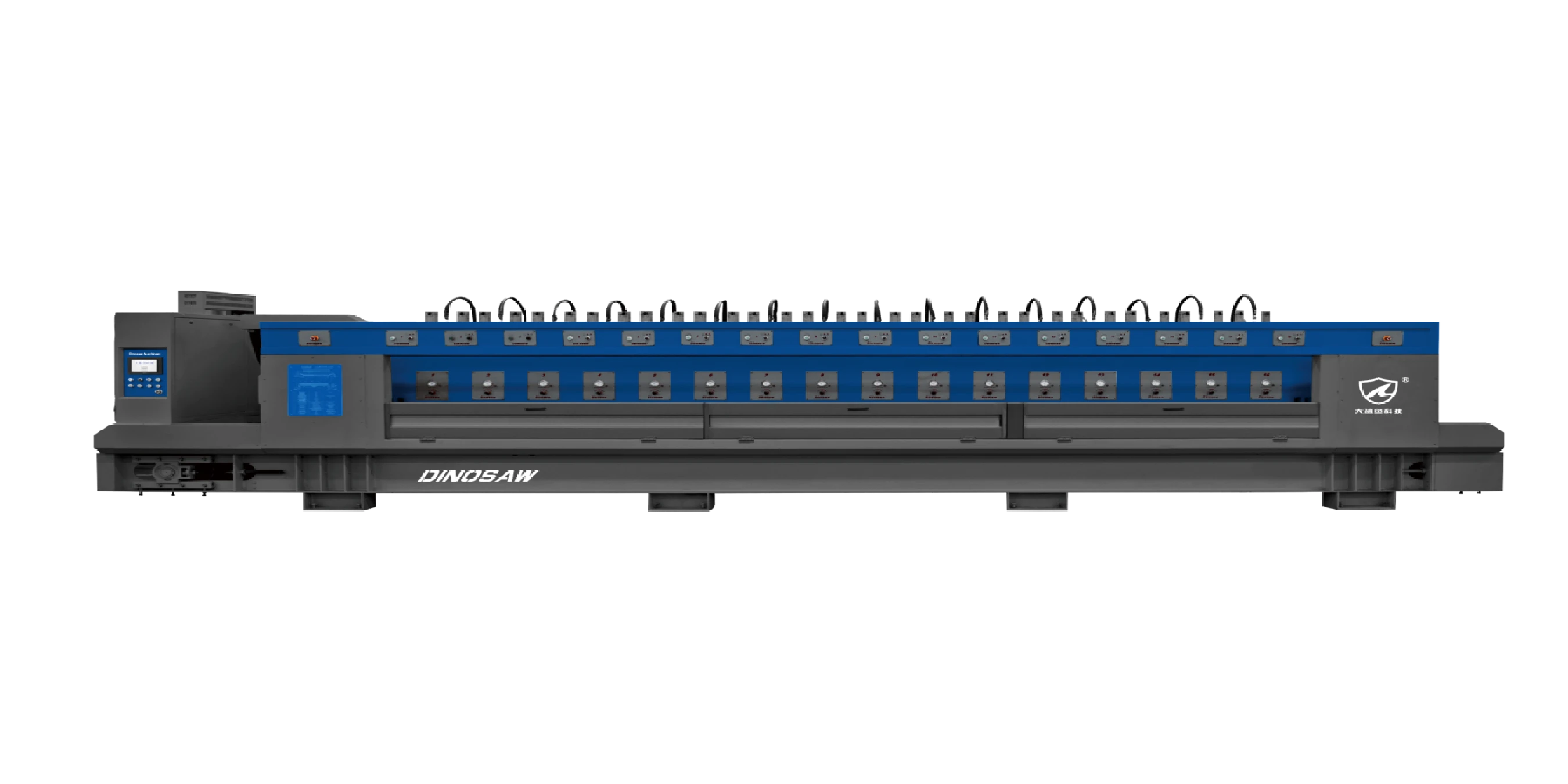

A continuous slab polishing line is engineered for high performance, but achieving and sustaining that output requires disciplined operational and maintenance practices. Clear Standard Operating Procedures (SOPs) and consistent periodic checks are what prevent most defects and consumable waste. For operators and maintenance technicians, rigorous adherence to these protocols is the key to hitting DINOSAW-reported benchmarks, such as a 16-head line polishing marble at 240 ㎡/h and granite at 290 ㎡/h shift after shift.

This guide provides a practical, field-level framework for the daily operation, routine maintenance, troubleshooting, and safety compliance of your automatic stone polishing machine for slab.

Ask for our detailed O&M checklist tailored to your specific line configuration.

Standard Operating Procedures (SOPs)

Follow these checklists to ensure safe, efficient, and consistent operation.

1. Daily Startup Checklist

- Safety First: Ensure all emergency stops are disengaged, safety guards are in place, and the work area is clear of obstacles.

- Utility Check: Confirm main electrical power is on. Verify pneumatic air pressure is at the required level (e.g., \(≈1.0 MPa\)). Check that the main water supply valve is open and the filtration system is active.

- Abrasive Inspection: Visually inspect each polishing head for significantly worn, cracked, or missing abrasive segments. Replace as needed.

- Conveyor Belt Check: Inspect the belt for tears or significant wear and ensure it is free of debris.

- Power On & HMI: Turn on the main control panel. Check the Human-Machine Interface (HMI) for any fault codes or alarms from the previous shift.

2. Material Changeover Procedure (e.g., Granite to Marble)

- Load Recipe: Select the pre-configured "Marble" recipe from the PLC/HMI. This will automatically adjust belt speed, cross-beam speed, and head pressure targets.

- Change Abrasives: Safely lock out the machine. Systematically replace the granite-specific Fickert abrasives with the softer Frankfurt abrasives required for marble.

- Verify Parameters: Manually double-check that the pressure regulators for each head match the new recipe's specifications. Lower pressure is critical for marble.

- Run Test Slab: Process a single test slab and inspect the finish for quality and consistency before beginning the full production run.

3. Shutdown Procedure

- Clear the Line: Ensure the last slab has completely passed through all polishing heads and is off the conveyor belt.

- Rinse Cycle: Run the water system for several minutes with the heads raised to flush any remaining slurry from the heads and drainage system.

- Power Down: Stop all motors via the HMI, then turn off the main control panel. Finally, shut off the main electrical disconnect.

- Close Utilities: Shut off the main water supply and compressed air line.

Preventive Maintenance Schedule

| Frequency | Task | Purpose |

|---|---|---|

| Daily | Clean slurry from machine bed and drainage channels. Visually inspect for water or air leaks. | Prevents blockages, slip hazards, and wasted resources. |

| Weekly | Check conveyor belt tension and tracking. Inspect abrasive wear patterns for uniformity. Lubricate grease points on the cross-beam and head slides. | Ensures even polishing, prolongs belt life, and prevents mechanical seizure. |

| Monthly | Clean or replace water filter elements. Check spindle motor amperage under load. Inspect pneumatic lines and fittings for wear or leaks. Calibrate head pressure sensors. | Maintains water quality, prevents motor overload, ensures consistent head pressure. |

| Quarterly | Inspect spindle bearings for noise or play. Check electrical cabinet connections for tightness. Verify alignment of the cross-beam. | Prevents catastrophic bearing failure, reduces electrical fire risk, and avoids gloss banding. |

Top 5 Troubleshooting Flows

When defects appear, use this systematic process to diagnose and resolve the issue.

1. Symptom: Gloss Banding (Streaks)

- Likely Causes: Mismatched belt/beam speeds; clogged water nozzle; uneven abrasive wear.

- Diagnosis: Check PLC recipe for correct speed ratio. Raise heads and run water to check for a full spray pattern from each nozzle. Inspect abrasives on the corresponding head.

- Fix: Correct speeds. Clean or replace nozzle. Replace worn abrasives.

- Prevention: Daily nozzle check during startup.

2. Symptom: Chatter Marks (Wavy Finish)

- Likely Causes: Worn spindle bearing; unbalanced abrasive; incorrect head pressure.

- Diagnosis: With the machine off, attempt to move the spindle shaft by hand to feel for play. Inspect abrasive for damage or uneven mounting.

- Fix: Replace worn bearings. Re-seat or replace abrasive. Adjust pressure.

- Prevention: Quarterly bearing inspection.

3. Symptom: Cloudy or Hazy Finish

- Likely Causes: Poor water quality; incorrect abrasive sequence; insufficient water flow.

- Diagnosis: Test water for hardness or contaminants. Verify the abrasive sequence (coarse to fine). Check water flow rate at the heads.

- Fix: Service water filtration system. Correct the abrasive sequence. Clean water lines.

- Prevention: Monthly water filter maintenance.

4. Symptom: Spindle Motor Overloads

- Likely Causes: Head pressure is too high; belt speed is too slow for the material; wrong (too coarse) abrasive.

- Diagnosis: Check the pneumatic pressure setting for that head. Review the PLC recipe against material type. Inspect the abrasive grade.

- Fix: Reduce pressure. Increase belt speed. Install correct abrasive.

- Prevention: Thorough checks during material changeover.

5. Symptom: Conveyor Belt Drifting

- Likely Causes: Uneven belt tension; worn roller or bearings; material buildup on rollers.

- Diagnosis: Observe belt tracking during operation. Inspect rollers for wear and debris.

- Fix: Adjust tensioning bolts according to the manual. Clean or replace rollers.

- Prevention: Weekly belt and roller inspection.

Safety and Compliance

Operator safety is paramount. Adherence to safety protocols is mandatory.

Operator Keyword Quick Tips

- Follow the maintenance schedule to prevent unplanned downtime.

- Use systematic troubleshooting to quickly resolve issues.

- Maintain the water filtration system for a better finish.

- Always wear mandatory PPE in the work area.

- Perform a daily belt speed check and beam swing calibration verification.

- Monitor consumables usage to control costs and ensure slabs/hour consistency.

Safety Protocols

- Personal Protective Equipment (PPE): Always wear steel-toed waterproof boots, safety glasses, and hearing protection when near the operating line.

- Lockout/Tagout (LOTO): Before any maintenance or cleaning, completely de-energize and lock out the main electrical disconnect. The machine must be at zero energy state.

- Water & Electrical Hazard: Never open electrical cabinets with wet hands or while standing in water. Ensure all electrical enclosures are kept closed and sealed. The machine must comply with standards outlined in the EU Machinery Regulation 2023/1230 .

- Slip & Trip Hazards: Keep the floor around the machine free of slurry buildup and tools. A non-slip floor surface is highly recommended.

- Guarding: Never operate the machine with safety guards removed or bypassed. Moving parts like the cross-beam and belts pose a serious entanglement risk.

Frequently Asked Questions

What water conductivity level is recommended?

While specifications vary, aiming for a low conductivity (e.g., under 500 μS/cm) by using filtered or deionized water helps prevent mineral deposits and haze on the final polished surface. A good water filtration system is a valuable investment for consistent quality.

When do I re-calibrate the cross-beam swing?

Re-calibrate quarterly or any time you notice gloss banding that isn't resolved by other means. Calibration ensures the beam's movement is perfectly perpendicular to the belt and its travel limits cover the entire slab width evenly.

How can I run thin slabs (e.g., \(<20 ~mm\)) without edge burn?

The key is to reduce mechanical and thermal stress. Use a specific PLC recipe with lower head pressures, slightly faster belt speeds, and increased water flow. Ensure the slab is perfectly flat before entering the line; using a calibrating machine upstream is often necessary.

Should I grease bearings weekly or monthly?

Follow the manufacturer's manual. However, a good rule of thumb is weekly for high-load points like cross-beam guide rollers and monthly for lower-load components. Use the specified grease type to prevent premature wear.

What does a high gloss reading (GU) mean?

A high Gloss Unit (GU) value, measured with a gloss meter according to standards like ISO 2813 , indicates a more mirror-like, reflective surface. For example, a high-quality polished black granite might measure over 90 GU at a 60° angle.

How do I know when abrasives need replacement?

This depends entirely on the material being processed and the abrasive quality. As a rule of thumb, inspect wear after every 8-10 hours of continuous operation. Establish a baseline for your specific material and replace abrasives based on square meters processed, not just time.

Look for visual signs like significant thinning, cracks, or glazing (a smooth, shiny surface on the abrasive itself). A drop in finish quality or an increase in motor amperage can also be indicators. The best practice is to track the total square meters processed and replace abrasives based on the manufacturer's recommended lifespan.

What PPE is mandatory around a wet polishing line?

At a minimum, mandatory PPE includes: steel-toed waterproof boots to protect from falling objects and water; ANSI-rated safety glasses to protect from splashes; and hearing protection (earplugs or earmuffs) due to the high noise levels of the motors and polishing process.

How do I keep the water recycling system efficient?

Regular maintenance is key. Clean settling tanks weekly to remove slurry buildup. Backflush or replace filter media (e.g., sand or cartridges) according to the system's manual. Consistently check and treat the water's pH to ensure flocculants work effectively, allowing solids to separate and be removed.

English

English 中文

中文