Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Automated slab polishing with consistent finish and lower rework. Covers granite and marble workflows, maintenance tips and shop‑tested practices. Read the guide.

For fabricators facing challenges with finish consistency, production speed, or high rework rates, a continuous stone polishing line offers a systemic solution. Unlike manual methods or single-head machines, this automated system is designed to provide a repeatable, high-quality finish across hundreds of slabs, directly addressing common production bottlenecks. It is an essential tool for workshops looking to scale their output while maintaining strict quality control.

Ask our engineer to size the line and abrasive system for your slabs.

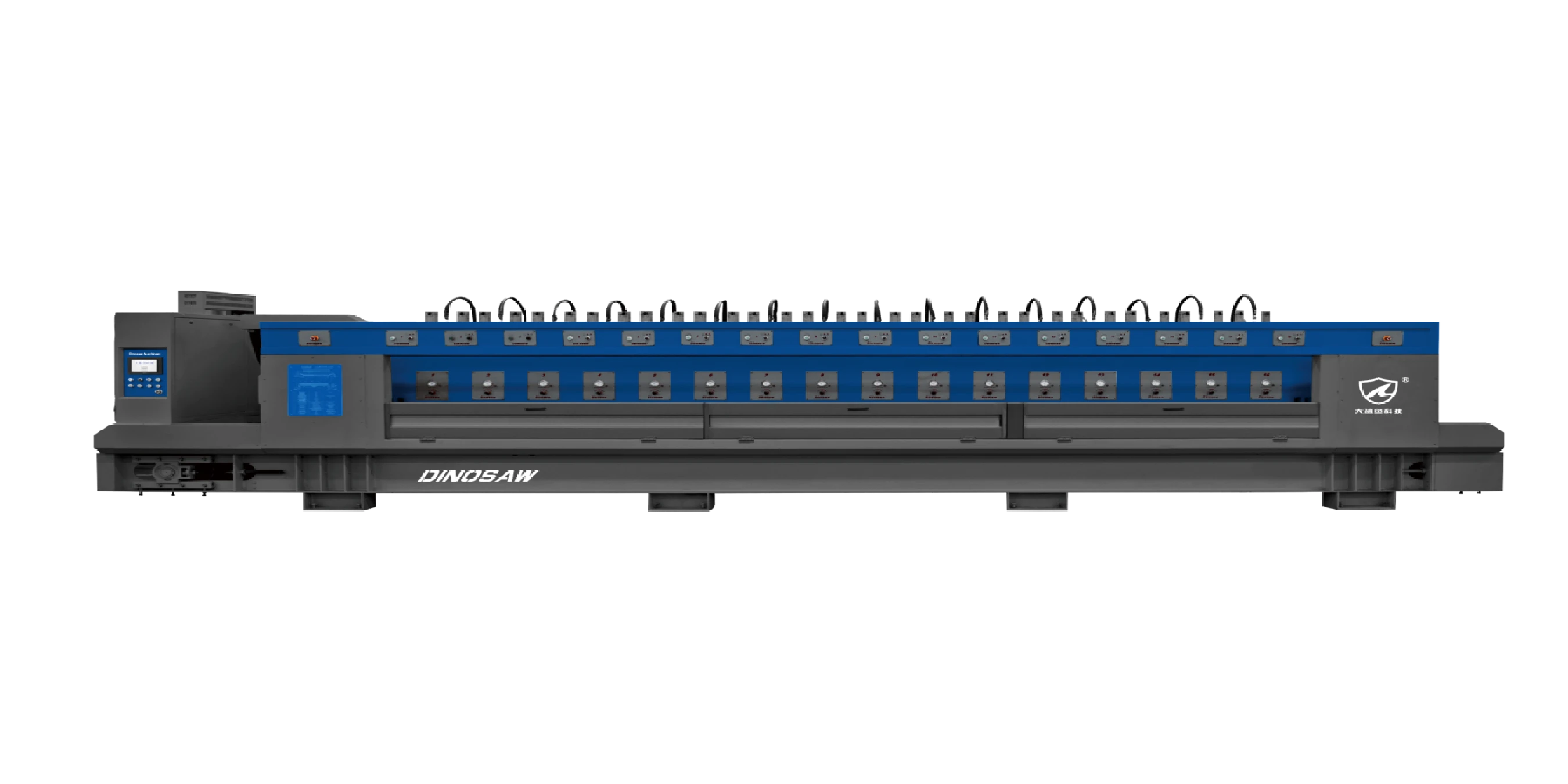

This guide explores what the TBMJ/DBMJ-series continuous polishing line is, what it does, and how it compares to existing processes, helping you determine if it’s the right fit for your workshop. For core specifications, you can refer to the main Automatic stone polishing machine for slab product page.

Materials & Capabilities at a Glance

This multi-head automatic polishing machine is designed for versatility. Below is a quick overview of what the stone slab polishing machine can do:

- A continuous slab polisher system for high-volume production, boosting slabs/hour.

- Specialized granite polishing equipment (G-series) using Fickert abrasives.

- Dedicated marble polishing machine (M-series) using Frankfurt abrasives.

- Variable belt advancement speed and cross-beam swing speed for precise control.

- Accommodates a useful working width/thickness suitable for industry-standard slabs.

- Optimized water consumption and spindle motor power for operational efficiency.

What This Machine Is and What It Does

A continuous stone polishing line is a large-format industrial machine that automates the process of finishing flat stone slabs. Slabs are placed on a conveyor belt and move sequentially under a series of rotating polishing heads—from 10 to over 20—that perform everything from initial grinding to final buffing. Here’s a breakdown of its capabilities:

- Applicable Materials: The system is highly adaptable. G-series models use Fickert or grinding disc abrasives for hard materials like granite. M-series models use Frankfurt abrasives for softer stones like marble and travertine. With the right parameters and abrasives, it can also effectively polish engineered stone (quartz、sintered stone).

- Processing Method: It performs a multi-stage, linear finishing process. The first heads use coarse abrasives for grinding and leveling, while subsequent heads use progressively finer grits to smooth the surface, remove scratches, and achieve a high-gloss or mirror finish. Slab edges are typically finished separately using dedicated edge profiling machines.

- Typical Slab Sizes: These machines are built for large slabs, accommodating working widths from 600 mm to 2100 mm and thicknesses between 15 mm and 50 mm, covering most standard industry formats.

Where It Fits and Where It Doesn’t

This technology excels in specific environments but is not a universal solution.

Ideal Scenarios

- High-Volume Production: Workshops processing dozens or hundreds of slabs per day.

- Strict Quality Control: Operations that require consistent, repeatable high-gloss finishes across large orders.

- Mixed-Material Fabricators: Facilities that need to efficiently switch between granite, marble, and other stones.

Less Suitable Scenarios

- Small Artisan Shops: Low-volume workshops where the capital investment and footprint are prohibitive.

- Complex 3D Shapes: Sculptures or custom furniture with curved surfaces require a CNC wire saw or robotic arm.

- Out-of-Spec Slabs: Extremely thick, thin, or narrow slabs that fall outside the machine's working dimensions.

Advantages Over Traditional Methods

A continuous polishing line offers significant operational advantages over conventional equipment.

- vs. Manual Polishing Benches: It replaces intensive physical labor with full automation, dramatically improving finish consistency and operator safety. It eliminates the variability inherent in hand-polishing.

- vs. Single-Head Bridge Polishers: A continuous line processes slabs in a single pass, offering much higher throughput. There is no need to stop and reposition the head or slab, creating a truly continuous workflow.

- vs. General Workshop Grinders: While handheld grinders are versatile, a continuous line is a specialized tool for slabs. Its PLC-controlled abrasive sequence, pressure, and speeds deliver a level of precision and repeatability that general-purpose tools cannot match.

From Common Problems to Effective Solutions

Fabricators often face challenges that a continuous line is designed to solve.

- Problem: Uneven Gloss & High Rework. Inconsistent finishes lead to rejection and costly rework.

- Solution: High Gloss Uniformity. The machine ensures every part of the slab receives identical treatment, achieving minimal variance in gloss units (GU).

- Problem: Low Throughput. Manual or single-head systems create a production ceiling.

- Solution: High-Speed Processing. A continuous line dramatically increases output. A 16-head line, for instance, has manufacturer-reported benchmarks of approximately \(240 ~m^{2}/h\) for marble and \(290 ~m^{2}/h\) for granite.

- Problem: High Consumable Waste. Inefficient processes lead to excessive spending on abrasives, energy, and water.

- Solution: Optimized Resource Use. An automated line ensures correct pressure, water flow, and abrasive sequencing, reducing waste.

- Problem: Lengthy Changeover Times. Switching between materials causes significant downtime.

- Solution: Repeatable Recipes. PLC-controlled recipes and automated adjustments minimize the time and error involved in starting a new batch.

High-Value Use Cases: Three Mini Case Studies

The value of a continuous polishing line becomes clear when applied to real-world production scenarios. Here are three examples illustrating the transformation.

Case A: High-Volume Granite Countertop Fabricator

- Initial State: A workshop using multiple standalone polishers struggled with inconsistent gloss on large granite orders and a throughput ceiling of 120㎡/h.

- Action: Implemented a 16-head G-series continuous polishing line with Fickert abrasives and an automated turnover machine.

- Quantified Result: Throughput increased to over 280㎡/h, rework rates dropped significantly, and gloss consistency improved to a variance of less than ±4 GU.

- Prerequisites: Stable power supply for the 181 kW total power, a water recycling system to handle 20m³/h consumption, and trained operators for abrasive sequencing.

Case B: Architectural Marble Supplier for Stairs & Flooring

- Initial State: A supplier specializing in marble faced high labor costs and quality control issues, with frequent edge-burning on thinner slabs.

- Action: Installed a 12-head M-series line using Frankfurt abrasives, with fine-tuned pressure controls and variable belt speeds.

- Quantified Result: Achieved a stable throughput of \(≈190㎡/h). Optimized abrasive and energy use reduced waste, and edge-burn defects were virtually eliminated.

- Prerequisites: A detailed understanding of different marble types to create specific PLC recipes for belt speed and pressure. See our Professional Stone Identification guide for more on this topic.

Case C: Mixed-Material Wholesale Distributor

- Initial State: A distributor handling both granite and marble found changeover between materials to be a major source of downtime, limiting overall flexibility and output.

- Action: Deployed a 20-head DBMJ-2000-20G/M model capable of handling both Fickert and Frankfurt abrasives, with quick-change head mounts.

- Quantified Result: Total output across both material types increased significantly. Changeover time was reduced from over two hours to under 30 minutes, allowing them to take on more diverse orders.

- Prerequisites: Investment in a comprehensive inventory of both Fickert and Frankfurt abrasives and cross-training staff on both systems. A general overview can be found in our Stone Grinder Machine Guide .

Risks and Prerequisites for Success

To achieve these results, several operational factors must be managed. Investing in a continuous slab polisher is more than a machine purchase; it's an upgrade to your entire process. Key considerations include:

- Water Quality and Filtration: Water hardness and impurities directly affect the chemical reactions of abrasives and can cause staining or haze on the final product. A closed-loop filtration system is highly recommended.

- Abrasive Compatibility: Using the wrong abrasive type or sequence (e.g., Fickert on soft marble) can damage the stone or result in a poor finish. Always follow manufacturer-reported guidelines for your G-series or M-series line.

- Slab Variability: Inconsistent thickness or tension in incoming slabs can lead to uneven polishing. A calibrating machine may be required upstream for optimal results. Parameter windows for specific slab types should be confirmed during commissioning.

- Safety and Compliance: These are large, powerful machines. Ensuring compliance with regional safety standards, like the EU's Machinery Regulation 2023/1230 , is essential for operator safety and legal operation. This includes proper guarding, emergency stops, and electrical safety protocols.

Frequently Asked Questions

How do I choose between a 12, 16, or 20-head polishing machine?

The choice depends on your primary material and throughput targets. For softer stones like marble or lower volume needs, a 12 or 16-head line is often sufficient. For hard materials like granite and high-volume production aiming for maximum 290㎡/h, a 16 or 20-head machine provides the necessary grinding and polishing stages to achieve a high-gloss finish at speed.

What gloss variance can be achieved on granite vs. marble?

With a properly calibrated continuous line, you can expect a very high degree of consistency. On marble, achieving a mirror finish with a variance of less than ±5 GU is standard. For granite, which is harder, a well-configured G-series line can achieve a high-gloss finish with a variance of ±4 GU or better, depending on the abrasive sequence and stone quality.

When should I switch abrasives during a run?

Abrasives are arranged in a sequence from coarse to fine. They are not typically switched "during" a single slab's run. Instead, the slab passes under each head in succession. You replace individual abrasive bricks or discs as they wear out, which is determined by visual inspection or scheduled maintenance based on the total square meters processed.

Can this technology polish engineered stone?

Yes, with the correct abrasive selection and parameter settings, continuous polishing lines are effective for engineered stone (quartz). However, the resin binders in engineered stone have different thermal properties than natural stone, so speeds and pressures must be adjusted to avoid overheating or burning. A dedicated parameter set is recommended.

Is a slab turnover machine necessary?

A turnover machine is optional but highly recommended for high-throughput operations. It automates the process of flipping slabs to polish both sides, significantly reducing manual labor, risk of damage, and downtime between sides. For workshops focused on maximizing slabs per hour, it is a critical component for efficiency.

How does water quality affect the final polish?

Water serves as both a coolant and a lubricant, and it flushes away slurry. High mineral content (hard water) can leave chemical deposits or a hazy film on the slab, dulling the final gloss. Suspended solids in recycled water can also cause scratching. Using filtered or treated water ensures a cleaner process and a more brilliant, defect-free shine.

How do I pick Fickert vs. Frankfurt abrasives for my stone?

The choice is material-dependent. Fickert abrasives are robust, rectangular blocks ideal for grinding hard, crystalline stones like granite. Frankfurt abrasives are wedge-shaped and offer a gentler action, making them perfect for polishing softer, calcite-based stones like marble and travertine.

What slab widths and thicknesses can the line handle?

These lines are built for standard industrial slabs, typically handling a useful working width from 600 mm to 2100 mm. The acceptable slab thickness generally ranges from 15 mm to 50 mm, which covers most applications for countertops, flooring, and cladding.

Should engineered stone (quartz) use different belt and pressure settings?

Yes, absolutely. Engineered stone contains resin binders that are sensitive to heat. It requires slower belt speeds, lower head pressure, and a good flow of water to prevent burning or discoloration. Specialized resin-bond abrasives designed for quartz should be used for best results.

English

English 中文

中文