Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Learn which CNC engraving method fits your work—lettering, reliefs, columns, statues, photo etching. Benefits, tools, workflow and business tips. Read the handbook.

Start with Your Vision Instead of Specifications

Choosing the right CNC stone engraving machine can feel overwhelming. Faced with a sea of technical specifications-spindles, axes, motors-it's easy to lose sight of the most important question: what do you want to create?

Whether you're a seasoned stonemason looking to scale production or an entrepreneur entering the profitable world of custom memorials, success isn't about complex jargon. It's about matching the right technology to your vision.

Most buyers get lost in technical details. Smart ones work backward from their masterpiece. This guide explores four primary stone carving methods-each linked directly to the products they create best.

Get direct solutions from DINOSAW expert

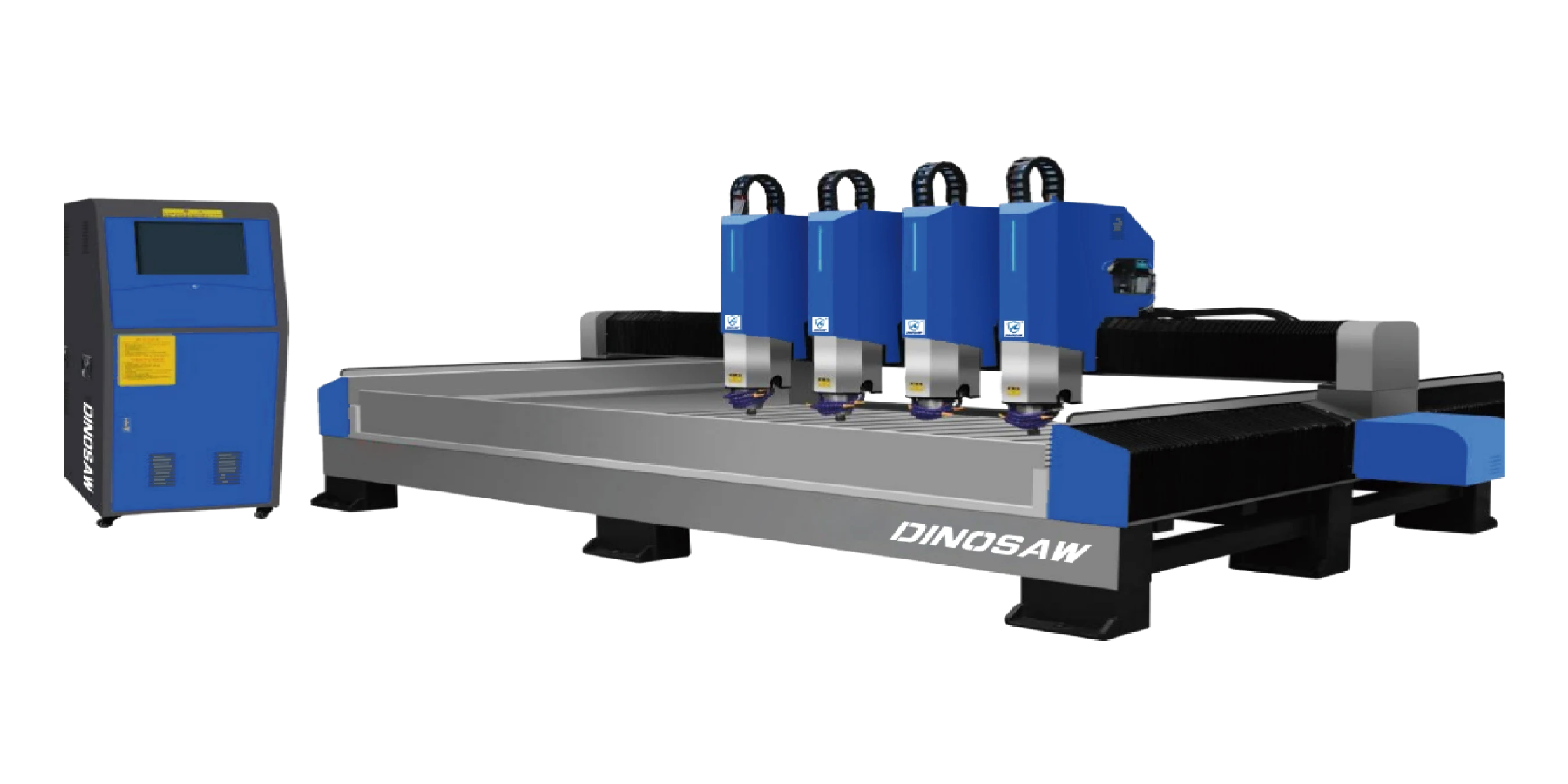

CNC Technology Options for Different Projects

2.5D Flat Carving

Best for: Lettering, reliefs, textures on flat surfaces

Your workhorse for tombstone inscriptions, architectural panels, and decorative signs. Most accessible and profitable starting point.

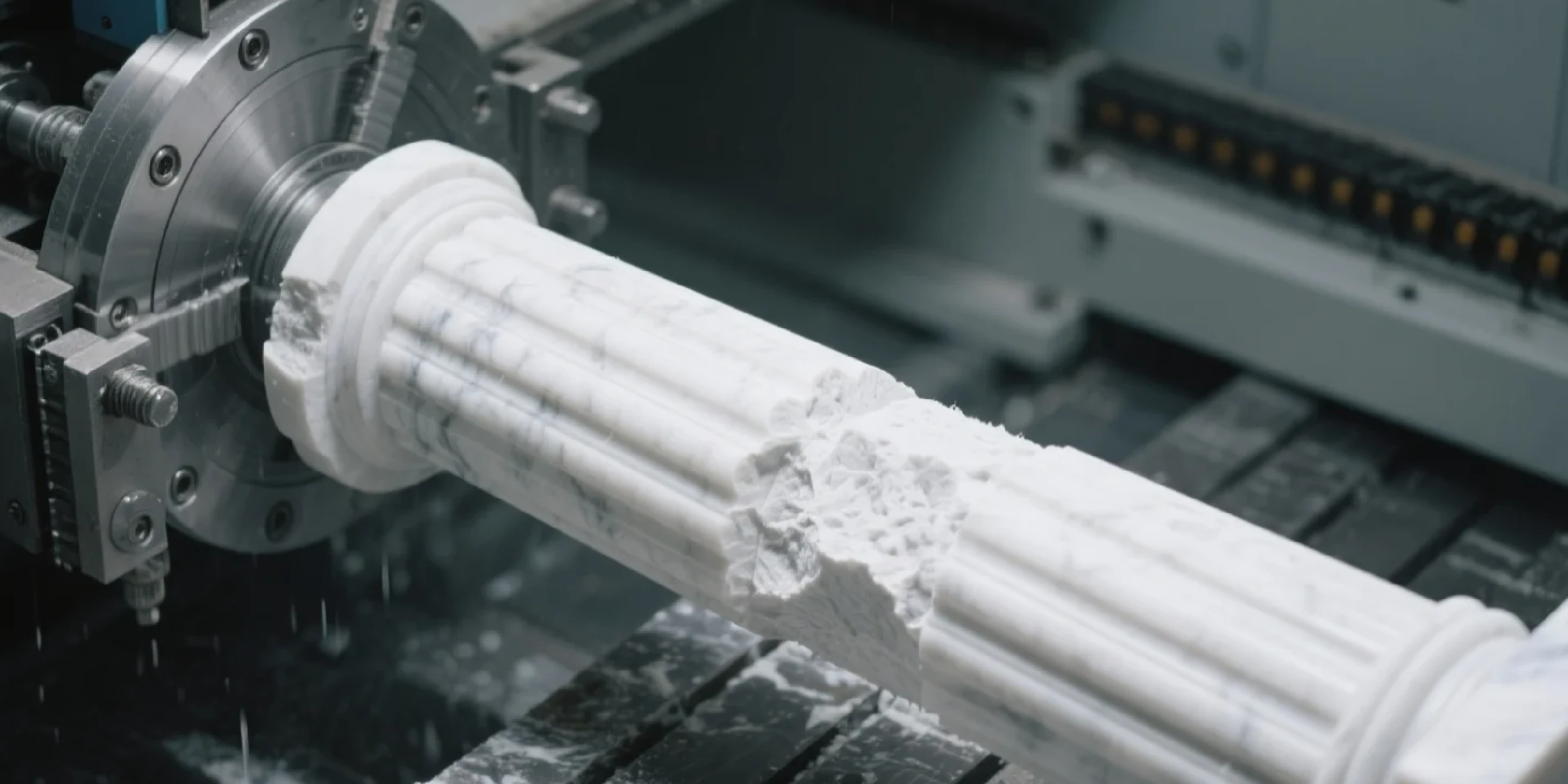

3D Rotary Carving

Best for: Columns, balusters, cylindrical sculptures

Adds rotation for 360-degree carving. Perfect for architectural elements and medium-sized statues with premium pricing.

5-Axis Stereoscopic Carving

Best for: Complex sculptures, artistic masterpieces

Ultimate design freedom for life-sized statues and intricate geometries. Highest investment, premium returns.

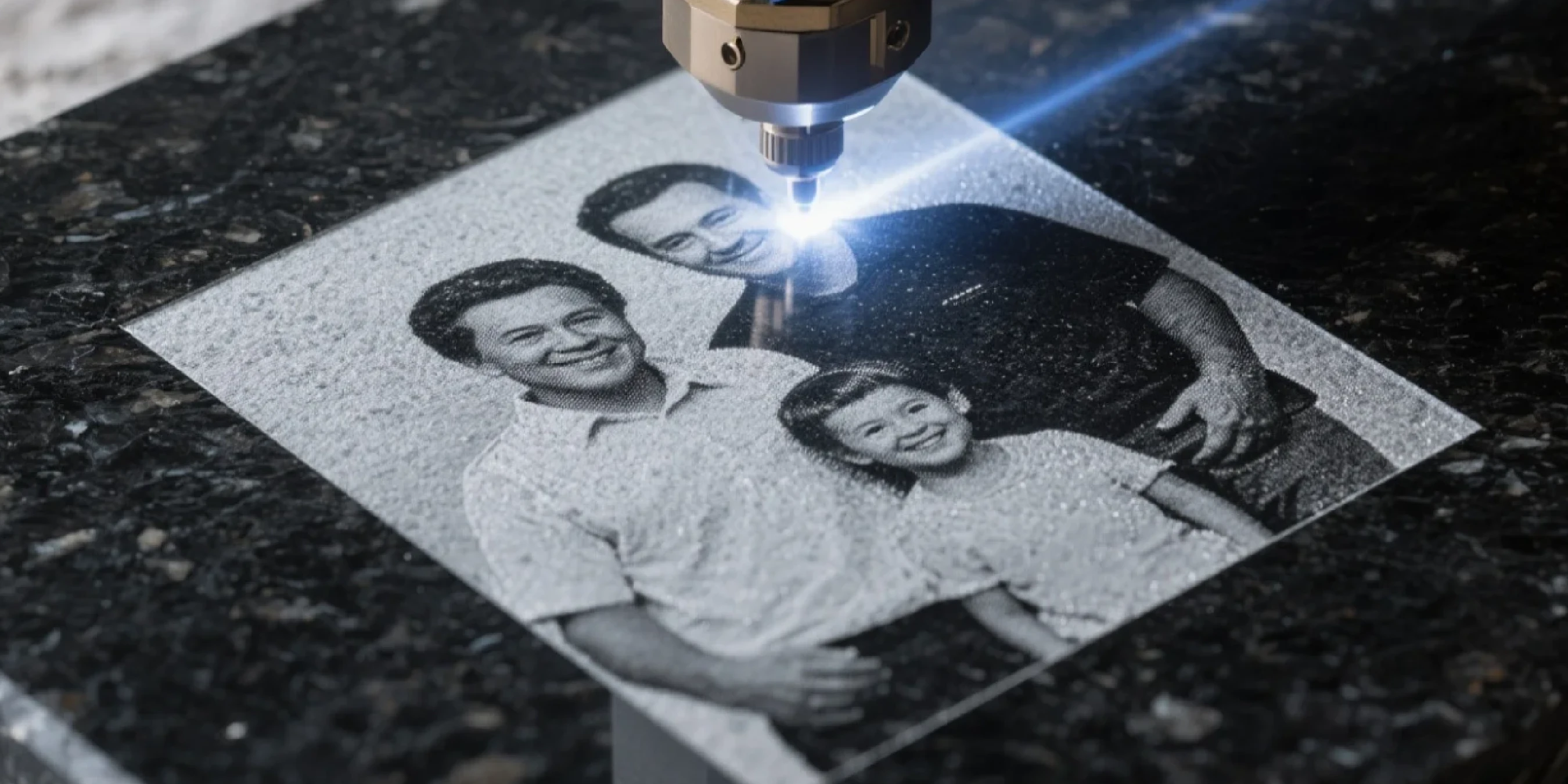

Laser Engraving

Best for: Photo etching, fine details, surface marking

Photorealistic images on dark granite. Complement to mechanical carving, not replacement.

2.5D Flat Carving for Beginners

This is where most successful stone businesses start. Why? It delivers the best return on investment while you're learning the market.

Using a standard 3-axis CNC router, you carve into flat stone surfaces creating varying depths and textures. Think beyond "flat"-this method creates stunning reliefs and dimensional lettering that commands premium prices.

Primary Applications

• Tombstone and headstone lettering with decorative borders

• Architectural wall panels featuring intricate relief patterns

• Custom stone signs, address plaques, and corporate logos

• Decorative marble and granite tiles for luxury interiors

Why This Works for Beginners

Manageable learning curve, proven market demand, and machines starting around $30,000. You can master the workflow while building customer relationships. Most importantly? Every project teaches you something new about stone behavior and customer preferences.

4-Axis Rotary Carving for Business Growth

Think beyond flat surfaces. 4-axis CNC machines add rotation to standard cutting, transforming solid stone blocks into columns, balusters, and sculptures.

The rotary attachment spins your workpiece while the cutting tool shapes every angle. Result? Perfect symmetry that's impossible by hand, opening doors to high-value architectural projects.

What You Can Create

• Ornate European-style Roman columns and decorative pillars

• Custom staircase balusters and ornamental handrails

• Religious figures and animal sculptures (medium-sized)

• Artistic pedestals and cylindrical architectural bases

Business Advantage

Automation ensures perfect symmetry and repeatability. Need a set of 20 identical balusters? Your machine delivers consistency that hand carvers can't match, at a fraction of the time.

5-Axis Carving for Maximum Investment

This is the pinnacle of CNC stone carving. The spindle head tilts and rotates independently, approaching your workpiece from virtually any angle.

No manual re-fixturing. No impossible geometries. Just pure creative freedom limited only by your imagination and the stone's natural properties.

Ideal Applications

• Life-sized human or animal sculptures with intricate details

• Seamless stone sinks and bathtubs with complex curves

• Historical artifact replication for museums and restoration

• High-precision industrial molds from stone composites

Investment Reality Check

5-axis machines start around $100,000+. But here's why successful shops justify the cost: you can charge premium prices for impossible designs. A custom stone bathtub might cost $2,000 in materials but sell for $15,000+ because no one else can make it.

Laser Engraving in Your Workflow

Laser engraving isn't about carving-it's about precision marking. The focused light beam vaporizes stone surface, creating permanent, high-contrast details impossible with mechanical tools.

Think of it as the perfect complement to CNC carving, not a replacement. You might use CNC for the main design and laser for photorealistic portraits or intricate patterns.

Perfect Applications

• Photorealistic memorial portraits on dark granite

• QR codes linking to digital memorials

• Extremely fine decorative patterns as finishing touches

• Serial numbers and small logos requiring precision

Machine Specifications That Actually Matter

Once you've chosen your carving style, focus on specs that impact your daily reality-not marketing fluff.

Spindle Power: Your Cutting Reality

Spindle power (measured in kW) determines cutting speed and depth capability. For soft stones like marble, 3.5-5.5kW handles most projects efficiently.

For granite? You need 7.5kW minimum. Anything less means frustrated waiting and premature tool wear. Pair this with high-torque servo motors for smooth power delivery without precision loss.

Machine Structure: Why Heavy Wins

Stone carving generates immense vibration. Your machine's ability to absorb this determines accuracy and lifespan.

Heavy machines are good machines. Look for stress-relieved welded steel or cast-iron frames. Ultra-thick steel frames and gantries provide the stable platform needed for flawless accuracy during aggressive cuts.

Software Integration: Your Design Pipeline

Your workflow involves CAD for design creation and CAM for toolpath generation. Ensure machine compatibility with industry standards like VCarve, Aspire, or Fusion 360. Seamless integration saves hours daily.

From Digital Design to Finished Stone

Understanding the complete workflow demystifies the technology and shows exactly what you're investing in.

Essential Cutting Tools: What Actually Works

Tool Selection Guide:

• Sintered Diamond Bits: Roughing and bulk material removal in granite

• PCD (Polycrystalline Diamond) Bits: Fine lettering with extended tool life

• V-Groove Bits: Sharp, incised letters and chamfered edges

• Ball Nose End Mills: 3D contouring and smooth organic surfaces

Real Project Walkthrough: 4-Axis Marble Baluster

- 3D Modeling (CAD): Design in Rhino or Blender, or 3D scan existing piece

- Toolpath Generation (CAM): Import to Aspire, define stone block size, select bits, generate G-code

- Machine Setup: Mount cylindrical marble block, set zero point

- Carving Process: Machine executes G-code, rotating block while spindle shapes-roughing first, then detail work

- Finishing: Remove, clean, hand-polish for final luster

Building a Profitable Stone Carving Business

A CNC machine is an investment. Success depends on smart pricing, market positioning, and understanding what customers actually value.

Pricing Strategy That Works

Simple lettered granite plaques? Price per character or square inch. Custom 3D reliefs and rotary sculptures? Premium pricing based on complexity and uniqueness.

Smart operators achieve 300%+ margins over material costs on custom work. Why? Because no one else can deliver the same precision and detail.

High-Demand Project Ideas for 2025

• Hyper-personalized memorials combining photo etching and 3D relief

• Custom stone furniture for luxury residential and commercial clients

• Architectural restoration replicating historical elements

• Branded corporate art featuring company logos and mission statements

Protecting Your Investment Long-Term

Your CNC investment pays off when it runs reliably. Daily cleaning, weekly lubrication, monthly inspections-these simple habits prevent costly breakdowns.

Essential Maintenance Checklist

• Daily: Clean dust and slurry, check water cooling flow

• Weekly: Lubricate linear guides and ball screws

• Monthly: Inspect electrical connections, tighten frame bolts

Solving Common Problems Before They Cost You

Problem: Uneven carving depth

Cause: Unlevel worktable or stone surface

Solution: Use surfacing bit to level spoilboard or stone top before final carving

Problem: Tools wear out too quickly

Cause: Incorrect feeds/speeds or insufficient cooling

Solution: Reduce feed rate, increase spindle RPM, ensure steady water flow at tool-stone contact

Ready to Turn Stone into Profit

Investing in CNC stone engraving isn't just buying equipment-it's unlocking creative potential in a thriving market.

Start with your vision, whether it's crisp 2.5D lettering, elegant rotary columns, complex 5-axis sculptures, or precise laser details. Match the technology to your application, prioritize machine rigidity and power, and never stop exploring what's possible when digital precision meets timeless stone.

The key takeaways are simple: Match technology to application. Prioritize machine rigidity and power. When you're ready to turn vision into profitable reality, the right machine is waiting.

Frequently Asked Questions

What is the best machine for stone engraving?

The "best" machine depends entirely on your primary application. For lettering, reliefs, and signs, a robust 3-axis CNC router offers the most cost-effective efficiency. Planning columns or statues? A 4-axis machine with rotary device is essential. For highly complex artistic sculptures with undercuts, 5-axis CNC provides unlimited capability. For photorealistic images on dark stone, laser engraving is your specialized tool.

Can a CNC router carve granite?

Absolutely. CNC routers effectively carve granite, one of the hardest stones available. Key requirements: highly rigid, heavy machine frame for vibration control, powerful water-cooled spindle (7.5kW minimum), and correct diamond tooling (sintered or PCD bits). Sufficient water cooling prevents premature tool wear. With proper setup, CNC routers handle everything from deep engraving to 3D granite carving.

How much does a stone CNC machine cost?

Pricing varies widely by size, capability, and build quality. Entry-level smaller 3-axis machines start around $10,000-$20,000 for hobbyists. Professional-grade large-format 3-axis and 4-axis machines typically range $30,000-$80,000. High-end 5-axis machines for complex industrial and artistic production start at $100,000+.

What software is needed for CNC stone carving?

You need two software types. First: CAD (Computer-Aided Design) for creating 2D/3D designs- AutoCAD, Rhino, or Blender. Second: CAM (Computer-Aided Manufacturing) for importing designs, defining carving strategies, and generating G-code-VCarve Pro, Aspire, or Fusion 360. Many modern programs combine both CAD and CAM functionalities for streamlined workflow.

Is a stone engraving business profitable?

Yes, stone engraving businesses can be very profitable. Strong market demand exists for personalized and custom stone products, particularly in memorial, architectural, and luxury home decor sectors. By transforming low-cost raw materials into high-value custom products, profit margins can be substantial. Success depends on niche identification, quality production, and efficient operation.

What is the difference between CNC and laser engraving on stone?

The primary difference is method and result. CNC engraving uses physical cutting tools (diamond bits) to carve and remove material, creating significant depth and 3D shapes. Laser engraving uses focused light beams to burn/etch stone surfaces, creating high-resolution permanent marks with minimal depth. CNC excels at carving and shaping; laser specializes in detailed surface marking and photo reproduction.

How long does it take to engrave stone with a CNC?

Time depends on design size/complexity, stone hardness, spindle power, and cut depth. Simple headstone text might take 30-60 minutes. Large, intricate 3D relief panels could require 8-10+ hours. CAM software provides precise time estimates before starting, enabling accurate project planning and pricing decisions.

English

English 中文

中文