Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

A readable executive guide to bridge cutting machine ROI, KPIs, and rollout. Learn to track value through throughput, cut quality, and blade life.

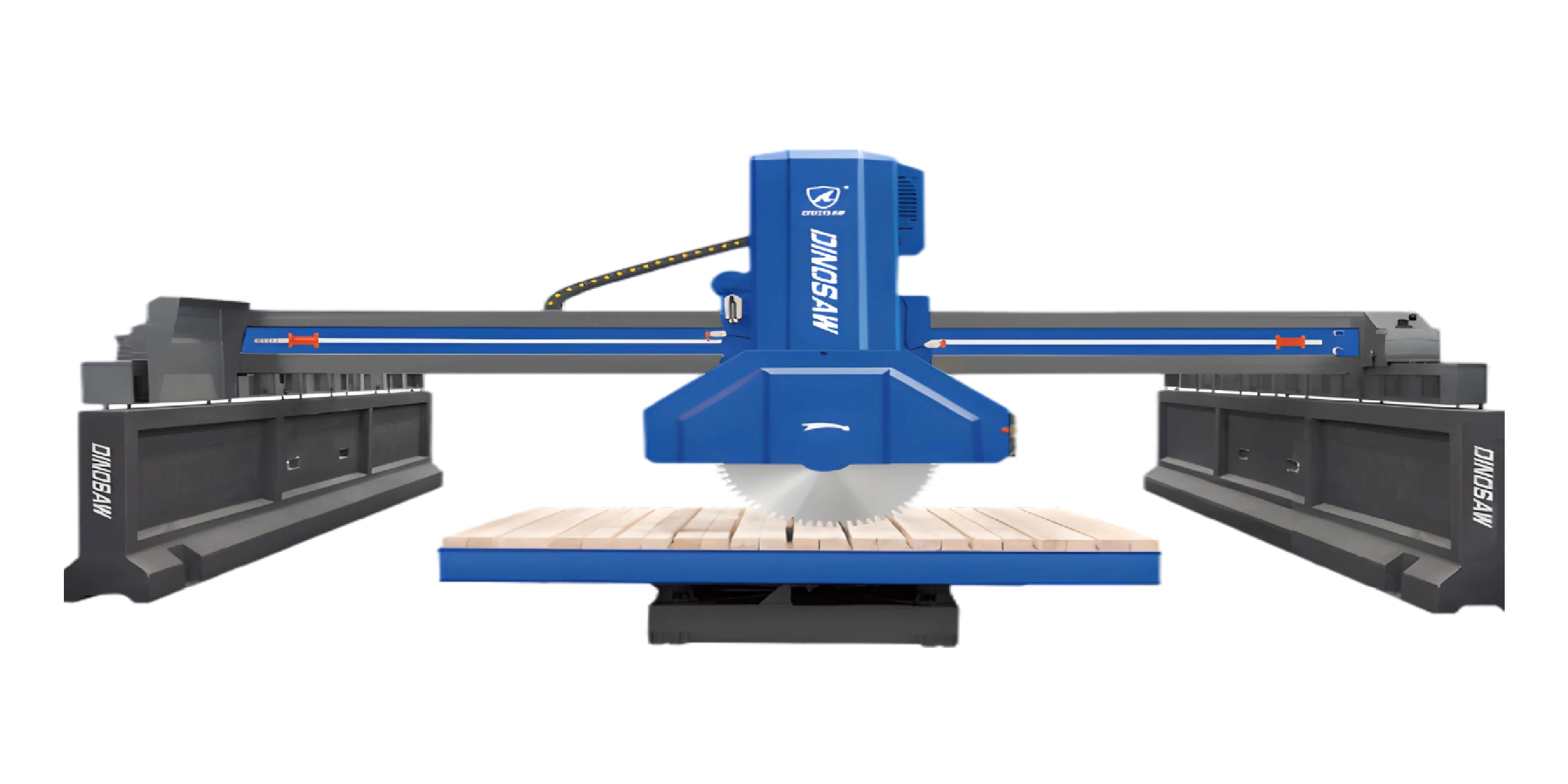

A bridge cutting machine pays for itself through a straightforward value proposition: it produces more usable cuts per day, reduces costly rework, and extends the life of your blades. The payback comes from superior vibration reduction, which is the foundation of stable, clean cuts and consistent daily output.

Talk to us for a tailored bridge saw setup today.

This guide distills the investment case into a simple narrative, focusing on qualitative signals and a phased rollout plan that any manager can track. It’s about seeing the value, not getting lost in spreadsheets.

Value & Key Performance Indicators (KPIs) to Watch

Instead of getting bogged down in data, focus on tracking these soft-but-critical performance indicators for your stone bridge saw:

- Throughput: A noticeable increase in the number of slabs processed per shift.

- Cut Quality: Cuts are consistently accurate, with a visible reduction in edge chipping.

- Blade Life: Blades last longer, measured in operating hours or linear meters cut.

- Rework Rate: A clear drop in the percentage of cuts that need to be re-done.

- Uptime: The machine is ready to run when you need it, with less unscheduled downtime.

What simple ROI signals should management track for a bridge saw?

Instead of complex calculations, management should track three clear signals: the increase in daily throughput (slabs cut per day), the reduction in the rework rate (percentage of cuts needing correction), and the extension of blade life (hours per blade). These are direct, tangible indicators of the machine's financial return.

The Simple ROI Storyline

The return on investment for a Bridge Cutting Machine isn't found in complex formulas. It’s a simple story: a stable machine with a heavy cast iron beam and precision ground rails makes better cuts, faster. This directly translates to more finished products, less waste, and lower consumable costs. The machine pays for itself by making your entire operation more predictable and profitable.

How do we track ROI without heavy spreadsheets?

Track these three simple signals on a weekly or monthly basis: (1) an increase in slabs shipped, (2) a decrease in the scrap pile, and (3) a drop in your monthly blade purchasing costs. These are tangible, real-world indicators of your bridge saw ROI.

What is a typical payback timeline for a bridge saw in a slab shop?

The payback period is highly variable, but for a busy slab shop, it is often in the range of 18–36 months, depending on utilization, job mix, pricing, and uptime. Factors that accelerate payback include high machine utilization, a significant reduction in rework, and moving to higher-margin jobs. A detailed ROI model can provide a more precise estimate.

A Phased Rollout Roadmap

Implement your new PLC-controlled bridge cutting machine in manageable stages, with clear goals for each.

- Phase 1: Pilot. Goals: Machine setup is faster than anticipated. Operators report consistent accuracy within a small tolerance. The machine meets its initial uptime targets.

- Phase 2: Acceptance. Goals: Operators feel confident and productive. The rework rate drops by a few percentage points. Throughput is stable and predictable.

- Phase 3: Standardization. Goals: The maintenance schedule is being followed consistently. SOPs are the default procedure for all operators. Auto lubrication systems are checked daily.

- Phase 4: Replication. Goals: The success of the first machine is replicated across other lines or in new facilities, using the established SOPs and training protocols.

How do phase KPIs differ between a pilot and full acceptance?

Pilot phase KPIs focus on technical feasibility: consistent cut accuracy, achieving target blade life, and high machine uptime. Acceptance phase KPIs shift to financial and operational impact: hitting a target throughput (m²/hour), reducing the rework rate to a specific percentage, and demonstrating a lower cost-per-cut.

At what point should we scale to multi-line replication?

Scaling to multiple lines is advisable only after the initial machine has consistently met its acceptance KPIs for at least one full quarter. Additionally, you should have standardized SOPs for operation and maintenance that have been proven effective. This ensures the success is repeatable and not dependent on a single "star" operator.

When should we standardize SOPs before replication?

You should standardize SOPs after the "Acceptance" phase, once you've proven the machine consistently meets its performance goals. Lock in the procedures that work before attempting to replicate them. This ensures your success is based on a process, not just a single talented operator.

Risks and Boundaries to Consider

A successful investment requires acknowledging potential constraints:

- Infrastructure: Ensure your facility has adequate power and clean water capacity.

- Supply Chain: Secure a reliable supply of compatible blades (blade diameter 1200mm, 1400mm, etc.).

- Operator Skill: Invest in proper training to maximize machine performance and safety.

- Safety & Compliance: Budget for PPE and adhere to all local safety regulations.

- Shop Footprint: Confirm you have sufficient space for the machine and for safe material handling around it.

Which risks most commonly derail a rollout, and how are they mitigated?

The most common risks are inadequate operator training, leading to errors and underutilization, and an unreliable blade supply chain. Mitigate these by investing in comprehensive manufacturer training and establishing relationships with multiple blade suppliers before the machine is even installed. Also, verify power and water utilities are sufficient beforehand.

What training baseline should be in place before expansion?

Before expanding, ensure you have at least two fully trained lead operators who can not only run the machine efficiently but also train new hires. A documented training program covering basic operation, safety procedures, daily maintenance, and simple troubleshooting is essential to create a self-sustaining knowledge base within your team.

How do compliance and PPE requirements affect the total cost?

Safety compliance is a non-negotiable operating cost. You must factor in the ongoing expense of personal protective equipment (PPE), dust and water management systems, and regular safety training for an accurate budget. While these items add to the cost, they prevent much larger expenses related to accidents, fines, and downtime.

Distilled Insights from Our Series

To make a fully informed decision, it helps to understand the full picture. This guide is the capstone of a four-part series:

- Bridge Cutting Machine Applications: See how a bridge saw for granite solves common shop-floor problems and delivers tangible results in countertop and slab yards.

- Bridge Cutting Machine Technology: Dive into the core components, like solid guide columns, and learn about the manufacturer-reported RPM ranges that drive performance.

- Bridge Cutting Machine Selection: Use a practical If-Then guide to choose the right machine configuration for your specific needs.

- Bridge Cutting Machine O&M: Master the SOPs and troubleshooting steps needed for maximum uptime.

When should we scale to multi-line replication?

You are ready to replicate once the pilot machine has consistently met its acceptance KPIs for at least one business quarter. Crucially, you must also have your SOPs and training documents finalized. This proves your success is process-driven and scalable, not just reliant on one team.

When is a bridge saw NOT the right investment?

A bridge saw is not the right investment if your production volume is too low to justify the capital expense, or if your primary work consists of complex 3D carving or highly artistic shapes. In such cases, a smaller manual saw or a more flexible 5-axis CNC machine might offer a better return on investment.

English

English 中文

中文