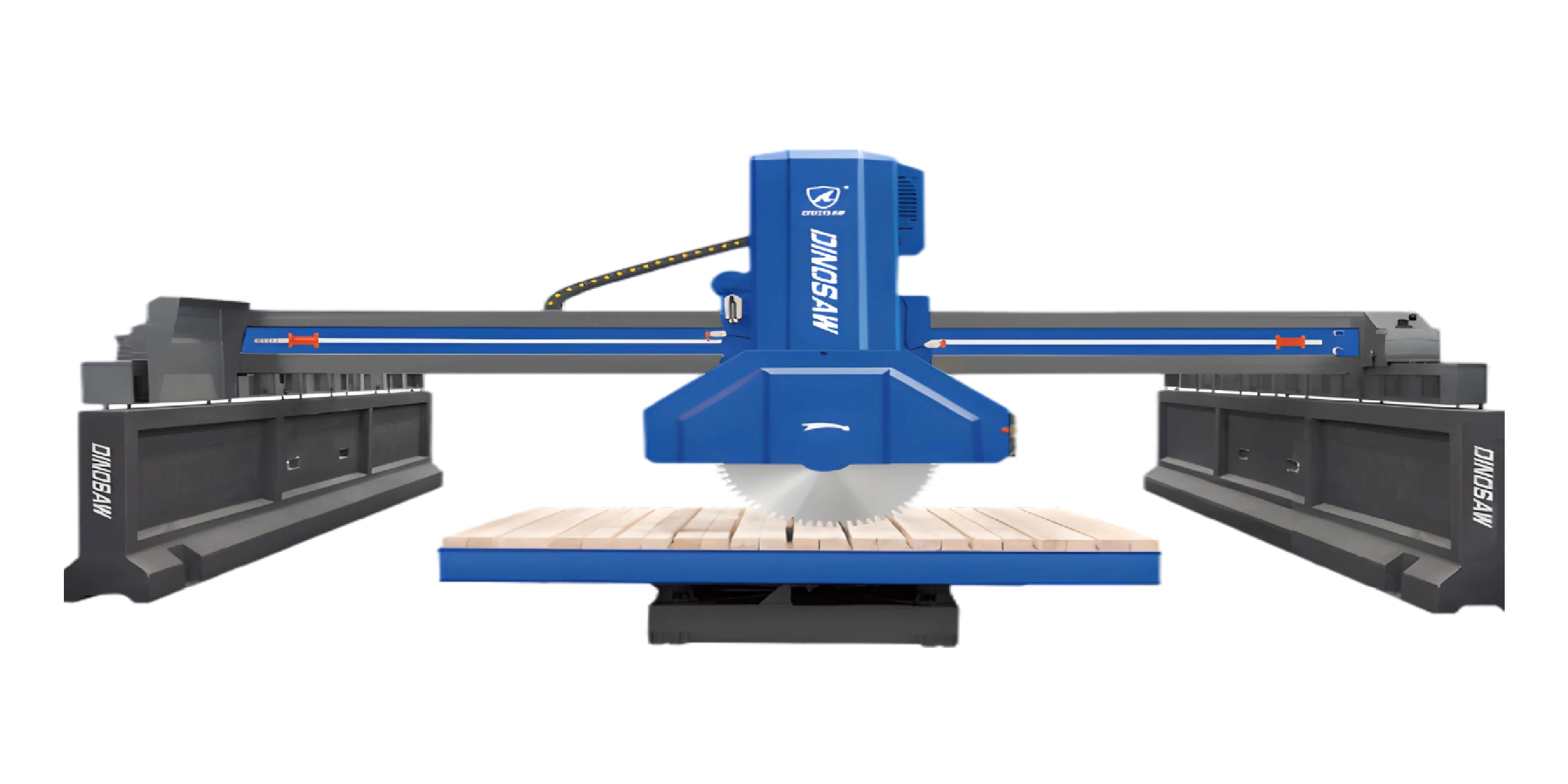

Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Maximize your bridge cutting machine's uptime with our O&M guide. Covers SOPs, a troubleshooting flowchart for common issues like blade wear, a full maintenance schedule, and essential safety protocols.

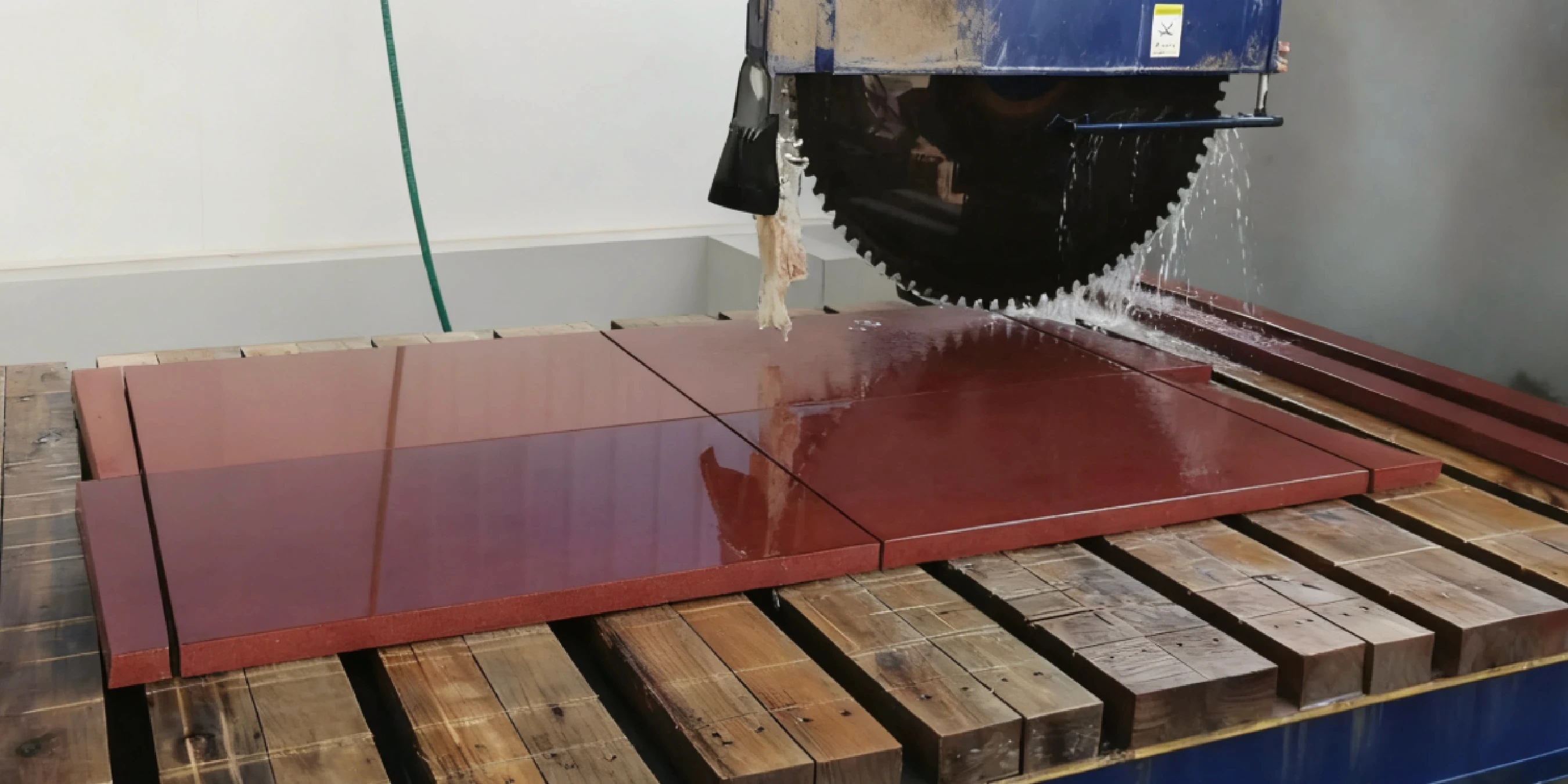

A world-class Bridge Cutting Machine is only as good as its maintenance. Disciplined Standard Operating Procedures (SOPs) and a proactive approach to upkeep are what separate high-uptime workshops from those constantly fighting fires. Great cut quality and predictable throughput from your stone bridge saw depend directly on consistent lubrication, calibration, and safety checks.

Talk to us for a tailored bridge saw setup today.

This guide provides a practical framework for bridge saw operation and maintenance, targeting the operators and technicians on the front line. We'll cover essential SOPs, a top-10 troubleshooting flow, a clear maintenance schedule, and non-negotiable safety rules to keep your machine running at its peak.

Standard Operating Procedures (SOPs) for Peak Performance

Consistency is key. Implement these SOPs to ensure every operator follows best practices for your PLC-controlled bridge cutting machine.

- Power-Up: Check that emergency stops are disengaged. Power on the main cabinet first, then the control panel (PLC/HMI). Allow the system to initialize before moving any axes.

- Blade Changeover: Always power down and lock out the machine. Use the correct tools to remove and mount blades. Ensure the blade is seated correctly and flanges are tight. Check that the new blade diameter (e.g., blade diameter 1200mm) is correctly entered in the PLC/HMI.

- Lubrication Checks: Visually confirm that the auto lubrication system's reservoir is full. Check for fresh grease on the solid guide columns and rails.

How often should guide columns be lubricated if the machine has auto-lube?

Even with an automatic lubrication system, you should visually inspect the guide columns daily to ensure grease is present and evenly distributed. The system's timer should be set according to manufacturer recommendations, typically to dispense lubricant every few hours of operation, and you must check the grease reservoir to ensure it is never empty.

- Consumables Check: Verify coolant flow is strong and nozzles are aimed correctly. Inspect the blade for signs of excessive or uneven blade wear.

- Safety Checks: Ensure all guards are in place and functioning. Confirm the work area is clear of obstacles. Test the emergency stop button before starting the first cut of the day.

Top 10 Troubleshooting Flowchart

When issues arise, use this logic to diagnose and fix them quickly.

What should be checked first when chatter or vibration appears?

First, check the blade itself: ensure it is securely mounted and free from damage or warping. Next, inspect the rails and guide columns for any debris or lack of lubrication that could impede smooth movement. These simple checks resolve the most common causes of vibration before you need to investigate more complex mechanical issues.

How do we handle scorch marks: adjust RPM, feed rate, or coolant?

Address scorch marks in this order: first, check and increase coolant flow to ensure the blade isn't overheating. If that doesn't work, reduce the feed rate to give the blade more time to cut without excessive friction. Adjusting RPM is the final step, as it should already be set based on the blade and material type.

How to fix chatter fast on a granite bridge saw?

First, check the blade flanges are tight and the blade is undamaged. Second, clean any sludge or debris from the ground rails. These two steps resolve over 80% of chatter issues related to a bridge saw for granite.

- Symptom: Increased vibration (chatter), poor vibration reduction.

- Cause→Fix: Loose blade→Tighten flanges. Debris on ground rails→Clean rails. Worn guide bushings→Inspect and replace. Prevention: Adhere to the maintenance schedule.

- Symptom: Poor cut quality (chipping on a bridge saw marble slab).

- Cause→Fix: Feed rate too high→Reduce feed rate. Wrong blade for material→Change blade. Blade wobbling→Check flange tightness. Prevention: Match parameters to stone type.

- Symptom: Cuts are not square.

- Cause→Fix: Machine out of alignment→Re-calibrate squareness. Worn components in bridge travel system→Inspect and replace. Prevention: Regular calibration checks.

- Symptom: Scorch marks or blade glazing.

- Cause→Fix: Insufficient coolant→Check nozzles for blockage. RPM too high or feed rate too low→Adjust settings per material. Prevention: Daily coolant system check.

What RPM change helps when marble shows glaze?

If you see glazing on marble, your blade RPM is likely too high for your feed rate. Try reducing the RPM by 5-10% (within manufacturer-reported RPM ranges) or slightly increasing the feed rate. This gives the diamond segments a better "bite" instead of polishing the stone.

How do you re-calibrate for squareness after moving the machine?

After transport or if you suspect misalignment, use a large, reliable machinist's square. Place it on the worktable against a known straight edge and run the cutting head along the axis to check for deviation. Use the machine’s adjustment points, typically on the bridge or rail mounts, to make fine corrections until the saw blade aligns perfectly with the square.

- Symptom: Motor stalls or loses power, especially in countertop cutting.

- Cause→Fix: Cutting too deep or fast→Reduce depth of cut or feed rate. Dull blade→Replace blade. Low voltage→Check power supply. Prevention: Operate within machine limits.

Should we adjust feed rate when using a blade diameter of 1400mm?

Yes. A larger blade like a blade diameter 1400mm has more surface area and removes more material. While powerful, you may need to start with a slightly lower feed rate compared to a smaller blade to avoid overloading the motor, especially when beginning a deep cut in hard granite.

What coolant water quality is needed to prevent blade glazing?

Use clean, filtered water with a neutral pH to prevent blade glazing and overheating. Hard water with high mineral content can leave deposits on the blade and in the cooling channels, reducing effectiveness. A closed-loop system with filtration is ideal for maintaining water quality and conserving water.

- Symptom: Coolant pump failure or low flow.

- Cause→Fix: Clogged filter/line or pump issue→Check flow. Clean filters/nozzles, prime pump, or replace if needed. Prevention: Weekly filter maintenance.

- Symptom: Auto-lube not dispensing grease.

- Cause→Fix: Empty reservoir, blocked line, or timer mis-set→Visually check for grease. Refill reservoir, clear the line, or re-set timer. Prevention: Daily reservoir check.

- Symptom: Blade drifts on long cuts.

- Cause→Fix: Loose bridge fasteners or worn guide wheel→Perform a test cut and inspect rails. Tighten fasteners or replace guide wheel. Prevention: Monthly fastener audit.

- Symptom: PLC/HMI alarm or parameters reset (e.g., OPC UA/Profinet link down).

- Cause→Fix: Unstable power or incorrect program loaded→Review logs. Restore parameters from backup and check power stability. Prevention: Keep regular backups and use a UPS where appropriate.

- Symptom: Rotary table indexing is misaligned.

- Cause→Fix: Debris under the table or worn index pin→Perform alignment test. Clean the base and replace the pin if needed. Prevention: Weekly cleaning and inspection.

Bridge Saw Maintenance Schedule for CNC/Infrared Models

What does a practical maintenance schedule look like (daily/weekly/monthly)?

A good schedule includes: Daily checks of coolant and lubrication levels. Weekly inspection of the blade and cleaning of the rails. Monthly checks on belt tension and major bolts. Quarterly, perform a full inspection of electrical connections and mechanical guide components as specified by the manufacturer.

Which spare parts should we stock to minimize downtime?

To minimize downtime, stock critical consumables and common wear items. This should include a spare cutting blade, coolant pump filters, and any specific fuses or relays for the control cabinet. Having a set of replacement guide bushings and a drive belt on hand is also a wise investment for long-term operational readiness.

- Daily: Clean sludge from table and machine base. Check coolant levels and flow. Visually inspect auto-lube reservoir and lines. Wipe down solid guide columns.

- Weekly: Clean and inspect ground rails for any nicks or debris. Check blade for damage or uneven wear. Inspect drive belts for proper tension. Test all PLC/HMI safety interlocks.

- Monthly: Check and tighten all major structural bolts on the cast iron beam and frame. Inspect electrical cabinet for dust and loose connections. Check guide wheel bearings for play.

- Quarterly: Perform a full squareness and level calibration on your infrared bridge saw. Inspect all wiring for wear or damage. Review the manufacturer-reported service points. Top-tier Stone Cutting Machine Brands often provide detailed guides.

Field Tips for a Smoother Operation

Experienced operators often share valuable advice online.

- Use a magnetic base indicator to periodically check for spindle runout. Catching even tiny deviations on your bridge cutter early can save a blade.

- To reduce chipping on a granite bridge saw, some operators make a very shallow initial scoring cut before the main full-depth cut.

- When cutting very abrasive materials, consider slightly reducing the RPM from the recommended setting to prolong blade life, even if it slightly reduces slab cutting speed.

Safety and Compliance: A Non-Negotiable Priority

Safety is everyone's responsibility. Adhere to these basics without fail.

- PPE: Safety glasses, hearing protection, waterproof steel-toed boots, and appropriate gloves are mandatory.

- Electrical: Never operate with frayed wires or in standing water. Use lockout/tagout procedures during maintenance.

- Mechanical: Keep hands clear of all moving parts. Ensure all safety guards are in place before operation.

- Dust & Water: Ensure proper ventilation and water management to control silica dust and prevent slippery floors.

What is a good daily safety checklist before starting operation?

A daily checklist must include: confirming all emergency stops are functional, checking that blade guards are in place, inspecting for water leaks near electrical components, and ensuring the work area is clear of trip hazards. Operators must also verify they are wearing appropriate PPE, including safety glasses, hearing protection, and steel-toed boots before the first cut.

O&M Wrap-Up

By integrating these SOPs, maintenance schedules, and safety protocols into your daily workflow, you transform your bridge saw from a simple machine into a reliable production asset. Proactive O&M is the most effective strategy for maximizing uptime, ensuring consistent cut quality, and achieving the lowest possible cost per cut over the machine's lifetime.

English

English 中文

中文