Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Choosing between a bridge saw and a 5-axis CNC? Our guide analyzes ROI, automation, and total cost of ownership to help you make the right investment for your shop's future.

Real talk from someone who's seen both machines in action. Here's what you actually need to know before dropping serious cash on cutting equipment.

Picking the right cutting machine? It's probably the biggest decision you'll make for your stone shop. And honestly, it affects everything. Your production speed, how much you spend on labor, material waste, and yeah - your bottom line.

For years, bridge saws were the obvious choice. Reliable workhorses that just kept cutting. But now? 5-axis CNCs are changing the game completely. They're turning regular shops into automated processing centers that would make you do a double-take.

This isn't just about straight cuts versus fancy curves anymore. We're talking about total ownership costs, the real power of automation, and figuring out which machine actually fits your growth plans. Let's cut through the marketing fluff and get to what matters.

Quick Reality Check: Which Stone Machine Fits Your Goals?

Before we dive deep, here's the honest breakdown:

| What You're After | Bridge Saw | 5-Axis CNC Saw |

|---|---|---|

| Main job | Fast straight cuts, miters | Everything in one shot |

| What it does best | High volume, keeps it simple | Complex stuff, runs itself |

| Perfect for | Standard countertops, basic work | Custom designs, integrated sinks |

| Labor needs | Skilled operator always needed | Runs on autopilot most of the time |

| Your goal | Volume production, proven results | High-margin work, market leadership |

Bridge Saws: Still the Smart Choice for Many Shops

Look, bridge saws aren't going anywhere. There's a reason they've been the industry standard for decades. They do one thing really, really well.

What Makes Bridge Saws Work So Well

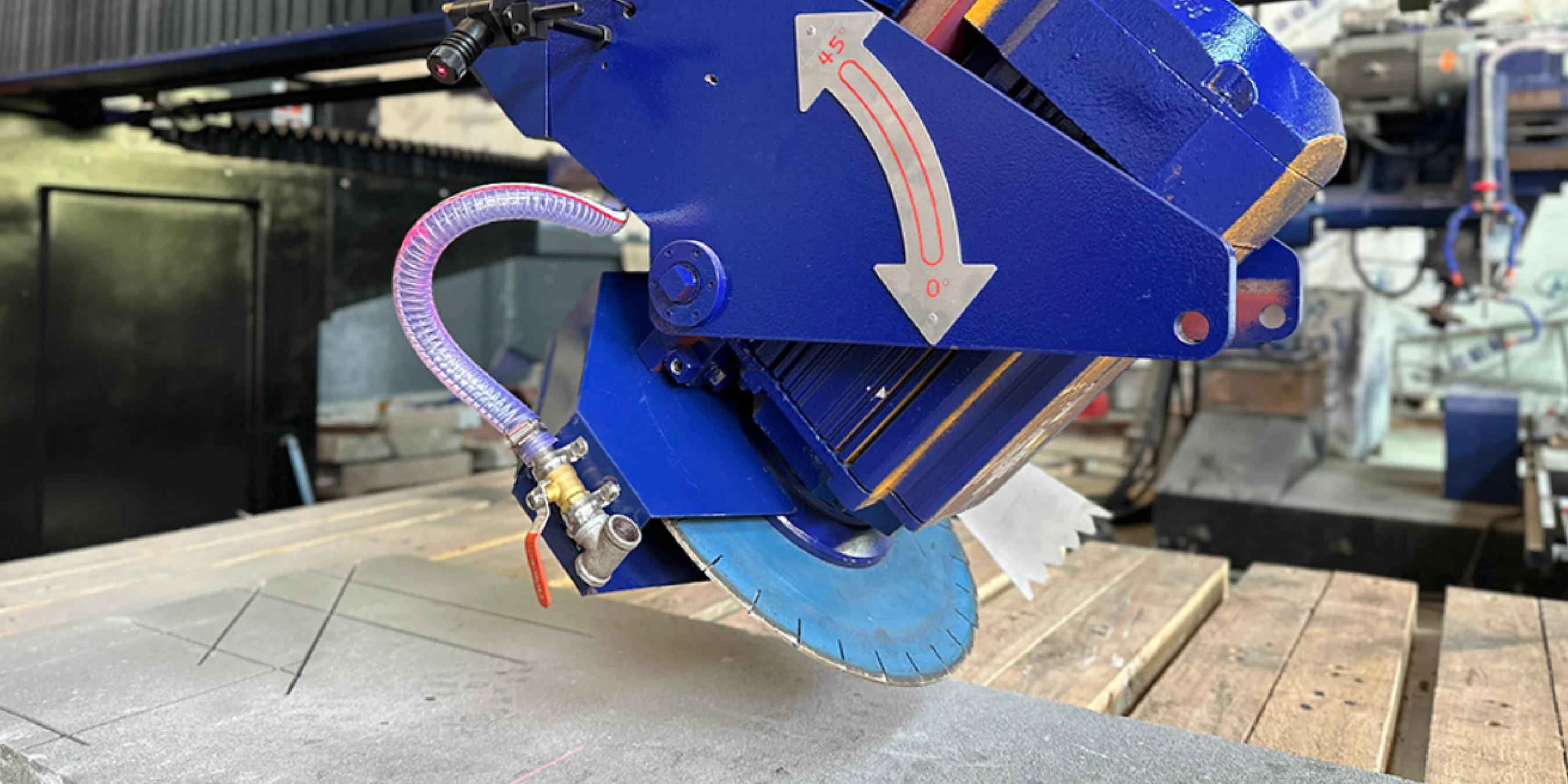

A bridge saw operates on three axes - front-to-back, side-to-side, up-and-down. Pretty straightforward, right? The magic happens in how efficiently it handles linear cuts. Plus, that tilting saw head? Perfect for 45-degree miters that make standard countertops look crisp and professional.

This covers maybe 80% of what most kitchen and bathroom projects need. And it does it fast.

When a Bridge Saw Still Makes Perfect Sense

Despite all the CNC hype, a quality bridge saw remains the most practical choice in several situations:

- You're just starting out: Managing cash flow is crucial when you're new. A bridge saw lets you get cutting and generating revenue without breaking the bank on initial investment.

- Volume is your game: Running hundreds of standard countertops? Bridge saws are speed demons for this kind of work. No complex programming, just cut and move.

- You're part of a bigger operation: Large shops often run bridge saws alongside CNCs. The bridge saw handles initial sizing and straight cuts, freeing up the fancy machine for complex work.

5-Axis CNC Saws: Welcome to the Future of Stone Processing

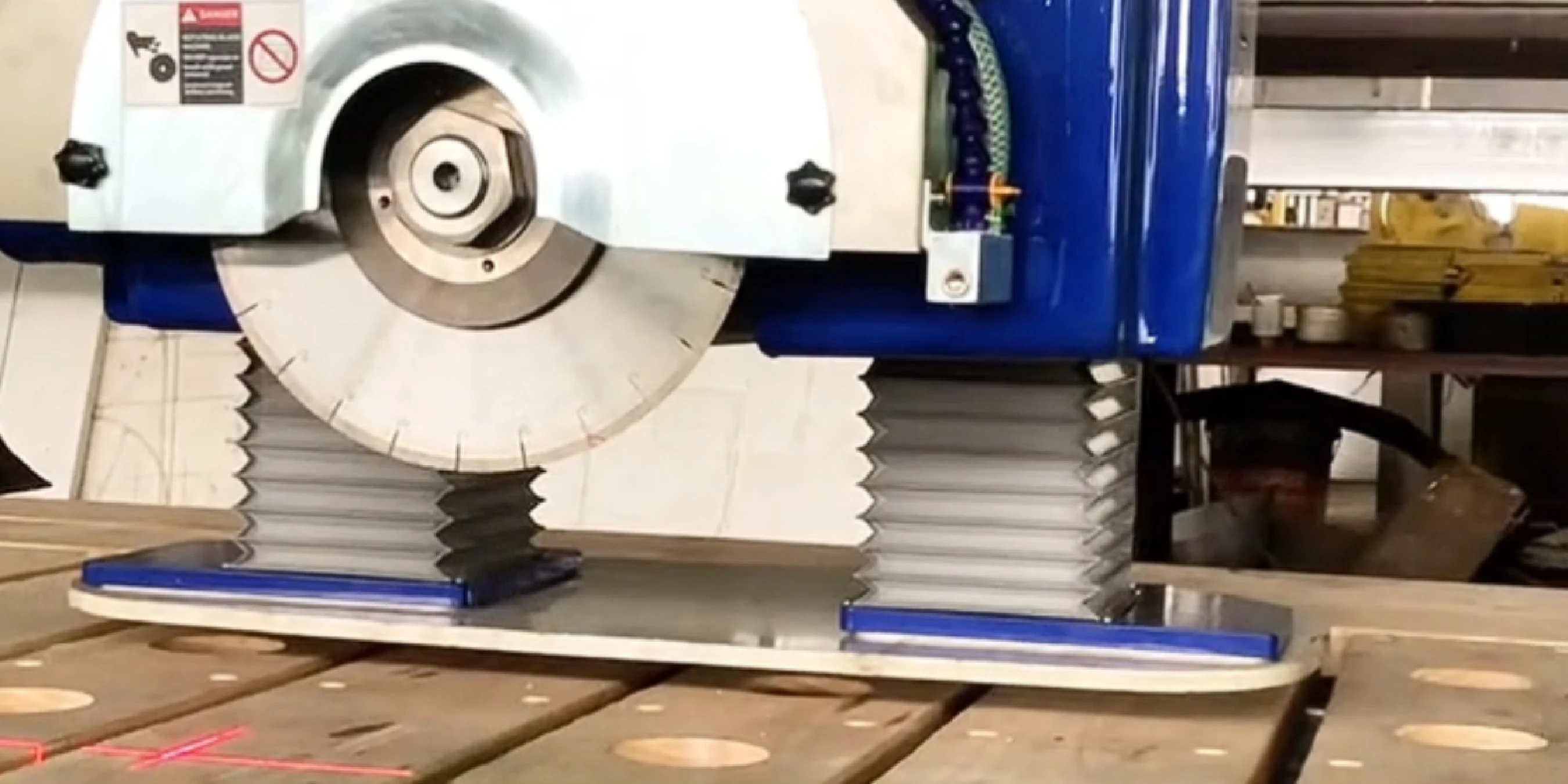

Here's the thing about 5-axis CNCs - they're not just upgraded bridge saws. They're in a league of their own. Those extra two axes? They let the cutting head move in ways that would blow your mind. Virtually any angle you can think of.

What Those Extra Axes Actually Mean for Your Business

This isn't just about making pretty curves (though it does that too). It's about completely changing what you can offer customers:

- Any angle, any curve: Forget being stuck with 45-degree miters. Want spiral staircases? Custom shower bases? Sculptural elements? No problem.

- One machine, multiple jobs: The cutting head can swap between saw blades, milling tools, and drilling bits. That means sink cutouts, faucet holes, and edge profiling all happen in one automated sequence.

So what does this mean for your shop? You can say "yes" to jobs that would have sent you scrambling for subcontractors.

The Automation Game-Changer

What makes these CNCs so special? The smart automation. And I mean really smart. These systems team up to cut down your labor costs, slash material waste, and make your whole workflow smoother than you'd believe.

AI-Powered Material Optimization

The process starts with an industrial camera photographing your entire slab. The software maps every contour, identifies grain direction, and lets you mark any flaws to avoid. Then comes the magic - AI nesting.

The system arranges all your required pieces like a puzzle, squeezing every possible inch of value from each slab. In an industry where material costs can make or break your margins, this feature alone can save thousands per year.

Smart Material Handling

Once cutting starts, integrated vacuum lifters automatically move finished pieces to safety. Why does this matter? It prevents the saw from accidentally cutting into completed work and keeps production running without constant babysitting.

Loading massive slabs becomes almost effortless with hydraulic tilting tables. Your A-frame stored slab simply tilts into position - no more risky manual handling that strains your crew and slows everything down.

Let's Kill Some Myths About CNC Technology

I've heard all the objections. Most of them were valid... five years ago. The industry has moved fast, and some old assumptions need updating.

Myth 1: "The Investment is Crazy High"

Reality check: European and American machines still cost a fortune, sure. But the game has changed. High-performance Chinese manufacturers like Dinosaw Machine have seriously disrupted the market.

These companies serve China's massive domestic stone market, so they've had to get really good at building reliable machines. The result? Advanced technology at prices that actually make sense for mid-sized shops.

Myth 2: "You Need a Computer Science Degree to Run These Things"

Not anymore. Early CNCs were programmer nightmares. Today's software? It's built for stone fabricators, not engineers.

Take Dinosaw's integration with Italian DDX EasyStone software. It's visual, intuitive, and designed specifically for our industry. A tech-savvy operator can be productive in weeks, not months.

Myth 3: "Maintenance Will Kill Your Uptime"

Quality machines are built for stone shops. That means robust dust and water protection, automated lubrication systems, and remote diagnostics.

The key is choosing a supplier with solid after-sales support and clear maintenance schedules. A good machine from a reliable partner shouldn't be giving you headaches.

The Real Cost Analysis: Looking Beyond the Price Tag

Smart buyers look at Total Cost of Ownership (TCO). Let's break down what each machine actually costs to operate.

Initial Investment Reality

- Bridge Saw: Lower upfront cost, but remember you might need separate equipment for material handling and complex operations later.

- 5-Axis CNC: Higher initial investment, but includes features like vacuum lifters and tilting tables that would be expensive separate purchases.

Daily Operating Costs

- Labor expenses: Bridge saws need skilled operators for constant setup and monitoring. CNCs? One operator can manage the automated workflow while handling other tasks. That's real money saved every single day.

- Material yield: Those AI nesting capabilities can reduce waste by 5-10% on every slab. Over a year, that translates to serious savings - sometimes enough to pay for the efficiency upgrade itself.

- Tooling costs: While both machines use blades, CNCs can use smaller, more efficient tools for specific tasks like sink cutouts. Often more cost-effective than using a large blade for everything.

Which Path Makes Sense for Your Shop?

The right machine aligns with where you are now and where you want to be in three years.

For New and Small Operations

If you're primarily doing standard countertops and capital is tight, a quality bridge saw is a smart foundation. Build your customer base, generate cash flow, then upgrade when growth demands it.

For Growing Fabricators

Turning down complex projects? Struggling with labor costs? Seeing too much material waste? A 5-axis CNC breaks through those limitations and opens up higher-margin opportunities.

For Market Leaders

In the high-end custom and commercial markets, advanced CNC capability isn't optional anymore. It's what enables you to deliver the complex, profitable projects that set you apart from commodity competitors.

The Supplier Relationship Matters as Much as the Machine

Buying equipment like this starts a long-term partnership. The quality of their support is as important as their engineering.

What to Look For

- Software ecosystem: Is it user-friendly and regularly updated? Can your team actually learn it?

- Training and support: Comprehensive on-site training and responsive technical support make the difference between smooth operations and constant frustration.

- Long-term reliability: A proven track record, solid warranty, and established service network ensure your investment stays productive.

Bottom Line: Invest in Solutions, Not Just Machines

The bridge saw versus 5-axis CNC decision really comes down to this: Do you want to keep doing things the proven way, or are you ready to embrace what's possible with intelligent automation?

Bridge saws remain excellent tools for specific applications. But 5-axis CNCs solve the biggest challenges facing modern fabricators - labor costs, material waste, and the growing demand for customization.

When you look at total ownership costs and focus on capabilities rather than just price tags, modern CNCs become investments in your shop's future. They're the tools that let you say "yes" to more profitable work, operate more efficiently, and establish real competitive advantages.

Ready to explore how a 5-axis solution could transform your operation? Talk to our experts for a customized consultation that fits your specific needs and growth plans.

Common Questions (The Ones Everyone Actually Asks)

What's the real advantage of 5-axis over 3-axis cutting?

Versatility, plain and simple. Bridge saws are stuck with straight cuts and 45-degree angles. 5-axis machines cut at any angle you can imagine. This opens up complex curves, integrated sink drainboards, and complete processing (cutting, milling, drilling, polishing) in one automated sequence. That versatility translates directly into higher-margin custom projects.

How much does a decent 5-axis CNC actually cost?

Anywhere from under $50,000 to over $500,000, depending on size, features, and brand origin. European and American brands command premium prices. But quality Chinese manufacturers like Dinosaw Machine offer competitive performance at much more accessible price points - making advanced technology available to shops that couldn't justify the traditional premium pricing.

Is a CNC worth it for smaller countertop shops?

Depends on your strategy. If you're happy focusing on high-volume standard work, a bridge saw might make more sense. But if you want to differentiate with custom residential projects, or if skilled labor is a challenge, a CNC can transform even smaller operations. The automation and material savings often deliver faster ROI than people expect.

How hard is it to actually learn CNC operation?

Much easier than it used to be. Modern software like DDX EasyStone uses visual, graphical interfaces designed specifically for stone fabricators. With proper training from the manufacturer, a tech-savvy operator can become productive in weeks. The focus is on setting parameters and visual programming, not computer coding.

Can bridge saws cut curves at all?

Not really. You can approximate large-radius curves by making tiny incremental straight cuts, but it's incredibly time-consuming and produces rough results that need extensive finishing work. True smooth curves are CNC territory.

How do CNCs actually save on material costs?

Through intelligent "nesting" software combined with camera systems. The camera maps your slab precisely, then the software arranges all required pieces for optimal fit, minimizing waste. This is far more accurate than manual templating and can increase usable yield significantly on every single slab.

English

English 中文

中文