Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Need a reliable Stone Polishing Machine that actually delivers results? Here's what works, what doesn't, and which brands you can trust with your money.

Why This Guide Matters for Your Business

Buying the wrong stone polishing equipment? That's a $50,000+ mistake many fabricators make. After testing dozens of machines and talking with shop owners across North America, I've narrowed down the field to five brands that consistently deliver results.

The Top 5 Stone Polishing Machine Brands That Actually Work

Based on reliability, innovation, and real-world performance, here are the manufacturers worth your consideration. No fluff, just facts.

1. Breton: The Automation King (If Budget Isn't an Issue)

Want to know who sets the standard in automated stone polishing? Breton. These Italian engineers have been perfecting their craft for decades. Their machines don't just polish stones - they practically run themselves.

What Makes Breton Special?

- Kappa Polishing System: Handles high-volume slab production like nothing else on the market

- Tetrix Technology: Changes slab widths without stopping the line (game-changer for custom work)

- Build Quality: These machines run 24/7 for years without major issues

The downside? Price. You're looking at serious investment here. But if you're processing hundreds of slabs monthly, the ROI justifies itself pretty quickly.

2. Achilli: Italian Craftsmanship That Lasts Forever

Ever wonder why some shops still run 20-year-old machines? Chances are, they're Achilli. This company builds equipment like tanks - overengineered, reliable, and practically indestructible.

Achilli's Standout Models

- LM/30-VE Floor Grinder: Perfect for restoration projects and large installations

- MEC7-VE Universal Grinder: Handles everything from granite to terrazzo without breaking a sweat

What's the catch? These aren't the flashiest machines around. No fancy touchscreens or automated everything. Just solid, dependable equipment that keeps working when others break down.

3. Park Industries: North America's Service Champion

Here's something you don't hear often: "Next Day or No Pay." That's Park Industries' parts guarantee. In an industry where downtime costs hundreds per hour, this kind of service commitment matters.

Why Countertop Shops Love Park

- FASTBACK® II: Grinds, polishes, and chamfers edges in one pass (major time saver)

- Wizard Deluxe: Handles complex sink cutouts and curved edges with precision

- Local Support: Technicians who actually understand your workflow

The reality check? You're paying for that service level. Park's machines cost more than some alternatives, but when your main competitor's machine is down for three days waiting for parts, you'll understand the value.

4. GMM: The CNC Precision Specialist

Need surgical precision in your stone work? GMM builds machines that think like computers and work like craftsmen. Their CNC systems handle complex curves and intricate details that would challenge even experienced operators.

GMM's Technical Edge

- Multi-Spindle Edge Polishers: Handle straight and curved edges with consistent results

- 6-Axis CNC Centers: Program once, repeat perfectly every time

- User-Friendly Software: Less programming headaches, more productive time

The learning curve? Steeper than manual machines. But once your team masters the software, productivity jumps significantly. Best suited for shops doing custom architectural work or artistic pieces.

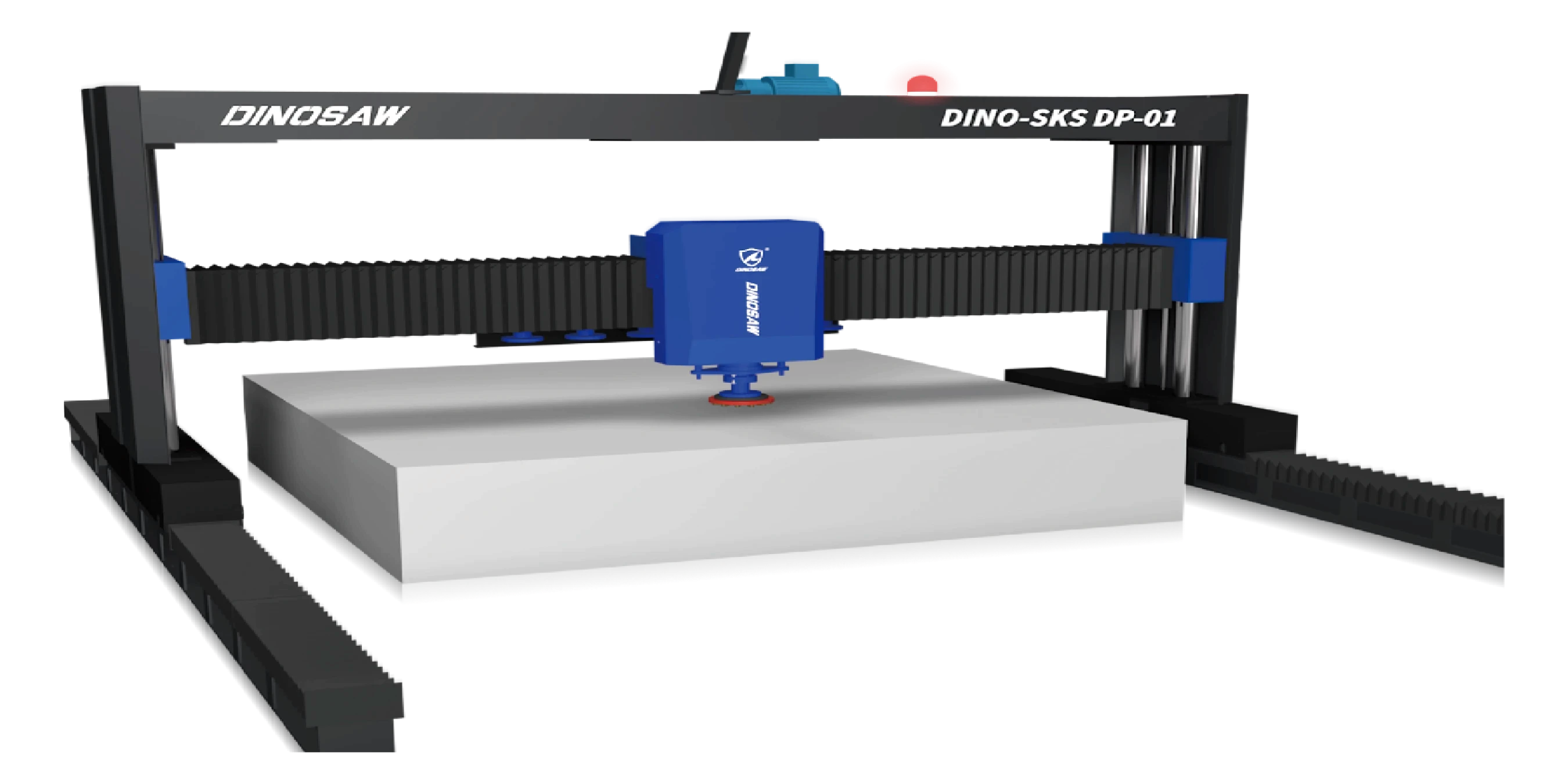

5. Dinosaw Machine: The Smart Automation Newcomer

What happens when you combine robotics with stone polishing? Dinosaw Machine figured it out. Their automated systems change tools, adjust pressure, and adapt to different materials without human intervention.

Innovation That Actually Works

- Auto Tool-Changing CNC: Switches abrasives automatically for different polishing stages

- Robotic Arm Systems: Handles complex 3D shapes and sculptures with precision

- Smart Controls: Learns your preferences and optimizes cycles accordingly

The trade-off? You're betting on newer technology. While the innovation is impressive, longterm reliability data is still limited compared to established brands.

How Do You Pick the Right Stone Polisher? Ask These Questions First

🎯What's Your Primary Material?

Granite needs power. Marble requires finesse. Quartz demands precision. Different stones need different approaches - make sure your machine handles your breadand-butter materials expertly.

🔧What About Local Support?

The best machine becomes worthless when it breaks and parts take weeks to arrive. Check local dealer networks and response times before you buy.

⚡How Much Volume Do You Process?

Processing 20 slabs weekly? Manual might work. Pushing 200+? You need serious automation. Don't over-buy for future growth that might never come.

💰Can You Handle the Real Costs?

Purchase price is just the beginning. Factor in installation, training, consumables, and maintenance. A $100K machine might cost $150K in year one.

The Problems And How Modern Stone Polishing Machines Solve Them

Problem: Scratches and Uneven Polish

You know the frustration. Perfect setup, quality abrasives, experienced operator - but still getting scratches or inconsistent results across the slab.

Modern Solution: Smart pressure control and vibration dampening systems. Brands like Dinosaw use sensors to maintain consistent contact pressure, while Breton's rigid construction eliminates vibration that causes scratches.

Problem: High Labor Costs and Skill Shortage

Finding skilled polishers is tough. Training new ones takes months. Meanwhile, labor costs keep climbing and mistakes get expensive.

Modern Solution: Automation reduces skill requirements dramatically. A machine like GMM's CNC polisher lets a junior operator produce results that previously required years of experience.

Problem: Overheating and Maintenance Nightmares

Old machines run hot, break down frequently, and require parts that take weeks to source. Every breakdown costs hundreds in lost production.

Modern Solution: Better cooling systems and modular designs. Park Industries designs machines with easy-access components, while Achilli builds systems that run cooler and last longer between services.

Questions Everyone Asks (And Honest Answers)

Should I buy new or used equipment?

Depends on your risk tolerance. Used machines from quality brands can offer 60-70% savings, but you're inheriting someone else's maintenance issues. New equipment comes with warranties and latest technology, but costs significantly more upfront.

How much automation do I actually need?

Start with your current bottlenecks. If labor shortage is your biggest issue, prioritize automation. If quality consistency matters most, focus on precision controls. Don't automate everything just because you can.

Which brand offers the best value for money?

For pure durability: Achilli. For automation ROI: Breton. For service support: Park Industries. For innovation: Dinosaw. For precision work: GMM. "Best value" depends entirely on what you value most.

What should I expect for maintenance costs?

Plan for 8-12% of machine value annually in consumables and maintenance. Higher for older machines, lower for newer automated systems. Parts availability and local service quality affect these numbers significantly.

Choose Stone Polishing Machines Based on Your Real Needs

After evaluating hundreds of installations, here's what matters most: reliability, local support, and matching the machine to your actual workflow. The fanciest automation means nothing if it breaks down and takes weeks to fix.

Test machines when possible. Talk to current users. Factor in total cost of ownership, not just purchase price. And remember - the best machine is the one that makes you money consistently, not the one with the most impressive specifications.

English

English 中文

中文