Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

A neutral guide to choosing a 7-axis stone carving robot. Use our If-Then framework to balance material class, finish quality, throughput, and footprint. Compare Dinosaw vs. alternatives on key decision dimensions.

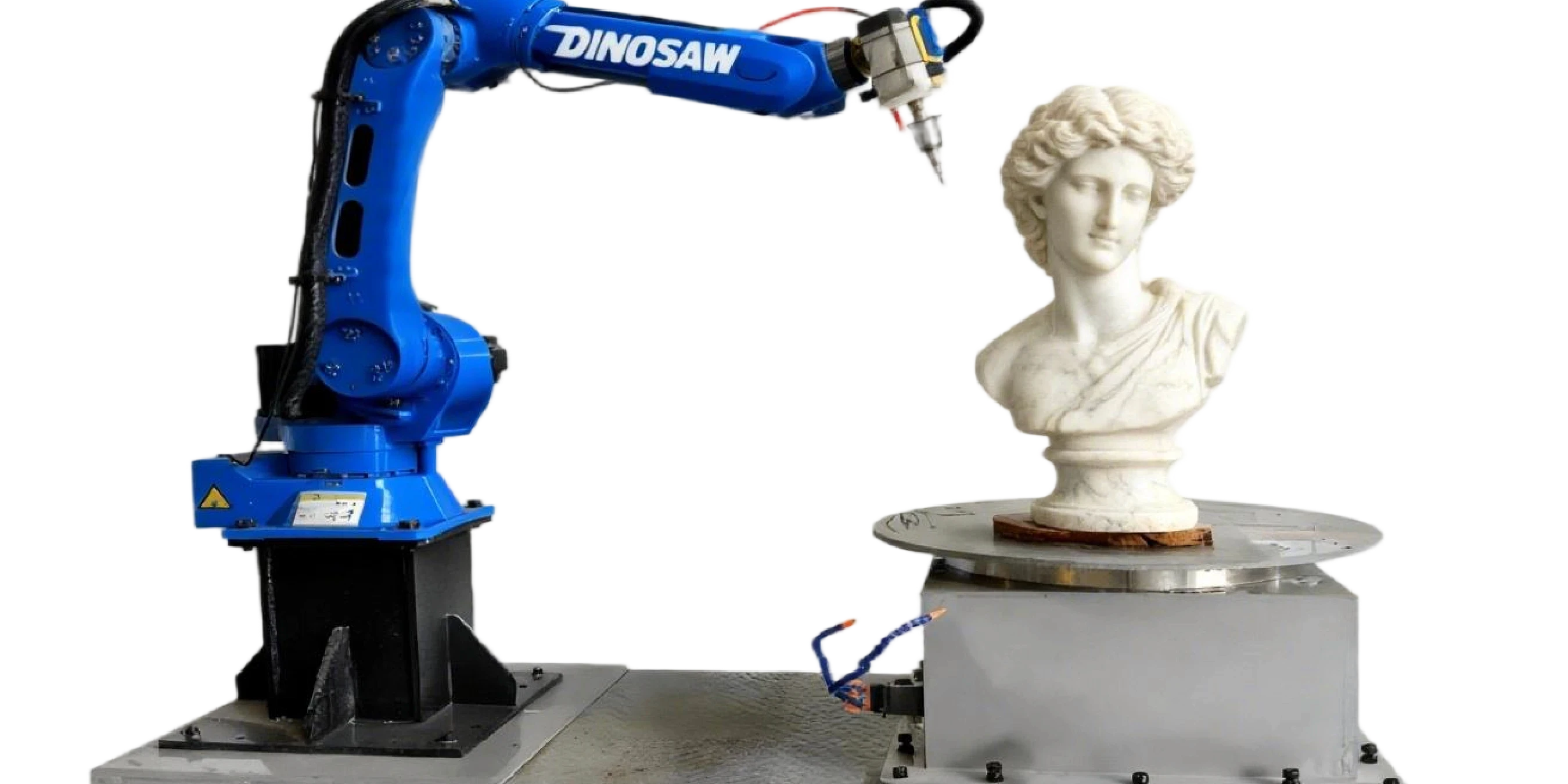

A stone carving robot decision should balance material class, finish quality, throughput, footprint, and safety integration. Use a neutral If-Then framework to converge on the right 7-axis configuration and tooling. See the Dinosaw robotic stone carving for a reference architecture.

Use this guide to build your requirements list, then talk to our engineers to validate your configuration.

Key Decision Dimensions for Procurement

Before comparing models, define your operational needs across these core dimensions. This turns a complex choice into a structured evaluation.

- Material & Cut Type: Are you primarily carving hard granite, softer marble, or friable limestone/sandstone? Is the work mainly lettering (engraving), 3D profiling, or deep relief?

- Batch Size & Finish Level: Are you doing high-volume batch production of memorials or one-off artistic sculptures? What level of surface finish is required before manual polishing?

- Dust/Water Protection: The environment is harsh. An IP65 rating or higher for the robot and key components is a critical requirement for longevity.

- Software Stack & Training: Evaluate the Offline Programming (OLP/CAM) software (e.g., SprutCAM) for ease of use and feature set. Factor in the learning curve and available training resources for your team.

- Footprint & Utilities: What is the available floor space (confirm during layout), \(m^{2}\)? Can your facility provide the required stable 3-phase power per local code (confirm during facility audit), compressed air, and water/drainage for a wet carving process?

- Tooling & Spares Availability: Is there a reliable supply chain for DINOSAW carving bits, including local spares and training support?

The If-Then Decision Tree: Matching a Robot for Granite Memorials vs. Marble Sculptures

IF your primary job is weekly granite memorial lettering (≈50 units) THEN prioritize a 7-axis cell with robust DINOSAW V-groove bits and a repeatable fixturing system.

Risks: Inadequate dust control, inconsistent fixture positioning.

IF producing marble sculpture replicas (batch 10–30), THEN you need a two-stage process with ball-nose roughing and tapered engraving bits, plus an integrated 3D scanning workflow.

Prerequisites: High-resolution scanner, skilled artisan for final QA.

IF restoring limestone architectural reliefs, THEN specify a 7-axis robot with sufficient reach sized to your largest part envelope (confirm during layout), mm/in for deep undercuts.

Risks: Material variability in old stone, insufficient enclosure airflow (provide high-volume airflow per dust system specification, \(m^{3}/h\)).

IF your shop handles mixed materials (granite, marble, sandstone), THEN invest in a water-cooled spindle and build a tool and parameter library for each material.

Prerequisites: Systematic process development and documentation.

IF workshop footprint is limited, THEN consider a system with a compact rotary table with a diameter matched to max block size (confirm during fixture design), mm/in.

Trade-off: This will limit your maximum workable block size.

IF your primary goal is cycle-time reduction vs. manual, THEN focus on OLP for offline job prep and continuous roughing-to-finishing programs.

Target: A ≈40–75% reduction is achievable (project-dependent).

Neutral Comparison: Roboticom ScultoRob vs Dinosaw Architectures

This comparison uses publicly available information to frame a decision between a vertically integrated system (Dinosaw) and a well-known competitor (Roboticom). It is for illustrative purposes; verify all specs with vendors.

| Dimension | Dinosaw 7-Axis System | Roboticom ScultoRob |

|---|---|---|

| Core Architecture | Integrated 7-axis cell (KUKA robot + rotary table) with water-cooled spindle. | 7-axis robotic milling system, emphasizing multi-material use. |

| Tooling | Vertically integrated DINOSAW diamond tools (end mills, engraving bits, etc.) from own factory. | Compatible with various standard tools; offers automatic tool change. |

| Software | Uses SprutCAM for OLP and complex toolpath generation. | Proprietary ARPP software for simplified programming and simulation. |

| Environmental Protection | High standard dust and water protection (IP65 rating) and optional protective raincoat for manipulator. | IP protection and dust extraction systems are highlighted as key features for durability. |

| Target Applications | Focused on stone processing: memorials, statues, architectural elements. | Broader focus on multi-material applications including art, design, aerospace, and automotive. |

Context: The trend towards robotic carving is growing, with companies like Monumental Labs expanding from statues to structural stone, signaling a maturing market.

Procurement & Long-Term Ownership Topics

- Spares & Consumables: Clarify the availability of critical spares (spindle, drives) and consumables. For DINOSAW, this includes spares kits and a resharpen/replace policy for their diamond tools.

- Maintenance & Warranty: Request a detailed preventative maintenance schedule. Understand the warranty period and what it covers (parts, labor, travel).

- Training & Support: A comprehensive training plan should cover robot operation, OLP software, and basic maintenance. Verify the provider's remote and on-site support capabilities.

- Certifications: Ensure the system complies with relevant safety standards (e.g., CE marking in Europe) for your market.

Scenario Recommendations

- For Memorial Producers: A 7-axis system with a robust fixturing system and a library of V-groove bits is ideal.

- For Art/Religious Statue Studios: Prioritize a system with high-fidelity scan-to-toolpath capability and a wide range of tapered engraving bits.

- For Architectural/Heritage Restoration: A large-reach robot with precise 7-axis control is critical for handling large blocks and complex undercuts.

FAQs — Selection & Procurement

How do we compare OLP/CAM software options?

Compare based on ease of use, simulation accuracy, and post-processor quality. Options like SprutCAM are widely used for multi-axis robotics. Evaluate the learning curve and available support.

What cycle-time gains are typical with a 7-axis system?

Project-dependent, but gains of 40–75% versus manual methods are typical by eliminating manual repositioning and enabling continuous operation. OLP is key to maximizing this benefit.

Which DINOSAW tools fit granite vs. marble?

For hard, abrasive granite, use robust V-groove and ball-nose bits. For softer, less abrasive marble, use a two-stage approach with ball-nose roughing and fine tapered bits for finishing.

What footprint and power constraints matter most?

Beyond the robot's operating envelope, plan for the full cell including the enclosure, control cabinet, and maintenance access. Confirm your facility can supply the required stable 3-phase power per local code (confirm during facility audit) and compressed air. A solid foundation is also critical.

What dust/water protection level is recommended?

An IP65 rating is a strong baseline for the robot and critical components to protect against abrasive dust and water ingress, ensuring long-term reliability.

Do we need scan-to-toolpath capability?

Yes, if you are replicating existing objects like artistic sculptures or restoring historical elements. It is essential for capturing organic shapes and creating accurate digital models for carving. For a broader market overview, see this list of Top stone cutting machine brands.

English

English 中文

中文