Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Practical routing for granite, marble and quartz—tool choices, sink cut‑outs, troubleshooting and shop‑tested workflows. Read the guide.

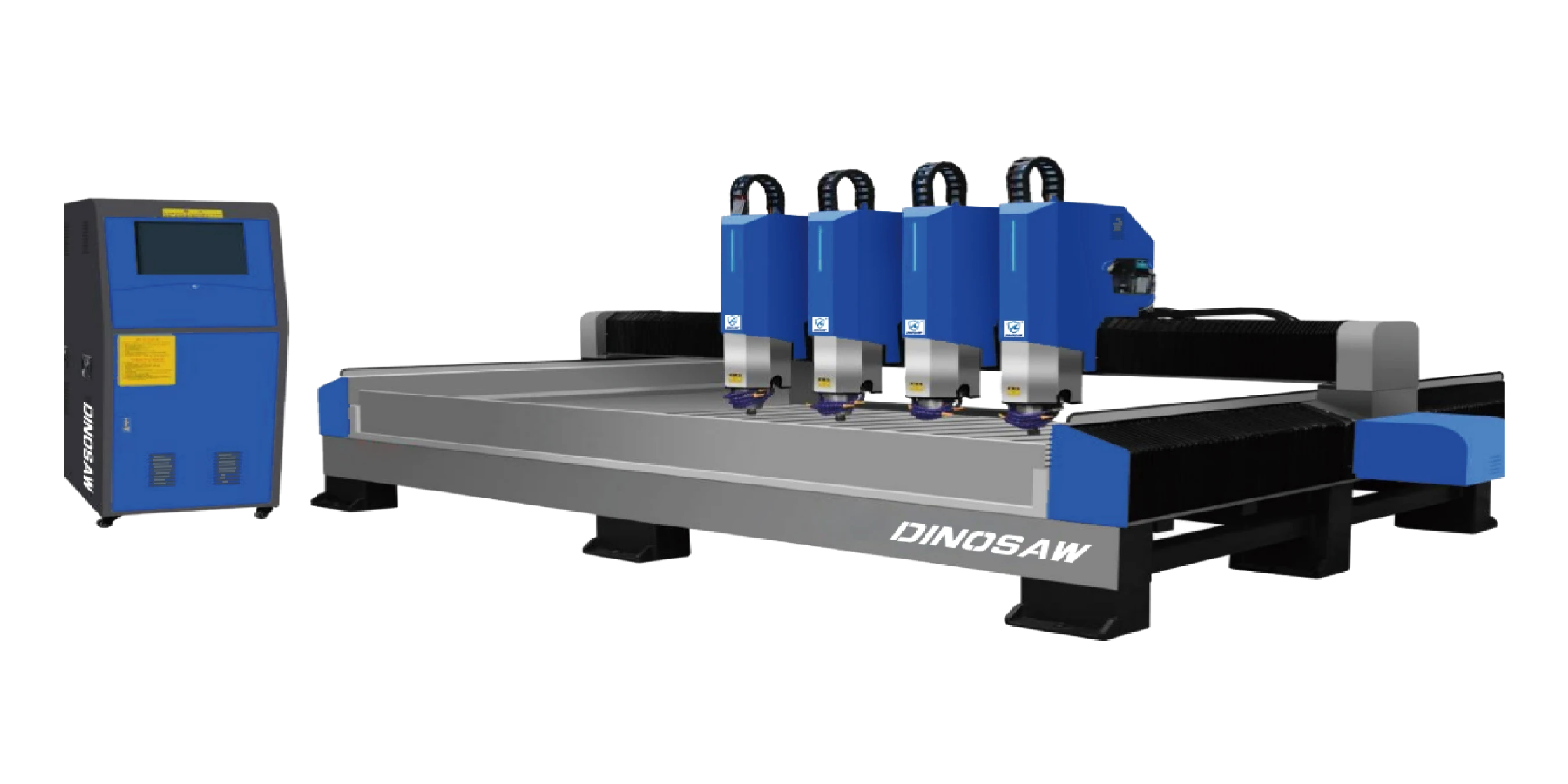

CNC stone routing delivers what manual methods can't: consistent precision cuts through granite, marble, and quartz using computer-controlled diamond-tipped tools. Your machine handles sink cut-outs, 3D carvings, and detailed engravings while you focus on growing your business.

This guide cuts straight to what works in real fabrication shops. You'll get tested parameters, proven tooling choices, and step-by-step workflows that minimize waste and maximize profit. Need specific advice for your material? Consult our engineers who've solved these challenges hundreds of times.

Quick Reference: Proven Parameters for Common Stone Materials

Wrong settings destroy tools and waste expensive slabs. These parameters work in production environments across dozens of shops we've equipped.

| Material Type | Tool Type | Spindle Speed (RPM) | Feed Rate (mm/min) | Depth per Pass |

|---|---|---|---|---|

| Granite (Hard & Brittle) | Sintered Diamond | 5,000 - 7,000 | 200 - 500 | 1 - 2 mm |

| Marble (Soft & Abrasive) | Electroplated or PCD | 6,000 - 8,000 | 400 - 800 | 2 - 4 mm |

| Quartz (High Resin Content) | PCD (Polycrystalline) | 7,000 - 9,000 | 500 - 1,000 | 1.5 - 3 mm |

Always test on scrap material first. Tool diameter, machine rigidity, and coolant flow affect these settings.

Choose the Right Diamond Tool: Your Results Depend on It

Tool choice makes or breaks your job. Each diamond tool serves specific materials and applications. Stock the right Diamond Tools and you'll handle any project that walks through your door.

Sintered Diamond Bits: Built for Heavy Production

Sintered bits fuse diamond particles into metal matrix layers. As the outer layer wears, fresh diamonds expose themselves. This self-sharpening design handles granite routing, deep carving, and bulk material removal without frequent tool changes.Use these for: Channel routing in granite countertops, 3D architectural carvings, high-volume production runs.

Electroplated Diamond Bits: Precision for Fine Details

Electroplated tools bond a single diamond layer to the cutting surface with nickel. You get razor-sharp edges perfect for marble engraving, detailed text work, and finishing passes where surface quality matters most.Use these for: Headstone lettering, decorative marble inlays, final edge profiling on soft stones.

PCD Bits: The Quartz Specialist

Polycrystalline Diamond (PCD) tools feature synthetic diamond tips brazed onto carbide bodies. Their exceptional thermal conductivity prevents the heat buildup that melts quartz resin. Run them fast and they'll deliver clean cuts in engineered stone all day.Use these for: Caesarstone and Silestone cutting, high-speed quartz fabrication, any engineered stone with resin content.

V-Carving and Engraving Bits: Sharp Lines Every Time

Vein cutters and engravers use pointed, V-shaped tips to create crisp lines and detailed patterns. The V-angle determines cut width and depth, giving you precise control over artistic details and text clarity.

Perfect Sink Cut-Outs: Step-by-Step Professional Process

Sink cut-outs demand precision – there's no fixing a mistake on a $2,000 granite slab. This process eliminates guesswork and delivers consistent results. For complete details, see our CNC Sink Cut-Out Guide: A Stone Fabricator's Playbook 2025

Step 1: Digital Template Capture

Measure twice, cut once applies here more than anywhere. Use digital templating systems (laser or probe) to capture exact sink dimensions. Import these measurements into your CAM software to generate precise toolpaths and G-code.

Step 2: Secure Slab with Vacuum System

Any movement ruins the cut. Position vacuum pods strategically across the machine bed to hold the granite slab completely flat and immobile.Test suction strength before starting – a 3cm granite slab weighs over 200 pounds and generates significant cutting forces.

Step 3: Tool Setup and Calibration

Mount your 1/2" (12mm) sintered diamond roughing bit first. Use the machine's automatic tool length sensor to calibrate exact height. Precise tool length measurement ensures accurate cut depth throughout the entire process.

Step 4: Roughing Pass Execution

Start the roughing program with continuous coolant flow aimed directly at the cutting point. The CNC removes material in shallow passes (1-2mm for granite) to prevent tool stress and stone chipping.Multiple light passes always beat trying to remove too much material at once.

Step 5: Finishing Pass for Clean Edges

After automatic tool change to the finishing bit, run the final edge pass at reduced feed rate. This creates smooth, chip-free edges ready for polishing – no hand work required.

Fix Common Problems Before They Cost You Money

Even perfect programming can't prevent every issue. Here's how experienced fabricators diagnose and solve problems quickly.

Edge Chipping and Blow-Out

Symptoms: Rough, chipped edges on top surface of cut.Solutions: Check tool sharpness first – dull bits cause most chipping. Reduce feed rate 15-20% on finishing passes. Switch to down-cut or compression bits that push material inward during the final pass.

Rapid Tool Wear

Symptoms: Diamond bits wear out faster than expected cutting life.Solutions: Poor cooling causes 80% of premature tool failure. Aim coolant nozzles directly at tool-stone contact point. Research from ScienceDirect confirms effective cooling extends diamond tool life significantly. Verify spindle RPM stays within manufacturer specifications.

Dimensional Inaccuracy

Symptoms: Cut-out doesn't match template measurements.Solutions: Check machine for backlash in gantry or spindle movement. Calibrate all axes according to manufacturer procedures. Verify CAM program tool offset calculations match your actual tool dimensions.

Machine Requirements: What Actually Works for Stone

Not every CNC handles stone fabrication. Professional shops need machines built for the job, sometimes evolving into advanced solutions like Robot Arm for Stone Grinding & Polishing .

Heavy-Duty Frame Construction

Stone cutting generates massive vibration that destroys accuracy on lightweight machines. Professional stone CNCs use stress-relieved steel frames and rigid gantries that maintain precision under heavy cutting loads.

High-Power Water-Cooled Spindle

10+ HP spindles with water cooling systems drive diamond tools through granite without stalling. Air-cooled spindles overheat quickly and fail under continuous stone cutting loads.

Professional Water Management System

Continuous coolant flow keeps tools cool and washes away abrasive stone particles. A closed-loop system with filtration conserves water and prevents slurry from damaging machine components.Based on OSHA guidelines, proper water systems also control crystalline silica dust – a serious health hazard in stone fabrication.

Frequently Asked Questions

What's the main difference between CNC routing for stone versus wood?

Stone CNC routing requires diamond-tipped tools, much lower spindle speeds (5,000-9,000 RPM vs. 18,000+ for wood), and significantly heavier machine frames. The cutting forces and vibration from stone demand robust construction that wood routers simply can't provide.

Can I engrave photos on granite with a CNC router?

Yes, detailed photo engraving works well on granite using diamond-tipped drag bits or fine V-bits. Convert photos to grayscale heightmaps in specialized software, then generate toolpaths where bit depth varies to create shading and detail.

How long do CNC diamond bits for stone last?

High-quality sintered bits cutting granite typically last 100-200 linear meters, while electroplated bits for detailed marble work may need replacement after 30-50 meters. Proper cooling is the single most important factor in maximizing tool life.

What's the minimum stone thickness you can safely route?

Generally 2 cm (¾ inch) minimum for most CNC routing operations. Thinner materials like 1 cm porcelain tiles require full-contact vacuum support and significantly reduced feed rates and cut depths to prevent cracking.

Do I need a 5-axis CNC for stone routing?

3-axis CNCs handle most 2D tasks like countertop cut-outs perfectly. 5-axis machines enable complex 3D carvings, undercuts, and angled profiles without repositioning slabs. For shops focused on custom architectural elements or sculptures, 5-axis capability justifies the investment.

What maintenance does a stone CNC router require?

Daily: Clean stone slurry and check coolant levels. Weekly: Lubricate linear guides and ball screws, inspect vacuum pods, clean water filtration system. Monthly: Check spindle runout and verify machine calibration for continued accuracy.

English

English 中文

中文