Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Compare bridge saws, sawjets, wire saws and routers for granite, marble and quartz. Pros/cons, workflows and ROI tips. Read the 2026 guide.

Looking for the right CNC setup for your stone shop? Here's what actually works in 2026.

CNC stone cutting machines are computer-controlled tools that cut, shape, and drill granite, marble, and quartz with precision that beats manual methods every time. Modern machines don't just cut - they drill, shape, polish, and engrave all in one setup, meaning better profit margins and fewer mistakes. The stone processing machine market is growing at 5.5% annually through 2030, making now the perfect time to invest.

Ready to find the perfect machine for your shop? Contact our experts for a free consultation and custom quote today.

Why Do Stone Shops Need CNC Machines?

So what exactly is a CNC stone cutting machine? Think of it as your digital craftsman - a computer-controlled tool that handles granite, marble, and quartz with precision that would make traditional stoneworkers envious.

The magic happens when digital meets physical. Your design becomes G-code (the machine's language), which controls every movement - cutting speed, tool position, feed rate. This eliminates human error and delivers consistent results whether it's piece one or piece one thousand.

What's more, modern CNC machines don't just cut. They drill, shape, polish, and even engrave - all in one setup. This means less material handling, fewer mistakes, and way better profit margins.

Which CNC Stone Machine Should You Buy in 2026?

Choosing the right machine is about matching technology to your daily workload. Here's what's actually working in real shops across different specialties.

Bridge Saws: The Backbone of Most Stone Shops

For countertop shops processing 20+ slabs daily, CNC bridge saws deliver the speed and precision you need. These machines excel at straight cuts and angles on large slabs.

What they do best:

- High-speed straight cutting of stone slabs

- Precise angle cuts for miters and bevels

- 5-axis versions handle complex waterfall edges and sink cutouts

Best for: High-volume countertop fabricators, architectural suppliers, and shops processing large quantities of engineered stone.

The newer 5-axis versions take things further - they can handle those tricky waterfall edges and sink cutouts that customers love. For busy countertop shops, they're basically essential equipment.

Dinosaw's approach: Our bridge saws use monoblock frames for rock-solid stability. Plus, the software is actually intuitive - your operators won't need a computer science degree to run them efficiently.

Wire Saws: When You Need to Cut Big or Get Creative

Wire saws handle the jobs other machines can't touch. Using diamond-impregnated wire, they slice through massive blocks and create complex 3D shapes.

Two main types:

- Multi-wire saws: Slice entire stone blocks into uniform slabs in one pass. Industrial efficiency at its finest.

- Single-wire contouring saws: Create curves, spirals, and 3D shapes that are impossible for blade-based machines.

Best for: Quarries, architectural restoration (columns, balustrades), and large-scale stone sculpture projects.

Real-world advantage: While a bridge saw might struggle with a 12-inch thick granite block, a wire saw treats it like butter. Plus, the cutting quality is exceptional - minimal finishing required.

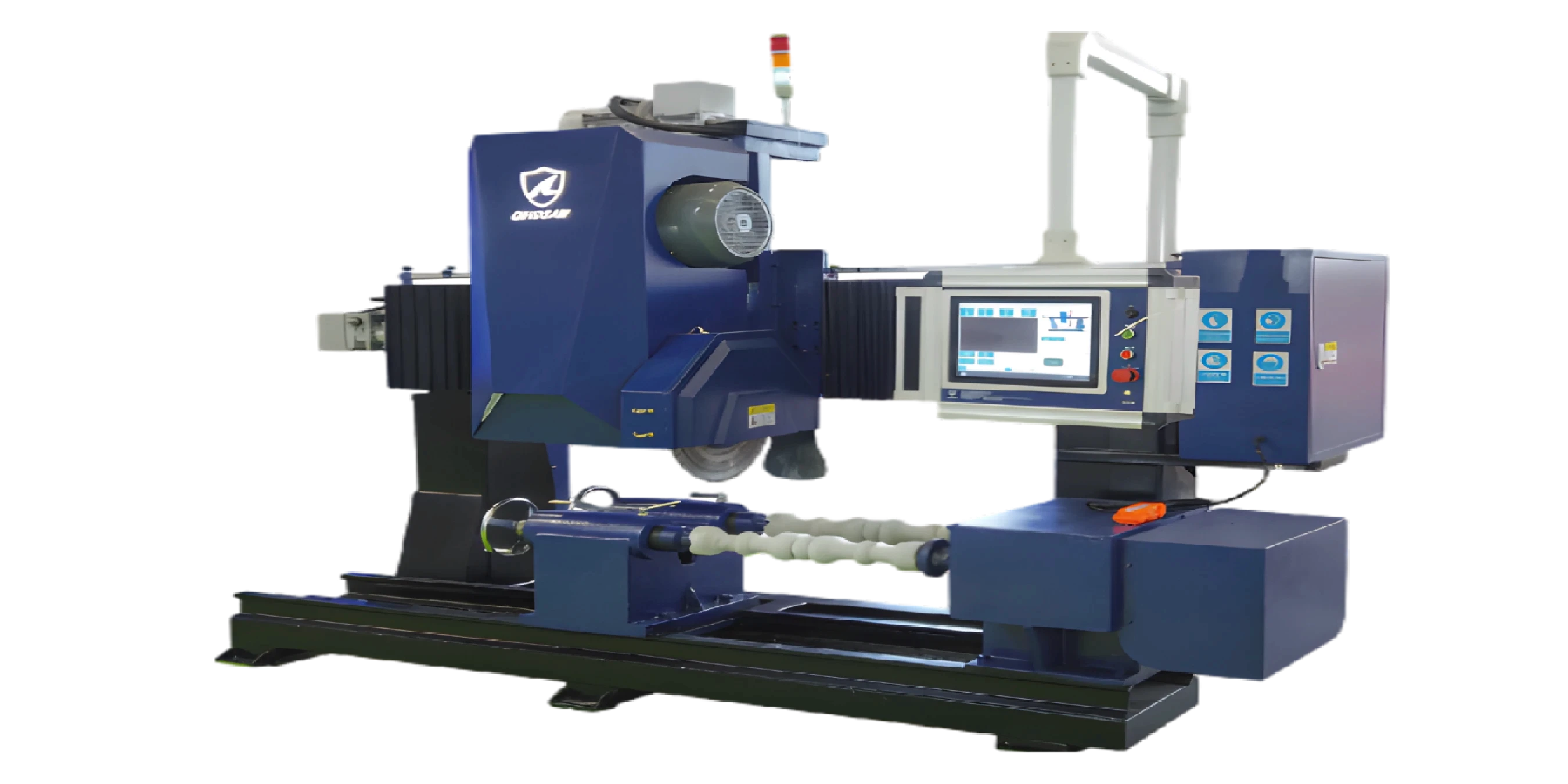

CNC Stone Lathes: For Round and Conical Work

Need perfectly round columns or decorative vessels? Stone lathes are your answer. They rotate the stone against cutting tools to create symmetrical, cylindrical pieces.

Core function: Turning stone blocks into round or conical shapes with precision that handcarving simply can't match.

Best for: Architectural restoration, landscape design (pillars, balustrades), and decorative stonework like vases and pedestals.

Why choose Dinosaw: Our stone lathes combine heavy-duty construction with precise control systems. Even the hardest granite turns smoothly, delivering superior finishes for architectural applications.

CNC Machining Centers: The Swiss Army Knife Solution

What if you could have one machine that cuts, drills, and polishes? That's exactly what a CNC machining center does - it's like having three machines in one.

The game-changer: Automatic Tool Changer (ATC) systems. The machine switches between saw blades, drills, and polishing heads without any manual intervention. Cut a sink hole, profile the edge, engrave drainboard grooves - all in one setup.

Best for: High-end custom shops, integrated sink manufacturers, and fabricators creating complex stone furniture or artistic panels.

Bottom line: If you're doing custom work with tight tolerances, a machining center pays for itself through reduced labor costs and eliminated setup time.

Waterjet Cutting: When Precision Meets Creativity

Here's where things get interesting. Waterjet technology uses pressurized water (60,000+ PSI) mixed with garnet abrasive to cut through stone. No heat, no stress - just incredibly precise cuts.

Why waterjet wins:

- Cuts any 2D shape imaginable

- Perfect for brittle materials like porcelain and ultra-compact surfaces

- Creates sharp internal corners that rotating tools can't achieve

- Zero heat-affected zone prevents cracking

Best for: Intricate inlays and medallions, ultra-compact surface cutting (Dekton, Neolith), precious stone work, and mixed-material projects.

Customer insight: "The waterjet allowed us to take on intricate inlay projects we previously had to turn down. It opened up a whole new revenue stream." - Maria S., Architectural Design Firm

How to Choose the Right CNC Machine for Your Shop

Making the right investment comes down to understanding your daily workflow and growth plans.

Match Your Primary Applications

Heavy slab processing? Start with a 5-axis bridge saw. It's the foundation most successful shops build on.

Custom edge work and integrated sinks? A machining center with ATC will transform your capabilities and profit margins.

Starting with raw blocks? Multi-wire saws are essential for efficient slab production.

Intricate artistic work? Waterjet technology opens doors to high-margin custom projects.

Architectural elements? Wire contouring saws or stone lathes handle 3D shaping that other machines simply can't do.

Consider Your Stone Types

Hard stones (granite, quartzite): You need robust, heavy-duty frames and high-powered spindles. Vibration dampening is crucial for maintaining accuracy over years of heavy use.

Brittle materials (porcelain, sintered stone): Waterjet is often your only viable option. The cold-cutting process eliminates thermal shock and micro-cracking.

Key Features That Actually Matter

Machine structure: Heavy, stress-relieved steel frames aren't just marketing - they're essential for long-term accuracy.

Control systems: Make sure the software plays well with your existing CAD/CAM workflow. Training time matters when you're paying hourly wages.

Spindle power vs. pump pressure: For cutting machines, spindle power (kW/HP) and speed (RPM) determine your productivity. For waterjets, pump reliability and pressure rating are everything.

Frequently Asked Questions

What's the real difference between 3-axis and 5-axis CNC machines?

Here's the simple breakdown: 3-axis machines move in three directions (X, Y, Z - left-right, front-back, up-down). Perfect for 2D cutting and basic drilling.

5-axis machines add two rotational movements, letting the cutting head tilt and rotate. This means complex angled cuts, full 3D carving, and undercut details - all in one setup. For modern countertop shops, 5-axis capability is becoming essential, not optional.

Can CNC routers handle granite cutting?

Yes, but with important distinctions. Stone CNC routers excel at detailed work - engraving, intricate edge profiles, and 3D reliefs. They can cut granite, but they're not designed for high-speed slab processing like bridge saws.

Think of it this way: use a bridge saw for breaking down slabs efficiently, then move to a router for detailed finishing work. Each has its place in a complete workflow.

How does waterjet cut stone without cracking it?

The secret is cold cutting. Waterjet uses hydro-abrasive erosion - basically wearing away the stone microscopically with high-pressure water and garnet particles. No heat means no thermal stress, which is what causes cracks and chips.

This makes waterjet perfect for brittle materials like porcelain, ultra-compact surfaces, and delicate natural stones. Plus, you can cut incredibly intricate shapes with sharp corners that blade-based tools simply can't achieve.

What software do I need to run a CNC stone machine?

You'll need two types: CAD (Computer-Aided Design) for creating your designs, and CAM (Computer-Aided Manufacturing) for generating the actual cutting instructions.

Popular CAD options include AutoCAD and Rhino. For CAM, Alphacam and FSTone are industry standards. Most modern CNC machines come with compatible software or integrate seamlessly with these established platforms.

The key is ensuring your software workflow matches your design process and skill level.

How much maintenance do these machines actually require?

Daily maintenance is straightforward - clean stone dust and slurry, check fluid levels. Takes about 15 minutes.

Weekly tasks include lubricating moving parts and inspecting wear items. Monthly checks cover alignments and filter changes. Annual service involves detailed spindle or pump maintenance.

Following the manufacturer's preventative schedule is crucial. It's the difference between years of reliable operation and costly unexpected downtime.

Is it hard to learn CNC operation?

Modern machines are designed for usability, not engineering degrees. The main learning curve is CAD/CAM software for creating designs and toolpaths.

With proper training, operators become proficient in basic operations within 1-2 weeks. Advanced programming takes more experience, but that's why machine suppliers like Dinosaw provide comprehensive training and ongoing support.

The investment in training pays back quickly through improved efficiency and reduced waste.

English

English 中文

中文