Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

An executive guide covering the value levers, decision map, glossary, FAQs, and next steps for investing in a 5-axis CNC bridge saw for stone fabrication.

If sink and countertop fabrication defines your business, a 5-axis CNC stone cutting machine is a strategic investment that compresses cycle times, reduces defect rates, and unlocks the capacity for high-margin curved and complex work. This executive overview distills the critical information for a joint decision-making team, moving beyond technical specifications to focus on business value and implementation pathways.

This guide is for shop owners, operations managers, and engineering and procurement leaders involved in evaluating capital expenditures for stone fabrication. We will summarize the machine's capabilities, map them to business needs, and outline a clear path from pilot to full-scale implementation.

What This 5 axis Saw Is: Application and Principle

Application Focus

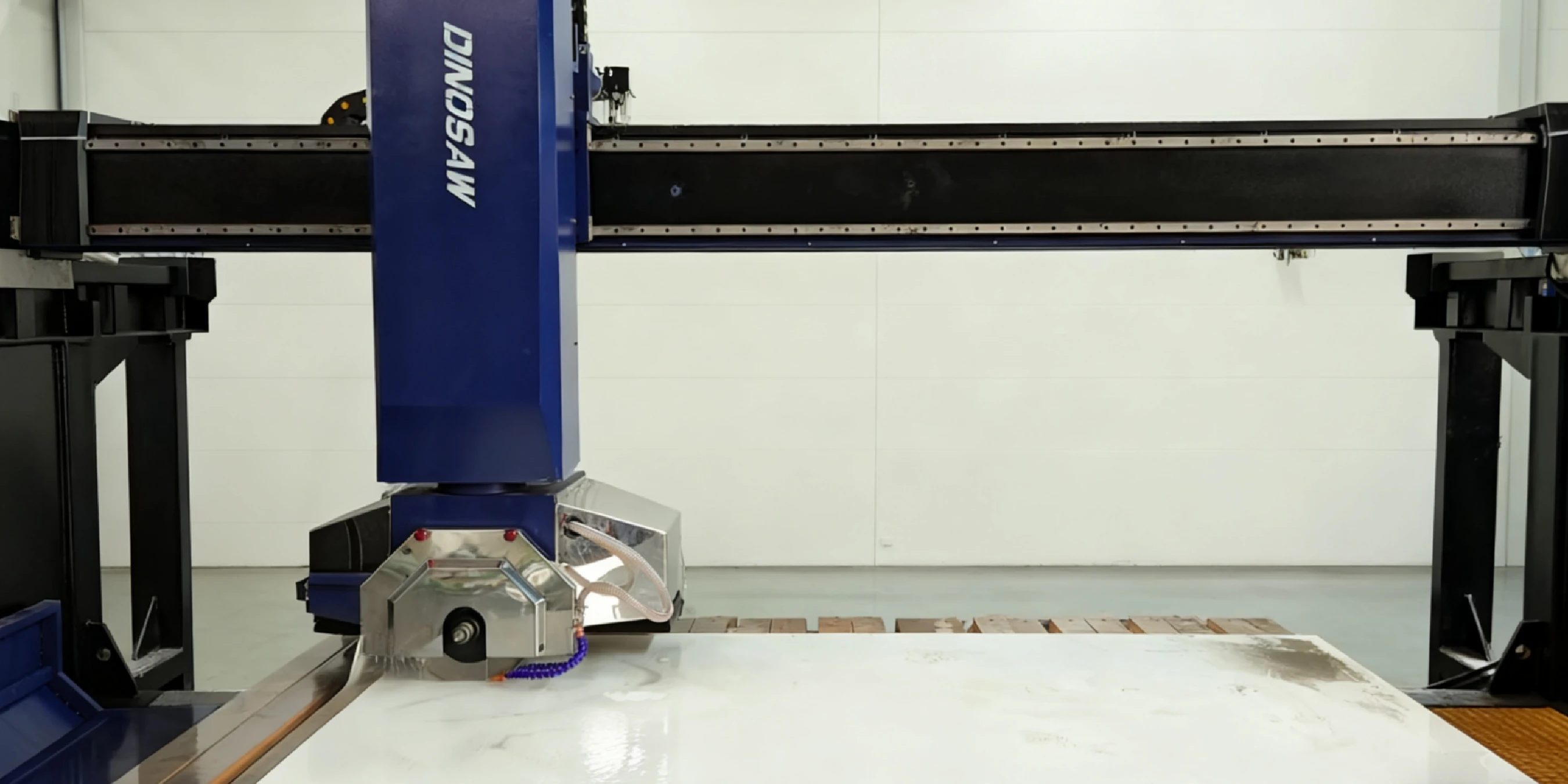

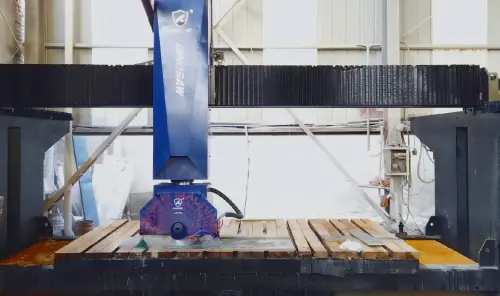

The DINOSAW 5-Axis Bridge Saw for Sinks is designed for the precision cutting of sinks, countertops, and curved architectural elements from granite, marble, quartz, ceramic, and sintered stone.

Core Principle

It operates on the principle of 5-axis interpolation, combining a monoblock structure with camera-based nesting and direct DXF/DWG file import to achieve a manufacturer-reported precision of ±0.05 mm.

Quick-Start Checklist

Before implementation, confirm your facility meets these core requirements:

- Environment: Adequate power supply, water access for cooling, and a drainage/reclamation plan.

- Interfaces: Standardized process for DXF/DWG file delivery; plan for PLC/production data logging (OPC UA/Profinet integration available on request).

- Safety: A clear plan for wet cutting to manage silica dust per standards like OSHA 29 CFR 1926.1153 and a mandatory PPE policy.

- Parameter Starting Points: Establish during commissioning with your top materials and validate via test cuts; record final recipes.

High-Level Decision Map

This map connects primary business cases to essential machine features and associated risks.

| If Your Primary Use Case Is... | Prioritize These Features... | And Be Aware of These Boundaries... |

|---|---|---|

| High-volume countertop production | Camera nesting, vacuum handling, DXF import | Vacuum grip can be less effective on heavily textured or porous surfaces. |

| Complex curved furniture or 3D sculptures | Ø800 mm (31.5 in) blade option, robust A/C axis dynamics | Requires advanced CAM programming and operator skill. |

| Cutting brittle materials (ceramic, sintered stone) | Precise coolant control, support for fine-grit blades | High risk of micro-cracks without optimized parameters. |

Related Insights from Our Team

- For detailed use cases and material-specific guides, see our 5 axis bridge saw Application Guide.

- To understand the machine's core components and performance envelope, refer to the 5 axis bridge saw Technical Principles breakdown.

- To compare this machine against other methods, use the 5 axis bridge saw Selection & Comparison Guide.

- For daily checklists and troubleshooting, review the 5 axis bridge saw Operations & Maintenance plan.

ROI Levers & Glossary

Key ROI Levers

- Increased Yield: Camera nesting can improve material utilization by up to 30% (manufacturer-reported).

- Reduced Labor: Automation of complex cuts allows skilled labor to be reallocated to finishing and quality control.

- Lower Defect Rate: Precision control minimizes chipping and breakage, reducing costly rework and waste.

- Higher Project Win Rate: The ability to confidently bid on high-margin curved and mitered jobs expands your market.

Glossary

- Miter: An angled cut, typically at 45 degrees, to create a corner seam.

- Nesting: Software-driven arrangement of shapes on a slab to maximize material yield.

- A/C Axis: The rotational axes that tilt (A) and rotate (C) the blade head for 5-axis movement.

- Tool Compensation: Software adjustment to account for blade wear and kerf width to maintain accuracy.

- Backlash: Mechanical play in an axis that can affect positioning accuracy; checked during maintenance.

Frequently Asked Questions

What is the typical payback period for a 5-axis bridge saw?

While this varies based on production volume and job complexity, shops often model payback periods of 8-12 months. Key factors include labor savings, reduced material waste from camera nesting, and the ability to capture higher-margin projects that were previously outsourced.

How does the training curve impact initial productivity?

With intuitive software and direct DXF import, operators familiar with CNC basics can become proficient in core operations within a week. The manufacturer-reported claim of "5 minutes skilled operation" refers to running pre-programmed jobs. Mastering advanced 5-axis programming for novel 3D shapes requires a longer learning curve, typically 1-3 months.

What certifications are important when considering a machine for export?

If exporting products to or operating within the European Union, CE marking is mandatory. This indicates compliance with health, safety, and environmental standards, such as those outlined in the EU Machinery Regulation 2023/1230. For North American markets, look for UL/CSA certification on electrical components.

How can we model the machine's throughput for our specific products?

Throughput modeling should be based on time studies of your most common jobs. Start with your validated shop recipes for feed rates; include slab loading/unloading, program load, and tool changes in the model. We recommend running a benchmark test with your own material and files as part of the final procurement stage.

What is the difference between a 5-axis saw and a waterjet for sink cutouts?

A 5-axis saw is generally faster and has lower consumable costs for standard sink and countertop work. A waterjet excels at extremely intricate, small-radius internal corners and cutting materials that a blade cannot, but it is typically slower and has higher operating costs due to the use of garnet abrasive.

Does a monoblock design have any performance trade-offs?

The primary benefit of a monoblock design is its simplified installation, as it doesn't require separate concrete foundations for rails. For the slab sizes and material thicknesses typical in countertop fabrication, a well-engineered monoblock frame provides more than sufficient rigidity. For exceptionally large or heavy industrial block cutting, a gantry or separate-rail design might be considered, but this is outside the scope of sink and countertop work.

Next Steps: From Pilot to Production

Pilot Program

Identify a specific product line (e.g., quartz undermount sinks) for a 30-day pilot. Define clear acceptance KPIs, including cycle time, defect rate, and material yield.

Standardize Recipes

Once KPIs are met, document the optimal cutting parameters (RPM, feed rate, etc.) for your top 3-5 materials as standardized, recallable programs.

Replicate and Scale

Use the validated KPIs and standardized recipes to build a business case for replicating the process across other production lines or at other company sites.

English

English 中文

中文