Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

A deep dive into the CNC Diamond Wire Saw Pro's architecture, from the 15 kW motor to the control system. Understand key components, specs, and failure modes.

A machine’s reliability is a direct result of its engineering. This technical deep dive breaks down the core components of the CNC Diamond Wire Saw , from its 15 kW motor to its multi-axis control system. You will learn exactly how it works, what its key specifications mean, and how to anticipate common failure modes.

Schedule a technical consultation to see how these components can be optimized for your materials.

System Architecture of a CNC Diamond Wire Saw (5‑axis CNC)

The DINOSAW CNC Diamond Wire Saw Pro is a complex, integrated system where each part plays a critical role in delivering precision and reliability. The architecture follows a logical flow of command and action, which can be visualized as a hierarchical chain:

Control System → Drive System → Cutting Mechanism → Worktable → Auxiliary Systems

This chain begins with the operator's commands at the CNC control system, which translates digital designs into electrical signals. These signals are sent to the drive system (motors and actuators), which provides the power and motion for the cutting mechanism. The diamond wire, guided by precision wheels, performs the cut on the material secured to the worktable. Throughout this process, auxiliary systems, like the water-cooling unit, ensure optimal operating conditions and safety.

Axis Configuration:

- 4-Axis Standard: The machine is equipped with a standard 4-axis configuration (X, Y, Z linear axes + A rotary axis). This setup is highly effective for a wide range of applications, including profiling, block squaring, and creating 2.5D shapes like Roman columns and curved slabs.

- 5-Axis Optional Upgrade: For workshops tackling the most complex jobs, an optional 5-axis upgrade (adding a B rotary axis) is available. This enables true multi-axis interpolation, allowing the machine to create complex 3D spatial forms, undercuts, and intricate sculptural pieces that are impossible with fewer axes. This is the choice for high-margin, bespoke architectural and artistic projects.

Core Components of a CNC Diamond Wire Saw Machine

The machine's performance is a direct reflection of its components. Here are the key subsystems that define its capabilities.

1. Main Motor

Specification: 15 kW.Function: This motor is the heart of the drive system, providing the power needed to pull the diamond wire through dense materials like granite and quartzite at a consistent speed. Its primary role is to deliver constant, unwavering torque to prevent the wire from slowing down or stalling mid-cut, which is critical for achieving a smooth surface finish and preventing wire breakage.

3. Guide Wheels

Function: These precision-machined wheels guide the diamond wire from the drive system to the workpiece. Their alignment, concentricity, and surface hardness are directly responsible for the final cut accuracy. Made from wear-resistant materials, they are designed to withstand the abrasive slurry. Worn or misaligned guide wheels are a primary cause of inaccurate cuts and should be a focus of preventive maintenance. For more details, see our CNC Wire Saw Pro O&M Best Practices guide.

2. Wire Drive & Tensioning System

Specification: Accommodates 3-15 mm wire diameter.Function: This electro-mechanical system maintains two critical parameters: constant wire speed and optimal tension. It automatically adjusts to compensate for wire stretch and cutting forces, preventing whipping, vibration, and premature breakage. Proper tension is paramount for cut accuracy and is a key factor in maximizing the lifespan of the diamond wire.

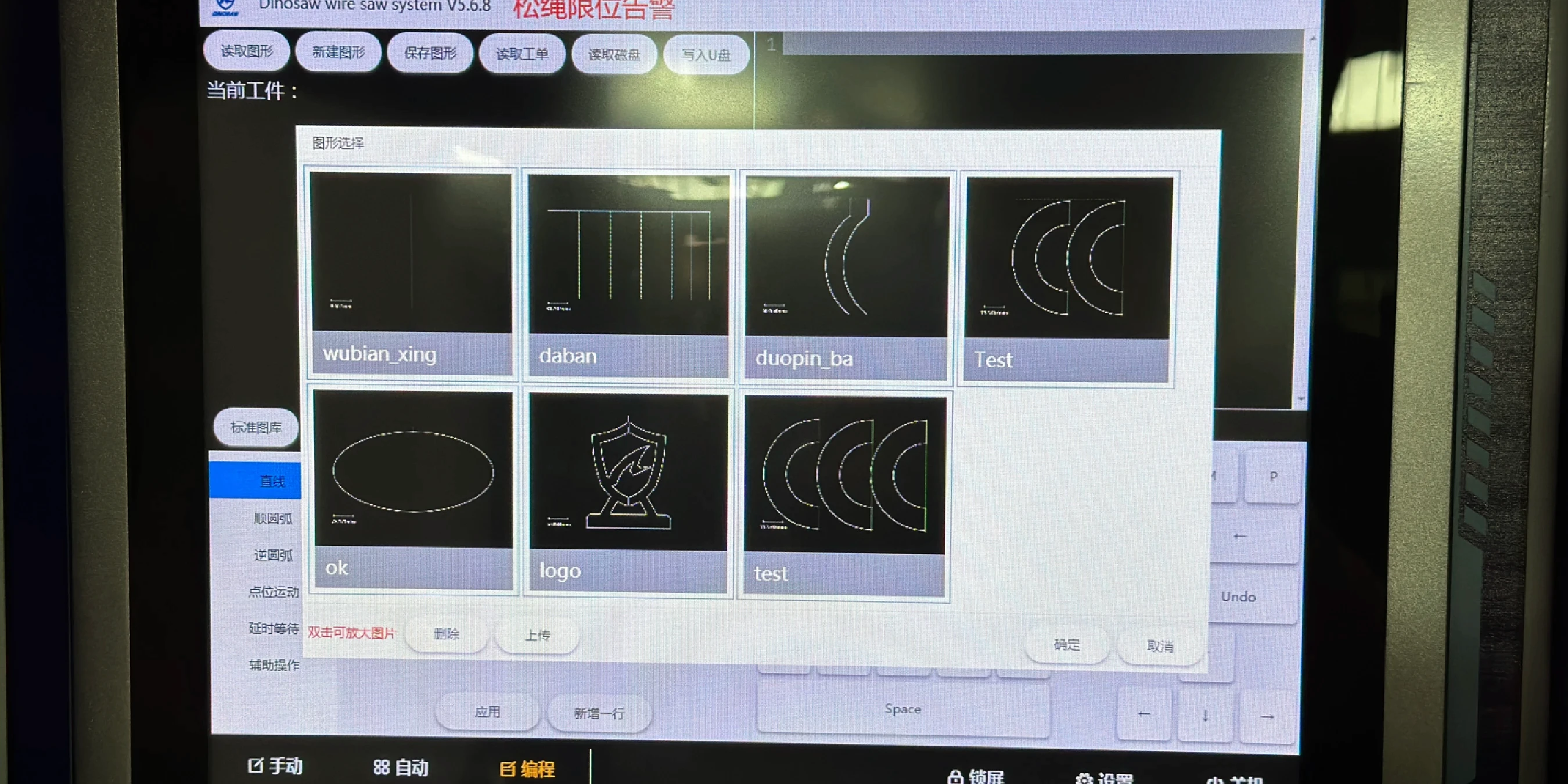

4. CNC Control System

Function: The brain of the operation, this system interprets standard G-code from CAD/CAM software and orchestrates the synchronized movement of all axes. It manages feed rates, wire speed, and tensioning parameters. A user-friendly Human-Machine Interface (HMI) allows operators to load programs, perform calibrations, and monitor the cutting process in real time. Compatibility with standard G-code ensures it can integrate into existing digital workflows.

5. Rotary Axes (A/B)

Function: These axes enable profiling and 3D kinematics. The standard A-axis allows for rotational cutting (e.g., columns), while the optional B-axis on the 5-axis upgrade provides an additional degree of freedom for complex contours. Their performance relies on high-precision bearings and encoder feedback to ensure accurate positioning.

6. Worktable

Specification: Standard size of 2.5 x 1.4 m.Function: This is the foundation that holds the workpiece. Its rigidity and flatness are essential for accuracy. The Pro series worktables are built to handle heavy stone blocks, with customizable options for size and rotation available to fit specific production needs. Load capacity depends on the machine's configuration and should be confirmed during the planning phase.

7. Water Cooling System

Specification: 3 m³/h water consumption.Function: This auxiliary system serves two purposes: it cools the diamond wire to prevent overheating and premature wear, and it flushes the abrasive slurry (rock dust and metal particles) from the cut. Effective slurry management is vital for a clean cut and for complying with environmental and safety regulations.

Common Failure Modes (wire breakage, rotary axis) & Mitigation

Even the most robust machines require proactive maintenance. Understanding common failure symptoms and their root causes is key to maximizing uptime. For a complete overview of what to look for, consult the Selection Guide to make an informed choice.

| Symptom | Likely Cause(s) | Diagnosis & Mitigation |

|---|---|---|

| Premature Wire Breakage | Incorrect tension; worn guide wheels; excessive feed rate. | Verify tension settings against material specs. Inspect guide wheel grooves for wear. Reduce feed rate and verify cutting parameters. |

| Inaccurate Cuts / Poor Finish | Wire vibration; loose worktable; worn guide wheels; incorrect axis calibration. | Check wire tension. Ensure workpiece is securely clamped. Inspect guide wheels. Run axis calibration routine from the CN controller. |

| Motor Overheating | Excessive cutting load (feed rate too high); insufficient cooling; worn motor bearings. | Reduce feed rate. Check for obstructions in motor cooling fan. Listen for abnormal bearing noise (whining/grinding). |

| Rotary Axis Misalignment | Encoder error; mechanical backlash in gearbox; incorrect homing. | Re-run homing sequence. Check for error codes on the controller. Manually check for physical play in the axis. Schedule professional calibration if needed. |

Integration (OPC UA/Modbus/MQTT) for CNC Wire Saw Data

A modern CNC machine must be able to communicate with the wider factory ecosystem. The Pro series is designed with this in mind.

Data Protocols for Automation:

While specific data protocols are a customizable option, the control system architecture is compatible with industry-standard communication gateways. This allows data to be exchanged with factory-level monitoring systems (SCADA) or ERPs. Common integration approaches include using gateways to translate the machine's internal data into protocols like OPC UA, Modbus TCP, or MQTT.

Physical Integration:

Foundation and space planning are critical. The machine's substantial weight requires a solid, level concrete foundation to ensure stability and prevent vibration.

To review the full technical specifications and discuss custom integration, please contact our team.

Frequently Asked Questions

Diamond wire lifespan-how long for granite/marble?

Wire lifespan varies significantly based on the material being cut, cutting speed, and tension. For hard granite, it might be 200-260 hours using a standard wiresaw, while for softer marble, it could be 600-1200 hours. Consistent operating parameters and proper cooling are the best ways to maximize its life.

CNC diamond wire saw accuracy-what tolerance?

With a properly calibrated machine and high-quality wire, dimensional accuracy is typically within ±0.5 mm, though this can be influenced by material type and cutting speed. The precision is sufficient for high-end architectural and monumental work.

15 kW motor-upgrade options for wire saw?

The 15 kW motor is engineered to provide the optimal balance of power and control for the specified wire diameter and machine structure. Upgrades are typically offered if you need. Customizations are also focused on worktable size and axis configuration.

YXSJ series CNC wire saw comparison

The primary difference is the maximum working dimensions they can accommodate: 2.5m, 3.0m, and 3.5m in length, respectively. This corresponds to a larger physical footprint and machine weight. The core components like the motor and control system are consistent across the Pro series.

Is the control system proprietary or based on a standard platform?

The control system is built on a robust industrial platform known for its reliability in harsh environments. It runs standard G-code, ensuring compatibility with major CAM software providers. Specific vendors may vary by region and integration needs. Details available upon request.

Which standards apply (ISO 12100, IEC 60204‑1)?

The machine is designed with fundamental safety principles in mind. According to ISO 12100: Safety of Machinery, risk assessment is integral to the design process. Furthermore, the electrical systems adhere to guidelines specified in IEC 60204-1: Electrical Equipment of Machines, which promotes the safety of persons and property. Regional certifications (e.g., CE/UL) should be confirmed during the procurement process.

English

English 中文

中文