Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Real-world use cases for CNC bridge saws—countertops, thin slabs, tiles, stair treads. Learn how shops cut rejects and lead time.

For countertop shops, slab yards, and tile makers, the daily challenge is turning raw stone into finished products quickly, accurately, and with minimal waste. Delays from manual errors, high reject rates, and inconsistent quality directly impact your bottom line. Integrating automated equipment is no longer a luxury but a core driver of profitability and customer satisfaction.

A modern CNC Stone Bridge Saw transforms fabrication by delivering repeatable precision and operational predictability. With multi-axis capabilities and accuracy reaching ±0.05mm (per manufacturer specifications) , these machines reduce lead times, cut down on costly rejects, and enable your shop to handle more complex jobs with confidence.

Contact us to review your application and see the CNC Stone Bridge Saw in action

Where a CNC Bridge Saw Fits

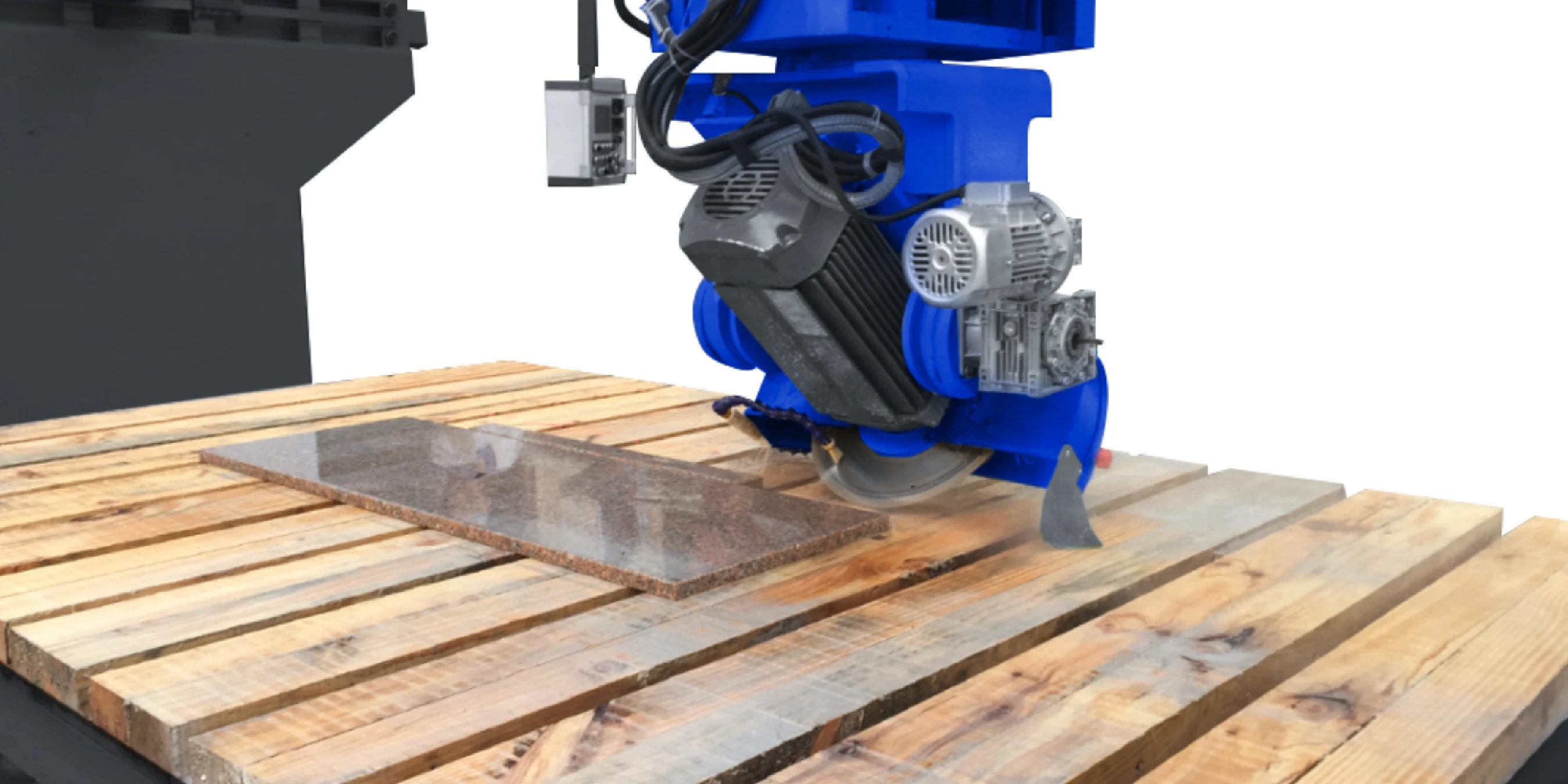

From an application standpoint, a CNC stone bridge saw is a gantry-style, multi-axis cutting system designed to process stone slabs like granite, marble, engineered stone, and ceramic. It automates the process of making straight cuts, miters, sink cutouts, and complex edge profiles, transforming a raw slab into a near-finished product.For a fabrication shop, this translates directly to better business outcomes: faster job turnarounds, fewer costly rejects, more predictable and competitive quotes, and a safer, less labor-intensive workflow.

- Typical Jobs: Countertops, floor and wall tiles, stair treads, and architectural panels.

- Job Formats: Efficiently handles both one-off custom jobs and large, repetitive batch runs.

- Supported Motions: Standard 3-axis (X/Y/Z) movement for cutting and depth control, with optional 4th or 5th axes (A/B rotation) for bevels and contours.

Countertop & Tile Use Cases

A CNC bridge saw excels in environments where precision and speed are paramount. Its versatility makes it a fit for a wide range of jobs, including:

- Countertops: Producing kitchen and bathroom countertops with precise sink cutouts and edge profiles.

- Thin Slabs:Safely cutting delicate or thin materials (e.g., under 20mm) without causing fractures.

- High-Polish Edge Jobs: Achieving consistent, high-quality edge finishes that require minimal secondary processing.

- Mixed-Thickness Batches: Quickly changing between jobs with different material thicknesses, increasing machine uptime.

- Tile Batch Runs: Executing large runs of floor or wall tiles with predictable cycle times and dimensional accuracy.

- Stair Treads & Risers: Ensuring high repeatability for architectural components where every piece must match.

Bridge Saw Job Flow for Kitchen Tops

The typical automated workflow simplifies operations significantly. After loading the slab, the operator uses the HMI to select the program. The machine then takes over: the gantry moves the cutting head into position, the blade lowers to the correct depth, and executes the programmed cuts. Once complete, the blade raises and the gantry returns to its home position, ready for the next slab. This automated sequence minimizes manual intervention and ensures consistent execution.

Case Studies: Granite Countertops & Tiles

Case 1: Reducing Countertop Rejects

- Problem: A mid-sized countertop shop was experiencing a high rate of rejects (over 8%) due to misaligned sink cutouts and inconsistent edge profiles, leading to late jobs and lost profits.

- Solution: They implemented a CNC bridge saw with guided recipes and an automated measurement system.

- Result: Rejects dropped from 8% to under 1.5%. Average lead time for custom countertops improved from 10 days to 6 days.

- Replicable Conditions: Success required operator adherence to the new SOPs and consistent coolant hygiene to prevent blade glazing.

Case 2: Processing Thin Quartz Slabs

- Problem: A fabricator specializing in modern designs struggled with thin (15mm) quartz slabs, which were prone to warping and chipping during cutting.

- Solution: Adopting a bridge saw with a vacuum-based fixture system and a fine-tuned parameter window (feed rate and RPM) for thin materials.

- Result: Material scrap from warping was reduced by over 70%, and throughput on thin slab jobs increased by 40%.

- Replicable Conditions: Proper operator training on the new fixturing and parameter selection was critical.

Case 3: Speeding Up Mixed-Batch Production

- Problem: A commercial tile supplier faced bottlenecks due to long changeover times between batches of different materials and thicknesses.

- Solution: A CNC bridge saw with a quick-change tooling system and a simple-to-use HMI for loading pre-saved job recipes.

- Result: Average changeover time was cut from 30 minutes to under 5 minutes. Daily throughput increased by an estimated 25%.

- Replicable Conditions: Having a well-organized library of job recipes and readily available tooling is key to maximizing speed.

Risks and Requirements for a Stone Bridge Saw

To maximize the benefits of a CNC bridge saw, shops must consider several factors:

- SOP Adherence: Operators must consistently follow standard operating procedures for setup, operation, and cleanup.

- Correct Blade Selection: Using the right diamond blade for the specific material and thickness is non-negotiable for quality and safety.

- Clean Coolant: A properly maintained coolant system prevents blade glazing and thermal shock to the material.

- Repeatable Fixtures: The clamping or vacuum system must hold the workpiece securely and consistently every time.

Additionally, while highly versatile, these machines may not be the first choice for highly porous or extremely fragile specialty materials without specific tooling and testing.

People Also Ask About CNC Bridge Saw

Will a cnc bridge saw help countertop quoting?

Yes. By providing predictable cycle times and minimizing material waste, a CNC machine allows for much more accurate and competitive job costing and quoting.

Can new staff learn a stone bridge saw fast?

Modern CNC bridge saws feature intuitive, graphical interfaces (HMIs) and guided recipe selection, significantly reducing the training curve for new operators compared to older, manual equipment.

How to avoid chipping on thin granite slabs?

Preventing chipping involves a combination of using the correct diamond blade, optimizing the feed rate and spindle RPM, and ensuring a steady flow of clean coolant. CNC control automates these parameters for consistency.

Is a bridge saw for kitchen top ceramic the right choice?

Jobs requiring complex 3D carving or true 5-axis simultaneous toolpaths may require more specialized machinery. Standard 3 or 4-axis bridge saws are optimized for straight cuts, miters, and basic contouring.

Helpful Reading

- How to choose a Granite Bridge Saw: Buyer’s Guide

- Professional Rock Cutting Saw | Mining & Factory Solutions

- How to Choose a Stone Cutting Machine for Your Stone Factory

Summary

By moving from manual or semi-automated processes to a fully integrated CNC bridge saw, stone fabrication shops can directly address the core drivers of profitability. The application scenarios and cases above demonstrate that investing in this technology is not just about cutting stone-it's about shortening lead times, improving margins, and reducing the rework that holds your business back.

English

English 中文

中文