Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Confused by all the options? Here's the truth about choosing granite cutting machines that actually make money. From bridge saws to CNC routers, we'll help you avoid the expensive mistakes most fabricators make.

Why Choosing Wrong Machine Could Kill Your Business

Let's be honest here. After 15 years in stone fabrication, I've watched too many good shops go under because they bought the wrong machine. That shiny new cutter isn't just equipment—it's the difference between profit and bankruptcy.

The best granite machine isn't the most expensive one. It's the one that delivers the highest return on your investment. But with so many options, how do you choose right?

Before You Write That Check: Ask Yourself These Questions

What Stone Are You Actually Cutting?

This sounds obvious, but you'd be surprised how many people get this wrong. Each material demands different treatment:

- Granite: Extremely hard. Needs serious power and premium diamond tools. Don't even think about cutting corners on blade quality.

- Marble: Softer, but chips easily. Precision beats power here.

- Engineered Quartz: Often harder than granite. Requires specialized diamond tools and robust machines.

How Much Volume Can You Really Handle?

Be brutally honest about your capacity. Your production volume dictates everything:

- Small Shops: Manual or semi-automatic bridge saw. Reliable, affordable, gets the job done.

- Growing Businesses: CNC stone cutting machine. Automation pays for itself when you're busy.

- High-Volume Operations: Multi-wire saws and production lines. Economics of scale start making sense.

Granite Cutting Machine Types Breakdown

Bridge Saws: The Workhorse

What it does: Straight cuts on slabs. That's it, but it does it really well.

Best for: Countertop shops, tile production, high-volume straight cutting.

Reality check: Limited to simple cuts. Can't do curves or intricate work. But for basic production? Unbeatable reliability.

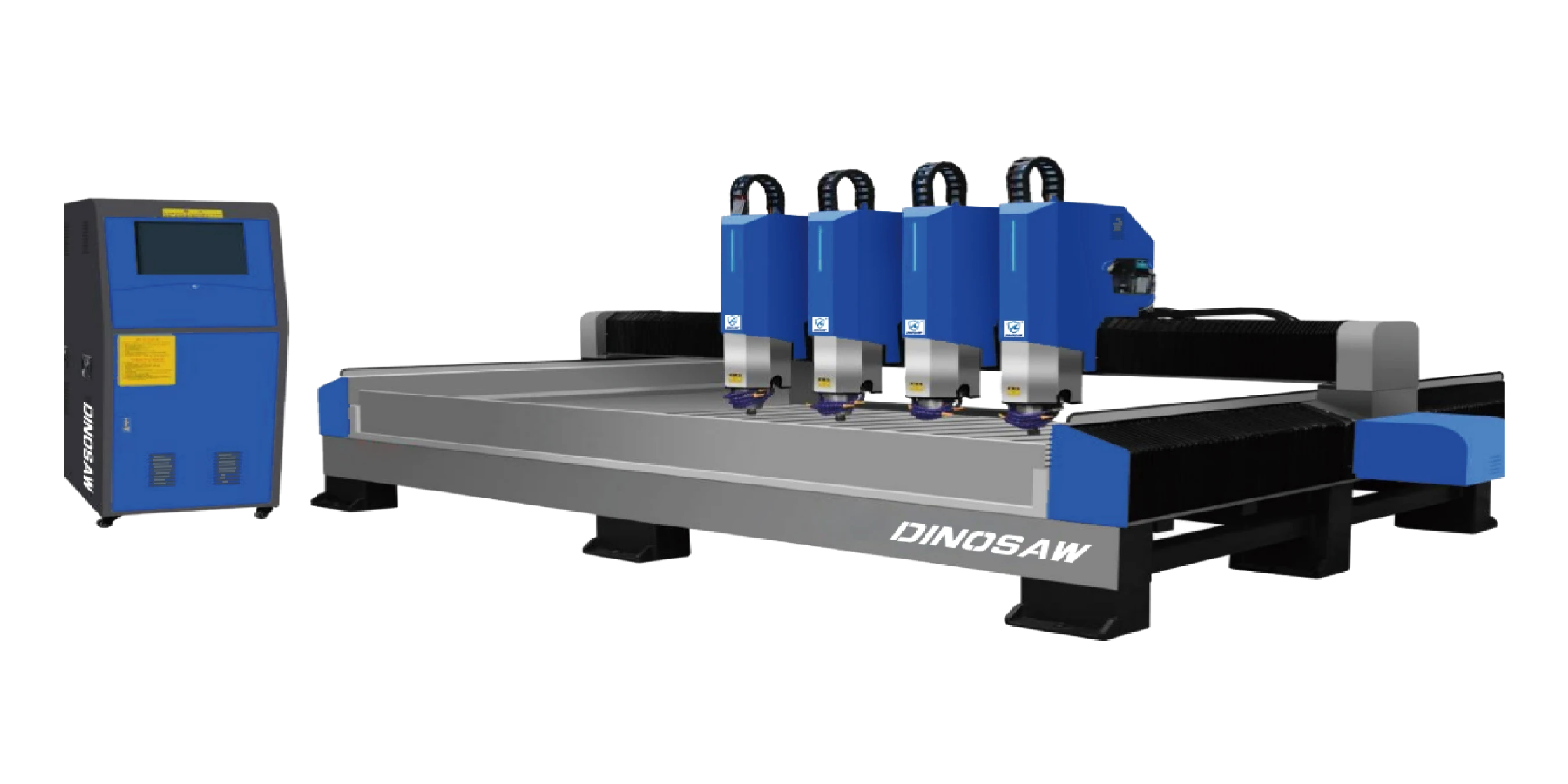

CNC Stone Routers: Precision King

What it does: Complex shapes, carvings, drilling, polishing. Computer-controlled precision.

Best for: Custom work, sinks, monuments, decorative pieces with high margins.

Reality check: Higher investment and learning curve. But once you master it? Game changer for custom jobs.

Waterjet Cutters: The Perfectionist

What it does: Cuts anything with extreme precision. No heat, no stress, perfect edges.

Best for: Ultra-thin materials, glass, complex shapes, premium projects.

Reality check: Expensive to buy and operate. Slow cutting speeds. But when precision is everything? Nothing beats it.

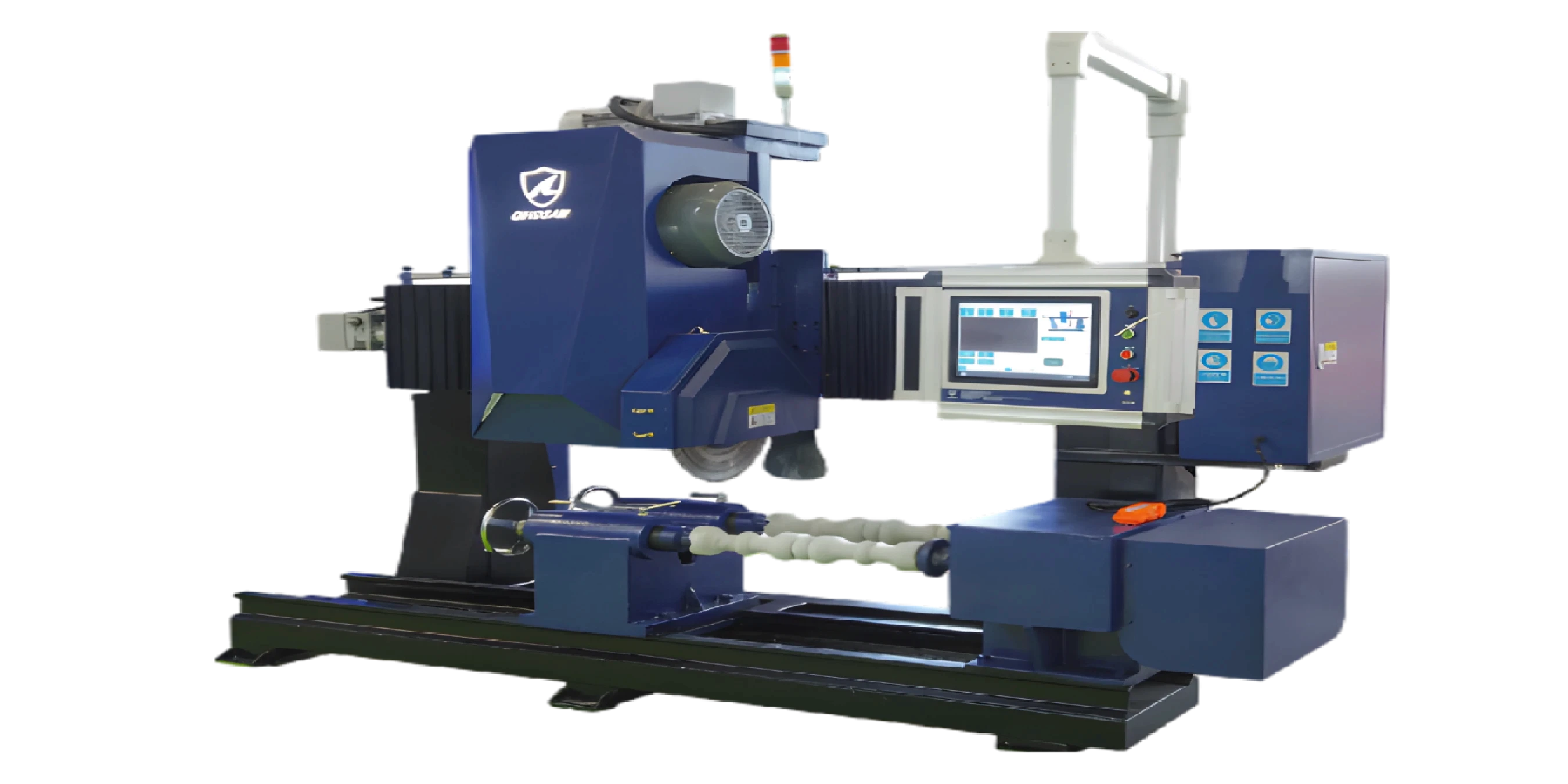

Stone Lathes: The Specialist

What it does: Turns stone blocks into columns, balusters, perfectly round shapes.

Best for: Architectural elements, fountains, custom rounded pieces.

Reality check: Very specific application. If you need round shapes, it's essential. Otherwise? Skip it.

The Granite Cutting Machine Real Cost: Beyond the Sticker Price

Here's where most people mess up. They focus on the purchase price and ignore everything else. Big mistake. The total cost of ownership includes:

Hidden Costs That Add Up Fast

- Installation and Training: Budget 10-15% of machine cost for proper setup and operator training.

- Consumables: Diamond blades, wires, and bits aren't cheap. Quality tools cost more but last longer.

- Maintenance: Regular service keeps your machine running. Skip it and you'll pay triple later.

- Energy and Water: Some machines are power hungry. Factor in utility costs.

Technical Specs of Granite Cutting Machine That Actually Matter

Don't get lost in the spec sheets. Focus on what actually affects your bottom line:

Power and Speed: Where the Magic Happens

Higher power (kW) means faster cuts through hard materials. Higher spindle speed (RPM) gives you cleaner finishes. But here's the thing: balance matters more than peak numbers.

Accuracy: Where Profits Are Made

Cutting accuracy determines material waste. Poor accuracy means rework, which kills profitability. Look for machines with precision linear guides and robust control systems.

Maintenance: The Make-or-Break Factor

Want to know the difference between a 5-year machine and a 20-year machine? Maintenance. Here's your survival guide:

- Daily: Clean dust and debris, check water levels, lubricate moving parts. Takes 15 minutes, saves thousands.

- 📊 Weekly: Inspect hydraulic lines, electrical connections, blade tension. Catch problems before they become disasters.

- 🔧 Monthly: Deep cleaning, wear inspection, safety feature testing. Your machine will thank you with years of reliable service.

Your Step-by-Step Buying Strategy of Granite Cutting Machine

- Audit Your Needs: Current volume, growth projections, material types. Be realistic.

- Set Your Budget: Include installation, training, and first-year operating costs.

- Research Manufacturers: Reputation matters. Look for established companies with local support.

- See Demonstrations: Don't buy sight unseen. Watch the machine work with your materials.

- Calculate ROI: How quickly will increased productivity pay for the machine?

Common Questions of Granite Cutting Machines

Bridge saw vs CNC router - what's the real difference?

Simple: bridge saws do straight cuts fast and reliable. CNC routers do complex shapes with computer precision. If you're doing basic countertops, bridge saw wins. Custom sinks and intricate work? CNC router pays for itself.

Is a waterjet worth the extra cost?

Depends on your work. Diamond saws are faster and cheaper for most granite work. Waterjets shine with delicate materials, ultra-thin pieces, or when you need absolute precision. But they're expensive to buy and operate.

How long should a quality machine last?

A well-maintained machine from a reputable manufacturer should give you 15-20 years of solid service. But that's only if you maintain it properly. Skip maintenance and you'll be shopping for a replacement in 5 years.

Can I finance a machine purchase?

Most manufacturers offer financing options. Equipment loans typically range from 3-7 years with competitive rates. The key is making sure your increased productivity can cover the monthly payments plus operating costs.

What about used machines?

Used can be a smart choice if you know what to look for. Check maintenance records, inspect for wear, and factor in potential repair costs. Sometimes a well-maintained 5-year-old machine is better than a cheap new one.

Bottom Line: You're Not Just Buying a Machine

You're investing in your business's future. The right granite cutting machine doesn't just cut stone—it cuts costs, reduces waste, and opens new revenue opportunities. Take time to evaluate your needs, understand the total costs, and choose a manufacturer who'll stand behind their equipment.

Remember: the most expensive mistake isn't buying the wrong machine. It's buying cheap and having to replace it in three years. Invest wisely, maintain properly, and your machine will be the foundation of a profitable business for decades.

English

English 中文

中文