Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Facing bridge saw problems like inaccurate cuts, blade wobble, or chipping? Our troubleshooting guide helps you fix 10 common issues. Save time on repairs.

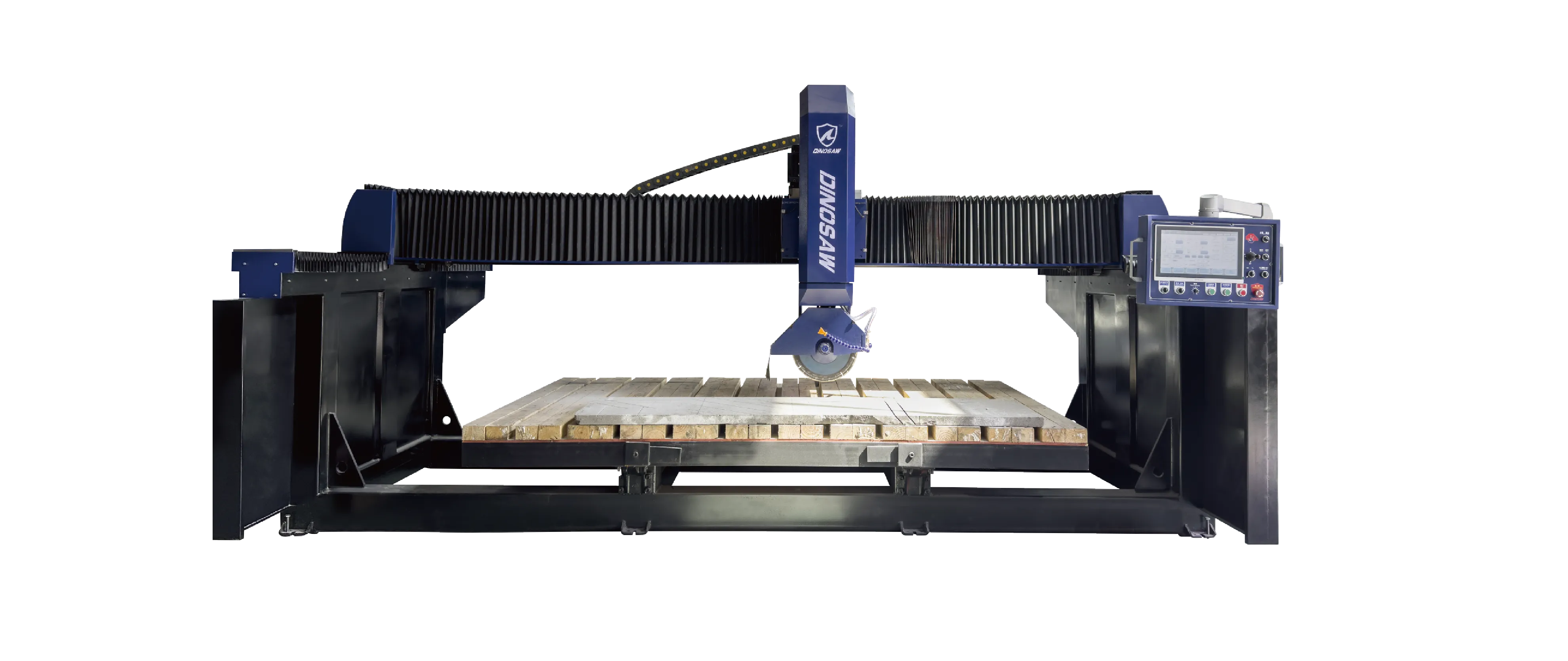

Your bridge saw is the backbone of your stone fabrication operation. When it breaks down, everything stops. Revenue disappears. Projects get delayed. Customers get frustrated.

The good news? Most common issues don't need a costly service call. With the right knowledge, you can diagnose and fix many problems yourself, getting back to cutting granite, quartz, and other materials quickly.

This bridge saw troubleshooting guide covers the ten most frequent issues you'll encounter. We'll show you exactly what to look for, how to fix it safely, and when to call for professional help.

Safety First: Your Pre-Repair Checklist

Never skip safety protocols. Even simple repairs can turn dangerous without proper precautions. One mistake can injure your team or damage expensive equipment beyond repair.

Power Down Completely: LOTO Procedures

Hit the emergency stop button? That's not enough. You need complete Lockout-Tagout (LOTO) Procedures following OSHA guidelines .

Shut off the main breaker. Lock it. Tag it. Only then is it safe to work.

Essential PPE for Maintenance

Gear up properly before touching anything:

- Safety glasses with side shields

- Cut-resistant gloves for blade work

- Steel-toed boots

- Hearing protection for testing

Know When to Stop

This guide handles common issues. But some problems need professional expertise. Call a technician if:

- You're unsure about any procedure

- Electrical components or PLC/CNC controllers are involved

- You lack the right diagnostic tools

- The problem persists after your fix

DINOSAW owners get priority access to our professional after-sales service for complex repairs.

Problem 1: Cuts Aren't Straight or Square

Nothing ruins expensive granite or quartz slabs faster than inaccurate cuts. When your saw starts drifting, quality suffers immediately.

Cause A: Misaligned Bridge Rails

Heavy use and vibration knock your bridge out of alignment over time. Even small deviations create noticeable cutting problems.

How to Fix It:

- Clean everything first. Stone dust hides alignment issues.

- Check with a precision square. Run it along both X and Y axes.

- Look for gaps. Consistent spacing means good alignment.

- Adjust gradually. Loosen rail bolts slightly, adjust, then re-tighten to spec.

Cause B: Worn Blade Flange or Arbor

The blade flange keeps your cutting disc perpendicular. When it warps or the arbor bearings wear out, cuts start wandering.

How to Fix It:

- Power down and remove the blade following LOTO procedures.

- Inspect flanges carefully. Look for warping, nicks, or embedded debris.

- Test arbor play. Wiggle the shaft gently. Any movement means worn bearings.

- Replace if needed. Bearing replacement typically requires professional service.

Problem 2: Blade Wobbles or Vibrates Excessively

A wobbling diamond blade is dangerous and destroys cut quality. Address this immediately before someone gets hurt.

Cause A: Improperly Seated Blade

Dropped blades or poor installation create wobble. Even tiny misalignments become major vibrations at high RPM.

Step-by-Step Fix:

- Complete lockout of all power sources.

- Remove and inspect the blade thoroughly.

- Clean everything. Blade, flanges, and arbor surfaces must be spotless.

- Check for damage. Never use a warped or cracked blade.

- Reinstall carefully. Seat flush against the inner flange.

- Tighten in a star pattern to manufacturer torque specs.

Cause B: Failing Spindle Bearings

Worn spindle bearings create vibration that transfers directly to your blade. The problem gets worse under load.

Diagnosis Method:

With power off and blade removed, hand-rotate the arbor. Smooth rotation is normal. Grinding, roughness, or noise means bearing failure. This repair needs professional attention.

Problem 3: Chipping on Stone Materials

Chipping destroys profitability. Re-polishing takes time. Ruined slabs cost money. Prevention beats repair every time.

Cause A: Wrong Blade or Worn Segments

Using a marble blade on quartzite? That's asking for trouble. Worn diamond segments hammer stone instead of cutting it cleanly.

The Solution:

Match your blade to your material. Hard granite need specialized diamond blades for granite designed specifically for its hardness. Stone World Magazine regularly covers advances in blade technology that reduce chipping.

Cause B: Wrong Cutting Parameters

Pushing too fast or running incorrect RPM forces diamonds to tear through stone. The result? Ugly chips and fractures.

Parameter Adjustments:

- Slow your feed rate especially on entry and exit.

- Check blade RPM against manufacturer recommendations.

- Listen to your machine. Struggling sounds mean you're pushing too hard.

Problem 4: Water System Problems

No water means disaster. Blade cooling stops working. Diamond segments overheat. Cutting quality plummets within seconds.

Cause A: Clogged Nozzles

Stone slurry builds up fast. Those tiny water nozzles clog easily, starving your blade of essential cooling.

Cleaning Process:

- Shut off water and power completely.

- Remove nozzles and scrub with a wire brush.

- Blow out water lines with compressed air.

- Reassemble and test water flow before cutting.

Cause B: Water Pump Failure

Clean nozzles but still low pressure? Your water pump might be failing or have a blocked intake filter.

Pump Troubleshooting:

- Check the intake filter for debris buildup.

- Listen while running. Unusual noises indicate bearing problems.

- Look for leaks around the pump housing.

- Replace if necessary - pumps are relatively inexpensive compared to blade damage.

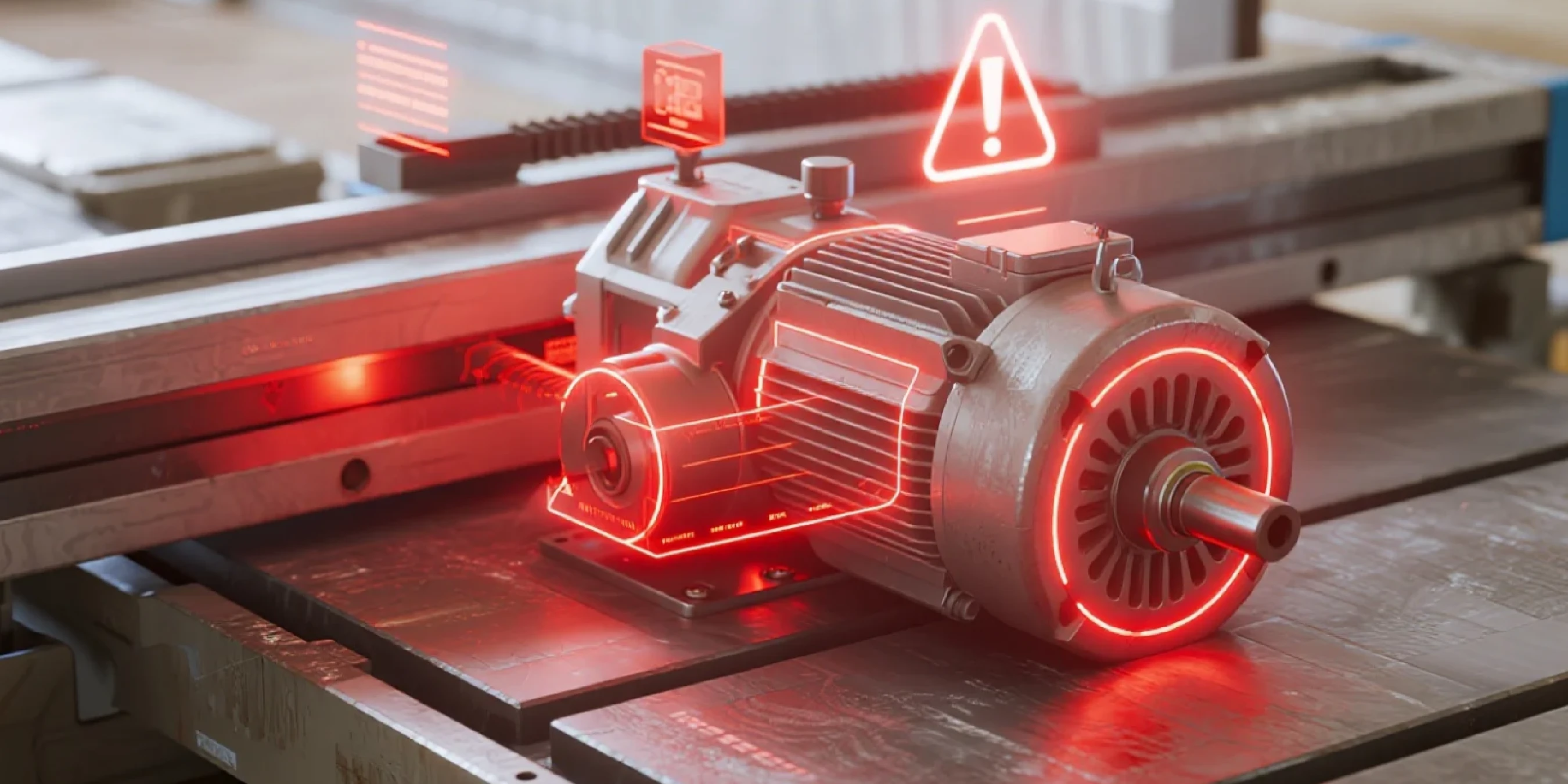

Problem 5: Motor Overheating

An overheated motor shuts down automatically to prevent permanent damage. Understanding why saves expensive repairs.

Cause A: Overloading from Fast Cutting

Pushing your saw beyond its limits overworks the motor. Thermal overload protection kicks in to prevent burnout.

Smart Feed Rate Control:

Listen to your machine's voice. Consistent motor sound means proper loading. Bogging down or whining means you're pushing too hard. Back off immediately.

Cause B: Electrical Issues

Low voltage, loose connections, or failing contactors make motors work harder than necessary. Heat buildup follows quickly.

Power Supply Check:

This needs qualified electrical expertise. Have an electrician verify:

- Voltage under load

- All control panel connections

- Contactor operation

Problem 6: Jerky Gantry Movement

Smooth cuts need smooth movement. Stuttering or jerky motion ruins surface finish and wastes material.

Cause A: Dirty Rails or Worn Wheels

Stone debris on guide rails creates bumpy movement. Worn or flat-spotted guide wheels make it worse.

Rail Maintenance:

- Clean all rails thoroughly along their entire length.

- Inspect each guide wheel for damage or flat spots.

- Lubricate properly following your maintenance schedule.

Cause B: Drive Motor Problems

Servo motors, stepper motors, and encoders control precise movement. When they fail, movement becomes erratic.

Encoder Fault Signs:

Watch for inconsistent positioning or error codes on your CNC screen. These electronic issues typically need professional diagnosis.

Problem 7: Frozen Control Screen

A locked-up PLC or CNC controller stops everything instantly. Quick action gets you running again.

Common Causes

Software glitches or power fluctuations freeze control systems just like any computer.

Proper Restart Procedure:

- Try controlled shutdown using the main power-off button first.

- If that fails, use the main electrical disconnect.

- Wait 2-3 minutes for complete discharge.

- Power back up and check for normal operation.

If problems persist after restart, you likely have hardware or software issues needing technical support.

Problem 8: Oil Leaks

Oil leaks create mess and indicate bigger problems developing. Catch them early to prevent major failures.

Finding the Source

Clean the area completely with degreaser. Run the machine briefly (if safe) and watch for fresh oil to pinpoint the exact leak location.

Tightening Fittings

Most leaks come from hydraulic fittings loosened by vibration. Gently tighten with proper wrenches. Don't overtighten - you'll damage threads.

For persistent leaks, hoses or seals need replacement.

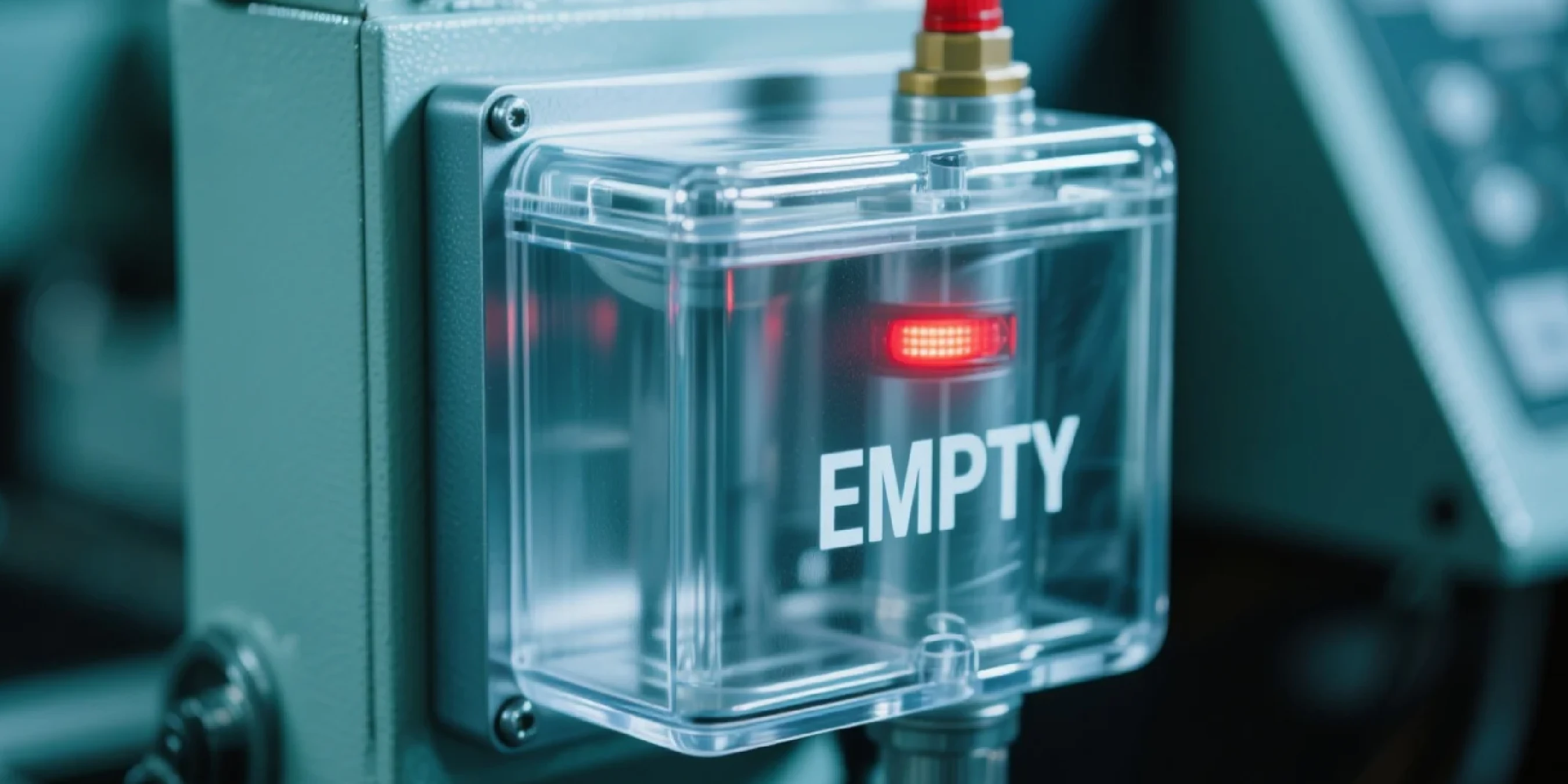

Problem 9: Auto-Lubrication Failure

Modern saws use automatic lubrication systems to keep components moving smoothly. System failure accelerates wear dramatically.

Most Common Cause: Empty Reservoir

Check the obvious first. Oil reservoir levels drop over time. Refill with manufacturer-recommended lubricant.

System Check Process:

- Verify oil level in the main reservoir.

- Inspect distribution lines for clogs or damage.

- Check the manifold for proper operation.

Problem 10: Blade Won't Raise or Lower

Z-axis movement failure prevents cutting entirely. Hydraulic or mechanical issues cause most problems.

Cause A: Hydraulic Problems

Many saws use hydraulics for vertical movement. Low fluid or pump failure stops operation.

Hydraulic Check:

Verify hydraulic fluid level and top off as needed. If levels are good, pump or solenoid problems may need professional attention.

Cause B: Mechanical Obstruction

Physical blockages or failed limit switches prevent proper movement.

Limit Switch Inspection:

Check upper and lower limit switches for cleanliness and proper mechanical activation. Failed switches need electrical expertise for replacement.

Prevention Beats Repair: Proactive Maintenance

The best repair strategy? Prevent problems before they happen. Regular bridge saw maintenance keeps your saw running reliably.

- Daily: Clean thoroughly, check water flow

- Weekly: Lubricate moving parts, inspect blades

- Monthly: Deep mechanical inspection, alignment checks

Quality equipment makes a difference too. DINOSAW machines are built for reliability with comprehensive support backing.

Frequently Asked Questions

How often should I professionally service my bridge saw?

Annual professional service is highly recommended. Qualified technicians perform deep inspections, precision calibration, and preventative maintenance that prevents costly breakdowns.

What causes granite chipping most often?

Wrong blade type combined with aggressive feed rates. Granite needs high-quality segmented diamond blades designed specifically for hard crystalline stones. Pushing too fast makes diamonds hammer instead of grind.

How do I know when my blade is dull?

Watch for increased chipping, slower cutting speeds, motor strain (sound changes), and glazed diamond segments. Sparks during cutting mean the metal bond is grinding stone instead of diamonds.

Can I use a blade with missing segments?

Never. Missing segments create dangerous imbalance causing extreme vibrations and potential catastrophic failure. Remove damaged blades immediately.

What do bridge saw repairs typically cost?

Service calls range from hundreds to thousands depending on the issue. Simple fixes cost less, while spindle bearing replacement or CNC controller problems cost more. This is why investing in reliable CNC bridge saws with strong warranties makes financial sense.

Why are my cuts angled instead of vertical?

Out-of-plumb cutting happens when the blade isn't perfectly perpendicular to the table. Causes include warped blades, damaged flanges, or cutting head misalignment. Use a precision square to check and adjust blade alignment.

English

English 中文

中文