Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Technical guide to stone lathe components. Compare vertical vs horizontal lathes, PLC vs CNC control, spindle motor for granite, and tooling like the diamond profiling wheel.

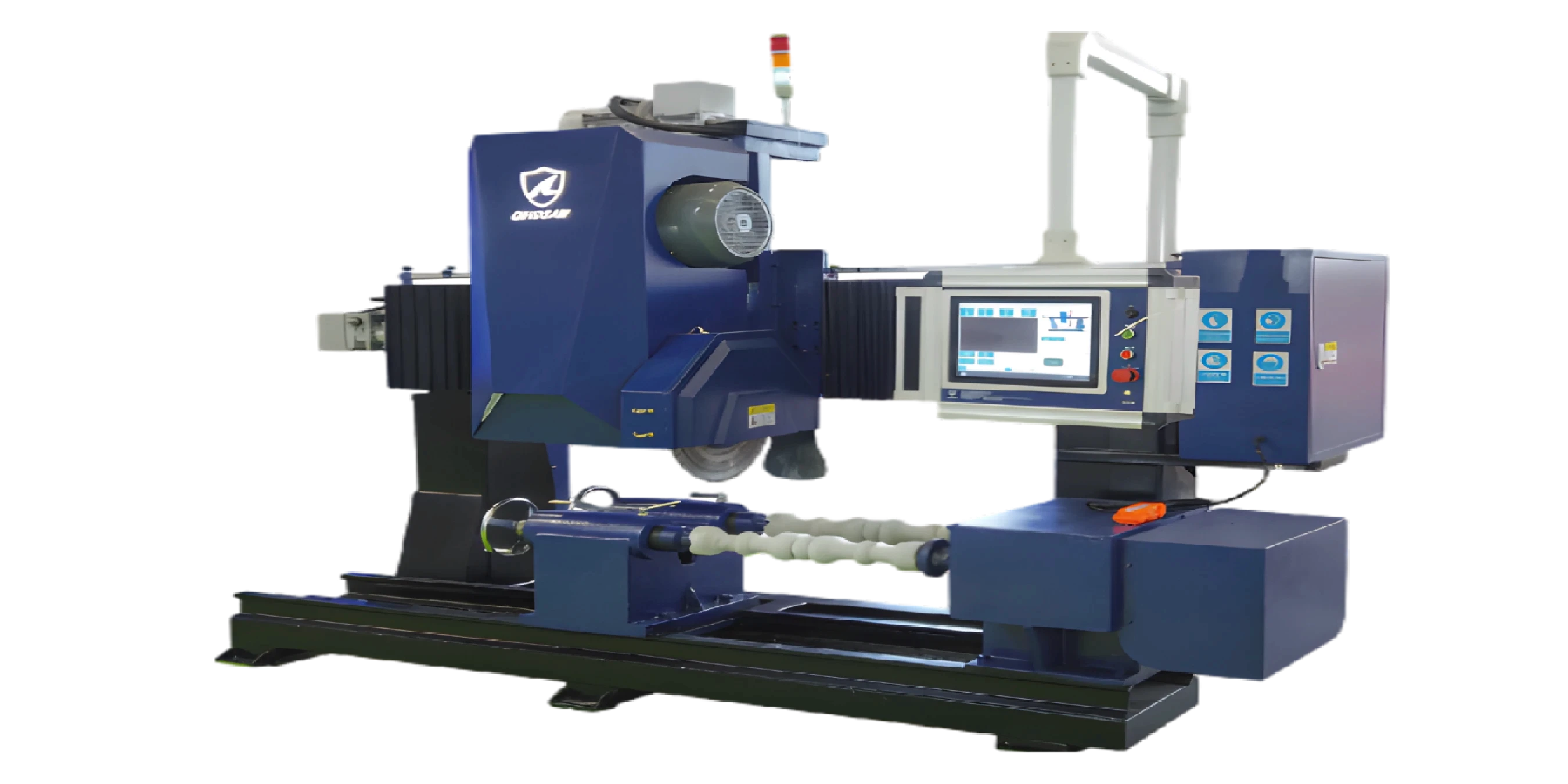

For engineers and maintenance professionals, understanding a machine's architecture is key to maximizing its performance and lifespan. This technical guide translates the structure of our stone lathe CNC machines-from the PLC vs CNC controls to the vertical or horizontal frame-into practical knowledge and parameter windows you can apply on day one.

We will deconstruct the core stone lathe components to clarify their function, capabilities, and impact on production. The goal is to move beyond marketing specifications and provide a clear, actionable framework for evaluating and operating the machine.

Request starter parameter ranges for your specific stone type (granite/marble).

What This Stone CNC Machines Is: A Technical Definition

Technically, a CNC stone lathe is a machine tool that rotates a stone workpiece on an axis of rotation to perform various operations such as cutting, profiling, and drilling. This model is configured with a CNC (Computer Numerical Control) system as standard for maximum programmability and precision, with a PLC (Programmable Logic Controller) option available for dedicated, high-volume repetitive tasks.

Architecture: Vertical vs Horizontal Stone Lathe

The machine's architecture is the foundation of its stability and precision. The core components include the bed, spindle, guideways, tool post, control system, and HMI (Human-Machine Interface). The choice between a vertical stone lathe and a horizontal stone lathe is a critical architectural decision:

- Horizontal Lathe: Ideal for long, slender workpieces like columns and balusters. The horizontal orientation provides easy access for setup and allows for support from a tailstock, minimizing deflection and vibration.

- Vertical Lathe: Better suited for heavy, large-diameter, but shorter parts. Gravity assists in seating the workpiece securely in the chuck, which simplifies clamping and can improve stability for certain geometries.

Key Stone Lathe Components & Parameter Windows

Understanding the function and limits of each component is crucial for maintenance and operation.

Spindle Motor

The heart of the lathe, providing the rotational power. A high-torque spindle motor for stone is essential for maintaining constant speed under heavy loads.Parameter Window: Speed/Power are model-dependent and sized for stone-class loads.

Guideways

High-precision linear guideways ensure smooth, accurate movement of the tool post. Regular lubrication and cleaning are critical to prevent wear and maintain accuracy.Maintenance: Lubrication per maintenance schedule; daily checks with weekly top-ups.

Stone Chuck Fixture

The stone chuck fixture must securely grip various workpiece diameters without causing stress fractures. Hydraulic or manual clamping options are available.Parameter Window: Clamping diameter is model-dependent; confirm against workpiece size.

Tooling System

Accommodates tools like a diamond segment blade. The rigidity of the tool post is critical for preventing chatter and achieving a fine surface finish.Tool Capacity: Tool capacity varies by configuration; confirm at order.

Control System (PLC vs CNC)

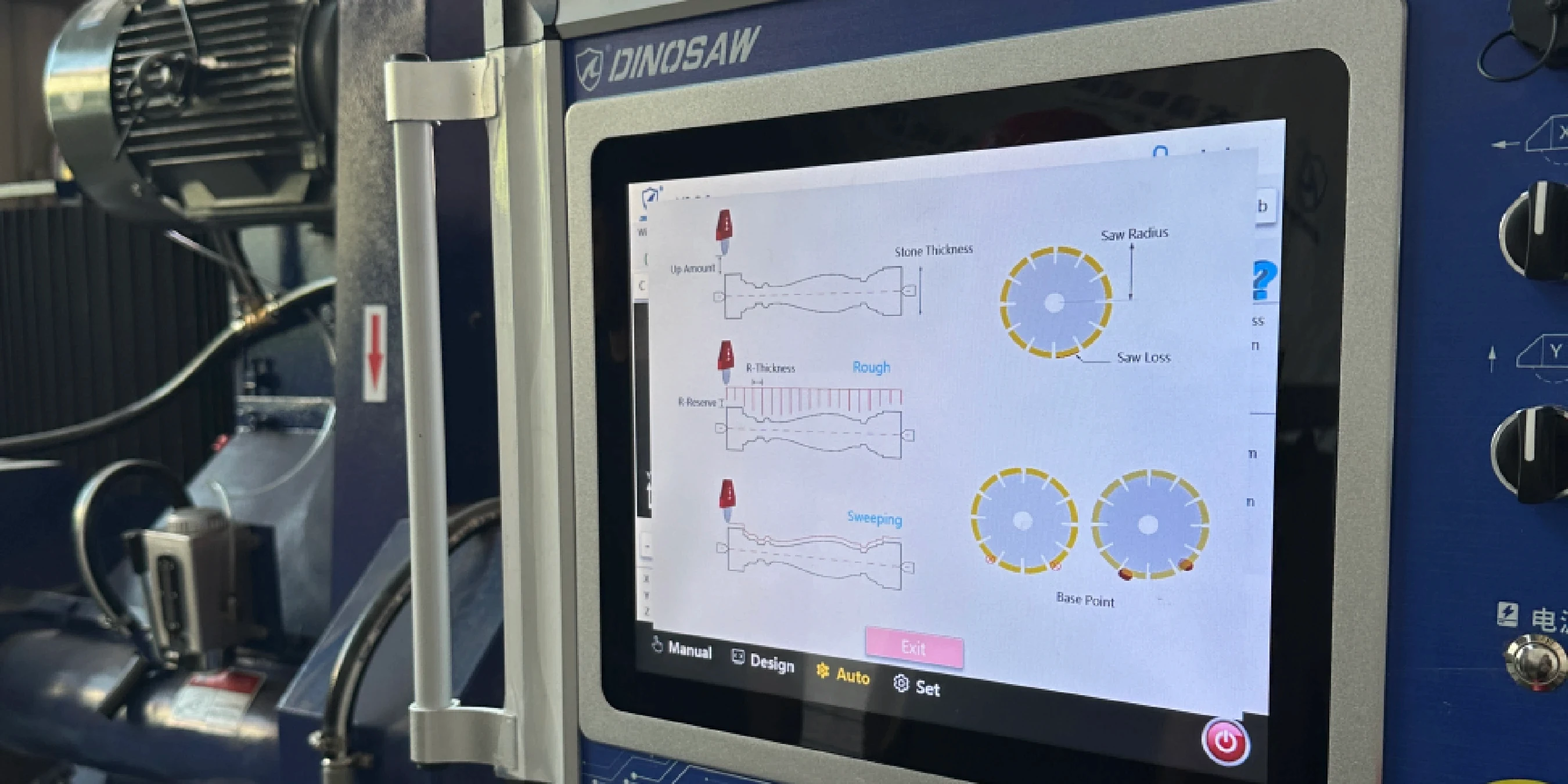

The CNC offers superior flexibility for complex profiles via G-code, while the PLC is simpler and more robust for fixed tasks. The HMI provides the interface for operation and diagnostics. For a deeper dive, see our article on How to Choose the Right Stone Lathe: CNC vs. PLC.

Operation Modes: Provided via the HMI: a Manual mode for direct jogs (tool up/down, spindle lift, etc.) and an Automatic mode with selectable routines (rough, fine, profiling), each started/stopped by the main motor button for safe control.

Coolant & Dust System

A high-volume coolant & dust system is non-negotiable for tool life and operator safety. It suppresses silica dust and prevents thermal damage to the tooling and workpiece.Flow Rate: Ensure continuous high-volume wet cutting and directed coolant flow.

Safety Interlocks

These are critical safety interlocks that prevent machine operation if guards are open or an E-stop is triggered, ensuring compliance with machine safety standards.

Failures & Mitigation for a Stone Turning Machine

| Symptom | Potential Cause | Diagnosis & Action |

|---|---|---|

| Excessive Runout | Worn spindle bearings; improper workpiece clamping. | Check spindle for play. Re-clamp and center the workpiece. If play persists, schedule bearing replacement. |

| Vibration/Chatter | Unbalanced workpiece; worn or incorrect tooling; feed/speed incorrect. | Reduce RPM. Check tool for wear. Ensure workpiece is balanced and supported. |

| Poor Surface Finish | Dull tooling; incorrect cutting parameters; insufficient coolant. | Replace or dress the diamond tool. Adjust feed rate and RPM for a finishing pass. Verify coolant is directed at the cutting zone. |

Request a Technical Consultation

Our engineering team is ready to help you match our machine's capabilities to your specific technical requirements. Contact us to discuss your application and receive a full component specification sheet for the stone profiling machine.

Frequently Asked Questions

When is PLC vs CNC control recommended for a stone lathe?

Choose CNC for varied or custom profiles; choose PLC for repetitive, standard parts.

- Flexibility: CNC uses G-code, allowing for complex geometries and easy changes.

- Total Cost of Ownership (TCO): PLC has lower operational complexity, making it more cost-effective for high-volume batch runs.

Vertical vs horizontal stone lathe - rigidity & finish differences?

Horizontal lathes offer better support for long parts, while vertical lathes excel at stabilizing heavy, large-diameter parts.

- Roundness: The support from a horizontal lathe's tailstock reduces deflection, leading to better roundness on long workpieces.

- Face Work: A vertical lathe is superior for face-turning operations on heavy parts, as gravity assists with stable clamping.

- Summary: A horizontal lathe provides better support for long parts, reducing vibration and improving finish. A vertical lathe uses gravity to stabilize heavy, large-diameter parts, which enhances rigidity for those specific geometries, often resulting in a superior finish for face-turning operations.

Typical size limits for the stone chuck fixture?

The size limit is model-dependent and should be confirmed based on your workpiece.

- Small Lathes: Can handle up to Ø ~400mm.

- Large Lathes: Can accommodate diameters up to Ø ~1500mm or more.

- Note: Proper clamping pressure and surface cleanliness are critical for a secure grip.

How do safety interlocks & coolant/dust systems reduce risk?

They prevent physical access to moving parts and control silica dust exposure.

- Interlocks: Automatically stop machine motion if a guard door is opened or an E-stop is pressed, preventing injury.

- Wet Cutting: The coolant system suppresses harmful silica dust at the source, protecting operator health and helping maintain a compliant work environment.

English

English 中文

中文