Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Navigate the full CNC stone carving workflow, from digital drawings to finished production. Compare 3-axis vs 5-axis machine performance to scale output, avoid costly purchasing pitfalls, and master high-efficiency, low-cost sculpting strategies.

What happens when ancient stone carving meets modern CNC technology? Everything you need to know about equipment, software, and techniques to create stunning stone artwork.

CNC technology has revolutionized the ancient art of stone carving, replacing hammer and chisel with computer-controlled precision that transforms how we create sculptural masterpieces.

Turning ideas into finished stone pieces requires understanding the right equipment, mastering software workflows, and handling different stone personalities-granite's tough as steel, while marble's more forgiving.

This guide covers equipment selection, design workflow, and common pitfalls to help you create beautiful pieces and build a profitable business. Contact DINOSAW experts for personalized Stone Carving equipment guidance tailored to your specific needs.

What Exactly Is CNC Stone Carving and Why Is It Taking Off?

💡 Simply Put: It's Computer-Controlled Stone Sculpting

CNC stone carving lets computers control machines to sculpt stone. Instead of needing chisels and hammers, the machine follows your 3D design and precisely cuts away material bit by bit. The whole process runs automatically-you just need to monitor it.

This technology is everywhere now. From park sculptures and monuments to kitchen countertops and decorative panels, even complex architectural details-CNC can handle it all.

🎯 Three Big Advantages: Precision, Speed, Creative Freedom

- 🎨 Unlimited Design: Complex geometric patterns, intricate textures, detailed 3D carving-if you can design it, the machine can make it.

- 🎯 Unbeatable Precision: Machines achieve accuracy far beyond human hands- down to millimeter-level precision. Your design gets reproduced exactly, every detail intact.

- ⚡ Incredible Efficiency: One machine can work 24/7, processing at speeds dozens of times faster than manual work. That means more orders and more profit.

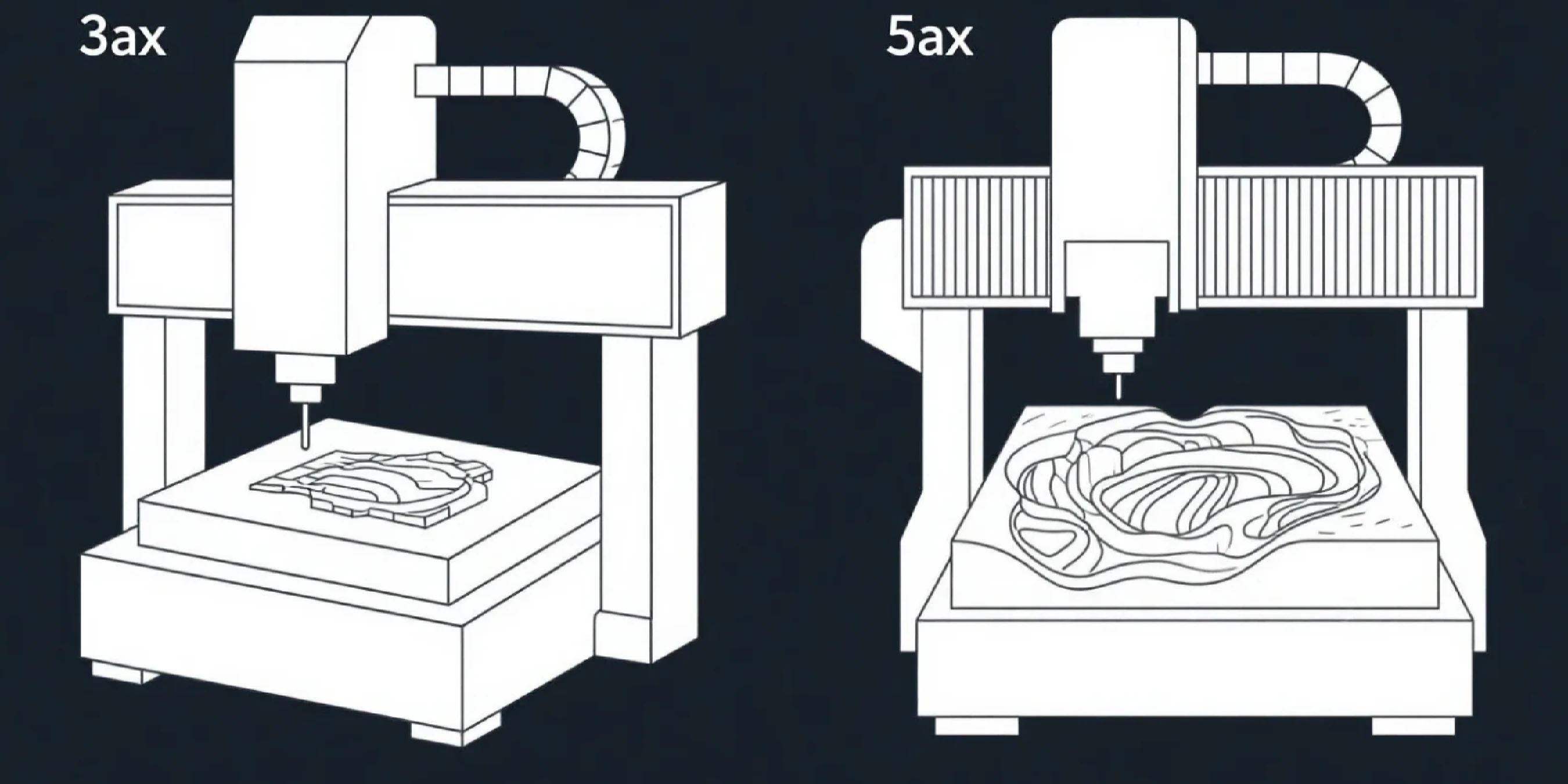

Choosing Your CNC Stone Machine: 3-Axis vs 5-Axis?

Picking equipment is the most critical decision-it directly determines what kind of work you can do. Many beginners get overwhelmed here, not knowing what to buy. Really, it comes down to your needs and budget.

🤔 Axis Selection: Get What You Need, Don't Overspend

✅ 3-Axis CNC Machines

Most common and budget-friendly choice. Handles flat designs, relief carving, lettering, and simple 3D shapes.

Best for: Signs, tombstones, decorative panels, simple sculptures

Price range: $10,000 - $50,000

⭐ 5-Axis CNC Machines

Adds two rotational axes, allowing carving from multiple angles without repositioning. Essential for complex full-round sculptures.

Best for: Full 3D sculptures, complex art pieces, precision components

Price range: $100,000 - $500,000+

⚙️ Key Specs That Actually Matter

🔌 Spindle Power: Your Cutting Force

Spindle power directly determines what stone hardness you can handle. Hard materials like granite need serious power or they'll just laugh at your attempts.

- Soft stones (marble, limestone): 3-5 kW works fine

- Medium stones (sandstone): 5-7 kW gives you comfort

- Hard stones (granite, quartz): 7+ kW is essential

🏗️ Machine Rigidity: Stability Beats Everything

Stone carving generates massive forces. Your machine frame must be rock-solid. Any vibration kills precision and can destroy tools.

Quality machines use heavy-duty welded steel frames. They weigh twice as much as cheap alternatives but it's worth every pound.

📏 Work Area: Size According to Projects

Common sizes include 1325 (1300×2500mm), 1530 (1500×3000mm), and larger. Remember: buy bigger rather than smaller-upgrading later costs a fortune.

🔧 Tool Selection: Using the Right Carving Bits

Stone carving demands specific tooling. Choose wrong and you'll get poor results plus equipment damage.

💎 Diamond Carcing Bits vs Carbide Carcing Bits

For natural stone, diamond tools are non-negotiable. Carbide tools only work on wood or plastic-they'll dull in minutes on stone.

✅ Diamond Carcing Bit Benefits:

- Ultra-hard, designed for stone

- Long-lasting despite higher cost

- Smooth cutting action

❌ Carbide Carcing Bits :

- Not hard enough, dulls quickly

- Chips easily, poor finish

- Only good for soft materials

🛠️ Essential Carcing Bit Types and Applications

- Ball End Mills: Perfect for carving smooth curves and 3D forms. Essential for figurative sculptures, organic shapes. Common sizes: 6mm, 8mm, 10mm

- Flat End Mills: Used for roughing operations-quickly removing large amounts of material before detail work. Common sizes: 12mm, 16mm, 20mm

- V-Carving Bits: Specialized for lettering and line work. V-shape creates variable line widths based on cutting depth. Common angles: 60°, 90°, 120°

- Tapered Ball End: Combines ball end and taper benefits-handles fine detail work while reaching deeper areas. Common tapers: 6°, 10°, 15°

Software Workflow: From Design to Production

CNC carving is fundamentally digital manufacturing-software skills are crucial. Many people think software is complicated, but once you understand the basic workflow, it's quite manageable.

🎨 CAD Software: Turning Ideas into 3D Models

CAD (Computer-Aided Design) software is where your creativity becomes concrete 3D models.

- Fusion 360: Powerful with integrated CAD/CAM. Best for: Product design, mechanical parts

- ZBrush: Professional sculpting with rich detail. Best for: Artistic sculptures, character modeling

- Rhino: Precise modeling, excellent surfaces. Best for: Architectural details, jewelry

⚙️ CAM Software: Creating Machine Instructions

CAM (Computer-Aided Manufacturing) software converts 3D models into machine instructions. This step determines your final quality.

Recommended Software Combinations:

- Vectric Aspire: User-friendly interface, great for beginners, excellent relief capabilities

- ArtCAM: Professional carving software, comprehensive but steep learning curve

- PowerMill: Industrial-grade software, outstanding complex surface handling

🎯 Two Popular Design Approaches

🏛️ Relief Carving

Designs project from background surface while remaining connected. Common for decorative panels, monuments, building facades.

Technical points:

- Control relief depth, typically 2-10mm

- Smooth transition areas carefully

- Keep background treatment consistent

🕸️ Lattice Work

Complex geometric patterns creating decorative screens. Requires high machine precision-5-axis machines handle these much better.

Technical points:

- Ensure connection points are strong enough

- Avoid overly thin structures that break easily

- Plan machining sequence carefully

Hands-On Process: Raw Stone to Finished Piece

Theory only goes so far-actual hands-on experience is what matters. Here's the real production workflow with practical tips for each stage.

Step 1: Material Selection and Prep

Different stones have vastly different characteristics. Choosing the right material is half the battle.

- Granite: Extremely hard, weather-resistant, perfect for outdoor work but challenging to machine

- Marble: Relatively soft, excellent detail reproduction, ideal for fine carving

- Sandstone: Loose texture, easy to machine but generates lots of dust-proper ventilation essential

Step 2: Workpiece Securing

Stone must be absolutely solid on the machine bed. Any movement ruins the project and can damage equipment.

Common methods: Mechanical clamps, vacuum tables, custom fixtures

Check: Even clamping pressure, no deformation during machining

Step 3: Program Setup

Set toolpath parameters in CAM software, including roughing and finishing operations.

- Roughing: Quickly removes bulk material using large-diameter tools

- Finishing: Fine detail work using small precision tools

Step 4: Machine Operation

Once machining starts, close monitoring is crucial, especially for initial passes.

Monitor: Coolant flow, tool condition, sound changes

Emergency response: Stop immediately if problems arise

Step 5: Post-Processing

After machining, manual finishing and polishing are usually needed.

Tasks: Remove tool marks, detail refinement, surface polishing

Tools needed: Sandpaper, polishing compound, hand carving tools

Common Problems and Solutions: Avoiding Expensive Mistakes

Beginners often encounter various issues during actual operation. Small problems can become big headaches if not addressed. Here's some hard-earned practical experience.

❌ Problem 1: Stone Chipping and Cracking

Common causes:

- Dull tools creating excessive force

- Feed rate too aggressive

- Insufficient cooling

- Internal stone flaws

Solutions:

- Replace with sharp tools promptly

- Reduce feed rates appropriately

- Ensure adequate coolant flow

- Inspect material carefully before use

⚠️ Problem 2: Tool Breakage and Wear

Common causes:

- Insufficient machine rigidity causing vibration

- Improper cutting parameters

- Excessive tool overhang

- Poor workpiece clamping

Prevention:

- Choose high-rigidity machine equipment

- Follow manufacturer's recommended parameters

- Minimize tool extension length

- Verify workpiece holding security

💡 Problem 3: Poor Surface Finish

Affecting factors:

- Finishing tool selection

- Toolpath spacing settings

- Spindle speed matching

- Feed rate control

Optimization tips:

- Use tapered ball end finishing tools

- Reduce toolpath step-over distance

- Increase spindle RPM

- Appropriately reduce feed rates

Business Potential: How Much Money Can CNC Stone Carving Make?

📈 Industry Outlook: Market Looking Strong

According to Grand View Research's 2023 report, the global stone market is expected to exceed $100 billion by 2028. Demand for customized, high-end products continues growing-exactly where CNC technology shines.

💰 Revenue Models

- Custom carving services

- Batch production decorative items

- Architectural decoration projects

- Artwork creation and sales

🎯 Target Customers

- Architectural decoration companies

- Landscape design firms

- Memorial manufacturers

- Artists and designers

📊 Investment Returns

- Equipment investment: $100K-500K

- Payback period: 1-3 years

- Annual profit margin: 20-40%

- Market growth rate: 8-12%

💼 Success Story: Small Workshop, Big Business

A friend of mine was a traditional stone mason who invested $200K in CNC equipment in 2020. First year focusing on tombstones and simple decorative work, he hit $800K revenue. Second year he started taking architectural projects and broke $1.5M annual income.

Key success factors:

- Clear positioning: Focused on mid-to-high-end custom market, avoided price wars

- Complete service: Offered design-to-installation one-stop service

- Technical excellence: Continuously learned new techniques, improved capabilities

- Digital marketing: Used online platforms to showcase work, expanded customer base

Frequently Asked Questions

❓ What stones can CNC machines carve?

Almost all natural stones are possible, but difficulty varies:

- Easy: Marble, limestone, sandstone - great for beginners

- Medium: Bluestone, granite - need good equipment and experience

- Difficult: Quartz, basalt - require professional equipment and expertise

Beginners should start with marble, then tackle harder materials as skills develop.

💰 How much does a CNC stone setup cost?

Cost structure is complex-beyond the machine there are many supporting expenses:

Equipment costs:

- Entry-level 3-axis: $100K-250K

- Professional 3-axis: $250K-500K

- 5-axis machines: $500K-1.5M

Other expenses: - Facility setup: $50K-100K

- Tools and consumables: $20K-50K

- Software licenses: $10K-30K

- Training costs: $10K-20K

🕐 How long to learn CNC stone carving?

This varies by person, mainly depending on your background and time investment:

Learning timeline:

- Basic operation (1-2 months): Machine startup, basic operations, simple carving

- Intermediate skills (3-6 months): Software mastery, complex designs, parameter optimization

- Professional level (6-12 months): Independent design, batch production, troubleshooting

- Advanced applications (1+ years): Innovation design, process improvement, teaching others

Recommend finding proper training-having an instructor accelerates learning significantly. Many equipment manufacturers offer free training services.

🏗️ How large sculptures can CNC machines create?

Theoretically no limits-it depends on your equipment specs and technical skill:

- Small works (under 1 meter): Regular machines handle these fine, perfect for crafts and decorative items

- Medium sculptures (1-3 meters): Need large equipment, usually require 5-axis machines

- Large sculptures (3+ meters): Typically machined in sections then assembled

English

English 中文

中文