Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

A deep-dive into multi-wire saw technology. Learn about the core components, from the ±0.5 N constant-tension system to the rigid HT250 frame, that enable high-yield, precision cutting.

For engineers and procurement specialists, understanding a machine's underlying technology is crucial for evaluating its performance and reliability. This article provides a technical deep-dive into the system architecture and core components of the DINOSAW Intelligent Multi-Wire Saw, explaining how its design achieves superior results in stone slabbing.

Have a question or need a quote? Contact us now.

What Is a Multi-Wire Saw?

In engineering terms, a multi-wire saw is a specialized machine tool designed for high-throughput slabbing of large material blocks, primarily stone. It employs an array of multiple, parallel diamond-impregnated wires (typically 0.45–0.6 mm in diameter) moving at high speed (e.g., 30 m/s) to perform simultaneous cuts. This method produces a very narrow kerf, or cut width, of approximately 0.5 mm, which significantly minimizes material waste compared to traditional single-blade saws.

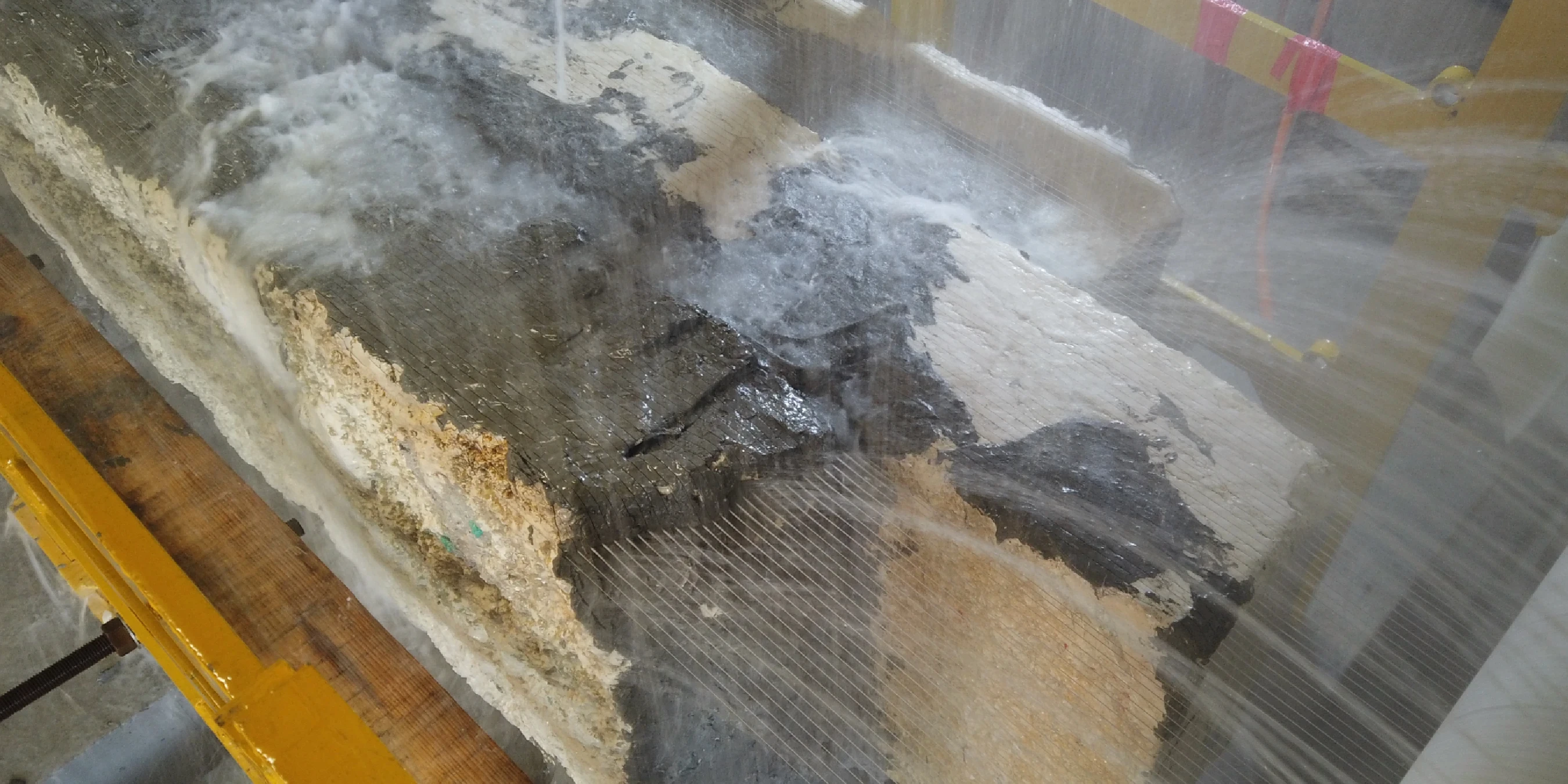

The machine's core function is to process large blocks (up to 3600×2200×2000 mm) into numerous thin slabs in a single operation. To ensure precision and stability during this high-speed process, the entire cutting mechanism is built upon a heavy, rigid frame (such as HT250 cast iron) and operates within a full enclosure that facilitates a mandatory wet cutting environment for cooling, lubrication, and dust/noise control.

How a Multi-Wire Saw Works

The cutting process follows a precise sequence of automated steps:

- Block Loading and Alignment: The raw stone block is securely loaded onto the machine's worktable and aligned for the cutting path.

- Wire Routing and Tensioning: A single, continuous diamond wire is routed through a circuit of guide pulleys to create the parallel wire array. The constant-tension control system then applies and maintains a precise, pre-set tension (with an accuracy of ±0.5 N) across the entire wire web to prevent deviation.

- Process Environment Initiation: The full enclosure is sealed. The wet cutting system activates, delivering a constant flow of coolant to the cutting zone, preparing for lubrication and slurry removal.

- Synchronized Motion Control: The 290 kW drive system powers the wire array to its operational speed of 30 m/s. Simultaneously, servo motors execute a controlled, pre-programmed down-feed, moving the cutting head vertically through the stationary block.

- Material Removal via Abrasion: As the high-speed wires move through the stone, the embedded diamond particles abrade the material, creating multiple, clean, and parallel cuts at once. The gentle abrasive action minimizes mechanical stress on the stone.

- Slurry Management and System Protection: The coolant flushes away the abraded stone dust (slurry), which is collected at the base. This process is managed to keep dust ingress below 0.1 mg/m³. Critical components like the oil-immersed traverse mechanism are sealed to an IP67 rating for protection. The collected slurry is then pumped to a filtration system for reuse.

- Cut Completion and Retraction: Once the wire array has passed completely through the block, the motion system retracts the cutting head, and the tensioning system automatically de-tensions the wire, completing the cycle.

System Architecture Overview

The machine's architecture is built around a philosophy focused on stability, precision, and efficiency. The system can be broken down into a mechanical structure, a cutting system, a motion control system, and a process management system.

- Mechanical Structure: A heavy, rigid HT250 cast-iron one-piece frame designed to absorb vibrations (amplitude reduced by 20%) and ensure geometric stability during high-speed (30 m/s) wire movement.

- Carbon-Fiber Rollers: These rollers, with a density of 1.7 g/cm31.7g/cm3 (a quarter of steel) and an elastic modulus of 230 GPa, contribute to stability and have a lifetime extended by approximately 200%.

- Cutting System: Comprises the multi-wire array, drive wheels, and the active tensioning system. This is the heart of the machine where the physical cutting takes place.

- Motion Control System: High-precision servo motors and drives (total power 290 kW) control the down-feed of the wire array and the positioning of the block.

- Process Management: Includes the HMI, the wet cutting system, and a fully enclosed structure for dust and noise control, ensuring the process is efficient, repeatable, and safe.

Component Deep-Dive

Multi-Wire Array & Diamond Wire

The "blade" of the machine is a web of parallel diamond wires. Understanding the wire is key to any diamond wire saw selection process.

Mechanism: A single, continuous wire is looped around a series of precisely grooved pulleys to create a parallel array. Wire Specification: The wire consists of a steel core with diamond beads. Wire diameter is typically 0.45–0.6 mm, which produces a narrow kerf of ~0.5 mm. Effect on Performance: The thin wire diameter directly minimizes kerf loss, increasing material yield by 10-25%! Wire quality affects cutting speed (up to 30 m/s), surface finish, and operational life.

Constant-Tension Control Loop

This is a critical system for ensuring accuracy and reducing wire breakage by ~60%. Mechanism: It is a closed-loop system where sensors continuously measure wire tension, which the controller compares to a setpoint. Control & Accuracy: If a deviation is detected, an actuator adjusts a tensioning pulley to restore the correct tension. This system maintains tension with a control accuracy of ±0.5 N. Importance: Without precise tension control, wires can become slack, leading to path deviation and tapered cuts, or over-tensioned, leading to premature wire failure.

Rigid Frame & Linear Guidance

The precision of the cut is only as good as the system guiding the wire array. Mechanism: The wire array is mounted on a carriage that moves along high-precision linear guide rails, which are mounted to the massive HT250 cast-iron frame. Performance: The rigidity of the frame prevents deflection and vibration, enabling stable high-speed cutting. This is a key differentiator from less robust machines, as discussed in a multi-wire vs. circular saw comparison.

Enclosure & Wet Cutting System

This integrated system is crucial for safety, quality, and environmental compliance. Mechanism:

A full enclosure surrounds the cutting area. Inside, nozzles spray coolant onto the wire-stone interface. The runoff (slurry) is collected and filtered for recirculation. Importance: The enclosure reduces noise levels by 30-50 dB. The wet cutting process is essential for cooling, lubrication, and dust suppression. An oil-immersed traverse mechanism is protected to an IP67 rating, with dust ingress below 0.1 mg/m³ and a mean time between failures (MTBF) of 18,000 hours for that subsystem.

Drive & Control (PLC/Servo)

The brain and muscles of the machine. Mechanism: A central Programmable Logic Controller (PLC) orchestrates all machine functions, sending commands to the servo drives that control wire speed and the down-feed rate. Performance: A servo-driven down-feed allows for precise control. For example, the PLC can monitor motor current and adjust the feed rate if it detects a harder section in the stone block, preventing wire overload. The total power of the system is 290 kW.

System Integration Considerations

For integration into a modern factory, communication protocols are key. A capable CNC diamond wire saw should have essential I/O signals available for integration with plant management systems. These include:

- Safety Signals: E-stop, safety guard interlocks, and light curtain status are non-negotiable for ensuring operator safety.

- Process Signals: Coolant flow/pressure interlock, machine status (running, idle, fault), and job completion signals are critical for process automation. Evaluating the ROI analysis of a multi-wire saw often includes its automation potential.

English

English 中文

中文