Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

This article provides a technical deep-dive into what causes chipping in granite and quartzite, the different types of edge damage, and how Dinosaw Machine can help.

An Introduction to a Fabricator's Most Costly Problem: Edge Chipping

In the stone fabrication industry, the quality of a finished edge is the ultimate signature of craftsmanship. Yet, a persistent and costly problem plagues workshops globally: edge chipping. This defect, particularly prevalent when working with hard, crystalline materials like granite and quartzite, can turn a high-value slab into a discounted remnant or, worse, unsalvageable waste.

Understanding the root causes of chipping is not merely an academic exercise; it is a critical step toward improving quality, reducing waste, and maximizing profitability. This technical guide will deconstruct the science behind stone chipping, categorize the types of damage, and present the definitive role that machine stability plays in achieving a perfect, chip-free edge.

The Anatomy of a Chip: Types of Edge Damage

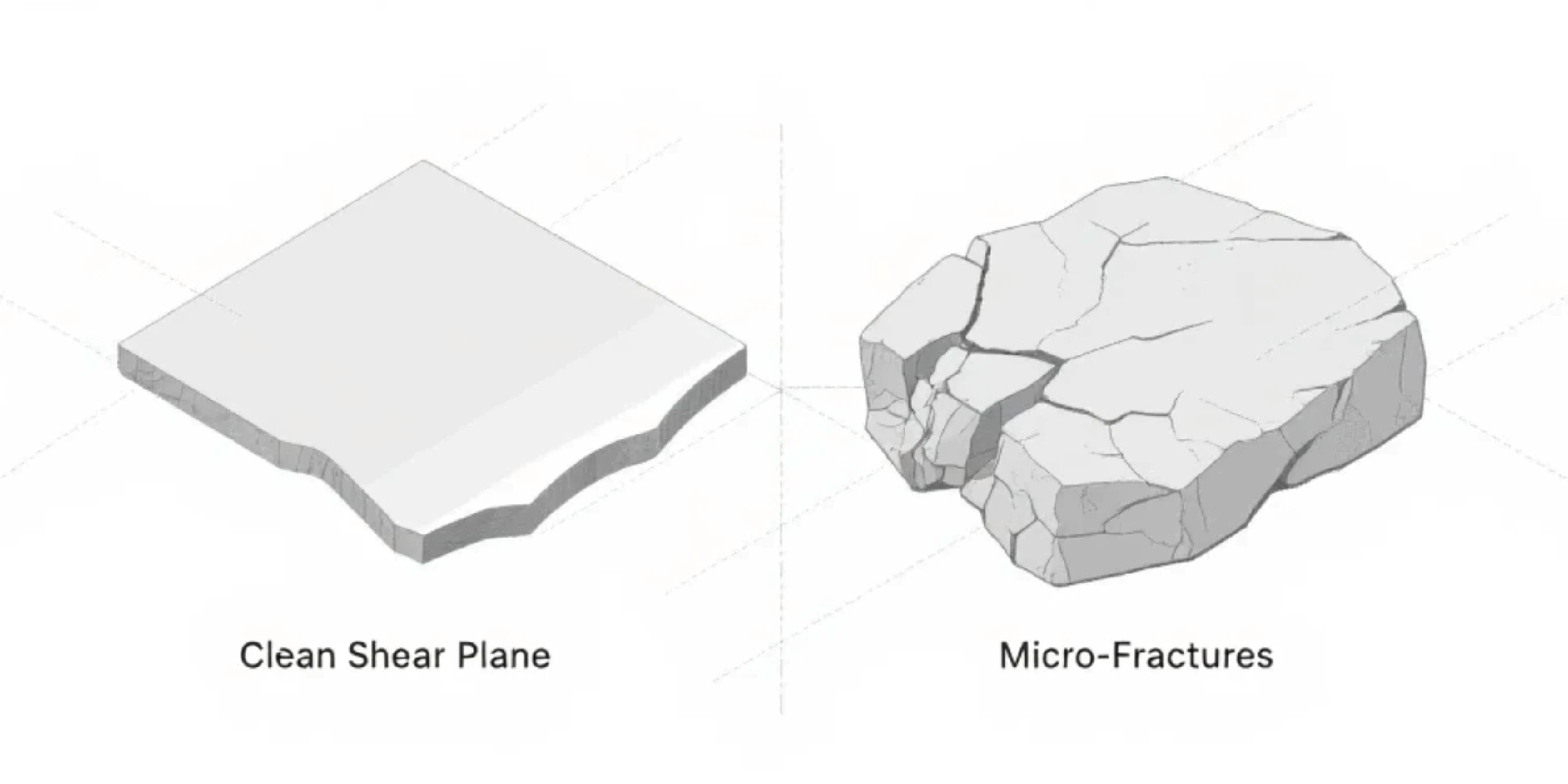

Not all chips are created equal. Identifying the type of damage is the first step in diagnosing the root cause. In fabrication, we primarily encounter two categories:

Micro-Chipping (Flea Bites)

Description: These are small, often subtle nicks and flakes along the cut line, creating a "saw-toothed" or rough edge that requires extensive secondary polishing to rectify. While individually small, they collectively degrade the final quality and significantly increase labor time.

Primary Cause: High-frequency vibrations from the machine's spindle or gantry, improper blade dressing, or using a blade with a diamond bond that is too hard for the specific material.

Blowouts & Spalling

Description: This is a more catastrophic failure, where larger chunks of stone break away from the edge, often at the entry or exit point of the cut. A single blowout can compromise the entire workpiece, rendering it useless for the intended project.

Primary Cause: This is almost always a result of excessive machine vibration, a sudden change in cutting speed, or a dull or damaged blade exerting immense pressure on the material instead of cleanly cutting it.

Why Chipping Destroys Profitability: The Hidden Costs

The financial impact of chipping extends far beyond the cost of the wasted material itself.

- Increased Labor Costs: Rectifying micro-chipping requires skilled technicians to spend hours on manual polishing and edge work, diminishing overall shop productivity.

- Tooling Damage: The same forces that cause chipping also lead to premature wear and damage on expensive diamond tooling, increasing operational overhead.

- Reputation Risk: Consistently delivering products with imperfect edges can damage a workshop's reputation, leading to lost customers and reduced pricing power in a competitive market.

The CNC Solution: How Machine Stability Fundamentally Prevents Chipping

While blades and feed rates are important variables, the foundational element in preventing chipping is the stability and rigidity of the CNC machine itself.

Many fabricators invest in expensive blades hoping for a solution, only to find the problem persists. This is because a blade, no matter how advanced, cannot compensate for a machine frame that flexes or a gantry that vibrates under the immense stress of cutting hard stone.

A machine like the Dinosaw Machine 5-Axis Bridge Saw is engineered specifically to solve this problem. Its massive, heat-treated, and stress-relieved steel frame provides an incredibly stable cutting platform. This rigidity eliminates the micro-vibrations that are the primary cause of chipping, allowing the diamond blade to perform its job with surgical precision. The result is a cleaner, faster cut that dramatically reduces the need for secondary finishing and minimizes the risk of costly blowouts.

From the Field: FAQ

We analyzed technical forums to answer the most pressing questions fabricators have about chipping:

Why does my new blade still chip quartzite?

Quartzite is extremely hard and requires immense stability to cut cleanly. If a new blade still causes chips, the issue is almost certainly machine vibration. A less rigid machine allows the blade to "bounce" on a microscopic level, fracturing the crystals on the edge rather than shearing them.

Can the right feed rate and RPM solve chipping?

They can help, but they cannot solve the root problem alone. Finding the "sweet spot" for speed is only effective if the machine provides a consistently stable platform. On a less rigid machine, the perfect speed for one part of the slab may cause chipping on another due to harmonic vibrations.

How does water flow affect chipping?

Adequate water flow is critical. It acts as a coolant and lubricant, and it clears stone dust (swarf) from the cut. Insufficient water flow can cause the blade to overheat and "glaze over," leading it to hammer the stone rather than cut it, which directly causes chipping.

Conclusion: Shifting Focus from Symptoms to the Source

Edge chipping is not a random occurrence; it is a direct result of physics. While tooling and technique play a role, the foundational solution lies in controlling and eliminating vibration at its source.

By investing in a CNC machine with superior structural rigidity, fabricators can move beyond treating the symptoms (endless polishing, constantly changing blades) and address the root cause. A stable and robust platform like a Dinosaw Machine provides the assurance of a chip-free edge, empowering workshops to take on the most challenging materials with confidence and profitability.

English

English 中文

中文