Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Discover practical applications of a PLC-controlled Bridge Cutting Machine for granite and marble. Learn how vibration reduction improves cut quality, blade life, and throughput. Cases and FAQs included.

In stone fabrication, vibration is the enemy of profit. It leads to chipped edges, inaccurate cuts, and accelerated blade wear—all of which drive up costs and rework time. A high-performance Bridge Cutting Machine tackles this problem head-on, delivering stable, precise cuts that boost throughput and protect your most valuable consumables.

Talk to us for a tailored bridge cutting machine setup today.

This article explores the practical applications of a well-designed PLC-controlled Bridge Cutting Machine. Note: This model uses a PLC system, which is distinct from many CNC bridge saws. We will show how the right machine architecture translates directly to better cut quality, longer blade life, and a healthier bottom line.

What is a Bridge Cutting Machine and Where Does It Shine?

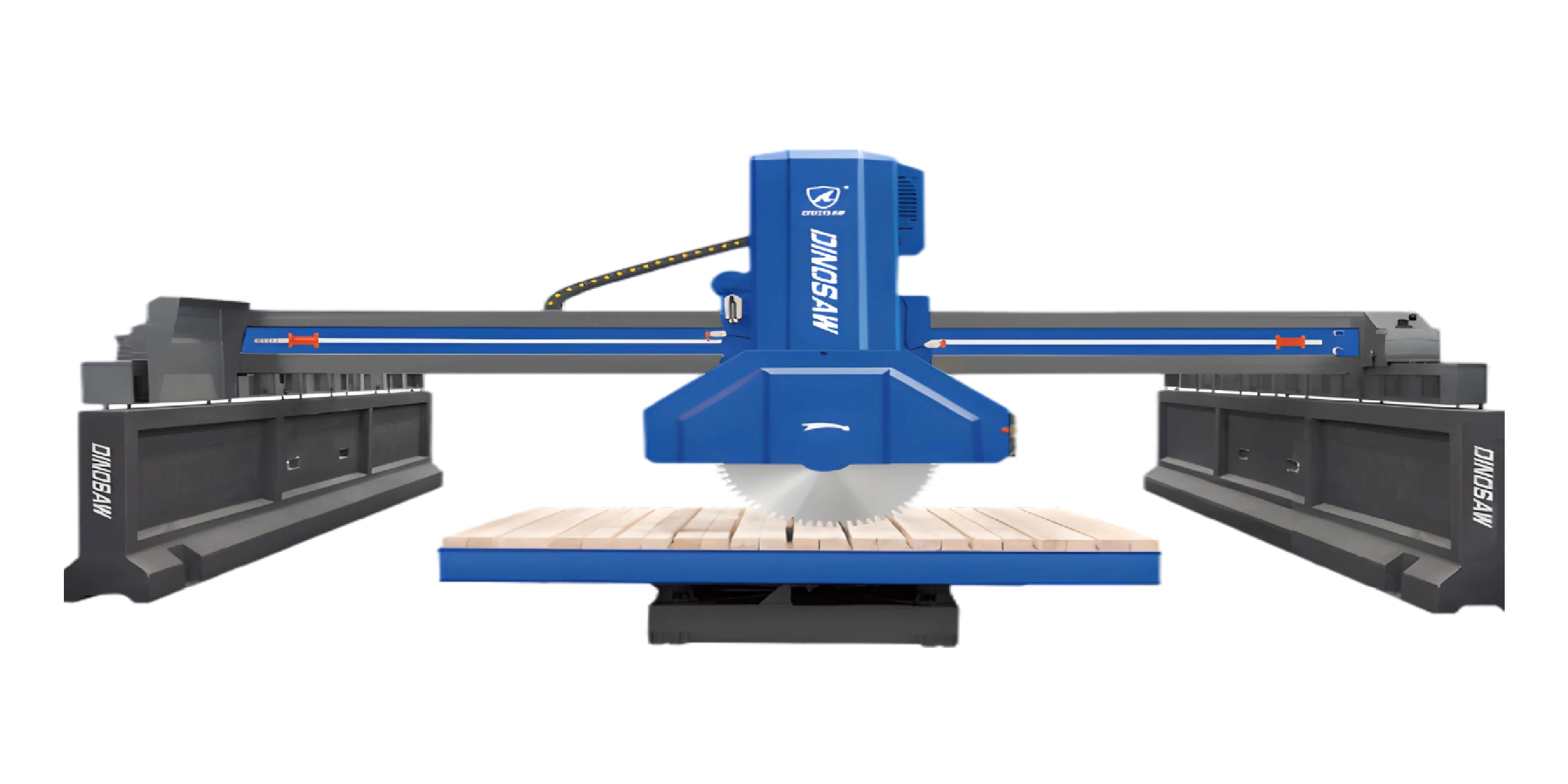

A Bridge Cutting Machine is a specialized stone saw built for making long, straight cuts in large slabs of natural and engineered stone. Its name comes from its core design: a bridge-like beam that travels along two parallel side rails, moving a cutting head and blade across a stationary workpiece.

This setup is the go-to solution for high-volume environments like granite countertop shops, marble slab yards, and monument fabrication facilities. Whether you are sizing large blocks or making precise cuts for custom kitchen islands, the stability of a Bridge Cutting Machine ensures consistent performance shift after shift.

From Common Pains to Key Performance Signals

If you run a stone workshop, these challenges probably sound familiar:

- Edge Chipping & Breakage: Micro-vibrations cause the blade to chatter, resulting in costly chipping, especially on brittle materials.

- Out-of-Square Cuts: Instability in the frame or rails leads to cuts that are not perfectly 90 degrees, requiring time-consuming rework.

- High Blade Wear: A vibrating blade dulls faster and is more prone to damage, significantly increasing your cost per cut.

- Inconsistent Throughput: When every cut requires manual checks and adjustments, your daily output becomes unpredictable.

A robust bridge saw transforms these pains into positive metrics. Instead of fighting defects, you start tracking improvements in cut speed, kerf quality (the precision of the cut channel), and overall blade life.

How does a bridge cutting machine reduce edge chipping in granite/marble?

A high-quality bridge saw minimizes edge chipping primarily by controlling vibration. Its heavy, stress-relieved cast iron beam and precision-ground rails ensure the cutting head moves smoothly without chattering. This stability allows the blade to slice cleanly through brittle materials like granite and marble, preventing the micro-fractures that lead to chipping and costly rework.

What makes it better than a gantry cutter for slab sizing?

For high-throughput slab sizing, a Bridge Cutting Machine's design offers superior rigidity. While gantry cutters are versatile, the dedicated structure—with a beam traveling on fixed, parallel rails—provides greater stability for long, fast, and perfectly straight cuts. This results in higher accuracy and more predictable output compared to a general-purpose gantry system.

The Solution: Engineering for Stability

The key to overcoming these issues lies in superior vibration control. Our Bridge Cutting Machines are built with a combination of heavy-duty components designed to absorb and dampen vibrations at the source.

- Precision-Ground Rails: The beam and side rails are meticulously ground to create a minimal contact gap. This precision fit prevents the chatter and wobble that cause poor cut quality.

- Stress-Relieved Cast Iron Beam: The crossbeam is made from heavy cast iron that has undergone an aging process. This dense material naturally absorbs vibrations, ensuring the cutting head moves smoothly and increasing both cutting efficiency and blade longevity.

- Reinforced Side Beams: The side beams are constructed from standard I-beam steel, welded for rigidity, and fitted with an anti-bump device to further resist operational vibrations.

- Solid, Lubricated Guide Columns: The vertical guide columns are made of solid round steel with a hard chrome plating for durability. A timed, automatic lubrication pump ensures these crucial components remain frictionless, contributing to a stable cutting process.

How do we keep cuts square without constant manual checks?

The machine's structural integrity is the key to maintaining squareness. The combination of precision-ground rails that prevent deviation and a rigid frame with reinforced side beams ensures the cutting head travels in a perfectly true line. Once calibrated, a well-built Bridge Cutting Machine reliably produces square cuts, which eliminates the need for constant manual verification.

Mini Cases: How a Bridge Saw Delivers Results

Theory is one thing; results are another. Here’s how a well-built infrared bridge saw performs in common scenarios.

When should we choose Ø1200 vs. Ø1400/Ø1600 blades for applications?

Choose large blades (Ø1400/Ø1600mm) for thick slabs and long, straight cuts where maximizing cutting depth and speed is the priority. Opt for smaller blades (e.g., Ø1200mm) for thinner materials or when performing more detailed, intricate work on custom shapes, as they offer greater control and can run at higher, manufacturer-reported RPMs for a finer finish.

Case 1: The Granite Countertop Shop

- Initial State: A shop struggled with minor edge chipping on 30cm granite slabs, leading to a rework rate of a few percentage points and unpredictable project timelines.

- Measures: They implemented a Bridge Cutting Machine with a heavy cast iron beam. They matched a Ø1200mm blade to the recommended, manufacturer-reported RPM band for hard stone.

- Outcome: The stable cutting platform virtually eliminated edge chipping. Reworks dropped, and throughput became consistent, allowing them to take on more jobs with confidence. The key was the machine's ability to maintain a smooth cut even under heavy load.

Case 2: The Marble Slab Yard

- Initial State: A slab distributor needed to quickly and accurately size large blocks of marble but found their existing gantry cutter was slow and often produced slightly out-of-square cuts.

- Measures: They adopted a PLC-controlled Bridge Cutting Machine, using its programming capabilities to pre-set a series of rip cuts. The saw's precision-ground rails ensured every cut was perfectly parallel.

- Outcome: The yard dramatically increased its slab cutting speed. The accuracy of the cuts meant less waste and higher customer satisfaction. Replicating this success was as simple as loading a new program for different dimensions.

Case 3: The Monument Shop

- Initial State: A monument maker faced high blade wear when cutting thick, dense stone for custom shapes, driving up their operating costs.

- Measures: They switched to a Bridge Cutting Machine with solid, auto-lubricated guide columns and selected a smaller Ø1400mm blade at a higher, manufacturer-reported RPM for detailed work. The reduced vibration put less stress on the blade.

- Outcome: Blade life increased noticeably, lowering the cost per monument. The machine's stability allowed for finer, more controlled cuts, expanding their creative capabilities.

Risks and Prerequisites for Success

To get the most from a stone bridge saw, a few factors must be in place:

- Blade Compatibility: Always match the blade diameter, type, and RPM to the material. Using the wrong blade negates the benefits of a stable machine.

- Cooling Water Quality: Ensure a consistent supply of clean water to prevent blade overheating and premature wear.

Can a rotating table speed up multi-angle countertop work?

Yes, significantly. For complex countertops with mitered edges or multiple angles, a rotating table is a huge efficiency booster. It allows the operator to position the heavy slab once and then rotate it for each new cut, drastically reducing the labor-intensive, time-consuming process of repositioning the slab manually and minimizing the risk of damage.

What are simple signals to watch for throughput improvement?

Instead of complex calculations, track three simple signals: a clear increase in the number of slabs processed per shift, a noticeable drop in the percentage of cuts that need rework, and an extension of your average blade life (measured in hours or linear meters). These are direct, real-world indicators of improved throughput and return on investment (ROI).

How does auto-lubrication impact day-to-day shop operations?

An automatic lubrication system simplifies daily operations by handling a critical maintenance task without operator intervention. It ensures key components like the solid guide columns are consistently lubricated, preventing wear and tear from missed manual checks. This leads to less unscheduled downtime, fewer interruptions, and more predictable machine performance.

Which shop prerequisites matter most before installing a Bridge Cutting Machine?

The most critical prerequisites are a solid, level foundation to ensure stability and adequate electrical power and clean water supply to run the machine effectively. Beyond the physical site, having skilled operators and a reliable supply chain for compatible blades are essential for maximizing the machine's performance and uptime from day one.

Summary: When is a Bridge Cutting Machine Your First Choice?

A Bridge Cutting Machine is the first-choice investment when your primary goals are high-throughput, repeatable accuracy, and low operating costs in slab fabrication. Its inherent stability, born from a robust structure featuring a cast iron beam and ground rails, directly translates to less rework, longer blade life, and a more profitable operation. For shops looking to scale production without sacrificing quality, this machine is an indispensable tool.

English

English 中文

中文