Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

A practical guide to choosing the right Bridge Cutting Machine. Learn how to match stone type, blade diameter (Ø600–Ø1400), and RPM to your needs with If-Then scenarios and FAQs.

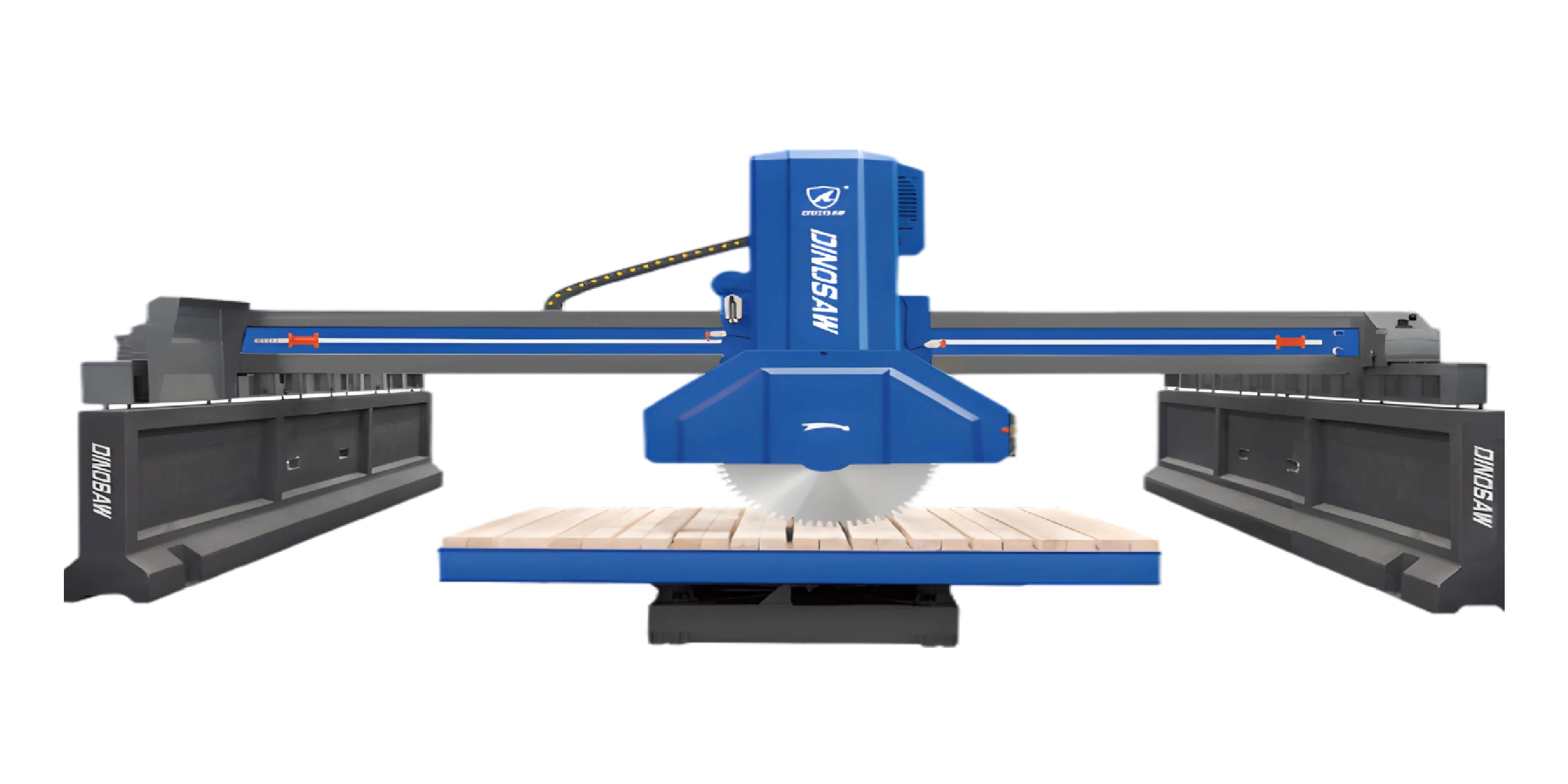

Choosing the right Bridge Cutting Machine isn’t just about price; it’s about making a clear-headed decision that matches the machine’s capabilities to your workshop’s reality. The goal is to align key variables—stone type, slab thickness, blade diameter, and worktable features—with your desired business outcomes: higher throughput, better cut quality, and lower operating costs.

Talk to us for a tailored bridge cutting machine setup today.

This guide provides a simple If-Then framework to help you navigate the selection process. We'll cover the most important decision dimensions, compare the stone bridge saw against other technologies, and give you the right questions to ask before you buy.

Key Decision Dimensions

Before looking at models, assess your needs across these factors:

- Workload: What materials do you cut most (e.g., granite, marble, quartz), and what are their typical thicknesses?

- Blade Diameter and RPM: The blade size (from Ø1200mm to Ø1600mm) dictates cutting depth, while the RPM must be matched to the material to avoid damage. The right RPM ranges are crucial.

- Worktable Features: Do you need a rotating table for complex countertop cuts, or is a fixed table sufficient for sizing slabs?

- Shop Infrastructure: Do you have the necessary footprint, 3-phase power, and a clean water supply?

- Total Cost of Ownership (TCO): Consider the initial price plus the ongoing costs of maintenance, spare parts, and consumables like blades.

What footprint, power, and water prerequisites affect selection?

Before selecting a machine, confirm you have a solid, level foundation large enough for its footprint and operational area. Ensure your facility can provide the required electrical power (e.g., 3-phase) and a consistent supply of clean cooling water. These infrastructure factors are non-negotiable and will limit your machine options if they cannot be met.

How do maintenance and spares factor into total cost of ownership (TCO)?

Total Cost of Ownership (TCO) goes far beyond the initial purchase price. You must consider the availability and cost of spare parts, as well as the ease and frequency of scheduled maintenance. A machine with features like automatic lubrication and readily available parts may have a higher initial cost but a lower TCO due to reduced downtime.

An If-Then Decision Tree for Bridge Saw Selection

Use these scenarios to guide your thinking.

If your primary business is high-volume countertop cutting with 3cm granite.

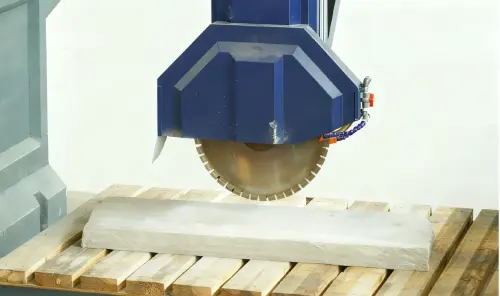

Then prioritize a machine with a rotating table and a blade diameter of 1200mm. The lower manufacturer-reported RPM band (~840 r/min) is ideal for hard stone. Features like a cast iron beam will ensure vibration reduction for clean edges. Risk: Insufficient cooling can cause blade glazing, so ensure your water system is robust.

If you mainly cut thinner marble slabs (2cm) for residential projects.

Then a smaller blade (e.g., Ø800mm) at a higher RPM may provide a finer finish. A rotating table is still valuable for sink cutouts and complex shapes. A machine with excellent ground rails will prevent chipping on the delicate bridge saw marble slab. Risk: Pushing the feed rate too high can cause micro-fractures, so start with conservative settings, then fine-tune after short test cuts.

How do we choose blade diameter Ø1200/Ø1400/Ø1600 by stone thickness?

Generally, use smaller diameters for thinner materials or intricate shapes where control is paramount. Reserve larger diameters for thick slabs to maximize cutting depth and speed. As a rule of thumb, ensure the blade diameter is at least double the material thickness for optimal performance.

What RPM bands should we start with for granite vs marble (manufacturer‑reported)?

RPMs vary, but a good starting point for hard stone like granite is a lower RPM to avoid glazing, while softer stone like marble can often handle slightly higher speeds. For example, a Ø1200mm blade might run at ~840 RPM on granite. Always consult the manufacturer's specifications for both the blade and the machine as your primary guide.

Should we select a rotating table for mitered countertops and multi‑angle work?

Absolutely. A rotating table is a critical feature for any shop doing frequent multi-angle or mitered edge work. It allows the operator to position a heavy slab once and then rotate it for subsequent cuts, dramatically reducing setup time, labor costs, and the risk of material damage during handling.

If you are a large distributor focused purely on sizing thick blocks (≥5 cm)

Then a fixed-table granite bridge saw with a large blade diameter of 1400mm is your workhorse. The key is raw power and rigidity for long, straight cuts. Slab cutting speed is the main metric. Risk: Ensure your lifting and handling equipment can manage the weight and size of the blocks to keep up with the machine.

If you run a mixed shop with a variety of materials and job types.

Then a versatile PLC-controlled bridge cutting machine with a rotating table and the ability to handle multiple blade diameters is the best fit. An intuitive HMI is crucial for quick job changeovers. Look for models with a well-documented maintenance schedule and features like auto lubrication. Risk: Higher complexity means operator training is non-negotiable.

If you want to integrate the saw into a fully automated production line.

Then your selection criteria must include industrial communication protocols like OPC UA or Profinet. This ensures the infrared bridge saw can communicate with conveyors and other machinery. Risk: Integration can be complex; work with a supplier experienced in factory automation.

If your shop has limited space and you are upgrading from manual cutting.

Then a compact bridge cutter with a smaller footprint is the logical first step. Focus on core functions: cutting accuracy from solid guide columns and reliability. You can forego advanced features like table rotation for now. Risk: Carefully measure your space and account for slab loading/unloading zones before purchasing.

Bridge Saw vs. Alternatives: Where Are the Boundaries?

- Bridge Saw: The champion of high-throughput, straight-line cutting of slabs. Its rigid design delivers speed and accuracy that are hard to beat for standard sizing and countertop fabrication.

- Wire Saw: The specialist for extremely thick blocks or intricate, curved designs. It cuts with an abrasive wire, offering flexibility a circular blade cannot. Choose this for artistic work or non-linear shapes.

- Gantry Cutter: A versatile machine where the cutting head moves on a gantry over the workpiece. While flexible, it typically lacks the specialized rigidity of a bridge saw for granite, making it slower for high-volume straight cuts.

When is a bridge saw preferred over a wire saw or gantry cutter?

A bridge saw is the preferred choice for high-throughput, precise straight-line cutting of standard slabs. In contrast, a wire saw excels at intricate curves and extremely thick blocks, while a gantry cutter offers versatility but often sacrifices the speed and rigidity of a dedicated bridge saw for simple slab sizing.

What risks make a bridge saw a “backup” rather than first choice?

A bridge saw might be a backup choice if your primary work involves complex 3D shapes or non-linear cuts, where a CNC wire saw or 5-axis machine is superior. Additionally, if your shop has severe space or power limitations, a smaller, less powerful machine might be the only viable option, with the bridge saw reserved for specific high-volume jobs.

Procurement Topics Beyond the Price Tag

A smart purchase considers the long term. Discuss these points with potential suppliers, including top Stone Cutting Machine Brands:

- Spares & Consumables: What is the availability and cost of common wear parts?

- Maintenance & Support: What does the recommended maintenance window look like? Is remote support available?

- Training & Warranty: Is on-site operator training included? What are the warranty terms?

- Installation: Who is responsible for delivery, installation, and initial calibration?

Final Recommendations

- First Choice: If your business relies on processing stone slabs with speed and precision, a Bridge Cutting Machine is your primary tool.

- Backup Option: If you primarily do complex 3D work with a 5-axis machine, a bridge saw can be a valuable backup for simple, high-volume jobs that would otherwise tie up your main asset.

- Not Recommended: If your production volume is very low or your work is exclusively artistic and non-linear, the investment may not be justified. A smaller manual saw or a wire saw would be more appropriate.

How do we set a simple acceptance checklist before purchase?

Your checklist should verify that the machine meets your core needs. Key items to confirm include: maximum cutting dimensions fit your typical slabs, motor power is sufficient for your hardest material, and the control system is intuitive for your operators. Finally, get a clear commitment on warranty terms and post-sales support availability.

English

English 中文

中文