Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

An executive guide to robotic stone carving investments. This summary covers the value proposition, ROI metrics (throughput, quality, scrap rate), a phased adoption roadmap, and key risks for decision-makers.

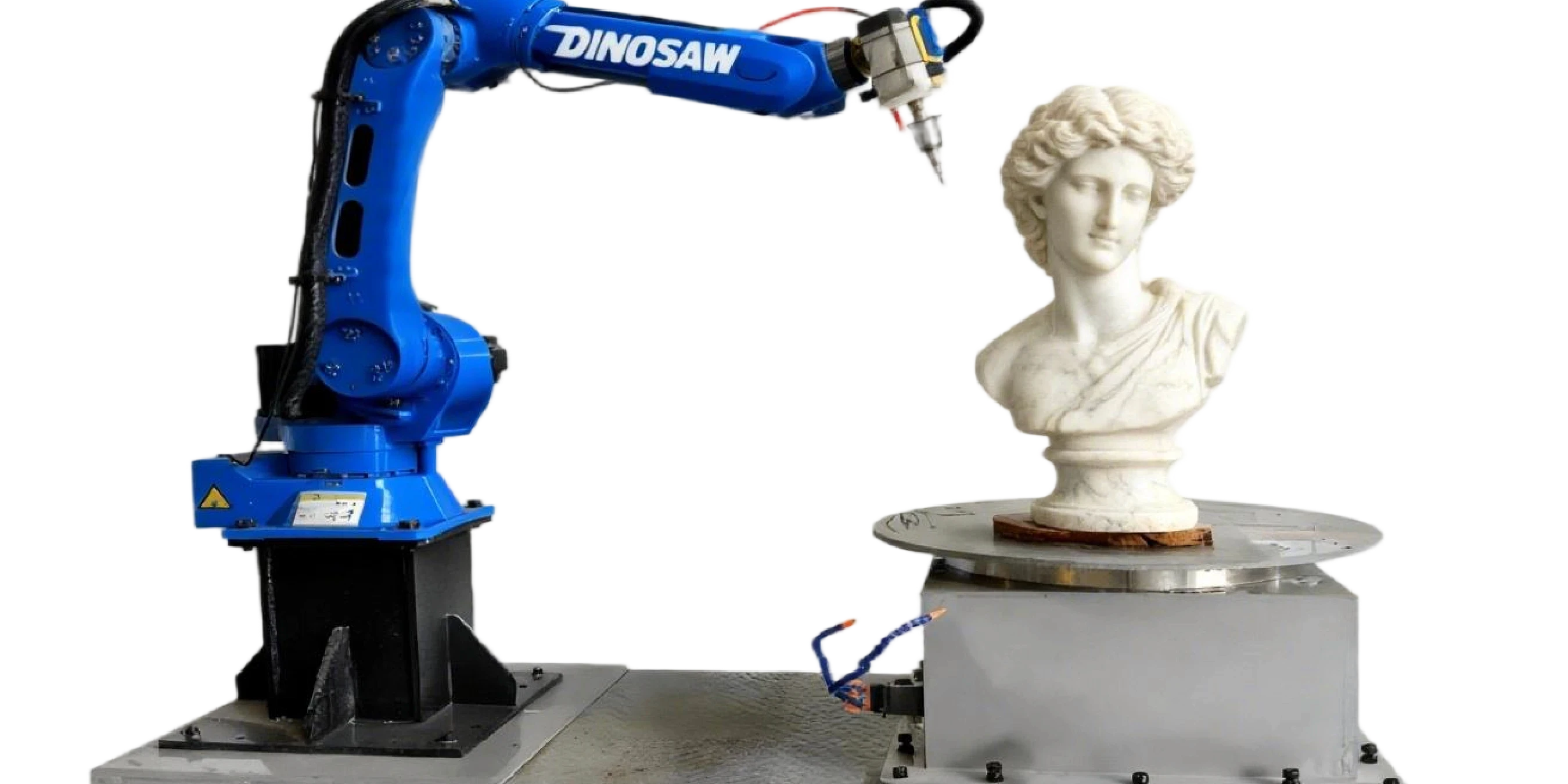

Investing in a 7-axis robotic stone carving cell is a strategic decision to address labor shortages, boost throughput, and enforce quality control. The core value lies in converting operational pain points into measurable ROI across throughput, quality, safety, and labor utilization. This standalone guide provides a clear investment framework for business leaders considering this technology.

Ready to align this technology with your five-year growth plan? Our specialists can help you build a business case based on your specific operational data.

What This Robot Does - In Plain English

- Applications: High-repeatability scenarios like memorials and architectural reliefs, or complex, high-value work like religious statues (Madonna, Buddha) and art replicas.

- Materials: Primarily granite, marble, limestone, and sandstone.

- Outcomes: Achieves consistent lettering depth with a positional repeatability of ±0.06 mm (manufacturer-reported). Reduces production time by approximately 40% versus manual engraving and can achieve weekly capacities around 50 tombstones in comparable deployments .

Quick-Start Investment Checklist

Use this checklist to frame your procurement and operational planning.

- Material Mix: What is your primary stone (granite, marble, etc.)?

- Product Types: Are you making memorials, reliefs, statues, or mixed products?

- Footprint & Power: Do you have the space for the full cell envelope and stable 3-phase power?

- Dust & Water: Do you have a plan for dust extraction and/or slurry management?

- Fixturing Plan: How will you securely hold your common workpiece sizes?

- Tool Library: Will you standardize on a single supplier like DINOSAW carving bits?

- OLP Workflow: Who will be trained to use CAM software for Offline Programming?

- Training Bandwidth: Have you allocated time for operator and maintenance training?

- KPI Baseline: What are your current metrics for cycle time, rework rate, and scrap?

- Pilot Scope: What is the first product you will automate to prove the ROI?

Step-by-Step Adoption Playbook

1. Pilot Project

- Select a single, high-impact product line (e.g., standard memorials).

- Define success by establishing baseline KPIs for quality variance, weekly output, and scrap rate.

2. Acceptance & KPI Validation

- Run the pilot for one quarter and measure against baseline KPIs.

- Accept the system if it meets predefined targets for quality, output, and safety.

3. Standardize

- Codify the wins by locking in optimized fixture designs and tool parameters.

- Formalize the SOPs for operation, maintenance, and programming.

4. Replicate

- With a proven blueprint, roll out the standardized cell to other product lines or facilities.

- Use internal data from the pilot to de-risk future investment cases.

Scenario Playcards

For Memorial Producers

- Recommended Config: 7-axis cell with robust fixturing for quick changeovers.

- Toolset: DINOSAW V-groove bits for lettering and ball-nose mills for motifs.

- Risks: Inadequate dust control, inconsistent fixture positioning.

For Art/Religious Statues

- Recommended Config: High-fidelity scan-to-toolpath capability.

- Toolset: Wide range of DINOSAW ball-nose and tapered engraving bits.

- Prerequisites: High-resolution 3D scanner, skilled artisan for final QA.

For Architectural/Heritage

- Recommended Config: Large-reach robot for big blocks and deep undercuts.

- Toolset: Large-diameter ball-nose mills and custom form tools.

- Risks: Material variability in old stone, insufficient enclosure airflow.

Explore the Full Series

This guide provides a high-level overview. For deeper dives, explore the rest of our series:

- Blog 1: Stone Carving Robot Applications & Case Studies: Explore real-world ROI in memorials, art replicas, and architectural restoration.

- Blog 2: Stone Carving Robot Technical Deep-Dive: Understand the core components, from the 7-axis architecture to the water-cooled spindle.

- Blog 3: Stone Carving Robot Selection Factors & Comparison: Use an If-Then framework to compare models and make a structured procurement decision.

- Blog 4: Stone Carving Robot Operations & Maintenance: Learn the SOPs, troubleshooting flows, and maintenance schedules to maximize uptime.

FAQs for Executive Decision-Makers

How do we validate ROI quickly?

Start with a paid pilot study on a core product line or a detailed simulation using your 3D models. Gather baseline inputs for your current cycle time, rework rate, and material cost per piece to build a data-driven business case.

What payback window is typical?

Payback depends on labor cost savings, increased throughput, and reduced material waste, and varies by market and product mix. High-volume, standardized memorial production generally achieves faster payback. Use a pilot or detailed simulation to quantify your own window; public sources do not specify a fixed period. See the product overview for documented drivers (~40% production time reduction; ~30% scrap reduction; weekly capacity around 50 tombstones in comparable deployments).

Is our facility ready?

A facility audit is critical. Verify you have the floor space for the robot's full envelope (mm/in), stable 3-phase power, and a plan for ventilation and water/slurry management. A solid, level foundation is non-negotiable.

Do we need scan-to-toolpath?

Yes, if you are replicating existing objects like artistic sculptures or restoring historical elements. It is essential for capturing organic shapes and creating accurate digital models for carving, but less critical for standardized production from CAD.

Which tools for granite vs. marble?

For hard, abrasive granite, use robust DINOSAW V-groove and ball-nose bits. For softer, less abrasive marble, a two-stage approach with ball-nose roughing and fine tapered engraving bits for finishing is more effective.

What cycle-time gains should we expect?

Production time reduction of ~40% versus manual engraving is a conservative, documented estimate . The key driver is eliminating manual repositioning and enabling continuous 24/7 operation via OLP.

How do we avoid vendor lock-in?

Choose systems built on industry-standard robots (e.g., KUKA, Fanuc) and software that uses open data formats (STEP, IGES). Using a vertically integrated supplier like DINOSAW for consumables can de-risk the supply chain for critical items like diamond tools.

What compliance risks matter most?

The main risks are non-compliance with local regulations for silica dust exposure (e.g., OSHA in the US) and wastewater disposal. Ensure your vendor provides system designs (e.g., IP65 enclosures, dust extraction) that meet your specific regional standards.

What are the primary compliance risks?

The main risks are non-compliance with local regulations for silica dust exposure and wastewater disposal. Ensure your vendor can provide documentation and system designs that meet your specific regional standards.

What is the ideal staffing and training plan?

Plan for a "cell champion" model: one or two key operators receive in-depth training on programming and maintenance. They then train other operators on daily tasks. Budget for at least 1-2 weeks of dedicated initial training.

What is this "structural stone" trend and how does it impact us?

As seen with firms like Monumental Labs, there's growing interest in using precisely carved stone as a structural component in buildings, not just for cladding. While a niche market, owning robotic carving capability positions you to potentially enter this high-value sector in the future.

English

English 中文

中文