Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Explore how the CNC Diamond Wire Saw Pro transforms cutting for granite, marble, and complex materials. See real-world case studies and find if it fits your needs.

Struggling with complex cuts in hard stone? The DINOSAW CNC Diamond Wire Saw Pro is engineered to solve this, creating precise profiles and intricate shapes with minimal material waste. This guide showcases real-world applications and case studies that prove its value and rapid ROI for fabricators, monument makers, and architectural designers.

What Is a CNC Diamond Wire Saw for Stone?

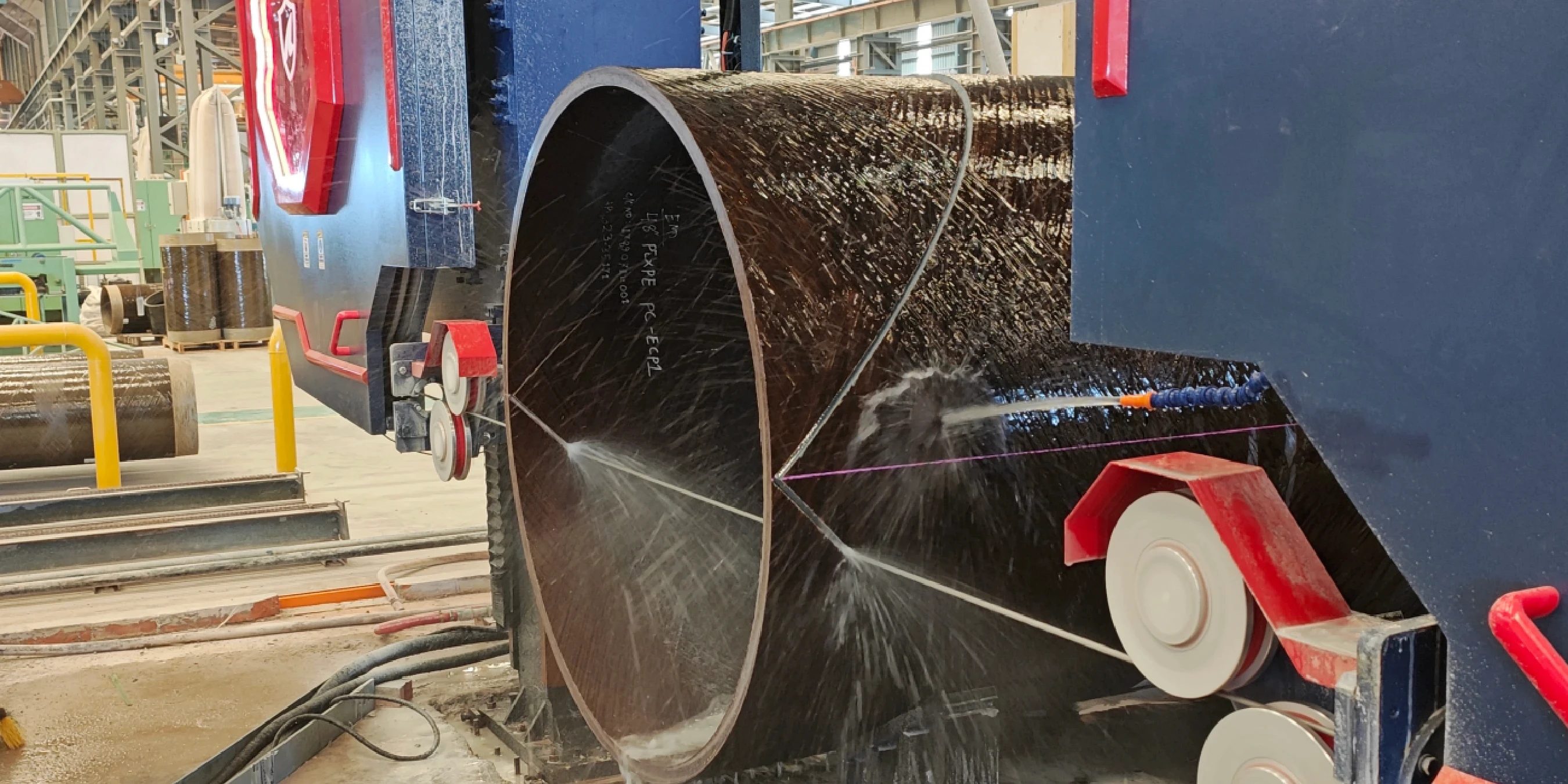

At its core, a CNC (Computer Numerical Control) diamond wire saw is a precision machine that uses a continuous loop of diamond-impregnated wire to cut through hard materials. Unlike traditional blades that are limited to straight lines, the thin, flexible wire can navigate complex 2D and 3D toolpaths programmed into a computer. This makes it the definitive tool for producing complex shapes, profiles, and contours with exceptional accuracy.

The CNC Diamond Wire Saw Pro is engineered for professionals who need to move beyond the constraints of conventional cutting methods. Its primary users include:

- Stone Fabricators: For creating custom countertops, architectural elements, and bespoke furniture with complex edge profiles and internal cutouts.

- Monument and Tombstone Makers: For detailed lettering, intricate shapes, and custom memorial designs that require high precision.

- Architectural Designers & Contractors: For producing unique building components like facade panels, columns, and decorative trim.

- R&D Labs and Prototyping Shops: For cutting advanced materials like foam ceramics, fused quartz, and fiberglass composites for testing and development.

Material Compatibility (limestone, travertine, quartz glass, FRP) & Processing Modes

The versatility of a CNC wire saw is defined by the range of materials it can process. The Pro series excels with a wide array of natural stones, engineered materials, and composites. Understanding material feasibility is crucial for project planning.

| Material | Feasibility | Notes |

|---|---|---|

| Marble, Limestone, Travertine | Excellent | Ideal for intricate shapes and sculptures due to softer composition. |

| Granite, Quartzite, Basalt | Excellent | Perfect for high-durability applications like countertops and cladding. |

| Concrete & Reinforced Concrete | Good | Requires appropriate wire specification. Ideal for architectural work. |

| Foam Ceramic, Fused Quartz, Quartz Glass | Good | Enables precision cutting for technical and industrial components. |

| Fiberglass (FRP) ,Refractory materials & Composites | Good | It can be used for cutting refractory bricks, FRP pipes, etc. |

For more detailed information on various stones, the Natural Stone Institute: Stone Types guide is an excellent resource.

Beyond material type, the machine supports several processing modes:

- Slicing: Cutting large blocks into uniform slabs.

- Block Squaring: Trimming raw quarry blocks to prepare them for further processing.

- Profiling & Contouring: Creating complex 2D and 2.5D shapes, such as decorative moldings or curved panels.

Typical Applications (tombstone cutting, curved slab, lettering)

The combination of material versatility and advanced CNC control unlocks a wide range of high-value applications:

- Monument & Tombstone Cutting: Precisely cuts intricate lettering, religious symbols, and custom shapes, a task detailed in our guide on How to Cut Custom Monument Shapes.

- Sculpture & 3D Craft Pieces: Enables artists and artisans to realize complex forms in stone that would be prohibitive by hand.

- Architectural Components: Produces everything from irregular window/door trim and fireplace surrounds to custom bathtubs and facade elements.

- Roman Columns: Easily machines classical architectural elements, including the shaft, capital (top), and base.

- Large Block Trimming & Splitting: Efficiently squares and sections massive quarry blocks for downstream processing.

- Stone Furniture: Creates unique tables, benches, and chairs with curved legs and custom tops.

- Landscape & Curbstones: Cuts large landscape boulders and produces curved curbstones for civil and design projects.

- Lettering & Typography: Delivers sharp, clean cuts for large-scale signage and artistic text installations.

From Pain Points to Precision: How It Solves Common Challenges

Adopting a CNC wire saw directly addresses several chronic issues in stone fabrication.

High Material Waste

Pain Point: Traditional block saws and bridge saws have thick blades, creating significant kerf loss. With expensive materials like quartzite or premium marble, this waste translates directly to lost profit.

Solution: The diamond wire has a diameter of just 3-15 mm, minimizing waste and maximizing the usable yield from every single block.

Inability to Cut Complex Shapes

Pain Point: Saws and mills are limited to straight lines and simple arcs, making internal corners, S-curves, and non-linear shapes impossible without multiple setups and manual finishing.

Solution: Full CNC control allows the wire to follow virtually any programmed path, enabling intricate designs in a single, automated operation.

Labor-Intensive Processes

Pain Point: Manual shaping, grinding, and finishing are time-consuming, physically demanding, and dependent on highly skilled labor, creating production bottlenecks.

Solution: Automation reduces the need for constant operator intervention, freeing up skilled workers for higher-value tasks like design and quality control.

Capabilities & Limitations: A Realistic Look

To ensure the machine fits your workflow, it is important to understand what it can and cannot do.

What it Can Do:

- Cut sharp internal and external corners with minimal radius.

- Produce smooth, curved profiles for applications like columns and arched windows.

- Process very large blocks, with the YXSJ-3500-16pro model handling dimensions up to 3.5m x 1.5m . For larger blocks, custom dimensions are available. If only edge trimming is needed, our Stone Squaring Wire Saw is suitable for cutting larger rough stones and splitting them into halves.

Limitations & Configuration Options:

- Standard 4-Axis Configuration: The machine comes standard with a 4-axis CNC system (X, Y, Z linear axes + one rotary axis). This is ideal for most profiling work, including curved slabs, cylinders, and Roman columns. It operates as a "2.5D" profiler, cutting a 2D shape through the material's thickness.

- Optional 5-Axis Upgrade: For projects requiring true 3D spatial forms, undercuts, or complex curved architectural components, a 5-axis upgrade is available. This adds a fifth rotary axis, enabling multi-axis interpolation for the most demanding sculptural and artistic work. The 4-axis configuration handles the vast majority of applications; the 5-axis is a specialized option for elite-level complexity.

Mini Case Studies: The Machine in Action

Case 1: Architectural Granite Cladding

Challenge: A contractor needed to produce hundreds of unique, non-uniform granite facade panels for a modern commercial building. Traditional cutting methods were too slow and produced excessive waste.Solution: Using a CNC Diamond Wire Saw Machine, the contractor was able to directly import DXF files from the architect. The machine ran continuously, cutting each unique panel shape from large granite slabs with minimal kerf loss. This reduced material costs by over 15% and cut the production timeline by half compared to their previous bridge saw and waterjet workflow.

Case 2: Custom Marble Monument

Challenge: A monument maker was commissioned to create a large marble memorial featuring intricate Celtic knotwork and detailed lettering. Handcarving was deemed too expensive and time-consuming.Solution: The design was programmed into the CNC wire saw. The machine precisely cut the delicate, overlapping patterns and sharp-cornered letters, producing a near-finished piece that required only minor polishing. The project was completed in under a week, a fraction of the time estimated for manual methods.

Case 3: R&D Prototyping with Foam Ceramic

Challenge: An aerospace research lab needed to create complex models from a brittle, abrasive foam ceramic material for aerodynamic testing. Traditional machining methods caused chipping and micro-fractures.Solution: The low-tension, non-impact nature of the diamond wire saw proved ideal. It cut the foam ceramic cleanly without inducing stress, producing dimensionally accurate prototypes with a smooth surface finish ready for the wind tunnel.

Is This the Right Solution for You?

If your business is limited by the geometric constraints of traditional saws, struggles with high material waste, or relies heavily on labor-intensive manual finishing, the CNC Diamond Wire Saw Pro is a compelling solution. It opens the door to higher-margin architectural, artistic, and custom fabrication projects while improving efficiency on standard jobs.

Frequently Asked Questions

Wire Saw vs Waterjet for Stone Cutting?

A wire saw is generally faster and more efficient on thick blocks of stone. While a waterjet can achieve incredible detail, it is typically slower and has a more complex system for managing water and abrasive garnet. For block squaring and thick profiling, a wire saw is often the more economical choice.

CNC wire saw operator learning curve-how long?

An operator with prior CNC experience can typically become proficient in a few minutes. For those new to CNC, training may take 1-2 hours to cover machine operation, software, and maintenance basics. DINOSAW offers training to ensure your team is fully prepared.

Can a diamond wire saw cut fine details and lettering?

Yes, the machine's precision makes it suitable for detailed work. However, the 3-15 mm wire diameter is the limiting factor. For micro-scale parts, a different technology might be necessary, but for most architectural and monumental details, it is highly effective.

What CAM/G‑code software runs a CNC wire saw?

The machine runs on standard G-code, which can be generated from most CAD/CAM software (e.g., AutoCAD, Mastercam). You design your part in CAD, create the toolpath in CAM, and load the resulting G-code file into the machine's controller.

Footprint for YXSJ‑2500‑16pro wire saw machine size?

The YXSJ-2500-16pro has overall dimensions of 6.3 x 7.9 x 4.0 meters. You should also account for clearance space for loading/unloading material and maintenance access, so a slightly larger footprint is recommended.

Power & water for diamond wire saw?

The Pro series features a 15 kW main motor. It requires a stable three-phase power supply. Water consumption is 3 m³/h which is used for cooling the wire and flushing away slurry. A water recycling system is highly recommended to reduce consumption and comply with environmental regulations.

What safety precautions are necessary when operating this machine?

Safety is paramount. Operators must wear appropriate PPE, including safety glasses and steel-toed boots. It is critical to manage the crystalline silica dust generated from cutting stone, as it poses a significant respiratory hazard. For guidance, refer to official resources like the OSHA: Stone Cutting Safety standards.

English

English 中文

中文