Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Elevate your stone factory's output. Our expert guide covers automatic polishing lines, bridge polishers, and selecting the right diamond pads and discs for a flawless finish on granite and marble.

Struggling with inconsistent gloss levels or swirl marks on your stone slabs? You're not alone. Getting that flawless, mirror-like finish isn't just about having expensive equipment – it's about understanding exactly why some factories consistently deliver premium results while others constantly fight quality issues.

What Does "Perfect Finish" Actually Mean in Stone Fabrication?

Before you can fix your polishing problems, you need to know what you're aiming for. In industrial stone production, "perfect" isn't subjective – it's measurable. Your customers expect consistency across every square meter, crystal-clear reflection, and absolutely zero visible defects.

But here's what most factory owners get wrong: they think all finishes are created equal. They're not.

The Four Finish Types Your Customers Actually Want

- Honed surfaces give you that smooth, satin feel without the mirror effect. Stop your polishing process around 200-400 grit, and you're done. Perfect for high-traffic areas where slip resistance matters.

- Semi-gloss finishes offer a gentle sheen – not quite matte, not quite mirror. Think of it as the middle ground that works in almost any application.

- High-gloss polished surfaces are what separate premium fabricators from the rest. That mirrorlike reflection requires a complete grit progression up to 3000+ grit, followed by proper buffing. Skip a step, and you'll see it in the final result.

- Textured finishes like leathered or antiqued surfaces need specialized abrasive brushes instead of flat pads. These create that tactile, non-reflective surface that's become increasingly popular in modern design.

The Surface Defects That Kill Your Reputation

Every stone that enters your factory comes with problems. Your polishing line's job is to eliminate them completely.

- Saw marks from gang saws or multi-wire cutting are the most obvious culprits. Those parallel lines need aggressive initial grinding to disappear completely.

- Natural pitting and voids can't be polished away – they need to be filled or accepted as character marks, depending on your quality standards.

- Inconsistent polish – those swirl marks, dull spots, and uneven gloss levels – almost always trace back to worn abrasives or incorrect machine settings. Fix your process, fix your problems.

Your Equipment: The Foundation of Consistent Quality

Equipment doesn't make a good fabricator, but bad equipment will definitely break one. For industrial-scale production, you need machinery that delivers consistent results hour after hour, day after day.

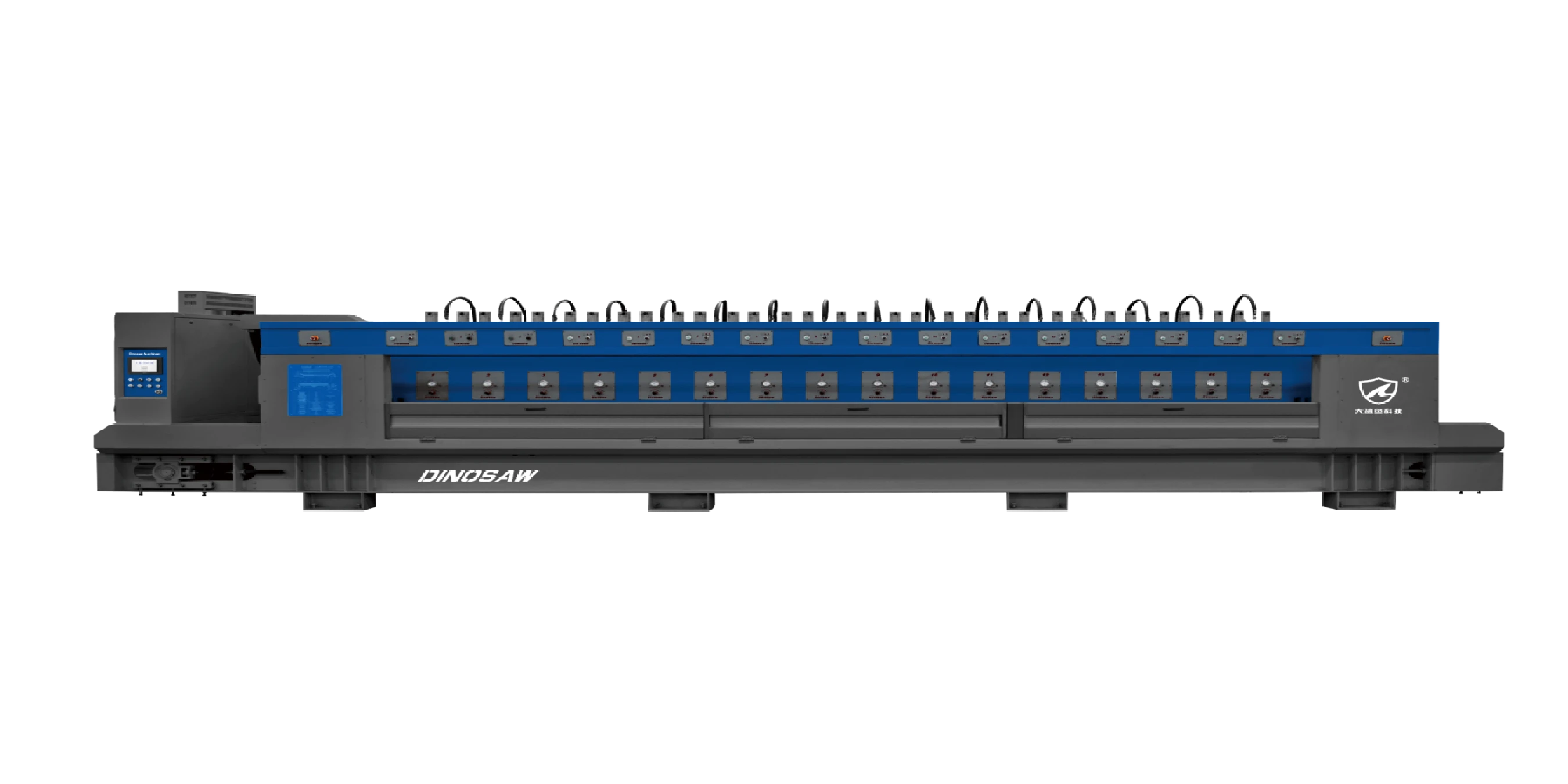

Automatic Polishing Lines: Your Production Powerhouse

Think of an automatic polishing line as a factory within your factory. Slabs travel on a conveyor system under multiple polishing heads, each equipped with progressively finer abrasives. It's consistent, fast, and handles the bulk of your production volume.

The magic happens in the details: synchronized conveyor speed, precise water flow, automated pressure control. Get these parameters right, and you'll produce hundreds of identical slabs. Get them wrong, and every slab becomes a custom problem.

Production advantage: High throughput with exceptional consistency – exactly what you need for large commercial orders.

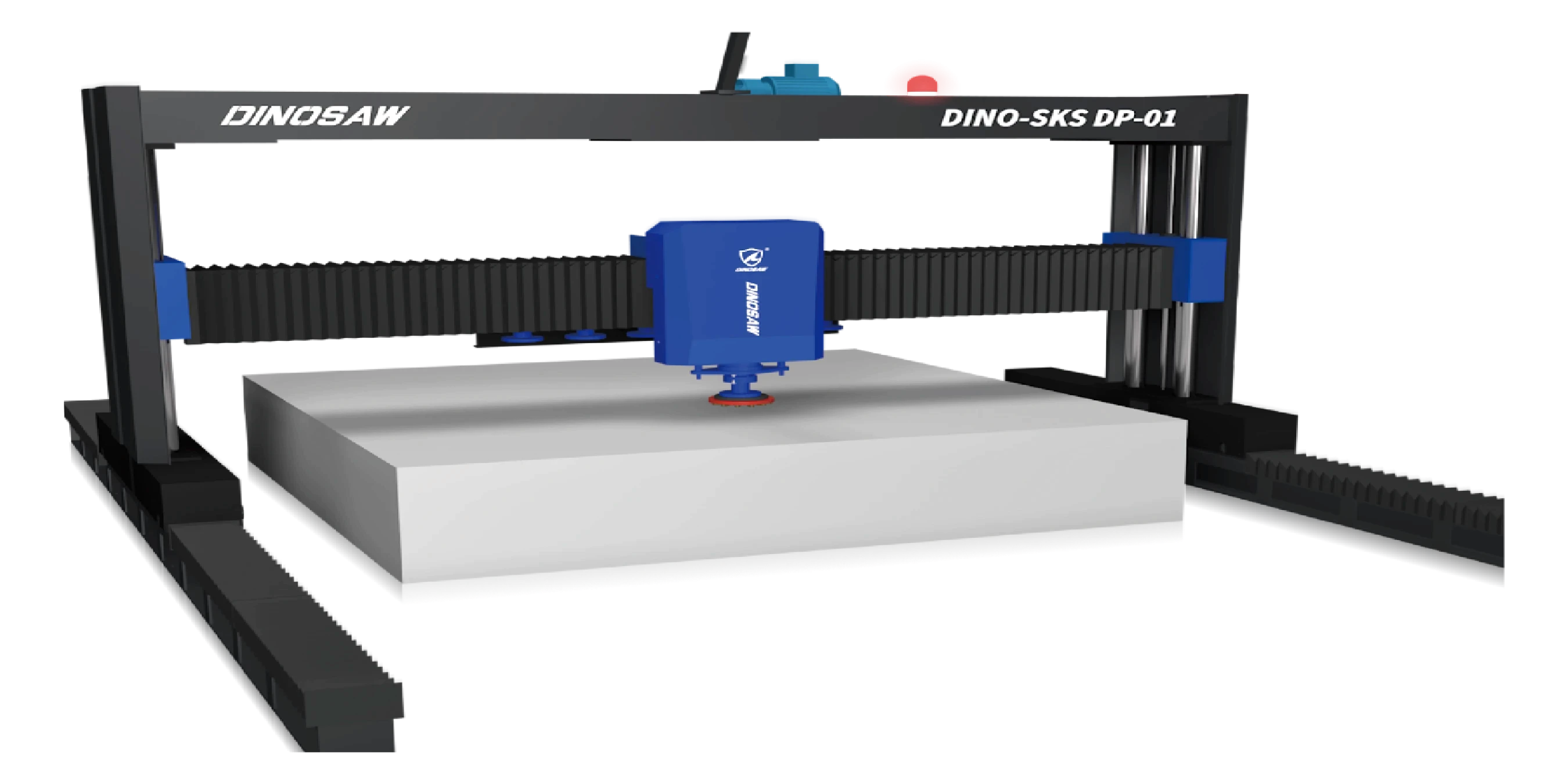

Bridge Polishers: Flexibility for Custom Work

Not every job fits the production line model. Bridge polishers give you the flexibility to handle cut-to-size pieces, countertops, and specialty work. Single-head operation means more operator control – perfect when you need to adapt to unique requirements.

The trade-off? Lower throughput, but higher flexibility. Many successful factories use both systems strategically.

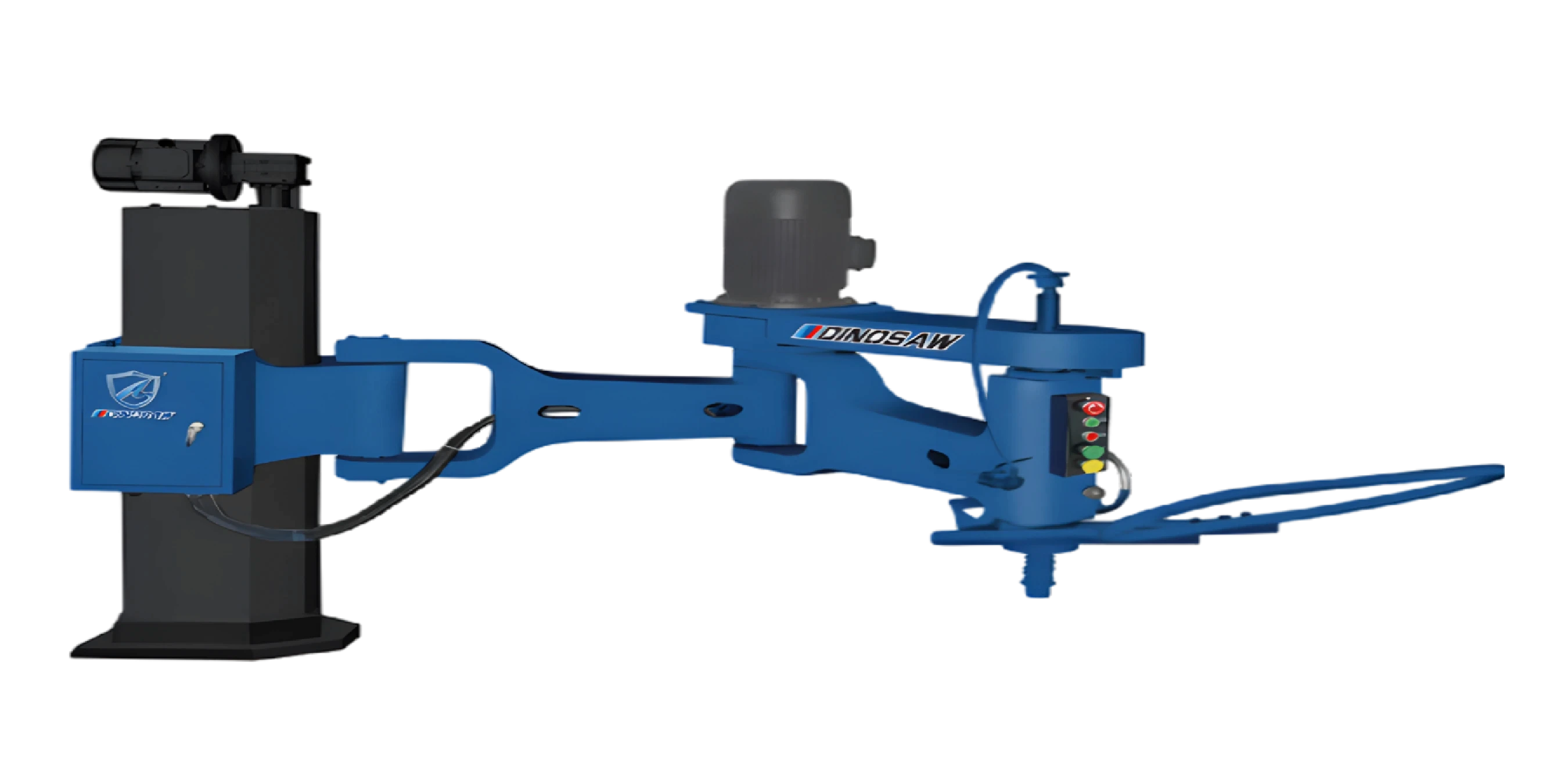

Why Dinosaw Equipment Delivers Better Results

We designed our polishing machines specifically for the demanding environment of modern stone factories. Here's what makes the difference:

- Built for 24/7 operation. Heavy-duty construction minimizes downtime and maintenance headaches. When your production schedule matters, reliability isn't negotiable.

- Precision engineering eliminates operator variables. Our polishing heads maintain consistent pressure and oscillation patterns, which means uniform results regardless of operator skill level.

- Smart economics. You get European-quality performance at a price point that makes sense for your business. Faster ROI, lower cost per slab, better profit margins.

The Real Secret: Choosing the Right Abrasives

Here's something most factory owners don't realize: your equipment is only as good as the abrasives you put on it. The wrong pad selection will sabotage even the most expensive machinery.

The Diamond Grit Progression That Actually Works

Achieving a high-gloss finish isn't magic – it's methodical progression through specific grit levels. Skip a step, and you'll fight quality problems for the rest of the process.

- Step 1: Grinding (50-200 grit) – Metal-bond diamond abrasives remove saw marks and create a flat, uniform surface. This stage removes material aggressively.

- Step 2: Honing (400-800 grit) – Switch to resin-bond diamond pads. These begin smoothing the surface and eliminating visible scratches. You'll see a matte finish emerge.

- Step 3: Polishing (1500-3000 grit) – Finer resin-bond pads develop reflection and gloss. The surface starts looking like what your customers expect.

- Step 4: Buffing (5000+ grit) – Final buffing pads, often with polishing compounds, create that deep, mirror-like shine that separates premium work from basic polishing.

Metal-Bond vs. Resin-Bond: When to Use What

Metal-bond diamond discs are your heavy hitters. The hard metal matrix grips diamonds securely for aggressive material removal. Use these for initial grinding when you need to remove significant amounts of stone quickly.

Resin-bond diamond pads use a softer matrix that allows worn diamonds to fall away, exposing fresh cutting surfaces. This self-sharpening action is crucial for achieving scratch-free surfaces.

Dinosaw's resin-bond pads are engineered for extended life and consistent performance, reducing your tool change frequency and improving productivity.

Textured Finishes: When Brushes Replace Pads

Popular "leathered" and "antique" finishes require a completely different approach. Instead of flat pads, you'll use abrasive brushes with diamond-impregnated bristles.

These brushes follow the stone's natural contours, selectively removing softer minerals while leaving harder ones intact. The result is that textured, tactile surface that's become a signature of high-end design work.

Beyond Polishing: Chemical Treatments and Advanced Techniques

Mechanical polishing gets you 90% of the way to a perfect finish. The remaining 10% comes from understanding when and how to use chemical treatments and advanced surface modification techniques.

When Chemical Enhancers Make Sense

- Penetrating sealers should be applied after final polishing. They soak into the stone's pores, creating a barrier against water and oil absorption. Essential for high-traffic commercial applications.

- Color enhancers darken natural stone to intensify its appearance and mask minor imperfections. Apply before sealing for best results.

Advanced Texturing: Sandblasting and Laser Technology

For specialty architectural projects, advanced texturing creates unique surface effects that can't be achieved with traditional polishing.

- Sandblasting creates uniformly rough, frosted textures perfect for slip-resistant surfaces or decorative applications.

- Laser etching offers precision pattern creation and fine texture control, though it remains a specialized, high-cost technology for specific applications.

Partnering with Dinosaw: Your Path to Consistent Excellence

World-class finishing isn't about one perfect machine or one amazing abrasive. It's about understanding how every component works together: robust machinery, precise process control, and methodical abrasive selection.

Dinosaw's integrated approach combines high-performance polishing equipment with specialized diamond tooling designed specifically for your production needs. This combination delivers the consistency, quality, and efficiency that separates industry leaders from everyone else.

The result? You meet demanding client specifications, reduce rework and waste, and improve the profitability of your entire operation.

Your Questions Answered: Solutions to Common Polishing Problems

Why am I getting swirl marks or "orange peel" texture on my finished slabs?

This almost always traces back to your abrasive progression. Either you're skipping grit levels (leaving scratches that finer grits can't remove), or you're using worn-out pads that burnish instead of cutting. Check your grit sequence and inspect pad condition on every polishing head.

How can I get deeper gloss on black granite?

Black granite requires a complete sequence up to at least 3000 grit, but the secret is in the final buffing step. Use a high-quality buffing disc with minimal water and correct pressure. The friction-generated heat helps create that deep, mirror-like luster.

Should I invest in a full polishing line or stick with bridge polishers?

Your production volume decides this. High-volume slab distribution requires an automatic line for speed and consistency. Custom countertop and specialty work benefits from bridge polisher flexibility. Many successful operations use both strategically.

How do I extend the life of expensive diamond polishing pads?

Three critical factors control pad life:

- Adequate water flow prevents overheating and clears away abrasive slurry that can clog the pad surface.

- Correct machine parameters – excessive pressure strips diamonds prematurely; insufficient pressure reduces cutting efficiency.

- Regular cleaning prevents slurry buildup that reduces cutting performance and shortens pad life.

Are cheap polishing discs worth the savings?

Usually not. Quality diamond tools from reputable suppliers like Dinosaw cost more upfront but deliver lower cost per square meter. Our engineered formulations last longer and maintain consistent cutting performance throughout their lifespan, reducing downtime and waste.

Can I use the same pads for both marble and granite?

While some "universal" pads exist, material-specific abrasives deliver better results. Granite's hardness requires aggressive, durable pads. Marble's softness needs gentler abrasives that won't scratch or burn the surface. Dedicated pads optimize both quality and efficiency.

Ready to Transform Your Stone Finishing Operation?

Dinosaw Machine provides complete stone polishing solutions for factories serious about quality and efficiency. Our combination of robust machinery and precision-engineered diamond tooling delivers the consistent results your business demands.

Contact our technical team today to discuss how Dinosaw equipment can elevate your production capabilities and improve your bottom line.

English

English 中文

中文