Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Master CNC automatic stone cutting with our complete guide. Reduce waste 30%, increase precision 20%, and achieve 24/7 production. Equipment selection and implementation strategies from 500+ installations.

CNC stone cutting automation reduces material waste by 30%, increases precision by 20%, and eliminates 50% of safety incidents while enabling 24/7 production. Modern fabricators cut waste from 15% down to just 5%, directly boosting profitability in today's demanding market.

Three factors determine success: equipment configuration matching production volume, software integration with existing workflows, and supplier support quality for training and maintenance. These decisions shape your ROI timeline and operational efficiency.

Dinosaw has guided 500+ stone fabricators through automation since 2015, from 50-person family operations to 500+ employee facilities. Get personalized equipment recommendations from our CNC specialists.

Quick Equipment Selector: Find Your CNC Solution

| What You Make | Choose This Equipment | Key Benefit |

|---|---|---|

| Kitchen Countertops & Vanities Straight cuts, sink cutouts, edge profiles | CNC Bridge Saw | Fast slab processing, automated sink cutouts, high-volume production |

| Architectural Columns & Balusters Round columns, spiral details, custom profiles | CNC Stone Lathe | Creates impossible-to-hand-carve profiles, bidirectional cutting capability |

| Intricate Patterns & Inlays Medallions, artistic designs, precision cuts | 5-Axis CNC Waterjet | No heat damage, ±0.1mm precision, cuts any material thickness |

| Valuable Material Processing Expensive slabs, minimal waste critical | CNC Wire Saw | Single-wire minimal kerf loss, irregular cutting & profiling specialist |

| Basic Operations & Repairs Simple cuts, custom repairs, artistic work | Manual Stone Cutter | Low investment, perfect for specialty work and custom applications |

What is CNC Stone Cutting Technology?

Computer Numerical Control (CNC) technology transforms digital designs into precise stone cutting operations through automated tool movement. Manual cutting depends on operator skill and fatigue levels. CNC systems deliver consistent accuracy regardless of complexity or time of day.

Modern CNC stone cutting systems process CAD files directly. They calculate optimal cutting paths while minimizing material waste and maximizing tool life. According to NIST Manufacturing USA standards, properly calibrated CNC systems maintain positioning accuracy within ±0.05mm over extended production runs.

5-Axis vs 3-Axis CNC Systems Explained

| Feature | 3-Axis CNC | 5-Axis CNC | Best Application |

|---|---|---|---|

| Movement Capability | X, Y, Z linear | X, Y, Z + A, C rotational | Complex 3D profiles require 5-axis |

| Setup Time | 15-30 minutes | 5-10 minutes | 5-axis reduces repositioning |

| Surface Finish Quality | Good (Ra 1.6μm) | Excellent (Ra 0.8μm) | Premium applications need 5-axis |

| Material Waste | 8-12% | 3-5% | 5-axis optimizes cutting paths |

3-axis systems dominate high-volume straight cuts and basic profiling. They're perfect for countertop fabrication and architectural panels. 5-axis systems handle complex sculptural work, curved edges, and intricate architectural details requiring multiple setups on traditional equipment.

CAD/CAM Software Integration Benefits

Modern CAD/CAM integration eliminates manual programming errors. It optimizes cutting sequences for maximum efficiency. Leading systems like Alphacam, EnRoute, and RhinoCAM generate tool paths considering material properties, tool wear, and machine capabilities simultaneously.Integration benefits include 60% reduction in programming time.

You get automatic tool path optimization for minimal waste. Real-time collision detection prevents costly machine damage. Advanced systems provide material usage reporting and cost analysis for accurate project bidding.

Precision and Tolerance Capabilities

Professional CNC stone cutting systems achieve positioning accuracy within ±0.1mm under normal conditions. Premium systems reach ±0.05mm precision levels. This consistency enables seamless assembly of complex projects without field adjustments.Temperature compensation systems maintain accuracy across seasonal variations. Linear encoders provide real-time position feedback. According to ISO/TC 199 Safety of Machinery standards, properly maintained CNC systems demonstrate long-term repeatability within specification for 5+ years.

Types of CNC Stone Cutting Equipment

Equipment selection depends on production volume, material types, and project complexity. Each CNC configuration offers distinct advantages for specific applications. Smart selection maximizes your return on investment.

CNC Bridge Saws for Complex Countertop Fabrication

CNC bridge saws dominate high-volume countertop production. They process full slabs efficiently while maintaining superior edge quality. Modern bridge saws feature automatic blade changers, laser measuring systems, and integrated vacuum handling for seamless workflow. Key specifications include cutting speeds of 0.5-3.0 m/min depending on material hardness. Maximum slab dimensions reach 3400mm x 2000mm. Blade tilting capabilities create beveled edges. Our 5-Axis CNC Bridge Saw processes complex sink cutouts in a single setup, eliminating secondary operations.

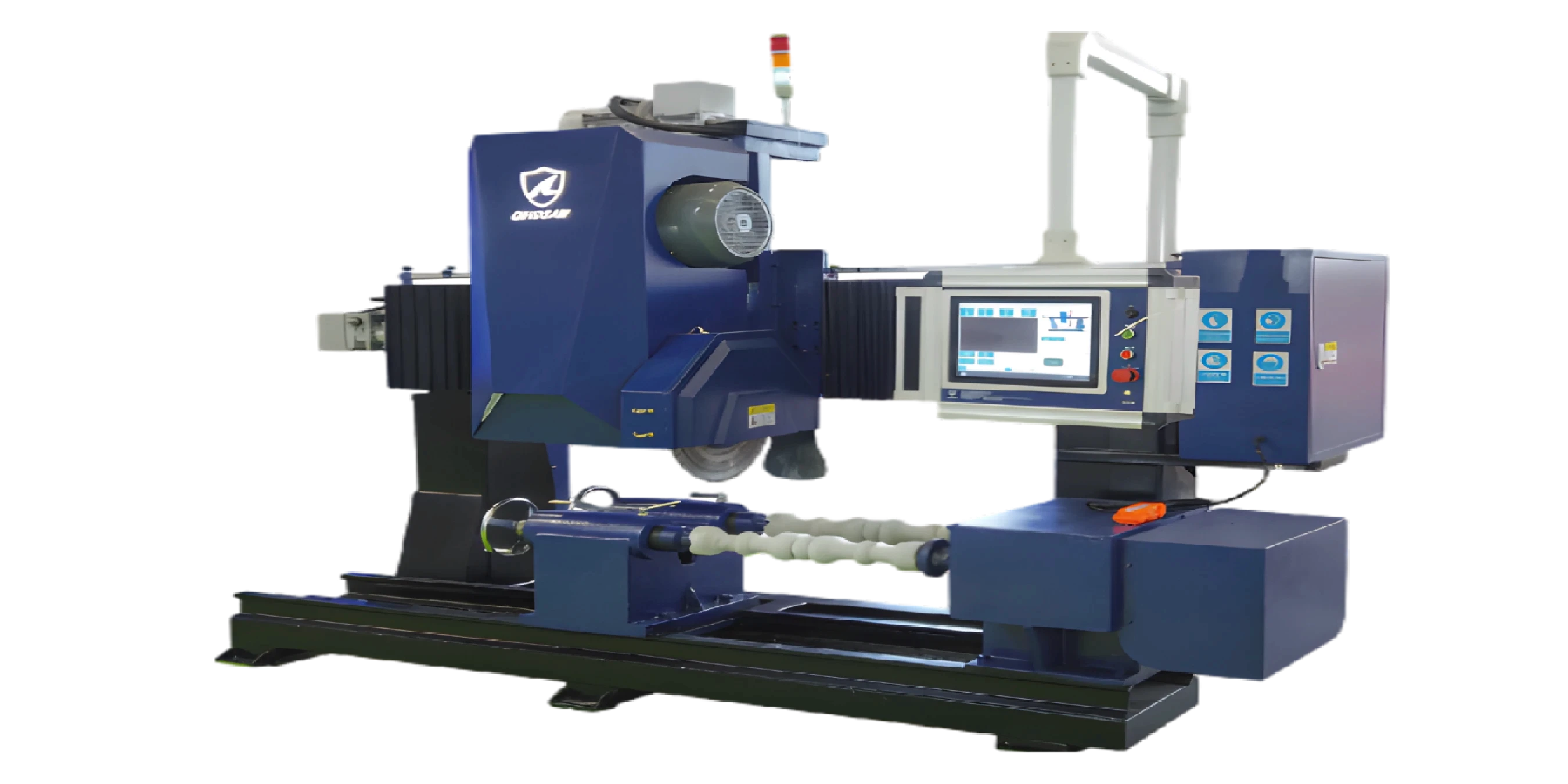

CNC Stone Lathe for Architectural Columns & Balusters

Specialized stone lathes create cylindrical and tapered profiles essential for architectural restoration. Custom millwork becomes achievable. These systems rotate the workpiece while CNC-controlled tools shape complex profiles impossible with traditional methods.Production capabilities include columns up to 4000mm length. Diameters range from 100-800mm. Surface finishes suit direct installation. The CNC Stone Lathe features bidirectional cutting for complex spiral patterns and variable diameter profiles.

Waterjet-CNC Hybrid Systems

Waterjet-CNC hybrid systems combine ultra-high-pressure water cutting (60,000+ PSI) with precision CNC positioning. Materials requiring minimal heat generation become manageable. These systems excel in cutting heat-sensitive stones and creating intricate patterns impossible with diamond tools.Cutting speeds range from 50-500mm/min depending on material thickness and composition. Kerf widths narrow to 0.8mm enabling minimal material waste. Edge quality typically requires no secondary finishing, reducing production time and labor costs. Our 5-Axis CNC Waterjet processes various materials with consistent quality - specific thickness capabilities vary by material type and configuration.

Professional CNC Wire Saw Solutions

CNC single-wire saws utilize a single diamond-embedded wire moving at high speeds to slice through stone with exceptional precision. This technology excels at irregular cutting and profiling applications where complex shapes and minimal material waste are critical. Single-wire systems prove essential for custom fabrication and precision cutting of valuable materials.

The single-wire design achieves ±1mm cutting precision with cutting speeds of 2㎡/ h for marble processing. Modern systems include automatic wire tensioning, coolant recycling, and programmable cutting parameters. The CNC Wire Saw handles specialty materials requiring precise thermal management during cutting, with maximum working dimensions up to 3.5×1.5 meters and processes materials up to several meters thick with easy operation.

CNC vs Manual vs Robotic: Technology Comparison

Understanding fundamental differences between manual, CNC, and robotic stone cutting enables smart investment decisions. Each approach offers distinct advantages depending on production volume, complexity requirements, and available skilled labor.

Precision and Speed Analysis

| Technology | Precision | Speed | Consistency | Best Applications |

|---|---|---|---|---|

| Manual Stone Cutting Machine | ±2-5mm | Slow | Variable | Custom repairs, artistic work |

| CNC Automation | ±0.1mm | Fast | Excellent | Production, complex profiles |

| Robotic Systems | ±0.05mm | Fast | Superior | Ultra-complex 3D shapes |

CNC systems operate 16-20 hours daily compared to 8-hour manual shifts, effectively tripling production capacity. Robotic systems achieve 24/7 operation with proper maintenance scheduling, but require significantly higher investment and specialized programming expertise.

Cost-Benefit Comparison

Initial investment for CNC systems varies significantly depending on configuration and capabilities. Manual operations require minimal equipment investment but face escalating labor costs and skills shortages. This makes automation increasingly attractive for medium to high-volume operations.Operational cost analysis reveals CNC systems reduce per-unit labor costs substantially while improving material utilization.

According to U.S. Bureau of Labor Statistics data , skilled stone cutters command competitive wages, making automation ROI achievable for medium-volume operations, though specific timeframes depend on individual circumstances.Energy efficiency also favors automation. Modern CNC systems consume 30-40% less power per unit produced compared to manual operations requiring extensive lighting, heating, and auxiliary equipment during extended work hours.

Future Trends: Robotic Integration with CNC

Emerging hybrid CNC-robotic systems combine traditional CNC machine stability with robotic flexibility for complex 3D operations. These systems use CNC platforms for primary positioning while robotic arms handle intricate detail work and finishing operations.Current developments include AI-powered quality inspection systems.

They automatically adjust cutting parameters based on real-time material analysis. Machine learning algorithms optimize tool paths for each stone type, reducing setup time from hours to minutes.Industry projections from International Federation of Robotics indicate 40% of stone fabrication facilities will incorporate some level of robotic automation by 2027, driven primarily by labor shortages and quality consistency requirements.

CNC Selection Guide: Matching Equipment to Your Needs

Successful CNC implementation requires systematic evaluation of production requirements, material specifications, and facility constraints. This framework ensures optimal equipment selection for long-term operational success.

Production Volume Requirements Assessment

Low-volume operations benefit from versatile 3-axis bridge saws with manual material handling.

Medium-volume facilities require automated loading systems and integrated measurement for consistent throughput.

High-volume production demands 5-axis systems with automatic tool changers, conveyor integration, and predictive maintenance capabilities.

Calculate required capacity including buffer for peak demand periods and equipment maintenance downtime. Consider seasonal variations in demand, particularly for residential markets experiencing 30-40% volume swings between peak and off-season periods.

Material Types and Thickness Considerations

Equipment selection depends primarily on production requirements and precision needs rather than material type. All stone materials can be processed on most CNC systems - the difference lies in cutting parameters and tool selection optimized for each material's properties.

Budget Planning and ROI Analysis

Total cost of ownership includes equipment purchase, installation, training, maintenance, and consumables over 7-10 year operational life. Factor 15-20% additional costs for facility modifications, electrical upgrades, and safety compliance requirements.Financing options range from traditional equipment loans to lease-purchase agreements with 3-5 year terms. Many suppliers offer installation and training packages bundled with equipment costs, simplifying budget planning and implementation timelines. According to Markets and Markets CNC Machine Market analysis , automation investments generate substantial returns in competitive markets when properly implemented.

CNC Implementation and Optimization

Successful CNC implementation extends beyond equipment installation. It includes facility preparation, operator training, and ongoing optimization processes. Proper planning ensures smooth transitions from manual to automated operations.

Workshop Setup and Installation Requirements

Foundation requirements include reinforced concrete pads 300-500mm thick with vibration isolation systems for precision operations. Electrical systems must provide stable industrial three-phase power with dedicated circuits for each major component - DINOSAW can customize machines according to local voltage requirements. Equipment retrofitting allows existing stone cutting machines to be upgraded with CNC Stone Cutting capabilities, extending equipment life while adding automation benefits.

Environmental controls maintain temperature within ±2°C for dimensional stability while dust extraction systems comply with OSHA silica exposure standards. Proper lighting (500+ lux) and ergonomic workstation design enhance operator safety and productivity.

Operator Training and Safety Protocols

Comprehensive training programs typically require 40-80 hours covering machine operation, programming basics, safety procedures, and preventive maintenance. Advanced programming courses add 20-40 hours for complex applications. Safety protocols include emergency stop procedures, lockout/tagout requirements, and personal protective equipment specifications. Regular refresher training ensures continued compliance with evolving safety standards and manufacturer recommendations.

Maintenance Schedules and Performance Monitoring

Preventive maintenance schedules include daily lubrication checks, weekly cleaning routines, and monthly precision calibration procedures. Modern systems provide automatic maintenance reminders and performance logging for trend analysis. Performance monitoring tracks key metrics including cutting accuracy, tool life, cycle times, and energy consumption. Data analysis identifies optimization opportunities and predicts maintenance requirements before failures occur.

Real-World CNC Applications and Case Studies

Documented case studies demonstrate proven CNC automation benefits across diverse stone fabrication applications. These examples provide realistic expectations for implementation timelines and performance improvements.

High-Volume Countertop Production Lines

A medium-sized fabricator significantly increased daily countertop output while reducing material waste using integrated CNC bridge saw systems. Quality consistency improved dramatically with edge profiles maintaining ±0.05mm tolerance across all production, utilizing the 18.5kW spindle power for reliable performance.Key performance metrics included substantial reduction in edge polishing time, decreased remake requirements, and improved delivery schedule reliability. ROI was achieved faster than initially projected despite higher-than-expected training costs during initial implementation.

Complex Architectural Stone Projects

Historic courthouse restoration required numerous custom limestone pieces with intricate molding profiles. 5-axis CNC machining completed the project significantly faster than traditional methods while achieving perfect profile matching for seamless restoration.Project benefits included digital archive creation for future maintenance, elimination of skilled carver dependency, and consistent quality across all architectural elements. Client satisfaction increased due to predictable delivery schedules and superior fit-and-finish quality.

Custom Monument and Memorial Fabrication

Family-owned memorial company expanded capabilities using CNC single-wire saw technology with ±1mm precision for intricate sculptural elements. Production time for custom monuments decreased substantially while maintaining artistic quality standards, achieving up to 30% material waste reduction.Business impact included increased custom orders, premium pricing for precision work, and reduced dependency on specialized artisan availability. The wire saw's complex contour capabilities significantly reduce hand-finishing time while preserving artistic integrity.

Ready to transform your stone fabrication operation with CNC automation? Our implementation specialists provide comprehensive support from initial assessment through full production optimization. Schedule your automation consultation via WhatsApp to discuss your specific requirements and ROI projections.

Frequently Asked Questions

What ROI timeframe should I expect from CNC stone cutting automation?

ROI achievement varies significantly based on production volume and operational efficiency gains.ROI depends on current labor costs, production volume, and material waste rates. High-volume operations typically see faster payback through labor savings and increased throughput, while specialty fabricators benefit from reduced waste and premium pricing capabilities. Dinosaw provides detailed ROI calculations based on your specific operational parameters during our consultation process, considering factors like current waste rates and production capacity.

How much space is required for a CNC stone cutting installation?

Space requirements depend on equipment configuration and production needs.Space requirements include machine footprint, material storage areas, finished goods staging, and operator access zones. Ceiling height should exceed 4 meters for overhead cranes. Additional space needed for dust extraction equipment, electrical panels, and maintenance access. Dinosaw's facility planning service optimizes layout for maximum efficiency within your available space.

What skill level is required to operate CNC stone cutting equipment?

Basic computer literacy plus 40-80 hours training enables competent CNC operation.Modern CNC systems feature intuitive interfaces requiring minimal programming knowledge for standard operations. Operators need understanding of material properties, tool selection, and quality control procedures. Advanced programming requires additional CAD/CAM training. Dinosaw provides comprehensive training programs from basic operation through advanced programming, with ongoing technical support ensuring operational success.

How does CNC automation affect material waste compared to manual cutting?

CNC automation typically reduces material waste from 12-15% to 3-5% through optimized cutting paths.Advanced nesting software maximizes material utilization by automatically arranging parts for minimal waste. Precision cutting eliminates overcuts and positioning errors common in manual operations. Real-time material tracking provides accurate usage data for cost control. On high-value materials like quartz and granite, waste reduction alone often justifies automation investment.

What maintenance requirements should I expect with CNC stone cutting systems?

Daily maintenance requires 30-45 minutes; comprehensive service every 500-1000 operating hours.Daily tasks include lubrication checks, coolant level verification, and basic cleaning. Weekly maintenance covers way cleaning, filter changes, and precision checks. Major service intervals include spindle maintenance, linear guide replacement, and calibration verification. Preventive maintenance costs typically range 3-5% of equipment value annually. Dinosaw's service network provides scheduled maintenance and emergency support to minimize downtime.

Can existing facilities be retrofitted for CNC automation, or do I need a new building?

Most existing facilities can accommodate CNC systems with foundation and electrical upgrades.Retrofit requirements include reinforced concrete foundations, 480V electrical service, adequate ventilation, and proper drainage. Structural modifications may be needed for overhead cranes or material handling systems. Ceiling height and floor loading capacity often require assessment. Dinosaw's installation team evaluates existing facilities and provides detailed retrofit specifications, typically completing installations within 1-3 weeks including facility modifications.

How do I choose between 3-axis and 5-axis CNC systems for my stone fabrication needs?

3-axis systems excel for flat work and basic profiles; 5-axis systems handle complex 3D shapes and beveled edges.Choose 3-axis for high-volume countertop production, architectural panels, and simple edge profiles. Select 5-axis for sink cutouts, complex moldings, sculptural work, and any application requiring multiple setups on 3-axis equipment. 5-axis systems cost 40-60% more but reduce setup time and improve surface quality.

Consider future growth plans and customer demands when making this critical decision. Dinosaw's application engineers analyze your specific requirements to recommend optimal axis configuration.

What safety considerations are specific to CNC stone cutting operations?

Primary concerns include silica dust exposure, noise levels exceeding 85dB, and emergency stop systems.Silica dust control requires enclosed cutting areas with negative pressure ventilation and HEPA filtration meeting OSHA standards. Noise protection includes sound enclosures and mandatory hearing protection.

Emergency stop systems must be accessible from all operator positions. Safety training covers lockout/tagout procedures, proper lifting techniques, and personal protective equipment requirements. Dinosaw systems include comprehensive safety features and documentation for regulatory compliance.

English

English 中文

中文