Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Discover how waterjet technology cuts everything from delicate textiles to hardened steel with unmatched precision. Explore material versatility advantages, applications across 6+ material types, and why Dinosaw Machine leads the industry. Complete guide for manufacturing professionals.

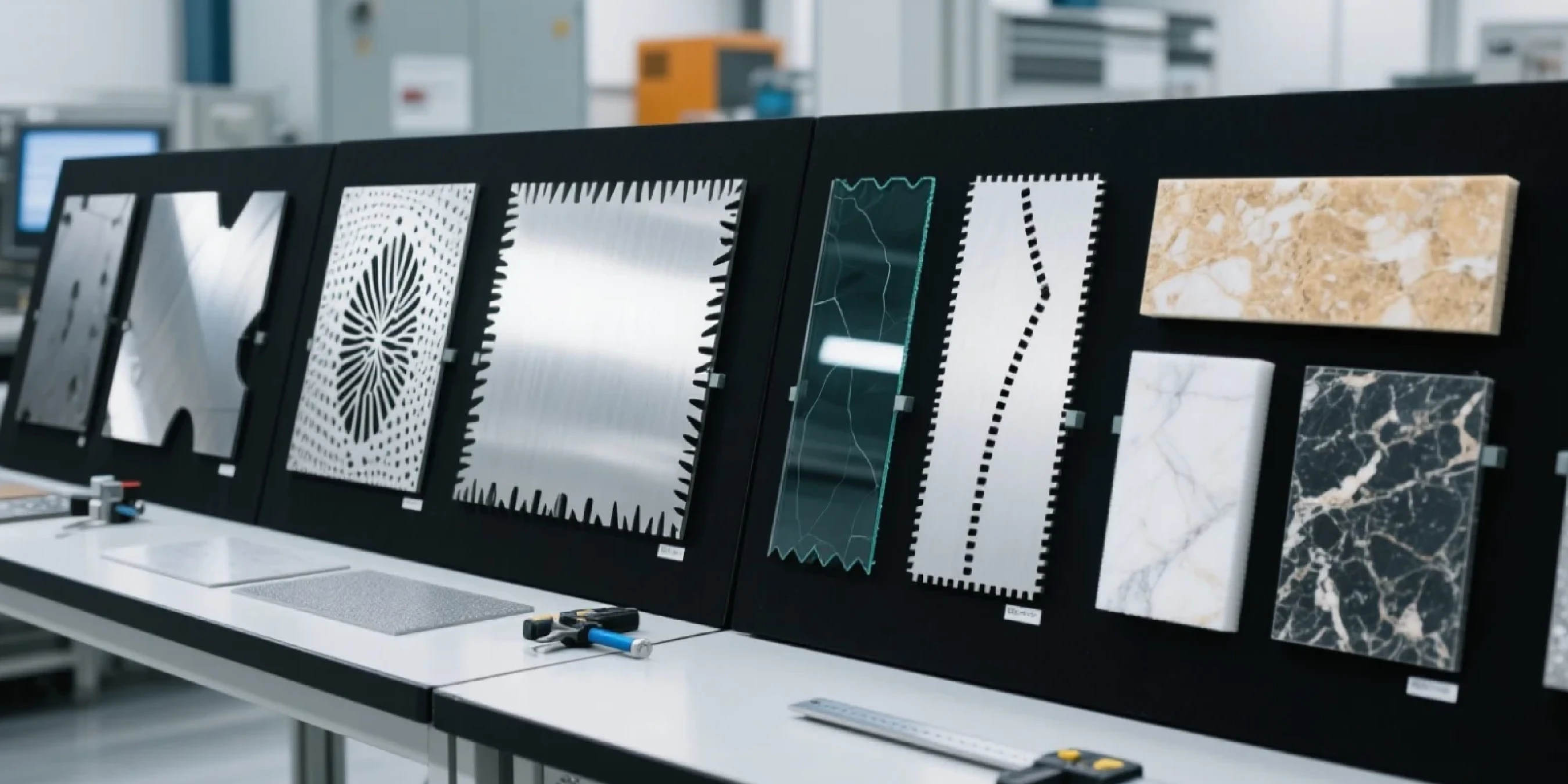

Unmatched Material Versatility

Manufacturing today demands cutting multiple materials-metals, glass, composites, textiles- typically requiring separate machines for each. Waterjet cutting machines have the ability to cut all metals, such as hardened tool steel, aluminum, titanium, copper, brass, and other exotic metals easily, while handling delicate materials like foam and textiles with precision.

Waterjet is the most versatile cutting technology, cutting almost any material (both metal and non-metal). One machine replaces multiple cutting systems, reducing equipment costs and eliminating tool changes across 6+ material categories.

How Waterjet Technology Works

Waterjet technology uses high-pressure water to cut materials, creating water pressure up to 94,000 psi (6,480 bar). For comparison, fire hoses operate at 390-1,200 psi.

Three-step process:

• Pressure Generation: High-pressure pumps create water streams at 94,000 psi

• Velocity Conversion: Tiny jewel orifices convert pressure to velocity

• Abrasive Addition: Garnet increases cutting power 1,000x for hard materials

This dual-mode capability enables cutting across all material types with consistent precision.

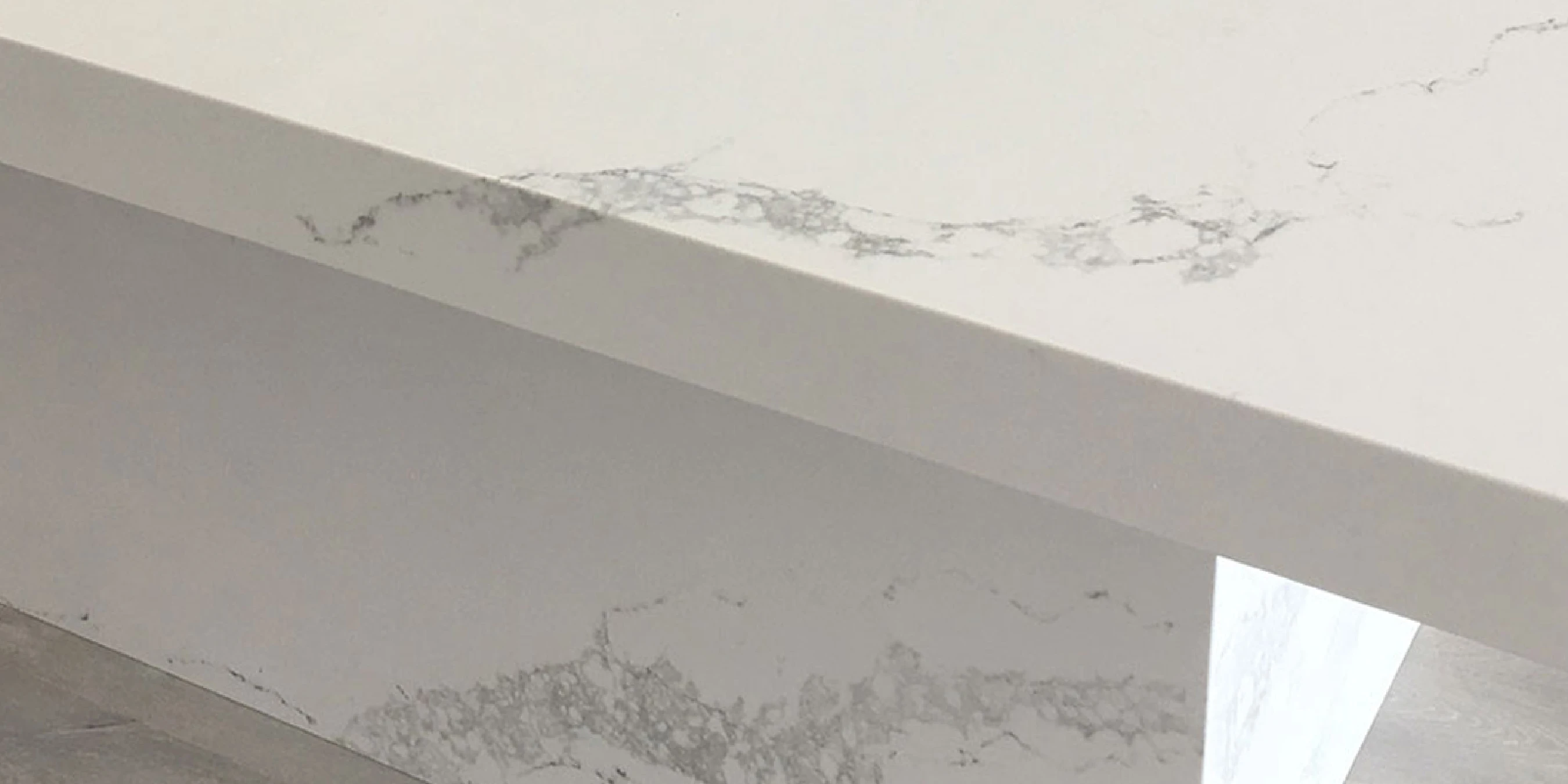

Stone and Granite Cutting Excellence

Waterjet cuts stone up to 12 inches thick. Most granite projects need only 2-4 inches, making waterjet ideal for countertops, monuments, and custom designs.

Key Advantages for Stone Processing

• Cold Cutting: No heat generation prevents thermal distortion and cracking

• Crack Prevention: Precise cutting eliminates chipping and breakage common with other methods

• Dust-Free Process: Water dissolves particles, creating clean working conditions

Complex architectural patterns become achievable with high-speed precision.

CNC control delivers accuracy within ±0.005″ (0.13mm), ensuring consistent quality.

Metal and Aluminum Processing Mastery

Waterjet cuts all steel grades with smooth, burn-free edges ideal for critical applications.

Thickness and Precision Capabilities

Waterjet handles metals up to 6 inches thick, from aluminum and stainless steel to titanium and copper. Precision reaches ±0.002″ for critical applications.

Heat-Affected Zone Elimination

Waterjet creates no heat-affected zones (HAZ), eliminating thermal distortion and preserving material integrity.

For aluminum, no HAZ preserves material integrity, making it ideal for aerospace and automotive applications.

Cutting speeds range 65-200 mm per minute, optimized for quality-to-speed ratios.

Glass and Ceramics Precision Handling

Waterjet cuts glass without interfering with internal structure, preventing stress-induced failures.

Thickness and Accuracy Specifications

Waterjet cuts glass up to 200mm thick with consistent precision.

Modern CNC systems achieve ±0.005 inches (0.127mm) tolerances.

Ceramic Processing Advantages

Ceramic cutting achieves ±0.003 inch tolerances with smooth, burr-free edges, critical for aerospace and medical applications.

Waterjet enables complex patterns and intricate designs previously impossible with conventional cutting methods.

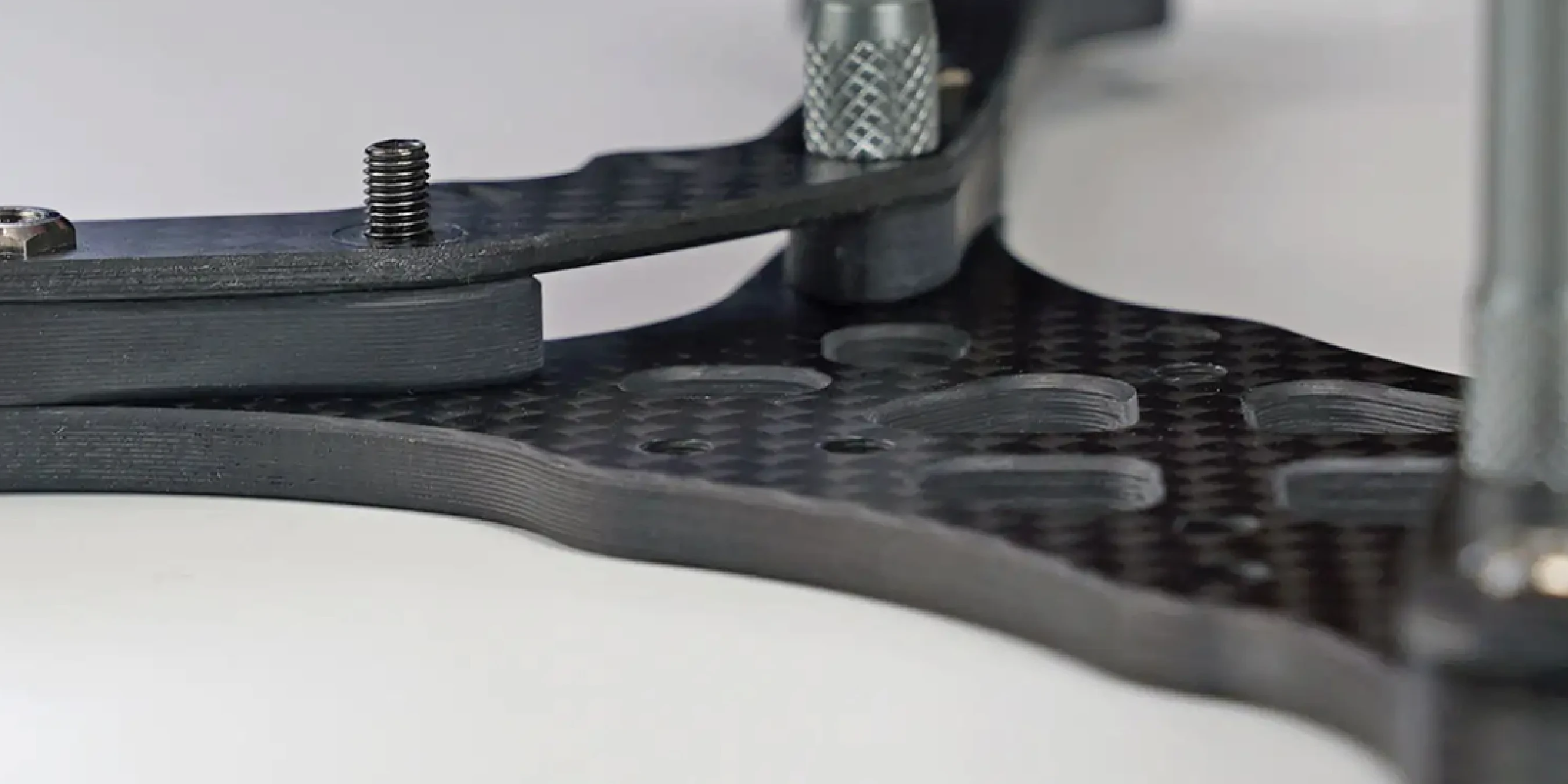

Composites and Carbon Fiber Solutions

Waterjet cuts carbon fiber without heat damage, preventing delamination.

Delamination Prevention

Waterjet produces clean, precise cuts without delamination, fiber pull-out, or thermal damage.

Water jets eliminate fiber pull and delamination, making them preferred for aerospace and automotive composites.

Precision and Thickness Capabilities

Carbon fiber cutting achieves ±0.1mm accuracy, meeting stringent requirements.

Waterjet cuts thick carbon panels easily, while routers require complex setups and risk quality compromises.

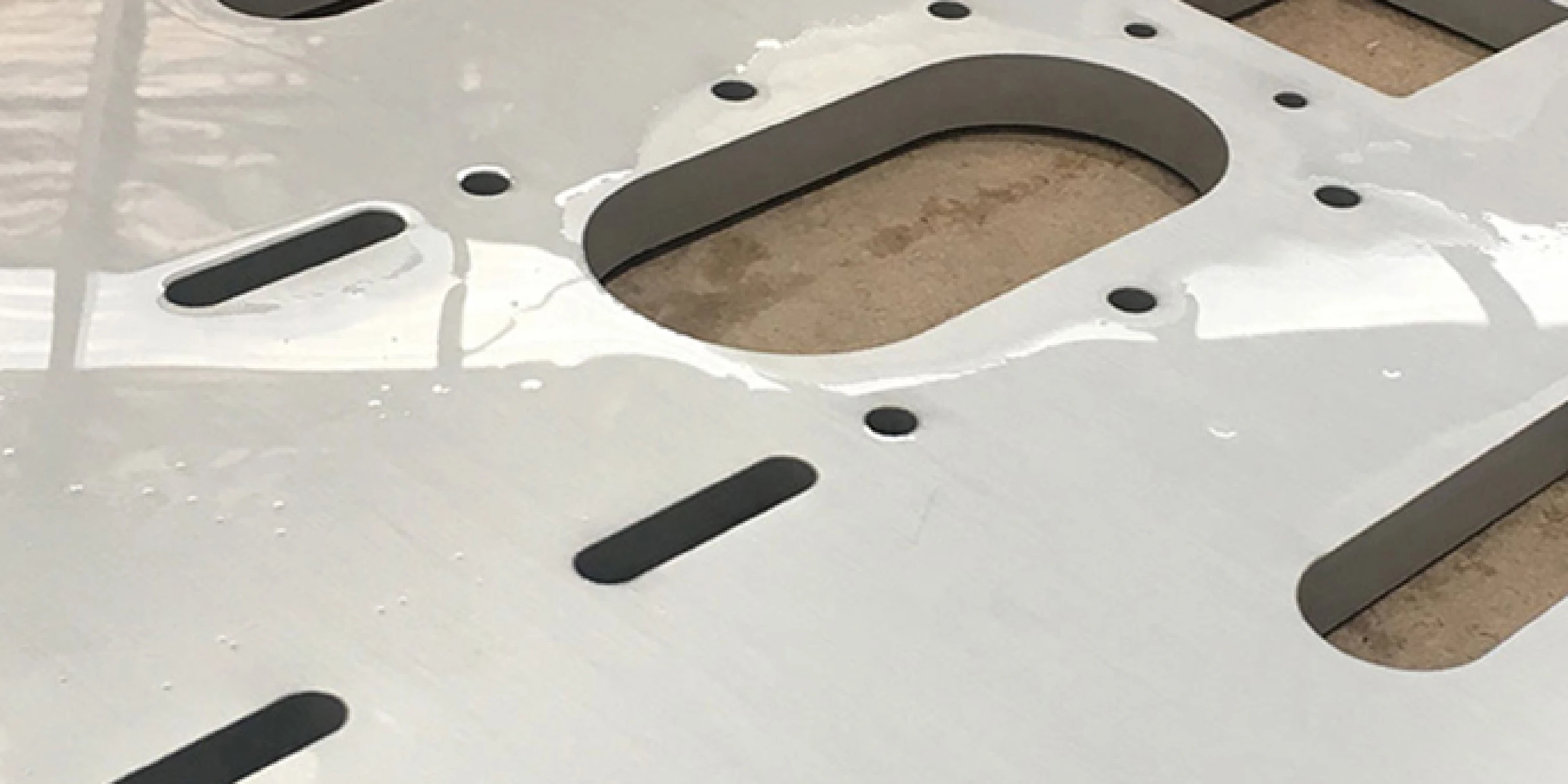

Rubber and Foam Applications

Waterjet cuts foams like polyurethane and memory foam with precise, deformation-free edges.

Production Advantages

Waterjet creates interior cuts without exterior entrances, offers computer programming, and delivers high-speed precision.

Waterjet cuts foam and rubber without compression or deformation, maintaining material properties.

Stack cutting enables efficient production-up to 8 inches of material with same accuracy as single sheets.

This reduces production time while maintaining precision, making waterjet cost-effective for volume production.

Textiles and Leather Manufacturing

Waterjet prevents heat damage to fabrics and allows precise cutting without altering fabric properties.

Multi-Layer Processing

Waterjet eliminates heat-affected zones and cuts multiple layers simultaneously, improving efficiency for apparel manufacturing.

Waterjet shapes textiles and leather without fraying or damage, ideal for high-quality goods.

Safety and Efficiency Benefits

Automated cutting reduces workplace accidents by 90% and consumes 25-30% less energy.

Safety, precision, and efficiency make waterjet popular in fashion and automotive applications.

Why Material Versatility Matters for Modern Manufacturing

Waterjet cuts different materials without tool changes, eliminating downtime and reducing complexity.

Economic Impact

The global waterjet market will reach USD 1.5 billion by 2026, growing at 6.2% CAGR, demonstrating strong market confidence.

Manufacturers recognize that waterjet reduces the need for multiple specialized cutting systems.

Operational Flexibility

Waterjet cuts materials from 1/16 inch to over 10 inches thick, adapting to diverse requirements.

This flexibility enables quick market response and optimized equipment utilization.

Small kerf width minimizes material waste, making waterjet cost-effective for expensive materials.

Frequently Asked Questions

Material Compatibility Questions

Q: What materials can waterjet cut?

A: Waterjet cuts all metals (hardened tool steel, aluminum, titanium, copper, brass), stone, glass, ceramics, composites, rubber, foam, and textiles. It handles virtually any material except tempered glass and some ceramics.

Q: Can waterjet cut multiple different materials in one setup?

A: Yes, waterjet cuts different materials without tool changes or nozzle modifications, making it ideal for mixed-material projects.

Q: What's the maximum thickness waterjet can cut?

A: Waterjet cuts materials from 1/16 inch to over 10 inches thick, with metals up to 6 inches and stone up to 12 inches being common capabilities.

Precision and Quality Questions

Q: How precise is waterjet cutting?

A: Waterjet achieves tolerances of ±0.002″ for metals, ±0.005″ for stone, and ±0.003″ for ceramics, making it suitable for high-precision applications.

Q: Does waterjet create heat-affected zones?

A: No, waterjet creates no heat-affected zones (HAZ), eliminating thermal distortion and preserving material integrity-a major advantage over laser and plasma cutting.

Cost and Efficiency Questions

Q: How does waterjet reduce manufacturing costs?

A: Waterjet eliminates the need for multiple specialized cutting systems, reduces tooling costs, minimizes material waste through small kerf width, and eliminates secondary finishing operations.

Q: What are typical cutting speeds?

A: Waterjet cutters cut at speeds averaging 15 cm per minute, with metal cutting ranging 65-200 mm per minute depending on material and thickness.

Technical Operation Questions

Q: How does waterjet compare to laser cutting?

A: Waterjet is more versatile, cutting almost any material, creates no heat damage, handles thicker materials, but operates slower than laser for thin metals. Laser is limited to specific materials and thicknesses.

Q: Is waterjet environmentally friendly?

A: Yes, waterjet cutting releases no fumes or hazardous waste, uses only water and recyclable garnet abrasive, and consumes 25-30% less energy than traditional cutting methods.

Choose Dinosaw Machine for Waterjet Versatility

Waterjet is the most versatile cutting technology, cutting almost any material and thickness. Dinosaw Machine leads this revolution with cutting-edge waterjet solutions combining German engineering precision with competitive pricing.

Whether processing stone, cutting precision metals, or handling delicate textiles, Dinosaw Machine's waterjet systems provide the versatility, precision, and reliability modern manufacturing demands. Contact us today to discover how our solutions can transform your manufacturing capabilities.

English

English 中文

中文