Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

An engineer's guide to multi-blade stone block cutting machines. Understand architecture, precision lift systems, spindle speed ranges (rpm), and failure mitigation for granite and marble.

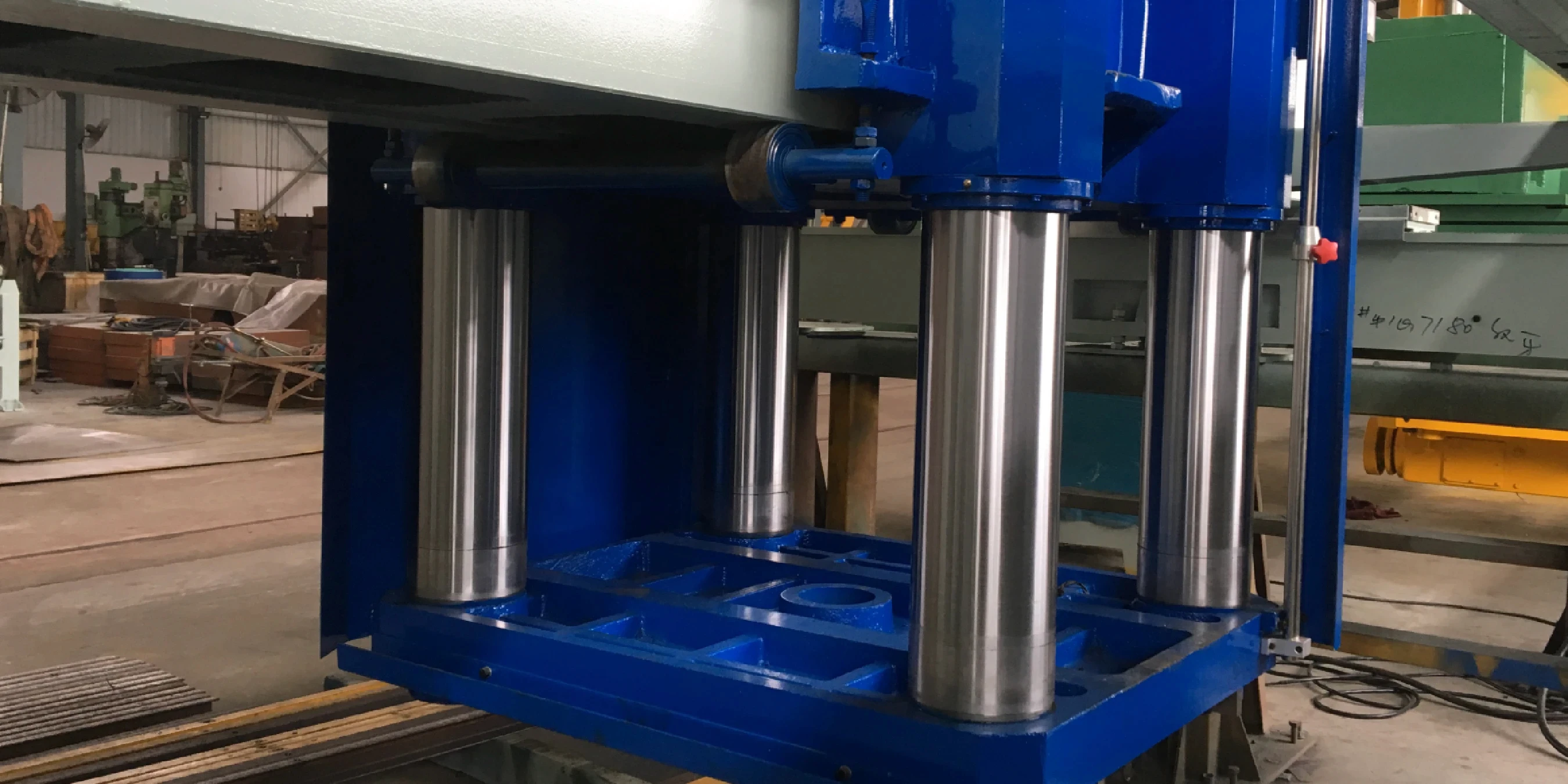

What this system is - A bridge-type stone block cutting machine configured as a multi-blade block saw for high-throughput block-to-slab conversion.

DINOSAW’s guide-post lift is the standard (custom slide lift available), combined with a rigid cast crossbeam overall frame for structural stability and cut accuracy, including hard stone tasks (manufacturer-reported).

Request a parameter sheet tailored to your blade diameter, slab thickness target, and kerf setup.

Architecture Overview

- Cast crossbeam overall frame: High rigidity, vibration dampening; maintains cut stability and tolerance on granite/marble (manufacturer-reported). For material behavior and processing context, see Stone Identification & Processing Solutions.

- Lift system: Guide-post lift (standard) with precise vertical motion; optional slide-type lift per customer need.

- Spindle train: Motor → V-belt pulleys → gearbox → main spindle; speed control via pulley diameters and gearbox ratio.

- Lubrication: Semi-fluid grease (000/00) on guide-posts; auto-lube available for slide type; oil indicators for inspection.

- Control & safety: Touch panel HMI, current/voltage sensing; auto feed-rate reduction on blade jam (manufacturer-reported); enclosure lighting.

- Surface protection: Shot-blasted and anti-rust coatings on exposed parts.

Parameter Principles and Example Ranges

1) Spindle Speed (rpm) vs. Blade Diameter

Spindle rpm should match blade diameter and slab thickness. Manufacturer-reported example ranges:

- Φ1650: 3.5–4.5 mm (≈0.14–0.18 in) slab base → 455 or 408 r/min; 5.5 mm (≈0.22 in) → 455 r/min.

- Φ1800 / Φ2000: 4.0–4.5 mm (≈0.16–0.18 in) → 455 r/min; ≥5.5 mm (≈0.22 in) → 408 r/min.

- Φ2200: 408 r/min (all thickness).

- Φ2500: 327 r/min (all thickness).

- Φ2800: 287 r/min (all thickness).

Note: Actual rpm depends on stone type (granite vs marble), feed rate, blade spec, and gearbox ratio; verify with site trials.

2) Speed Calculation (for Reference)

Spindle rpm ≈ motor speed × (motor V-pulley diameter ÷ spindle V-pulley diameter) ÷ gearbox ratio.

- Typical motor: 6-pole ≈ 980 r/min.

- Typical gearbox ratio: ≈ 1.5.

Example: 980 × (250 ÷ 500) ÷ 1.5 ≈ 326 r/min (illustrative).

3) Multi-Blade Spacing and Kerf

- Set blade spacing from target slab thickness + kerf width; keep spacing consistent for SKU families (marble).

- Guide-post precision helps maintain vertical alignment, reducing blade deviation and uneven kerfs.

- Hanging length options (manufacturer-reported): 400 mm (slide standard), 400 mm (guide-post standard), 500 mm (optional for both types).

When cutting complex shapes or planning alternative methods, review our Diamond Wire Saw Guide as a complementary approach.

Failures & Mitigation

- Blade wobble/vibration: Causes - worn bearings, misaligned pulleys, improper rpm/feed. Mitigation - inspect bearings, re-balance pulleys, match rpm to diameter; reduce feed.

- Deviation/uneven kerf: Causes - lift play, blade wear, inconsistent spacing. Mitigation - verify guide-post clearance, refresh blades, re-set spacing; run QA checks.

- Overheat/burn marks: Causes - excessive rpm/feed, poor lubrication/cooling. Mitigation - lower rpm or feed; check lube and coolant delivery.

- Feed stall/jam: Causes - inclusion/hard vein, aggressive feed. Mitigation - enable current-based auto slow-down; step the feed; pre-scan block face.

- Electrical anomalies: Causes - unstable power or wiring. Mitigation - verify supply; inspect cabinet; use surge protection; maintain grounding.

Compatibility

- PLC/drive integrations: Standard digital/analog I/O; support for industrial protocols (e.g., OPC UA/Profinet if applicable).

- Fixtures and guarding: Configurable clamps/guards; ensure clearance for Φ1650–Φ2800 diameters. To benchmark equipment families and vendor strengths, explore Top Brands in Stone Cutting.

- Operator aids: Enclosure lighting; touch panel displays current/voltage; optional wireless controls (manufacturer-reported).

Starting Settings

Use these as orientation only; finalize via trials and QA checks.

- Granite, Φ1800–Φ2000: Start at 455 r/min for 4.0–4.5 mm slabs; if ≥5.5 mm start 408 r/min; feed rate: set to avoid current spikes; spacing per target thickness.

- Marble, Φ1650: Start 408–455 r/min depending on finish requirements; maintain constant spacing for SKU families.

- Mixed inventory (export yard): Schedule by diameter bands (Φ1650/Φ1800/Φ2000/Φ2200/Φ2500/Φ2800); keep rpm within the example ranges; standardize kerf targets to aid downstream finishing.

All parameter examples above are manufacturer-reported or derived from typical setups; confirm on site.

Frequently Asked Questions

How do I choose spindle rpm for a given blade diameter?

- Use diameter bands: e.g., Φ1800–Φ2000 → 455 r/min (4.0–4.5 mm), ≥5.5 mm → 408 r/min; Φ2500 → 327 r/min; Φ2800 → 287 r/min (manufacturer-reported).

- Validate onsite against stone hardness, feed rate, and gearbox ratio.

What’s the formula to estimate block saw rpm?

Spindle rpm ≈ motor speed × (motor V-pulley ÷ spindle V-pulley) ÷ gearbox ratio. Example with 6-pole ~980 r/min and ratio ~1.5 → ~326 r/min.

Guide-post vs slide lift - which is more precise?

- Guide-post: Tighter vertical guidance, lower deviation; routine grease (000/00) and clearance checks.

- Slide: Suitable for certain retrofits; expect more alignment maintenance and track inspection.

How do I set multi-blade spacing?

- Define slab thickness target.

- Account for blade kerf.

- Keep spacing constant for SKU families; run QA checks at pack-out.

What are typical failure signals and mitigations?

- Blade wobble/vibration → check bearings/pulleys, match rpm to diameter, reduce feed.

- Deviation/uneven kerf → verify lift clearance, refresh blades, re-set spacing.

- Overheat → lower rpm/feed; check lubrication/cooling.

- Feed stall/jam → enable current-based slow-down; step feed; pre-scan block face.

How to estimate feed rate without overheating?

- Monitor current spikes; reduce feed or rpm if they occur.

- Ensure consistent coolant delivery across all blades.

- Trial small adjustments based on stone hardness and blade condition.

English

English 中文

中文