Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

The executive case for CNC bridge saws-lead time, yield, predictability, risk. PLC vs CNC options.

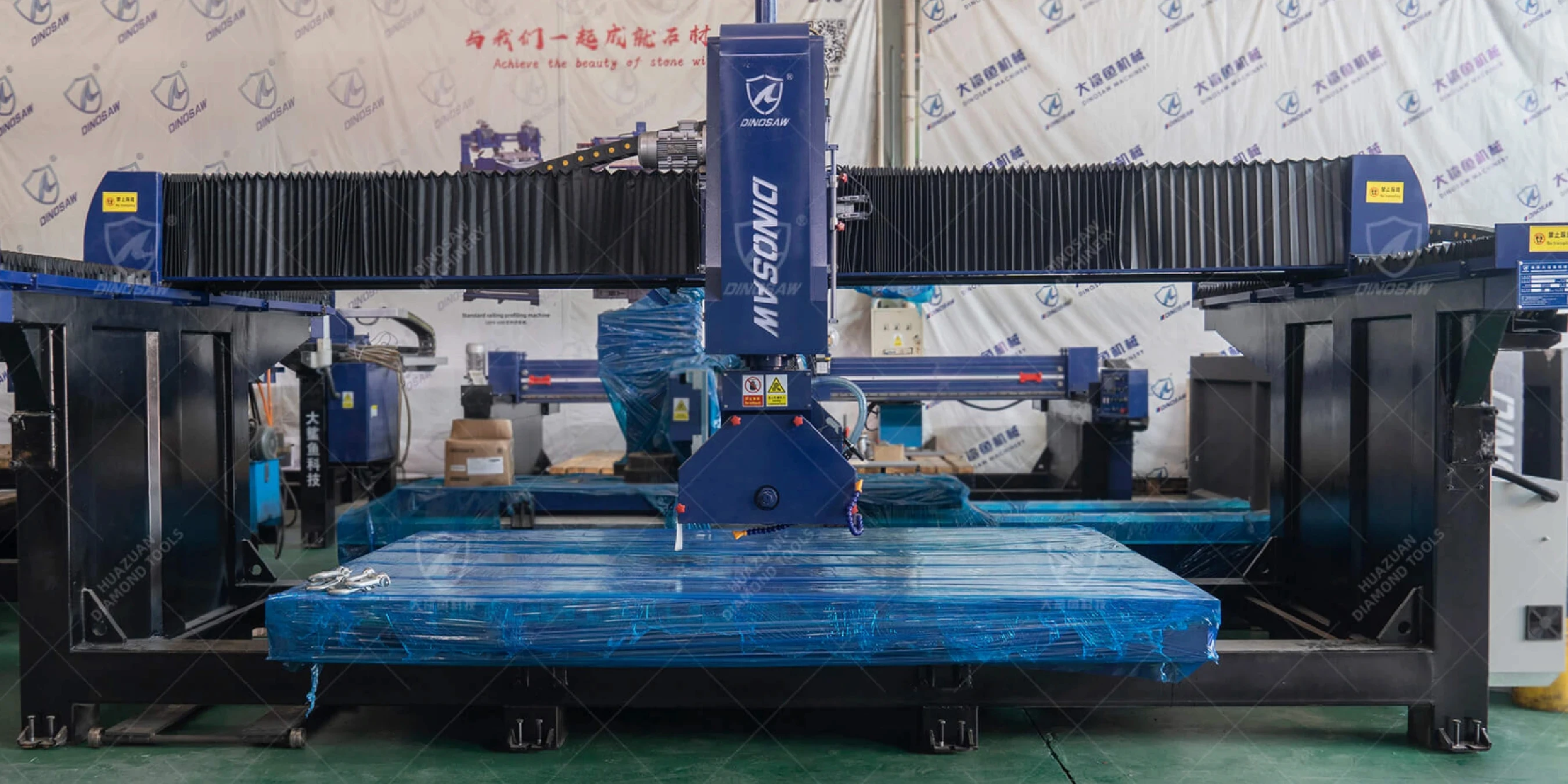

The business case for a CNC bridge saw is straightforward: it delivers shorter lead times, higher material yield, and more predictable operations, all while controlling risk through standardized routines. DINOSAW offers both PLC and full CNC configurations to match your shop's needs.

For many shops, a PLC-based system (3-axis, 4-axis, or 4+1) with laser positioning is the ideal fit for straight cuts, miters, and slotting. For those focused on complex sink cutouts, custom countertops, or 5-axis contouring, a full CNC system is necessary. Key options like vacuum cups, a camera, a milling cutter, or a tilting table can further enhance productivity.

Contact DINOSAW to discuss bridge saw ROI for your shop

The CNC Bridge Saw ROI Value Storyline

- Lead Time: Predictable cutting cycles allow you to make and keep delivery promises.

- Margin: Reduced material scrap and less rework directly increase job profitability.

- Customer Promises: Consistent, high-quality output builds trust and secures repeat business.

- Training: A guided HMI and simple job loading reduce the time and cost of onboarding new staff.

- Service: Modular machine designs and clear maintenance SOPs reduce unplanned downtime.

Calculating Simple ROI for a Stone Bridge Saw

The levers for improving cost-per-slab are clear:

- Precision: Less rework means lower costs.

- Nesting & Layout: Optimized cutting paths increase material yield.

- Automation: Reduced manual labor lowers direct costs.

- Coolant Management: Proper care extends blade life, reducing consumable costs.

- Camera/Vacuum Systems: Faster setup times mean more cutting time per shift.

Implementation Roadmap: From Pilot to Scale

- Pilot: Define the scope and acceptance KPIs for the first machine.

- Acceptance: Verify the machine meets agreed-upon performance targets.

- Standardize: Lock in SOPs, documentation, and training protocols.

- Scale: Plan the rollout to multiple lines or facilities based on the successful pilot.

Series Overview & Internal Links

For deeper context, explore the full series below. This executive summary builds on the detailed insights provided in each dedicated article.

- Applications & Cases - Learn how fabrication shops cut lead times and reduce rejects with real-world scenarios

- Technical Principles - Dive into the architecture, core components, and machine setup that enable high precision

- Selection & Comparison - Use our no-jargon buyer’s guide to choose the right machine based on throughput, job mix, and budget.

- Operations & Maintenance - Access practical SOPs, troubleshooting flows, and preventive care plans to maximize uptime.

Risks & Boundaries for Granite Countertop Work

Strategic investment requires knowing what not to do. Avoid over-investing in capabilities you don't need or under-investing in a machine that can't handle your core business. For extremely porous or fragile specialty materials, always confirm tooling and process parameters with your vendor before committing to a job.

FAQs: Executive Questions

What payback period is realistic for a CNC bridge saw?

The payback period varies widely by shop throughput, job mix, and local costs. A credible ROI calculation must be based on your own data for labor savings and waste reduction.

Can a CNC bridge saw connect to ERP or scheduling?

Integration may be possible if the machine exposes compatible industrial data interfaces. This is a critical point to verify with your vendor and software provider to ensure compatibility.

Biggest financial lever-rework or changeover on a stone bridge saw?

For most shops, it's the powerful combination of reduced rework (higher yield) and faster job changeovers (higher throughput), which together boost both revenue and margin.

Is 5-axis necessary for stone bridge saw buyers?

No. A 5-axis machine should only be considered if your job mix justifies its higher cost and complexity. Base the decision on a clear ROI assessment, not features alone.

English

English 中文

中文