Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Complete stone grinder machine selection guide. Compare industrial vs workshop equipment specs, power requirements, safety standards. Expert technical advice included.

Choosing the right stone grinder machine comes down to three key factors: your production volume, the types of stone you process, and your workspace setup. This guide gives you the exact specifications you need for each scenario, so you can pick the right equipment without getting lost in technical jargon. Here's what you need to know upfront: industrial operations need 15-50HP systems for continuous production, while workshop setups work fine with 1-10HP machines for project-based work. The wrong choice costs you time, money, and potentially safety compliance issues. We'll break this down into simple decision trees based on your specific needs. Whether you're setting up a new facility or upgrading existing equipment, you'll know exactly what to buy by the end of this guide.

Stone Grinder Equipment Categories and Technical Specifications

Quick Decision Guide: Industrial vs Workshop

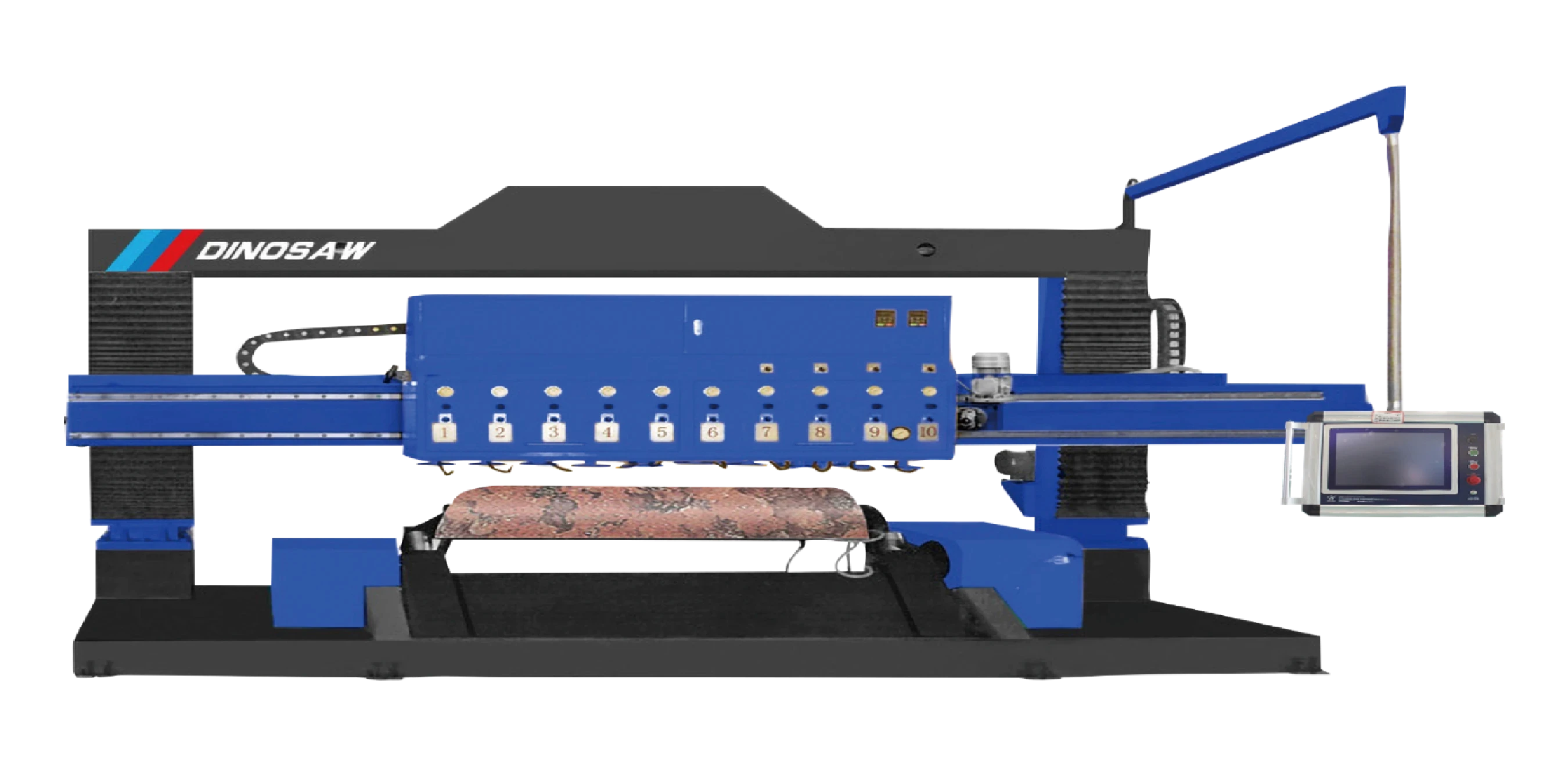

- If you process more than 50 slabs per week: You need industrial-grade systems with 15-50HP motors. These handle continuous operation without overheating or performance drops.

- If you process less than 20 slabs per week: Workshop-level machines with 1-10HP motors will handle your volume efficiently. They cost less upfront and use standard electrical connections.

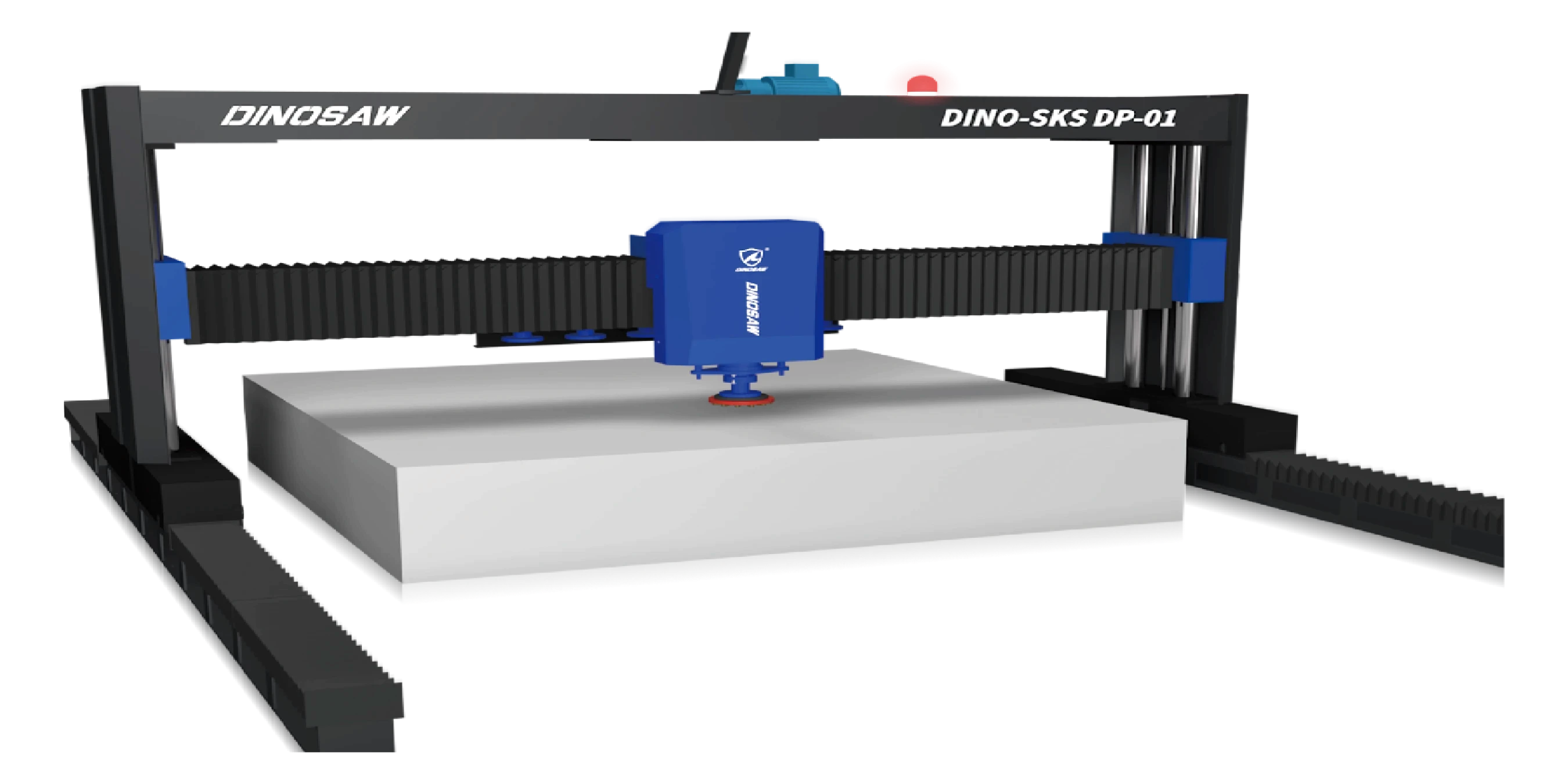

- If you need both flexibility and automation: CNC-controlled systems with automatic tool changing give you the best of both worlds. One machine handles rough grinding through final polishing, saving space and labor costs.

- If you're planning to grow: Start with modular systems that let you add automation later. This avoids the "too small too soon" problem that forces expensive equipment replacement.

Power and Safety Requirements Made Simple

- For granite and quartz: You need minimum 15HP for consistent results. Lower power creates heat buildup, poor finishes, and excessive tool wear. Safety requires OSHA-compliant dust collection systems.

- For marble and limestone: 5-10HP handles these softer materials easily. The key is gentler grinding pressure to avoid damage, not more power.

- For safety compliance: You must have dust collection that meets CDC/NIOSH standards - this isn't optional. Look for systems with integrated water cooling and 99.9% filtration efficiency.

- For consistent quality: Continuous calibrating systems maintain ±0.5mm accuracy across large slabs. This eliminates the hand-sanding and rework that kills profitability.

Technical Consultation Available: Need help figuring out the optimal specs for your stone grinding project? Our equipment experts are standing by on WhatsApp for personalized technical consultation.

Grinding Wheel Selection Simplified

- For rough grinding: Metal bond diamond wheels last 3-5 times longer than resin wheels on hard materials. Start with 30-50 grit for stock removal.

- For finishing work: Resin bond wheels give you better surface quality and less heat generation. Essential for marble and other heat-sensitive stones.

- For grit sequence planning: Follow proven progressions - don't skip grits or you'll create scratches that take longer to remove. Check our systematic grit sequence guide for specific recommendations.

- For automatic tool changing: CNC systems handle multiple wheel types without manual intervention. This maintains consistency and speeds up production significantly.

Stone-Specific Grinding Solutions

Hard Stone Processing: What You Need

- For granite processing: You need pressure monitoring systems that prevent overheating. Too much heat causes micro-cracks that ruin expensive slabs.

- For consistent results: Automated pressure control eliminates the hand variations that create swirl marks and uneven finishes.

- For eliminating operator error: Robotic systems maintain perfect pressure and speed across varying surface contours. No more training headaches or quality issues from inexperienced operators.

- For engineered stone challenges: Variable hardness zones in quartz require adaptive grinding parameters. Check our polishing guide for specific techniques that work with different manufacturers' products.

Soft Stone Processing: Gentle Approach

- For marble and limestone: Use lower pressure and specialized tools. These materials scratch and stain easily, so gentle is better than fast.

- For texture creation: Diamond abrasive brushes create uniform surface textures without deep scratches that ruin the appearance.

- For automatic parameter switching: CNC systems automatically adjust speed and pressure when you switch stone types. No manual calculations or guesswork.

- For acid-sensitive stones: Use separate water systems to prevent contamination that causes etching and discoloration.

Specialized Stone Grinding Technologies

Edge Processing Equipment Guide

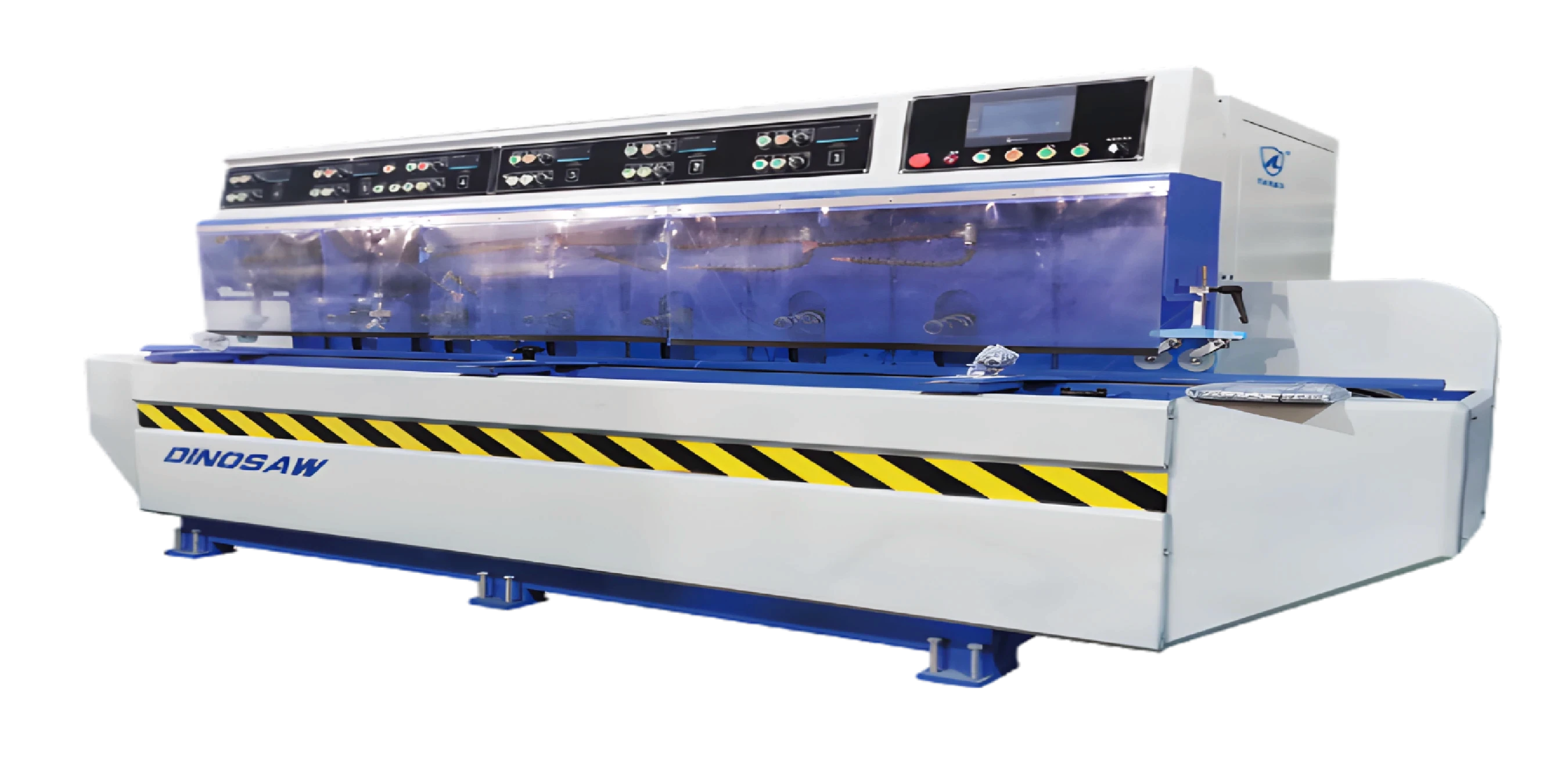

- For standard edge profiles: Automated edge grinding machines maintain ±0.1mm tolerances without operator skill requirements.

- For bullnose edges: Dedicated bullnose machines process various radii consistently, eliminating hand-finishing work.

For glass and stone combination: Dual-material machines automatically adjust parameters when switching between

materials. Check out advanced edging systems that handle both materials efficiently.

Tool life optimization in edge processing depends on proper diamond wheel selection and conditioning. Metal-bond wheels provide extended service life for straight edge grinding, while resin-bond wheels deliver superior surface finishes for decorative profiles. Regular wheel conditioning and truing operations maintain cutting efficiency and prevent surface defects.

Curved Surface Solutions

- For curved surfaces: Standard flat grinding equipment won't work. You need specialized machines designed for curved geometry.

- For arc-shaped slabs: Dedicated arc polishing systems use flexible grinding heads that follow curved surfaces automatically.

- For complex 3D shapes: Multi-axis CNC polishing robots handle sculptural elements and architectural details that manual methods can't achieve.

Curved surface quality control requires specialized measurement techniques and equipment designed to verify dimensional accuracy across non-planar surfaces. Digital scanning and measurement systems provide comprehensive quality documentation for complex geometries, ensuring compliance with design specifications and installation requirements.

Stone Grinder Machine Selection Criteria and Implementation

Avoid These Common Mistakes

- Don't undersize your power requirements: Underpowered equipment creates heat problems, poor finishes, and constant frustration. Better to have 20% more power than you think you need.

- Don't skimp on dust collection: Inadequate systems create health violations and equipment damage from dust buildup. This isn't where you save money.

- Don't forget future growth: Equipment lasting 10+ years should handle more than today's volume. Plan for 50% growth minimum.

Future expansion considerations should influence initial equipment selection, particularly regarding electrical infrastructure, floor space requirements, and integration capabilities with automated handling systems. Modular equipment designs provide flexibility for capacity expansion without complete system replacement.

Getting Started: Installation Basics

- Electrical requirements: Most industrial systems need three-phase power with proper load calculations. Follow electrical codes for safe installation.

- Training investment: Budget for comprehensive operator training. Poor training leads to equipment damage and safety problems that cost more than the training itself.

- Maintenance planning: Set up preventive maintenance schedules from day one. Regular maintenance prevents expensive breakdowns and extends equipment life.

- Quality verification: Process test samples during initial setup to establish baseline parameters. Document everything for future reference and troubleshooting.

Ready to Upgrade Your Stone Processing Capabilities? Get personalized equipment recommendations and competitive pricing through WhatsApp consultation with our specialists.

Frequently Asked Questions

What power requirements are needed for industrial stone grinding operations?

Industrial operations typically require 15-50HP grinding systems. Power requirements depend on material hardness, production volume, and processing methods. Granite processing demands higher power levels (25-50HP) for continuous operation, while marble and softer stones can be processed effectively with 15-25HP systems. Industry standards recommend oversizing motor capacity by 20-30% to accommodate varying load conditions and ensure consistent performance during peak demand periods.

How do I choose between metal and resin bond grinding wheels?

Metal bond wheels excel for hard materials; resin bonds work better for soft stones. Metal bond matrices provide extended tool life and aggressive cutting action suitable for granite and engineered quartz processing. They maintain sharp cutting edges longer and resist wear under high-pressure applications. Resin bond wheels offer superior surface finishes and gentler cutting action ideal for marble, limestone, and acid-sensitive materials. The choice also depends on cooling methods, with water cooling being essential for metal bond wheels to prevent glazing and maintain cutting efficiency.

What safety considerations are critical for stone grinding operations?

Silica dust control and OSHA compliance are paramount safety requirements. Crystalline silica exposure must remain below \(50 \mu g / m^{3}\) according to federal regulations. This requires integrated dust collection systems with minimum 99.9% filtration efficiency and proper water cooling to suppress airborne particles. Safety guards must comply with OSHA 1926.303 standards, wheel speed ratings must not be exceeded, and operators require proper respiratory protection and safety training. Regular air quality monitoring and equipment maintenance ensure ongoing compliance.

What's the difference between workshop and industrial grinding equipment?

Industrial systems offer higher power, automation, and continuous operation capabilities. Workshop equipment (1-10HP) suits intermittent use and smaller production volumes, while industrial systems (15-50HP) handle continuous operation and high-volume processing. Industrial equipment features automated tool changing, robotic operation capabilities, and integrated quality control systems. Workshop systems prioritize flexibility and cost-effectiveness for custom fabrication work. The investment difference typically ranges from $50,000-150,000 for workshop systems to $200,000-500,000 for industrial automation.

How do I maintain consistent quality across different stone types?

Automated parameter control and proper tool selection ensure consistent results. CNC grinding systems with material-specific programming automatically adjust pressure, speed, and feed rates for different stone types. Continuous calibrating systems monitor thickness variations and apply real-time corrections to maintain dimensional accuracy within ±0.5mm. Proper wheel conditioning, regular calibration, and documented processing parameters create reproducible results. Advanced systems store material profiles that optimize processing conditions for specific stone varieties and grades.

What ROI can I expect from investing in automated grinding equipment?

Payback periods typically range from 18-36 months depending on production volume. Automated systems reduce labor costs by 40-60% while increasing throughput by 200-300% compared to manual operations. Quality improvements reduce rework rates from 5-8% to under 2%, while consistent output enables premium pricing for high-quality products. Energy efficiency improvements of 15-25% reduce operating costs, and improved safety compliance reduces insurance and liability expenses. Total cost of ownership calculations should include productivity gains, quality improvements, and reduced supervision requirements.

English

English 中文

中文