Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Stop wasting money on water and slurry disposal. Our 2025 guide for stone fabricators shows how a water recycling system can cut costs and improve equipment life.

For stone fabrication shops, untreated wastewater hits you with three brutal costs: massive water and sewage bills, expensive slurry hauling fees, and the early death of your diamond tools and CNC spindles.

This isn't another product manual. It's your step-by-step blueprint for making a strategic investment that actually pays for itself.

What you'll get from this guide is a clear financial roadmap built on real industry data. We'll show you exactly how to justify the investment, pick the right technology, and maximize your return without making costly mistakes.

Why Water Management Isn't Optional Anymore

Years ago, water was just another cost of doing business in the stone industry. Not anymore. Rising utility rates and stricter environmental laws have completely changed the game.

Today, efficient water management is what separates profitable shops from struggling ones. Ignoring it means watching your competitors pull ahead while you bleed money on avoidable expenses.

The Real Cost of "Single-Use" Water

Your water bill is just the tip of the iceberg. The real killer is municipal sewage fees – often double your fresh water costs for high-volume users like stone shops.

Then there's stone slurry management. Vacuum truck services, disposal fees, settling pit maintenance – these "hidden" costs can add $15,000 to $30,000 to your annual expenses.

Most shop owners don't realize how much they're really spending until they add it all up. The numbers are usually shocking.

Staying Compliant with EPA Standards

Government enforcement is getting tighter every year. According to the EPA's Guide for Industrial Waste Management , improper disposal can trigger severe penalties.

A closed-loop system virtually eliminates process water discharge. This keeps you compliant with local and federal standards while protecting your reputation as a responsible operator.

More importantly, it protects you from the nightmare of forced shutdowns or five-figure fines that can cripple smaller operations.

How Dirty Water Destroys Your Most Expensive Equipment

Using recycled water full of stone particles is like sandblasting your tools from the inside. Diamond blades, polishing pads, and core bits wear out 2-3 times faster than they should.

But the real damage happens to your precision machinery. Take a sophisticated CNC bridge saw like our 5-axis model – those fine particles infiltrate cooling systems and destroy spindle bearings.

The result? Unexpected downtime, emergency repairs, and replacement costs that can hit $20,000 or more when you least expect it.

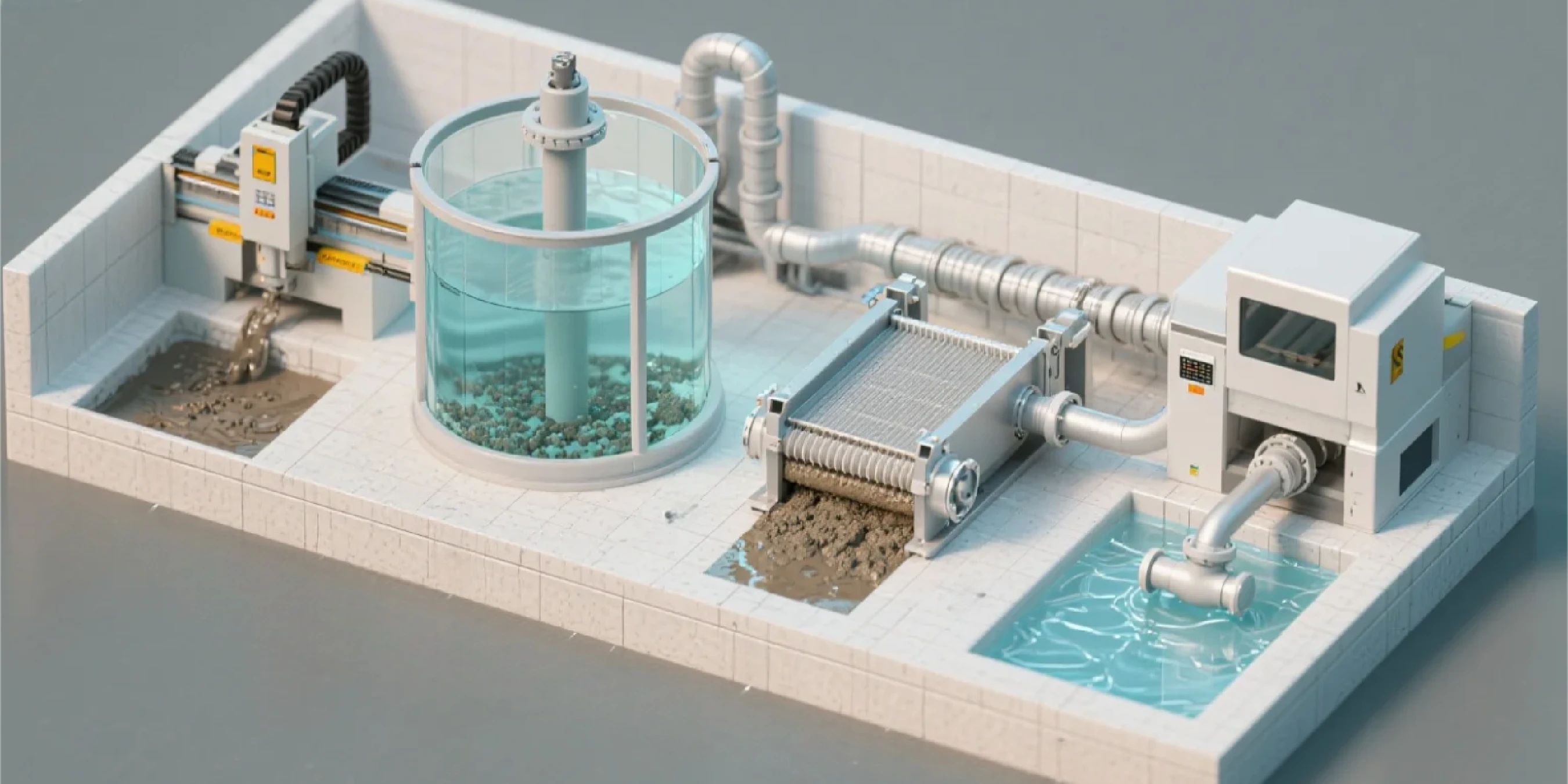

How Closed-Loop Water Recycling Systems Actually Work

Think of a closed-loop water recycling system as your shop's kidney. It captures dirty water, cleans it to crystal clarity, and sends it back to your machines in an endless cycle.

The magic happens in four distinct stages that transform muddy slurry into clean, equipment-safe water.

Stage 1: Collection

Everything starts with your floor drainage system. Pit sumps and trenches capture every drop of slurry from your saws, CNCs, and polishing lines.

A heavy-duty sump pump then moves this slurry cocktail to the main processing unit where the real cleaning begins.

Stage 2: Flocculation & Clarification

Here's where chemistry meets engineering. The system automatically doses flocculant into your slurry water. This chemical acts like a magnet, binding microscopic stone particles into heavy clumps called "floc."

In a vertical clarifier, gravity does the heavy lifting. Those clumps sink to the cone-shaped bottom while clean water rises to the top.

It's simple physics, but the results are dramatic – murky slurry becomes clear water in minutes.

Stage 3: Dewatering & Filtration

The concentrated sludge gets pumped to a filter press – the workhorse of the system. High pressure squeezes out remaining water, forming compact, dry "cakes" of solid waste.

This process reduces waste volume by over 90%. Instead of paying to haul away liquid slurry, you're disposing of neat, stackable solids.

The recovered water? It goes right back into the system for another cleaning cycle.

Stage 4: Storage & Re-Pressurization

Clean water overflows from the clarifier into a dedicated storage tank. A booster pump repressurizes this water and delivers it back to your machines at the right pressure and flow rate.

The loop is complete. Your equipment gets the clean water it needs while you slash operating costs and environmental impact.

The ROI of Water Recycling: Real Numbers That Matter

Let's talk money. A water recycling system isn't an expense – it's a capital investment with a clear, rapid return. Most systems pay for themselves in 18 to 36 months through massive cost reductions.

A 2025 study on Cost–Benefit Analysis of Using Reclaimed Water confirms significant economic viability when all benefits are factored in.

Investment vs. Savings Breakdown

Initial costs range from $30,000 for smaller shops to $150,000+ for large facilities. This covers your clarifier, filter press, pumps, and professional installation.

But here's what really matters – the recurring savings that hit your bottom line every month:

- Water & Sewage Bills: 90-95% reduction typical

- Slurry Disposal Fees: Completely eliminated

- Tool & Equipment Life: 2-3x longer lifespan from clean water

Calculate Your Potential Annual Savings

To estimate your annual savings from a water recycling system, calculate your current monthly costs in these four key areas:

- Water Bills: Multiply your current monthly water costs by 0.90 (representing 90% savings), then by 12 for annual savings.

- Sewage Bills: Multiply your current monthly sewage costs by 0.95 (representing 95% savings), then by 12 for annual savings.

- Slurry Disposal: Multiply your current monthly disposal costs by 1.00 (representing 100% elimination), then by 12 for annual savings.

- Tool Replacement: Multiply your current monthly tool costs by 0.20 (representing 80% reduction from longer tool life), then by 12 for annual savings.

- Total Annual Savings = Sum of all four categories above

Note: Tooling savings vary based on material type and usage patterns. These percentages represent typical industry results.

Real Case Study: $25,000 Annual Savings

One of our Dinosaw customers runs a mid-sized granite shop with one bridge saw and two CNC routers. They were hemorrhaging $2,800 monthly on water, sewage, and slurry disposal.

After installing a properly sized closed-loop system, their combined water and sewage bill dropped to under $150 per month. The $800 monthly slurry hauling fee? Gone completely. Add in longer-lasting diamond tools, and they calculated over $25,000 in annual savings.

Payback period: just under two years.

Want to know your potential savings? Get a free cost-benefit analysis via WhatsApp

Buyer's Guide: Choosing the Right System

Picking the wrong water recycling system is an expensive mistake that haunts shops for years. Get it right, and you'll maximize ROI while future-proofing your operation.

The key is matching system capacity to your actual needs – both current and projected.

Sizing Your System: Calculating GPM Requirements

Start by listing every water-consuming machine in your shop. Check each machine's manual for maximum GPM requirements. Your peak demand is the sum of all these numbers.

Here's the critical part: choose a system with 20-25% more capacity than your calculated peak. This buffer accounts for future equipment purchases and ensures consistent water pressure during high-demand periods.

Undersizing costs more than oversizing. A struggling system means equipment damage and emergency repairs.

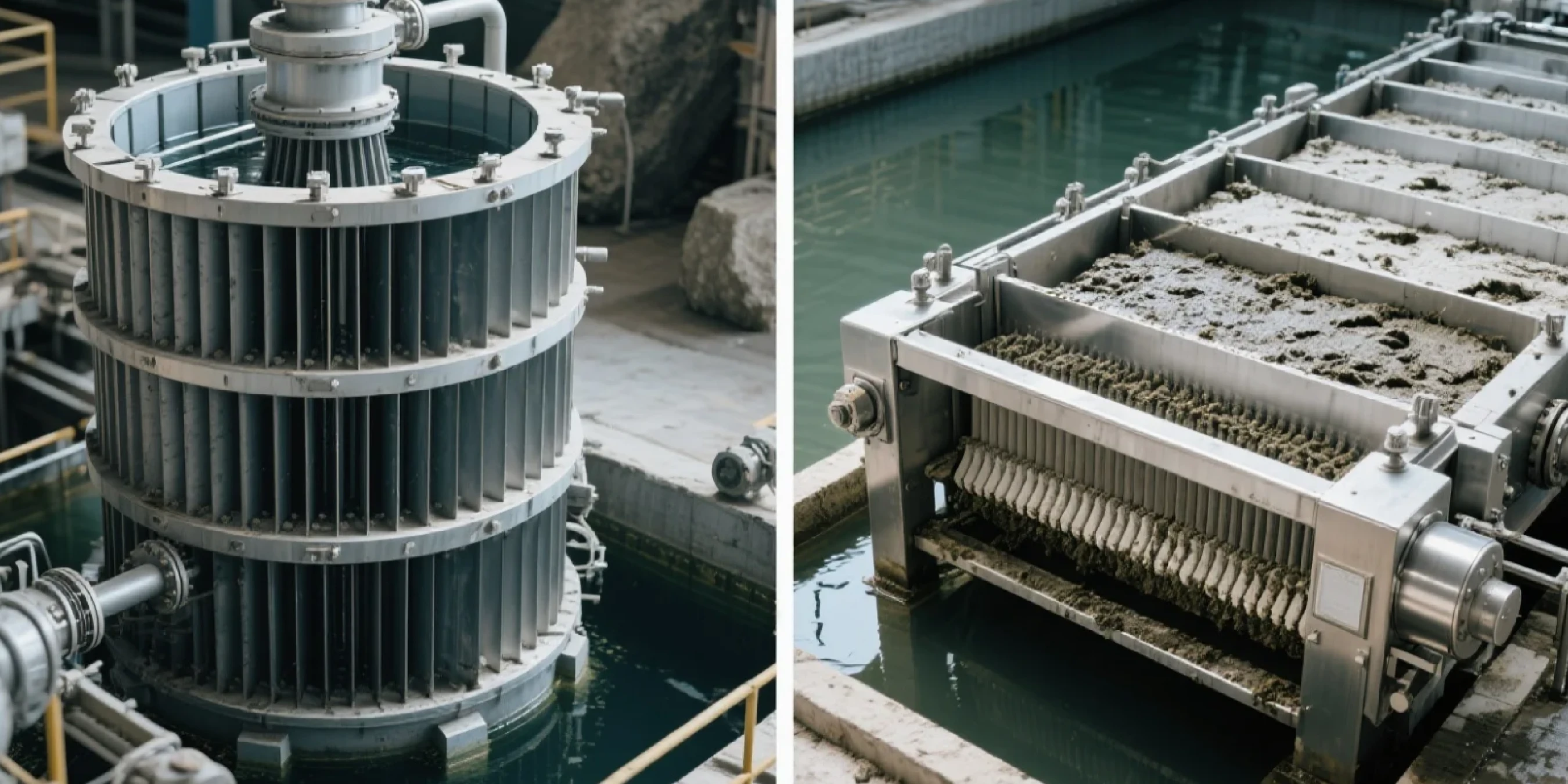

Technology Comparison: Lamellar Clarifiers vs. Filter Press Systems

- Lamellar clarifiers: use inclined plates to dramatically increase settling surface area. They're compact and excel at initial water/solid separation in tight spaces.

- Filter press systems: are the gold standard for dewatering collected slurry. They produce the driest waste cakes, minimizing disposal volume and costs. Higher upfront cost, but massive long-term savings.

For most stone shops, combining both technologies offers the most efficient, automated solution. Want to understand different cutting technologies and their water needs? Check out our comparison of marble gang saw and wire saw .

Essential Features for Long-Term Value

Look beyond basic GPM ratings. The features that separate good systems from great ones include:

- Full Automation: Automatic flocculant dosing, sludge pump activation, and filter press cycles

- Durable Construction: Stainless steel or hot-dipped galvanized tanks that resist stone slurry corrosion

- Efficient Sludge Management: Automated cake disposal mechanisms that save hours of daily labor

5 Costly Buying Mistakes to Avoid

- Under-sizing the System: Buying for today's needs without planning for growth

- Ignoring Build Quality: Choosing painted steel systems that rust and fail within years

- Manual System Selection: Underestimating daily labor costs of non-automated systems

- Poor Vendor Support: Buying from suppliers without proven installation and service records

- Forgetting Consumables: Not factoring ongoing costs of flocculant and filter press cloths

Installation, Operation & Maintenance

A properly installed and maintained water recycling system operates efficiently for decades. But neglect the basics, and you'll face costly downtime and premature equipment failure.

Smart maintenance prevents problems rather than reacting to them.

Installation Requirements

You'll need a dedicated concrete pad with adequate space for the clarifier, filter press, and clean water tanks. Three-phase power for pumps and press is essential.

Plumbing connects your shop's trench system to the unit and routes clean water back to machines. Professional installation typically takes 3-5 days.

Don't cut corners on installation. Poor setup leads to ongoing operational headaches and warranty issues.

Maintenance Schedule That Prevents Problems

- Daily (10-15 minutes): Check flocculant levels and dosing accuracy. Visually inspect recycled water clarity. Empty filter press cakes as needed.

- Weekly (30 minutes): Inspect pump screens for debris. Check all plumbing connections for leaks. Clean filter press cloths per manufacturer specs.

- Monthly (1 hour): Calibrate pH sensors if equipped. Inspect clarifier for excessive sludge buildup. Lubricate motors and bearings as specified.

Troubleshooting Common Issues

- Cloudy Water: Usually indicates improper flocculant dosage or system overload. Check chemical supply and flow rates.

- Low Water Pressure: Points to booster pump problems. Check intake screens and electrical connections.

- Poor Filter Press Performance: Often due to worn cloths, insufficient pressure, or wrong flocculant type.

Future-Proofing Your Water Treatment Investment

Water treatment technology evolves rapidly. Staying informed about emerging trends helps you make smarter long-term investments and optimize operations.

A recent 2025 review on Innovative approaches to sustainable wastewater treatment highlights rapid advancements transforming the industry.

Smart Systems: IoT and AI Integration

Next-generation water recycling systems incorporate IoT sensors and AI optimization. These smart systems monitor water quality continuously, automatically adjusting flocculant dosage, pH levels, and pump speeds.

More importantly, they predict maintenance needs before failures occur. Your phone gets alerts about potential issues days before they cause downtime.

This predictive capability reduces labor costs and improves system reliability significantly.

Zero-Liquid Discharge: The Ultimate Goal

Zero-Liquid Discharge (ZLD) represents the future of sustainable fabrication. All water gets recovered, all contaminants become solid waste. No liquid discharge whatsoever.

While full ZLD systems require significant investment, the principles drive innovation in more efficient filter presses and evaporation technologies.

As water becomes increasingly regulated, ZLD principles may become mandatory rather than optional. The Natural Stone Institute Sustainability Resources emphasizes forward-thinking water management for green certifications.

Investing in high-quality water recycling systems today is your first step toward future-proofing against rising costs and stricter regulations.

Frequently Asked Questions

How much does a stone cutting water recycling system cost?

Complete systems range from $30,000 to $150,000+ depending on capacity and features. Investment is determined by your shop's GPM requirements, automation level, and specific technology choices like filter press size.

Smaller shops typically invest around $45,000, while large multi-machine facilities may spend over $100,000. Dinosaw helps size systems properly to ensure investment matches production needs for optimal ROI.

How much space do I need for installation?

You typically need 200 to 600 square feet (20 to 55 square meters) of dedicated space. Small to medium systems often fit in a 15' x 20' footprint including clarifier, filter press, and clean water tank.

Account for clearance around equipment for maintenance and forklift access to remove dewatered sludge cakes.

What's the typical maintenance schedule?

Daily checks take 10-15 minutes, weekly tasks about 30 minutes, and monthly inspections an hour. Daily tasks involve checking flocculant levels and emptying the filter press.

Weekly maintenance includes inspecting pump filters and hoses. Monthly tasks involve pump lubrication and sensor calibration. Dinosaw provides detailed maintenance checklists to maximize uptime.

Can recycled water damage my CNC machine's spindle?

Yes, if water isn't filtered correctly. High-quality recycled water should be filtered to at least 25 microns for high-speed spindles.

Properly functioning closed-loop systems with effective clarification produce water clean enough for all equipment. However, poorly maintained or undersized systems pose major risks to expensive machinery.

How dry are filter press "cakes"?

Filter press cakes are typically 80-85% solid material with only 15-20% residual moisture. They have dense, soil-like consistency and handle easily with shovels or front-end loaders.

This high dewatering level drastically reduces waste volume and weight, making disposal significantly cheaper than liquid slurry.

Do I need to use chemicals like flocculants?

Yes, flocculants are essential for effective operation. High-quality, pH-neutral flocculant is automatically dosed in controlled amounts. This chemical binds fine stone particles so they separate from water.

Cost is minimal – typically only a few dollars daily – but the effect on water clarity and system efficiency is critical.

What's the difference between GPM and system capacity?

GPM (Gallons Per Minute) refers to real-time processing flow rate. System capacity (measured in gallons) refers to total water volume held in tanks – clarifier, clean water tank, etc.

You need GPM that meets peak machine demand and total capacity providing sufficient buffer for continuous operation.

English

English 中文

中文