Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Professional guide to selecting the right CNC wire saw machine based on cutting dimensions. Compare specifications, applications, and technical requirements. Expert recommendations for optimal sizing and ROI.

Complete Wire Saw Machine Selection Guide

Choose your wire saw machine based on cutting requirements and production needs. All machines feature ±1mm precision cutting with diamond wire technology.

By Cutting Size Requirements:

- Small Projects (up to 1.9×1.9×0.8m): LSSJ-1900-9H Vertical Wire Saw - Space-saving design, ideal for memorial stones

- Medium Projects (up to 2.5×1.5m): YXSJ-2500-16H CNC Wire Saw - Standard industrial cutting

- Large Projects (up to 3.5×1.5m): YXSJ-3500-16H CNC Wire Saw - Heavy-duty industrial applications

- Ultra-Large Blocks (up to 5×3.3×2.3m): XBSJ Series Block Wire Saw Machines - Block Squaring

- Quarrying for Stone Blocks(Moblie Unit): Quarry Wire Saw - Quarry and mining operations

- Ultra-Thin Slabs (3mm+): DSY Multi-Wire Saw Series - Premium stone processing

- Batch Production (up to 1.2×2.4×0.4m): LYSJ-1300-04H Automated Kerbstone Cutter

By Production Type:

- Custom Fabrication: Single-wire CNC machines (LSSJ, YXSJ series) for complex shapes and artistic cutting

- High-Volume Slab Production: Multi-wire machines (DSY series) for maximum material yield

- Quarry Operations: Block squaring machines (XBSJ series) and quarry wire saws (KSSJ series)

- Automated Manufacturing: Conveyor-integrated systems (LYSJ series) for continuous production

Understanding Your Cutting Size Requirements

Selecting the right CNC wire saw machine depends primarily on your maximum cutting dimensions, material type, and production volume. Similar to choosing the correct drill size for specific applications, wire saw selection requires precise technical matching of capabilities to requirements.

This comprehensive guide will help you determine the optimal DINOSAW machine for your specific size requirements, drawing from industry best practices and real-world applications across stone fabrication, construction, and manufacturing sectors.

Critical Factors for Size-Based Selection

Consider length × width × height of your largest workpieces, including future project requirements and material handling clearances. Account for 10-15% additional capacity for project growth. Machine footprint, ceiling height, and material handling space significantly impact selection. Balance initial investment with long-term production capabilities and evaluate daily cutting requirements, batch sizes, and automation needs.

Complete Diamond Wire Saw Machine Product Specifications

Complete Machine Specifications Comparison Table

| Machine Type | Model | Max Cutting Size (L×W×H) | Cutting Capability | Primary Applications |

|---|---|---|---|---|

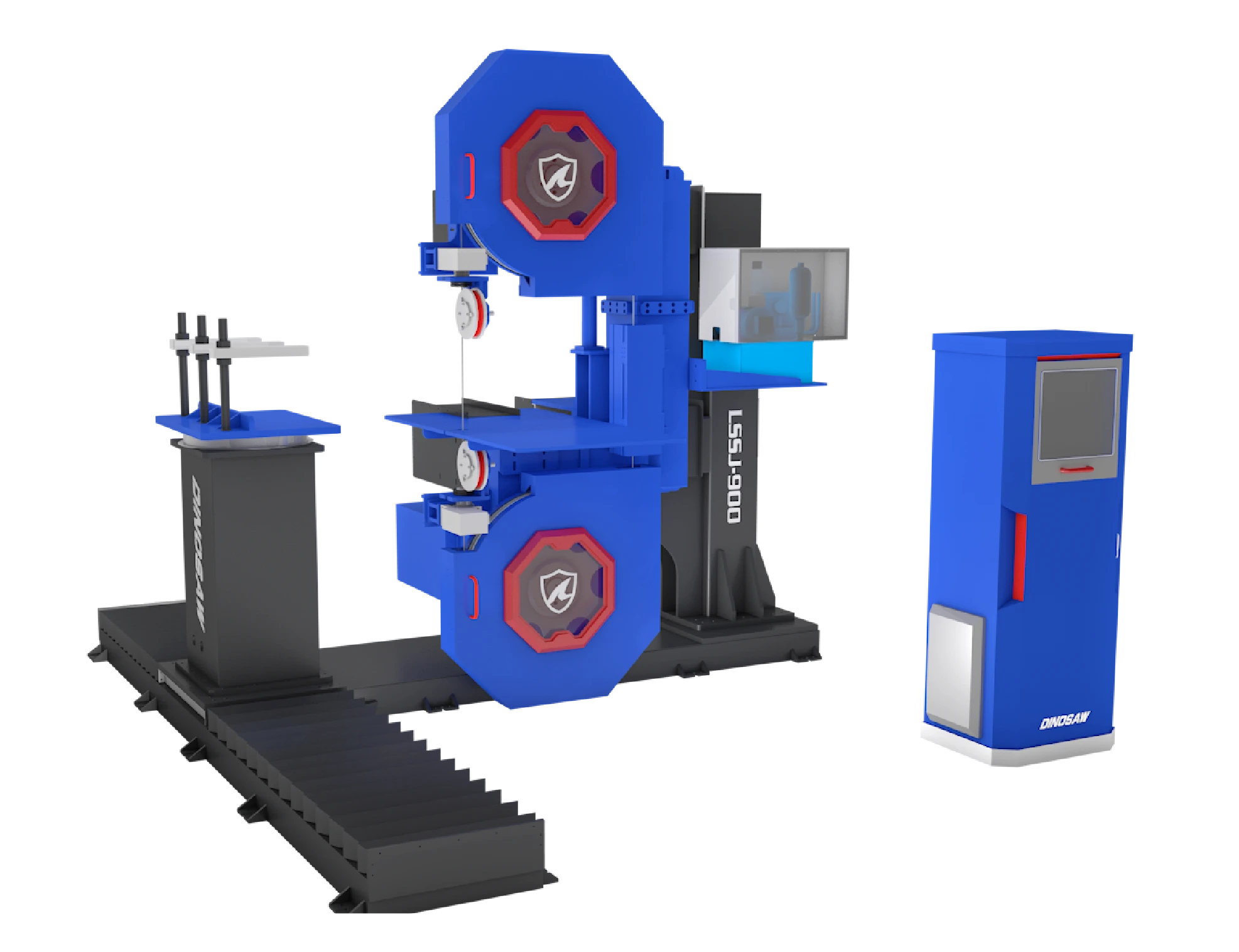

| Vertical CNC Wire Saw | LSSJ-1900-9H | 1900×1900×800mm | Straight & Irregular | Memorial stones, architectural elements, sculptures |

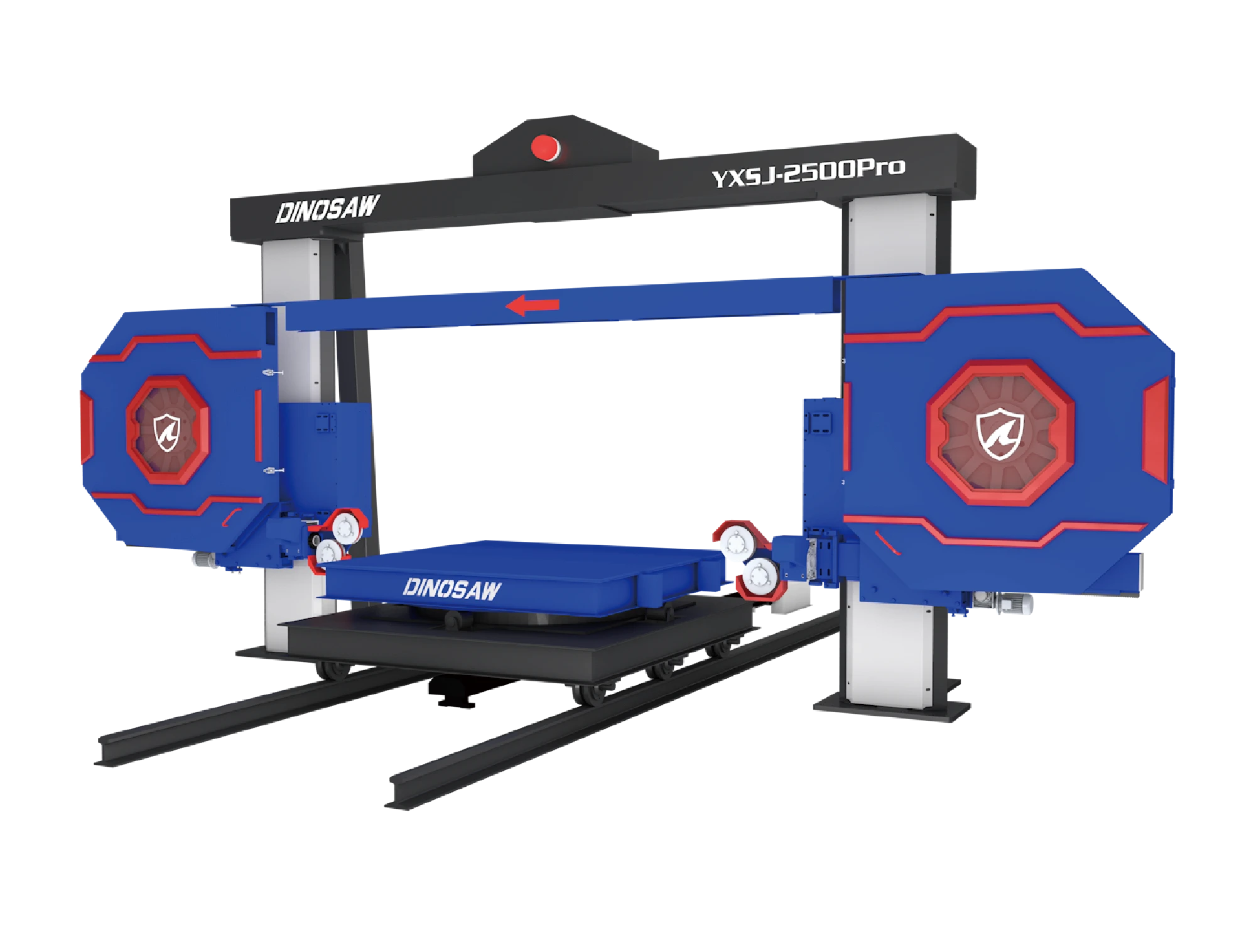

| Standard CNC Wire Saw | YXSJ-2500-16H | 2500×1500mm | Straight & Irregular | Large blocks, artistic sculptures, industrial cutting |

| Standard CNC Wire Saw | YXSJ-3000-16H | 3000×1500mm | Straight & Irregular | Industrial stone processing, large sculptures |

| Heavy-Duty CNC Wire Saw | YXSJ-3500-16H | 3500×1500mm | Straight & Irregular | Quarry blocks, heavy industrial cutting, large slabs |

| Automated Kerbstone Cutter | LYSJ-1300-04H | 1200×2400×400mm | Straight & Irregular | Kerbstones, batch production, curved elements |

| Multi-Wire Slab Cutter | DSY-XY3411 | 3400×1100×2200mm | Straight Only | Ultra-thin slabs, premium marble, luxury stones |

| Multi-Wire Slab Cutter | DSY-JS3411 | 3400×1100×2200mm | Straight Only | High-precision slabs, onyx, travertine |

| Multi-Wire Slab Cutter | DSY-XY3623 | 3400×2000×2200mm | Straight Only | Large block processing, high-volume production |

| Multi-Wire Slab Cutter | DSY-JS3623 | 3400×2000×2200mm | Straight Only | Premium material processing, maximum yield |

| Block Squaring Machine | XBSJ-3000-25H | 3000×3000×2000mm | Straight & Squaring | Block squaring, granite blocks, marble blocks |

| Block Squaring Machine | XBSJ-4000-25H | 4000×4000×2300mm | Straight & Squaring | Large quarry blocks, industrial squaring |

| Block Squaring Machine | XBSJ-5000-25H | 5000×3300×2300mm | Straight & Squaring | Maximum capacity blocks, quarry operations |

| Quarry Wire Saw | KSSJ-M/G | Variable (quarry size) | Straight Cutting | Quarry extraction, mining operations, block separation |

Application-Based Selection Guide

Small to Medium Workshop Requirements

Recommended: LSSJ-1900-9H Vertical Wire Saw

Space-saving design reducing footprint by 40% while maintaining ±1mm precision. Ideal for memorial stones and custom sculptures with 18-24 month ROI.

Large Industrial Applications

Recommended: YXSJ-3500-16H CNC Wire Saw

Handles massive workpieces up to 3500×1500mm with cutting speeds up to 2m²/h. Delivers 300-400% productivity increases for high-volume operations.

Ultra-Thin Slab Production

Recommended: DSY Multi-Wire Saw Series

0.35mm diamond wire creates 0.5mm kerf width for slabs as thin as 3mm. Provides 10-30% better material yield for luxury applications.

Frequently Asked Questions

How do I choose the right wire cutting machine for my needs?

Start by assessing your maximum cutting dimensions, production volume, and material types. Consider factors such as the types of wires you work with, the required precision of cuts, the volume of production, and any specialized cutting requirements unique to your industry. Account for 20-30% growth capacity above current needs to accommodate business expansion.

What precision can I expect from CNC wire saw machines?

Precision is critical in wire cutting applications, especially in industries such as electronics and automotive, where small tolerances are required. When selecting a wire cutting machine, consider its accuracy and repeatability to ensure consistent results. DINOSAW machines deliver ±1mm precision across all cutting operations with proper setup and maintenance.

What are the workshop space requirements for wire saw machines?

Machine footprint varies significantly by model. Different wire cutting machines are designed to handle varying wire diameters and materials. Ensure that the machine you choose is compatible with the types of wires you commonly work with. Vertical machines like LSSJ-1900-9H reduce space by 40% compared to horizontal configurations. Consider material handling, crane access, and safety clearances in planning.

How fast can wire saw machines cut different materials?

In general, when cutting marble, a suitable linear speed for a diamond wire saw is usually set between 25 to 35 meters per second. Cutting speeds vary by material: marble 1.5-3m²/h, granite 0.8-1.5m²/h, concrete 0.5-1.2m²/h. The cutting speed of a wire cutting machine directly impacts productivity. Evaluate the machine's speed capabilities and determine whether it aligns with your production requirements.

What maintenance is required for wire cutting machines?

Regular maintenance is essential to keep wire cutting machines operating at peak performance. Evaluate the maintenance requirements of each machine and consider factors such as ease of maintenance, availability of spare parts, and technical support. This may include cleaning, lubrication, blade sharpening or replacement, and software updates, depending on the type of machine. DINOSAW provides 24/7 remote diagnostics and preventive maintenance programs.

Can diamond wire saws cut both wet and dry?

Diamond Wire Saw Machine can be used for both wet and dry cutting, though wet cutting is recommended for most applications. Water cooling reduces heat buildup, extends wire life, and improves cut quality. Dry cutting is possible for specific applications but may reduce wire lifespan and cutting speed.

What should I consider when cutting stone with diamond wire saws?

According to stone cutting forums, key considerations include proper start point positioning for inner cuts, maintaining consistent wire tension, and using appropriate post-processing tools for complex geometries. For thick materials over 500mm, consider multi-pass cutting and reduced feed rates to prevent wire breakage.

What are the automation capabilities of modern wire saw machines?

Automation features can streamline production processes and improve overall efficiency. Consider wire cutting machines that offer automation capabilities, such as programmable settings and integration with other manufacturing equipment. DINOSAW machines offer CNC programming, robotic integration, conveyor systems, and automatic wire tensioning for enhanced productivity.

What industries commonly use wire cutting machines?

Wire cutting machines are used in a wide range of industries, including electronics, automotive, aerospace, medical devices, and jewelry manufacturing. They are essential for producing precise wire components for various applications. The diamond wire saw machines are often used to cut granite, marble, and limestone in stone fabrication, construction, and monument industries.

Custom Support

DINOSAW Custom Engineering Services

For unique cutting requirements beyond standard specifications, DINOSAW offers custom machine design and modification services. Our engineering team can adapt existing models or create purpose-built solutions for specialized applications.

Custom Capabilities Include:

- Extended cutting capacity beyond standard limits

- Multi-material processing configurations

- Specialized cooling and waste management systems

- Integration with existing production lines

- Environmental compliance modifications

Technical Support Services:

- 24/7 remote diagnostics and troubleshooting

- Preventive maintenance programs

- Operator training and certification

- Performance optimization consulting

- Technology upgrade pathways

Contact DINOSAW technical experts for personalized machine recommendations and detailed project analysis.

Get Expert Consultation →

English

English 中文

中文