Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Looking for profitable CNC stone projects? Go beyond countertops. Discover 7 high-value architectural and artistic applications only possible with a CNC wire saw, from parametric furniture to monolithic sculptures.

Your stone fabrication business is likely built on 2D slabs: countertops, tiles, and wall panels. But what if you could break free from the flat plane and enter the high-profit world of 3D architectural and artistic pieces? The key isn't a better bridge saw; it's a paradigm shift in technology: the CNC diamond wire saw.

This machine liberates stone from its two-dimensional constraints, allowing you to transform raw blocks into complex, high-value forms. As a leader in this technological revolution, Dinosaw Machine is empowering fabricators worldwide to explore this new dimension of possibility.

This article reveals 7 profitable project categories exclusively enabled by the precision and power of CNC wire saws. We'll explore the technology, the workflow, and the clear business case for upgrading your workshop to move "beyond the slab" and position your business as a leader in high-end custom creation.

From 2D Slabs to 3D Forms: The Wire Saw Revolution

To grasp the opportunity, it's crucial to understand how CNC wire saws fundamentally differ from traditional stone cutting methods. It's a difference in creative dimension, not just efficiency.

What is a CNC Wire Saw?

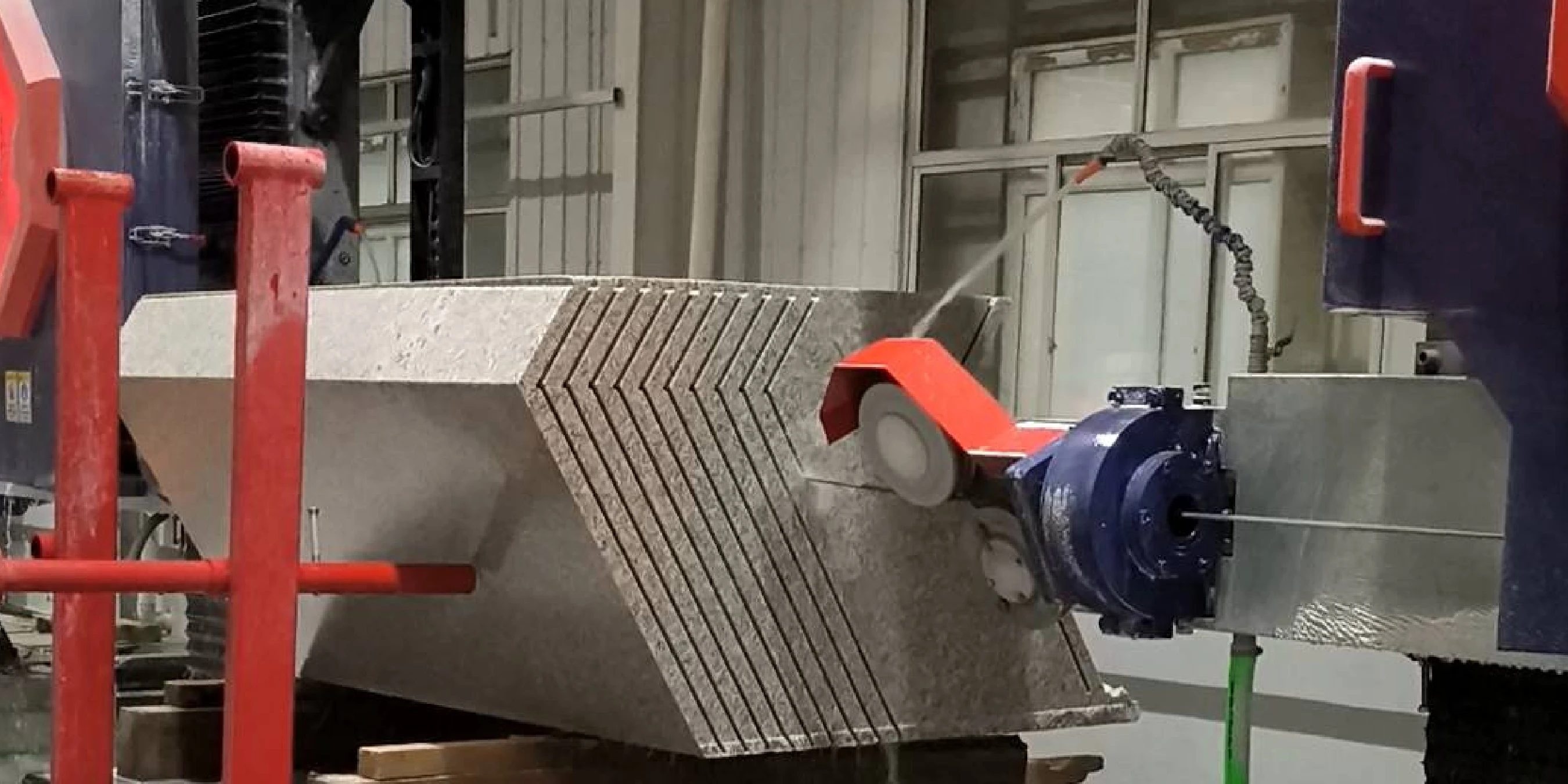

A CNC wire saw operates like a massive band saw, but instead of a blade, it uses a continuous loop of steel wire embedded with diamond beads. Guided by a multi-axis CNC controller, this diamond wire runs at high speed to slice through entire stone blocks. Unlike saws that are limited to a single plane, the wire can cut from any direction, enabling complex contours and internal hollowing.

Why Wire Saws Are Key to 3D Creation

- Wire Saw vs. Bridge Saw: A bridge saw excels at cutting blocks into flat slabs for products like countertops. Its movement is linear. A CNC wire saw, however, carves complex curves and shapes directly from a multi-ton block, creating forms a bridge saw could never produce.

- Wire Saw vs. CNC Machining Center: A CNC machining center is a finishing expert, handling surface details like edge profiling, engraving, and polishing on already-shaped pieces. The wire saw performs the initial macro-shaping, carving the 3D "blank" from the raw block. They are not competitors but partners in a high-efficiency workflow.

Core Advantages of CNC Wire Saws

- Massive Block Capability: Process blocks weighing 13 tons or more, essential for large architectural elements and monumental sculptures.

- Minimal Material Waste: The wire's thin kerf means less stone turns to dust. This saves costs and allows for nested parts to be cut from a single block, maximizing material yield.

- Unlimited Geometric Freedom: Smooth curves, twisted columns, and complex profiles are all possible.

- Millimeter-Level Precision: Achieve cutting accuracy of 1mm, ensuring parts fit together perfectly in complex assemblies.

This leap from surface finishing to true 3D subtractive manufacturing is the key to the wire saw's value. It's not just a faster machine; it's an entry point to a new business model focused on high-value, bespoke creations.

Technology Capability Matrix

FeatureCNC Bridge SawCNC Machining CenterCNC Wire SawPrimary FunctionLinear slab cuttingSurface engraving, edge profiling, polishing3D block contouring & shapingMax Cutting DepthLimited (by blade diameter)Limited (by tool length)Extreme (can cut entire block)Curve CapabilityNone / Very limited2D surface curves onlyFull 3D complex curvesSurface DetailingNoneExcellentPoor (for macro shaping only)Material WasteMediumLowVery LowIdeal ProjectsCountertops, tiles, flat panelsReliefs, sink cutouts, decorative edgesSculptures, custom furniture, architectural parts

The Digital Workflow: Concept to Creation

Powerful tools require a modern workflow. The CNC wire saw has given rise to the "digital stonemason," a new type of artisan who merges artistic vision with precision technology.

Step 1: The Vision (Artist/Designer)

Every project starts as a 3D digital model. Using CAD software, designers sculpt their ideas like digital clay. The critical advantage here is the "undo" button. Designs can be perfected without the risk of a single mistake ruining an expensive block of stone.

Step 2: The Strategy (CNC Programmer)

The 3D model is imported into CAM software, where the CNC programmer—the modern stone carver—takes over. They strategically plan the cutting path of the diamond wire. This requires deep technical skill, balancing the stone's properties, wire specifications, and complex collision avoidance calculations to ensure a safe and efficient cut.

Step 3: The Execution (Machine Operator)

The programmer's G-code is sent to the Dinosaw CNC wire saw. An experienced operator secures the multi-ton block, sets reference points, and initiates the automated cutting process. The machine then executes the program flawlessly over hours or even days, with the operator monitoring its progress.

Step 4: Finishing & Assembly

After the wire saw completes the heavy lifting, the piece may move to a CNC machining center for fine polishing or be handed to a traditional mason for final hand-finishing touches. This blend of machine efficiency and human artistry is the hallmark of modern, high-end stone manufacturing.

7 High-Profit Projects for Your CNC Wire Saw

These seven project categories are where CNC wire saws create value that is impossible or cost-prohibitive to achieve with other methods.

1. Parametric & Organic Furniture

Think beyond simple stone benches. Imagine a flowing, wave-like bench for a luxury hotel lobby or a dining table with twisted marble legs. These are statement pieces whose value is measured in artistry, not material cost.

- The Wire Saw's Role: It's the only tool that can efficiently cut the smooth, continuous curves required for these fluid forms.

- Market Value: Sold as functional art to top-tier designers and architects, these pieces command enormous profit margins.

2. Complex Architectural Components

Modern architecture is embracing stone in bold new ways, from twisted columns to curved facade panels and precision-cut blocks for complex vaults (digital stereotomy).

- The Wire Saw's Role: It is the most effective method for producing these non-linear structural and decorative elements from solid blocks.

- Market Value: This is a high-barrier, high-reward field. Securing contracts with architectural firms can lead to stable, lucrative work.

3. Monumental Art & Abstract Sculptures

This is the pinnacle of the value chain, where material cost is negligible compared to artistic value. CNC wire saws give artists unprecedented freedom to realize complex 3D concepts for public squares or corporate headquarters.

- The Wire Saw's Role: It dramatically shortens production time by carving the rough form with incredible accuracy, allowing the artist to focus on the final details and expression.

- Market Value: A single successful public art commission can be worth hundreds of thousands of dollars.

4. Interlocking & Post-Tensioned Structures

This is a cutting-edge engineering application. A wire saw's precision allows stone blocks to be cut with interlocking joints, like wood joinery, creating strong, mortar-free structures. It can also carve internal channels for steel cables, enabling the construction of long-span post-tensioned stone beams and bridges.

- The Wire Saw's Role: Only the millimeter-level accuracy of a CNC wire saw can produce these complex internal and external geometries.

- Market Value: Mastering this technology places a company at the forefront of structural engineering, giving it a powerful advantage in high-end construction projects.

5. Custom Landscape Features

High-end landscape design relies on large, bespoke stone elements like multi-tiered fountains, curved planters, or water walls carved from a single piece of granite.

- The Wire Saw's Role: It excels at hollowing out solid blocks and shaping the elegant curves required for these features.

- Market Value: Often part of large-budget luxury residential or civic projects, a single custom fountain can be more valuable than an entire kitchen renovation.

6. Monolithic Luxury Bathtubs & Sinks

The ultimate statement in luxury: a bathtub or sink carved from a single, solid block of marble or onyx. These are bespoke items for the world's most exclusive properties.

- The Wire Saw's Role: It first cuts the exterior profile, then is used to hollow out the interior—a process that is extremely difficult, risky, and time-consuming with any other method.

- Market Value: A solid stone bathtub can sell for tens or even hundreds of thousands of dollars, defining a brand as a true luxury provider.

7. Artistic Monuments & Headstones

The memorial market is shifting toward personalized, artistic designs that go far beyond a simple engraved slab. This includes sculpted figures, complex gothic shapes, or flowing abstract forms.

- The Wire Saw's Role: It makes unique, art-driven memorials accessible and affordable to produce, giving designers and families far greater creative freedom.

- Market Value: An artistic memorial commands a price several times that of a traditional headstone, opening a high-value niche in a conventional market.

The Business Case: Maximizing Your ROI

Investing in a CNC wire saw is about transforming your business model—from selling a commodity (stone by the square foot) to delivering unique works of art (valued by design).

Shifting Your Value Proposition

The profit on countertops is squeezed by price competition. The profit on a custom marble bench is determined by its design, complexity, and uniqueness. A CNC wire saw is the tool that enables this shift, moving you from a low-margin commodity market to a high-margin custom market.

Profit Margin Analysis

While a custom piece takes longer to make than a few countertops, its sale price can be 10 to 100 times higher. By focusing on high-value projects, a fabricator can achieve greater total profit with fewer orders, building a premium brand reputation in the process.

Reducing Labor Costs & Skill Dependency

Master stone carvers are rare and expensive. A CNC wire saw automates the most physically demanding and time-consuming part of the process—rough shaping. This reduces reliance on top-tier manual labor and allows you to build a more scalable team of skilled designers and CNC programmers.

Market Diversification & Resilience

With a CNC wire saw, your business is no longer tied only to the construction market. You can serve clients in public art, luxury furniture, landscape design, and memorials. This diversification protects your business from fluctuations in any single market, creating greater stability and resilience.

FAQ: Your Questions Answered

Here are straightforward answers to the most common questions we hear from aspiring digital stonemasons.

Q1: What are the real-world processing limits? How large of a block can I actually cut?

A: This depends on the machine model. Key factors to consider are your typical block size, primary stone type, and target output. Dinosaw's flagship models can easily handle blocks over 2 meters high and weighing more than 13 tons, which is sufficient for most large-scale architectural and sculptural work. Our experts can help you select the right configuration for your specific needs.

Q2: How do I handle common technical issues like wire breaks or uneven cuts?

A: Proper operation and maintenance are key. Here’s a quick guide:

- Wire Breakage: Often caused by excessive tension, machine misalignment, or a worn-out wire. Solution: Check tension settings, verify guide wheel alignment, and replace wires on a regular schedule.

- Uneven Cutting: Typically caused by cutting too fast, using the wrong wire for the material, or an unstable workpiece. Solution: Adjust cutting speed for the stone's hardness, select the correct wire type, and ensure the block is securely clamped.

- Excessive Wire Wear: Usually due to insufficient cooling, improper feed rates, or the wrong diamond grade. Solution: Ensure the cooling system is flowing properly, optimize feed rates to reduce friction, and match the diamond grade to the stone.

Q3: What software do I need to get started?

A: You need two types of software: CAD (Computer-Aided Design) for creating 3D models and CAM (Computer-Aided Manufacturing) for generating the G-code that runs the machine. You must ensure your CAM software has a compatible "post-processor" for your specific wire saw model to translate the design into machine commands correctly. For advanced applications, a custom post-processor might be needed to optimize specific tasks like automated drilling and wire threading.

Q4: Is operating a CNC wire saw difficult? What training is required?

A: While it requires specialized knowledge, modern control systems are becoming increasingly user-friendly. More importantly, a reputable manufacturer like Dinosaw provides comprehensive training and support. Our service includes installation, calibration, and systematic training for your operators and programmers. We ensure your investment quickly becomes a productive asset. For example, we provided full training for a factory in Egypt, helping them boost their efficiency by 50%.

Conclusion: Carve Your Niche in the Future of Stone

The stone industry is at an inflection point. The leap from 2D to 3D is more than a technical upgrade; it's a strategic evolution. The rise of the "digital stonemason" signals a new era blending ancient craft with cutting-edge technology. Businesses that embrace this shift and move "beyond the slab" will secure a dominant position in the market of tomorrow.

A Dinosaw CNC wire saw is more than a machine—it is the foundation for a future-proof, high-profit stone fabrication business. It gives you the power to turn imagination into reality and transform cold stone into works of art.

Ready to take the next step? Contact a Dinosaw expert today to explore how a CNC wire saw can revolutionize your business and open a new dimension of creativity and profitability.

English

English 中文

中文