Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

A comprehensive guide for factory owners on selecting the right stone edge polisher. We compare automatic straight-line machines for large slabs and thick materials vs. robotic arms for curved profiles. Make a profitable investment today.

Look, I've watched too many shop owners get burned by equipment that looked perfect in the brochure. Your polishing machine isn't just another tool-it's what determines whether you're scrambling to keep up with orders or confidently taking on bigger projects.

Here's what really matters: Most shops think they need a machine that "does everything." That's where the trouble starts. The truth? Your business model should pick your machine, not the other way around.

Ready to make the right choice? Don't buy expensive equipment based on guesswork.

What Type of Stone Fabrication Work Actually Pays Your Bills?

Before you even look at specifications, pull out your last 50 invoices. I'm serious. What percentage is standard countertop work versus custom curved pieces? This isn't about what you want to do-it's about what customers actually order.

Countertop Edge Finishing: The Volume Reality Check

Most shops live in the countertop world. Kitchen islands, bathroom vanities, commercial installations. The money's in moving volume efficiently, not showing off fancy profiles.

Your bread-and-butter profiles:

• Flat/eased edges - Clean, modern, goes with everything

• Bevel cuts - Just enough detail without being fussy

• Mitered edges - Makes thin slabs look expensive

If this describes 80% of your work, you need straight-line production power. No question.

Custom Edge Polishing Equipment: High-Risk, High-Reward Market

Now here's where things get interesting. Custom profiles separate premium shops from the commodity crowd. Think about those sink cutouts that eat up your best guy's entire afternoon.

High-value work includes:

• Bullnose edges - Classic rounded look customers pay extra for

• Ogee profiles - That S-curve screams "luxury"

• Sink cutouts - Where most shops lose money on labor

• Architectural pieces - The holy grail of profit margins

Stone Edge Polishing Machine: Two Different Approaches

Once you know your primary work type, the equipment world splits cleanly. Don't let salespeople convince you there's one magic machine that does everything perfectly-that's not how manufacturing works.

Automatic Edge Polishing Machines: Built for Speed and Consistency

These are your workhorses. Load a slab on one end, it travels through polishing heads, comes out perfect. But even here, you've got two very different needs:

Large-Format Stone Fabrication Equipment (Most Modern Shops)

If you're like most shops, your biggest headache is those massive kitchen island slabs everyone wants now. You need a machine that handles wide, long pieces and does multiple operations in one pass.

Versatile profiling machines handle slabs up to 120mm thick. They'll do chamfers, grooves, and simple profiles while polishing. It's like having three machines in one, which matters when overhead costs are killing you.

Perfect for: Residential kitchens, commercial countertops, large-format engineered stone. If "big slabs" is your main challenge, this solves it.

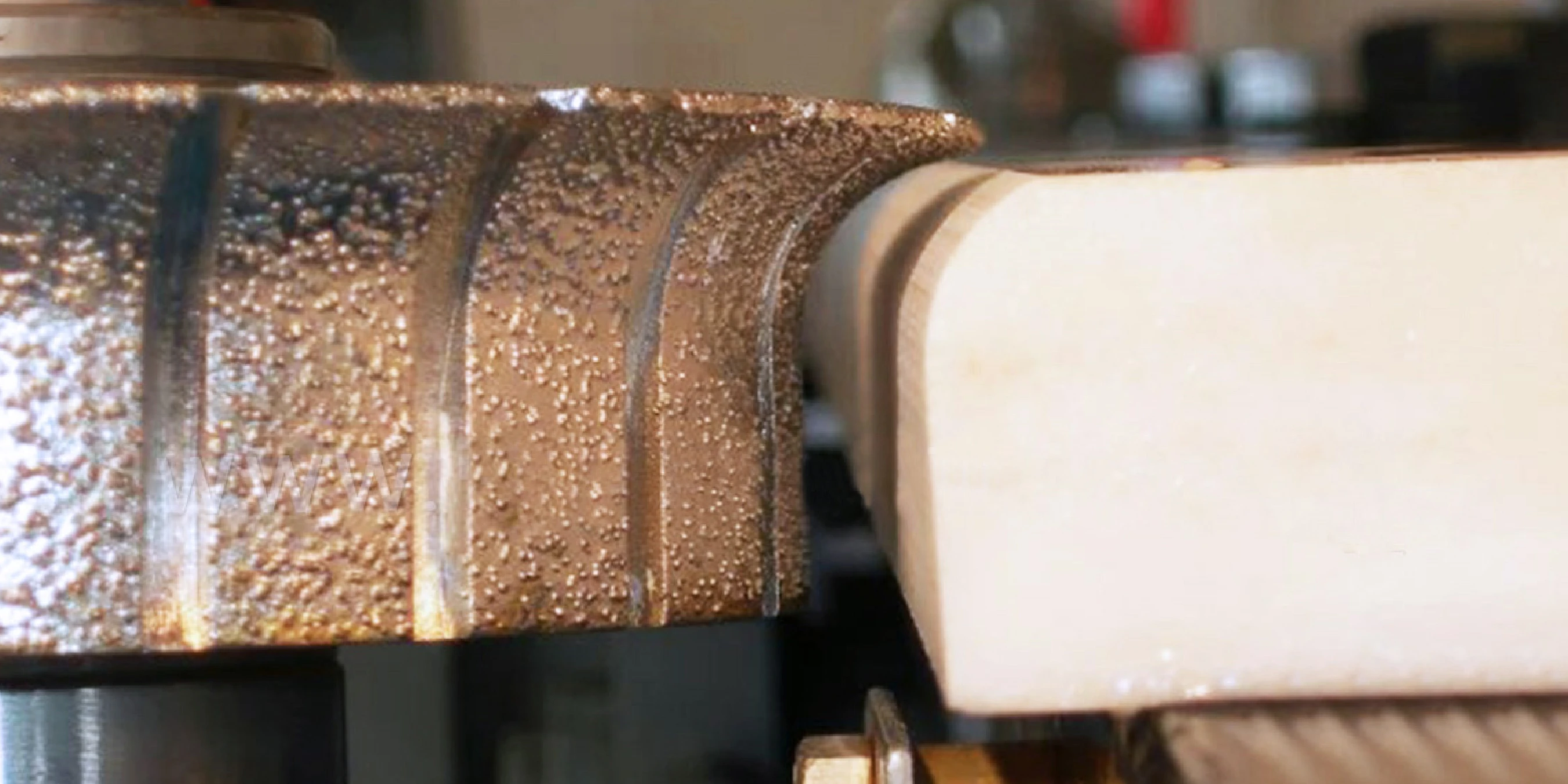

Heavy-Duty Edge Polishing Machinery for Ultra-Thick Materials

Some shops live in a different world entirely. Monument work, thick laminated edges, architectural elements. These need serious horsepower for materials up to 300mm thick.

Heavy-duty specialist machines are built like tanks. Massive motors, rigid frames, enormous pressure capability. The trade-off? You'll manually change polishing wheels between grits, so you need skilled operators.

Perfect for: Monument shops, architectural suppliers, anyone regularly working materials thicker than 120mm. If thickness is your bottleneck, nothing else works.

Robotic Polishing Automation: When Custom Curves Pay the Bills

Here's where everything changes. Robotic polishing arms aren't just fancy gadgets-they're what let high-end shops automate work that used to require master craftsmen.

A properly programmed robot does that three-hour sink cutout in 45 minutes. Zero variation in quality. Can follow any curve, handle any angle, work around the clock without coffee breaks.

According to Growth Market Reports, the global stone edge polisher market is projected to reach USD 3.79 billion by 2033, driven largely by automation advances like this.

Perfect for: Shops competing on craftsmanship, not price. Custom fabricators, architectural suppliers, anyone wanting to escape the commodity market.

Stone Edge Polisher Selection: Making Your Decision

Alright, let's get practical. Here's how to actually decide:

Step 1: Audit Your Stone Fabrication Order Book

Don't guess-count. Go through recent jobs:

• How many were straight edges only?

• How many needed curved or profiled work?

• What's your typical slab thickness?

• Where do you currently lose the most time?

Step 2: The 80/20 Rule for Edge Finishing Equipment

If 80% or more is straight edges: Choose between versatile profiler (for large slabs) or heavy-duty specialist (for thick materials). Keep doing that 20% custom work by hand or subcontract it.

If 30% or more involves curves and custom profiles: Seriously consider the robotic route. That's enough custom work to justify the investment and position you for higher-margin growth.

Step 3: Calculate Edge Polishing Machine ROI

Look at your labor costs for edge work. A good automatic polisher pays for itself in 18-24 months through labor savings alone. If you're spending more than $3,000 monthly on hand-polishing labor, automation makes sense.

Stone Edge Polishing Machine FAQs from Shop Owners

What's the difference between an edge polisher and stone profiling machine?

Simple: a polisher smooths and shines an existing edge shape. A profiler actually creates the shape (bullnose, ogee, etc.) then polishes it. Most modern machines do both, but understanding the difference helps when comparing specs.

How much do automatic stone edge polishing machines cost?

Straight-line machines start around $50,000 for basic models, with advanced versions running $100,000+. Robotic systems are bigger investments-typically $200,000+ depending on configuration. But don't just look at purchase price; calculate labor savings over three years.

Can you polish granite, quartz, and marble on the same edge finishing equipment?

Absolutely, but you need different tooling and settings. Quartz is harder and needs diamond abrasives designed specifically for it. Granite is more forgiving. Marble is tricky-too much heat or pressure and you'll burn or chip it.

How fast can automatic edge polishing machines work?

Automatic straight-line machines typically run 1-3 meters per minute, depending on profile complexity and finish quality. That kitchen that takes your best guy all afternoon? Done in 15 minutes of machine time. That's the real game-changer.

What maintenance do stone fabrication machines need?

Daily: clean off slurry and stone dust, check for loose bolts. Weekly: inspect belts and polishing heads. Monthly: lubricate moving parts and check alignment. Modern machines are designed with accessible maintenance points and reminder systems.

How do edge polishing machines achieve high-gloss finishes?

It's all about the progression. Start coarse (50-100 grit) to shape and remove saw marks, then step through increasingly fine grits: 200, 400, 800, 1500, 3000. Final step is usually a buff pad that generates just enough heat to bring out the stone's natural luster. Skip a grit or rush the process, and you'll never get that wet-look shine.

Your Stone Fabrication Equipment Path Forward

Your edge polishing equipment isn't just a production tool-it's a strategic decision about where you want your business in three years. Are you competing on speed and efficiency, or craftsmanship and custom capability?

Shops that get this right don't just increase output; they transform their entire business model. They take on bigger projects, charge higher margins, and stop losing good people to hand-polishing burnout.

So take that honest look at your order book, calculate the real costs of your current process, and choose the path that matches where your business is actually heading. The right machine won't just make you faster-it'll make you different from every other shop in your market.

English

English 中文

中文